Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fermat 2012 Machine Catalog

Caricato da

WalkerMachineryCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fermat 2012 Machine Catalog

Caricato da

WalkerMachineryCopyright:

Formati disponibili

SPECIALIZING IN PRECISION

HORIZONTAL BORING MILLS

www.fermatmachinery.com

WRF 150 CNC

COMPANY INFO 04

Fermat Fast Facts 05

About Fermat 08

Fermat machining shop 10

Customer service 12

TABLE TYPE HORIZONTAL BORING MILLS

WFT 13 CNC 16

WRFT 130, 150, 160 CNC 16

WFC 11 (13) CNC 16

WFC 10 CNC 16

FLOOR TYPE HORIZONTAL BORING MILLS

WRF 130, 150, 160 CNC 16

WF 11, 13 CNC 16

WF 13 CNC 16

OTHER PRODUCTS

MILLING MACHINES 16

FGU (RT) CNC 16

WRF MILL CNC 16

GRINDING MACHINES 16

BUC E 63 CNC 16

BUT E 63 CNC 16

MACHINE COMPONENTS 16

Headstock 16

Table 16

Control System 16

Electric | Hydraulic | Lubrication Units 16

Ballscrews, Rack, Covers 16

Other Components 16

SPECIAL ACCESSORIES 16

Automatic Pallet Changer System APC 16

Automatic Tool Changer ATC, Robots 16

Milling Heads, Face plates 16

Platforms | Workspace Enclosure 16

Other Accessories 16

REFERENCE MACHINES 16

Content:

for Pytyn Koneistuspalvelu, Finland

Parameters: x=14700 mm/579|y=6000 mm/236|z= 1200/47|w=1000mm/39|v=5500mm/217; Heidenhain iTNC 530 Control System

C

O

M

P

A

N

Y

I

N

F

O

T

A

B

L

E

H

B

M

F

L

O

O

R

T

Y

P

E

C

O

M

P

O

N

E

N

T

S

O

T

H

E

R

P

R

O

D

U

C

T

S

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

4 5

2

nd

8 100+

535

Number of employees largest consumer of Heidenhain and

Fanuc in local market

Annual production/sold machines Branches in Czech Republic

1902

Oldest member of FERMAT Group Annual sales in 2011

Fermat Fast Facts Web page

Search our products in 10 diferent languages.

www.fermatmachinery.com

Our website is a key tool to help us grow closer to

our customers anywhere around the world.

Micron (1 m) has the most accurate

production machine from our

machining shop

1

57

Football playgrounds would ft in foor

space of FERMAT Production facilities

5

mil.

C

O

M

P

A

N

Y

I

N

F

O

T

A

B

L

E

H

B

M

F

L

O

O

R

T

Y

P

E

C

O

M

P

O

N

E

N

T

S

O

T

H

E

R

P

R

O

D

U

C

T

S

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

6 7

About Fermat

FERMAT Machinery is a renowned Czech manufacturer of

machine tools with a focus on Horizontal Boring and Milling

machines. The history of the oldest Fermat member dates

back to 1902 when Mr. Frantisek Wawerka started his frst bu-

siness and built a new factory specialized in the production of

Lathes & Drilling machines. Over a one hundred year long tra-

dition in machine tool production places the company among

dominant Machine Tool Manufacturers in the European as

well as the Worldwide market.

Fermat horizontal boring machines allow CNC machining

with a spindle diameter from 100 to 170 mm. Thanks to the

modular production system we supply our customers with

reliable and fexible machines. Our components and accesso-

ries are produced directly in Fermat or delivered by the world-

-renowned companies (FH, SKF, Thyssen Krupp, Schneeberger,

Siemens, etc.). This kind of production provides our customers

with a better service, fast delivery time and high quality.

Industrial Applicability

FERMAT horizontal boring mills are used mainly in heavy ma-

chinery such as construction, marine, aircraft or defense indu-

stry as well as in mining, oil-gas or railway sector. Various parts

such as crane jibs, gantry cranes or pedastals, winches, frames,

storage tanks etc. make example of common workpieces of

horizontal boring mills.

FERMAT Number of Employees

Production

Fermats annual production is now over 100 machines. Thanks

to this number we do guarantee customers reliable, con-

venient and most standardized design table or foor boring

machines with fast delivery. The modular system of produc-

tion, experienced engineers and technicians allows Fermat to

supply machines according to our customers needs whether

in standard or special design. This Flexibility and inovation is

our guarantee for future success!

Production facilities

FERMAT occupies 29 500m

2

(317 535 sq ft) production and

assembly halls. The most important centers are situated in

Prague and Brno (Prague 5300 m

2

/57 049 sq ft/ Brno 4800 +

3 600m

2

/ 38750 sq ft). The company sales soared despite the

recent economic crisis. In the same period Fermat acquired

several traditional manufacturers like Pressl Company in Pil-

sen and Strojtos Lipnik to increase the production facilities.

Worldwide sales

and distribution

Based in the heart of Europe, Fermat is one of the leading

suppliers of machine tools - horizontal boring machines (both

table/foor type machines) in Central Europe. The company

celebrated achievements not only in European markets, but

also in Canada, USA, Russia, India, China and South America,

exporting to more than 40 countries worldwide. Fermats con-

stantly growing and increasing its market share and partici-

pates at main International Fairs around the world including

EMO- the leading international Trade Fair for the machine tool

industry and IMTS the largest machine tool exhibition for the

North American market.

Lipnik Plant 1920

Brno Plant 2006

Fermat Assembly Shop

FERMAT Total Turnover

60 ml.

2009 2008

30 ml.

10 ml.

40 ml.

20 ml.

50 ml.

2010 2011

35 ml.

36 ml.

49 ml.

57 ml.

0

300

400

150

50

200

100

250

350

450

500

500 535

2008 2009 2010 2011 2012

339 340

449

0

C

O

M

P

A

N

Y

I

N

F

O

T

A

B

L

E

H

B

M

F

L

O

O

R

T

Y

P

E

C

O

M

P

O

N

E

N

T

S

O

T

H

E

R

P

R

O

D

U

C

T

S

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

8 9

ROKYCANY

C

O

M

P

A

N

Y

I

N

F

O

T

A

B

L

E

H

B

M

F

L

O

O

R

T

Y

P

E

C

O

M

P

O

N

E

N

T

S

O

T

H

E

R

P

R

O

D

U

C

T

S

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

BRNO

PRAGUE

LIBEREC

LIPNIK

EU

Fermat Production Plants

Czech Republic

GERMANY

AUSTRIA

VIENNA PARIS

ROME

FRANKFURT

MUNICH

BRNO

SLOVAKIA

Brno-Vienna 2hrs

Prague-Liberec 1hrs

Prague-Rokycany 1hrs

Brno-Lipnik 1hrs

Prague-Brno 2hrs

POLAND

PRAGUE

8

10 11

Service Policies

First-class customer service is one of our most signifcant

company qualities. The people in Fermat know that the qual-

ity of maintenance services signifcantly afects customer sat-

isfaction. Therefore, the Service Center continuously tries to

improve the services and information management service

cases. For this purpose we agreed on the following service

policies:

Overview and quick reaction times.

Automatic registration of all service cases

Remote diagnostics

Linguistic diversity of employees

at Customer Service Center

Large stock of spare parts in EU, U.S., Canada, India, China.

Library of solutions for Frequently asked

questions or problems

Classifcation, Monitoring and analysis of all service cases.

These are the main advantages of the new service system in

Fermat. After reporting a new service case our service sup-

port will automatically process its administration. Responsi-

ble service workers are immediately assigned to the individual

message.

Customer Service hours

With Fermat, you are guaranteed to customer during pro-

longed service Mon-Fri 7.00-a.m 7.00p.m. CET. as well as ur-

gent service issues are handled anytime including weekends.

We provide Services in English/German/Chinese/Czech/Rus-

sian language.

Machine Remote Diagnostic

All FERMAT machines are equipped with machine remote di-

agnostics. This option provides customers with quick on-line

problem solving analysis of their machine by skilled FERMAT

Service Technicians. Machine problems such as programming

difculties, electronic and mechanical error messages can be

diagnosed and in most cases solved. Main advantages of re-

mote diagnostics are:

The quickest possible way howtodetect a failure at the machine

Very short time between the message about a failure and

the frst on-line contact with the customer

It is possible to consider immediately together with

the customer whether a spare part is necessary

Efciency at PLC problem solution is approx..80%

Machine data backup, statistics are later used to

improve the Customer Service.

Microsoft Service Data Preview Classifcation of service problems

Customer service

FERMAT Stock spare parts

Microsoft Dynamics System

supports Customer service

A step forward, according to Service Manager for Germany,

Mr. Josef, was an implementation of Microsoft Dynamics In-

formation System. All service cases are automatically regis-

tered in the service database together with the time schedule

of the particular case and a personal responsibility. This sys-

tem allows a better management and communication with

the customers. "As soon as the case gets recorded under the

regulations, we immediately send our responsible technician

with the necessary equipment or spare parts to the customer,

says Mr. Krkavec, the Head of Fermat Service Center. Fermat

has large stocks of spare parts in Europe, U.S., Canada, India

and China so our customers do not have to wait any longer.

After resolving service case a fnal report is sent to the cus-

tomer and a feedback monitoring is saved to be helpful for

our intern statistics.

Library Service and Monitoring

Documented service events are regularly reported to Produc-

tion and Design Department. These Statistics are used to im-

prove the design of machines.

Knowledge database is well maintained and every new prob-

lem leads to solution manual.

C

O

M

P

A

N

Y

I

N

F

O

T

A

B

L

E

H

B

M

F

L

O

O

R

T

Y

P

E

C

O

M

P

O

N

E

N

T

S

O

T

H

E

R

P

R

O

D

U

C

T

S

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

12 13

WFC 13

See page 24

WFC 10

See page 26

Table type HBM Our products

Horizontal Boring and Milling

Machines Table Type

WFT 13, WRFT 130, WFC 13 and WFC 10 repre-

sent the table type of horizontal boring mills.

The former is a version with a movable life

spindle; whereas the latter possesses a movable

ram. Among the machine characteristics there

is a powerful milling and drilling chip removal

(even with top Y-axis stroke) and higher preci-

sion then other machines available on the

market. A modular concept allows great opera-

tional variability in confgurations, according

to the clients requirements. Modern control

systems provide very comfortable manipula-

tion of the machine and many useful functions

for the user. Horizontal Boring Mills WRFT ofer

6 axes travel (X, Y, Z, V, W and B) while WFT

and WFC adopts the movement on 5 diferent

axes. Given additional optional accessories, it is

possible to increase number of controlled axes.

During the metal processing, the column of

the machine adopts Z-axis movement and the

workpieces are clamped on a rotary table that

travels in the X-axis.

T

A

B

L

E

H

B

M

H

O

R

I

Z

O

N

T

K

Y

F

R

Z

K

Y

P

S

L

U

E

N

S

T

V

R

E

F

E

R

E

N

C

E

WFT 13

See page 16

WRFT 130

See page 20

There are many features of the FERMAT machine

that allowed us to improve our efciency. Value

for the money was an important consideration

and Fermat machines are excellent value for the

money. The features of the machine, for example:

large box ways, planetary gear boxes between the

servo motor and each of the ball screws, guided

counter weight, choice of CNC controls and well

known, high quality purchased components

all infuenced my decision to purchase Fermat

WFT 13 CNC machine. Sales support from the Fer-

mat Factory as well as from the local dealer was

excellent, the company responded with informa-

tion quickly any time it was needed.

Jerry Decker,

President of Precision Boring Company, USA

14 15

Machine confguration:

WFT 13

Basic machine on box guide ways

WFT 13 R

Machine on box guide ways with ramtravel 600 mm| 23.62 "

WFT 13 Linear

Machine on linear guide ways

WFT 15

machine on box guide ways

and linear guide ways on Z Axes

150 mm | 5.91" with 1000 mm | 39.37" travel

Horizontal Boring Mill WFT 13 CNC repre-

sents the newest technology and concept

of table type horizontal borers that are cur-

rently on the market. Thanks to the power-

ful headstock, high axial forces and the most

precise table in its category, Fermats WFT 13

can fulfll the needs of the most demanding

customers.

The accuracy and reliability of this machine

type is proven by years of use and hundreds

of installed machines. Annually, over 80 piec-

es of FERMAT WFT 13 are sold worldwide.

The machine allows efcient processing of

large and heavy workpieces while utilizing

high precision and quality of operation.

WFT 13 CNC is optionally equipped with the

Automatic Tool Changer (ATC) or the Au-

tomatic Pallet Changer System (APC) and

with diferent kinds of Manual or Automatic

Milling Heads.

WFT 13 CNC

Technical parameters

Metric System | Inch System

WFT 13 WFT 15

Diameter of Spindle mm | in 130 | 5.12 150 | 5.91

Taper of Spindle ISO-50, BT-50, CAT-50

Range of Spindle speed RPM 10-3 100

Rated Power of Main Engine S1/S6 kW | HP 37/56 | 50/75 51/77 | 68/103

Travel Table X

mm 2 000, 2 500, 3 000, 3 500, 4 000, 4 500, 5 000

in 78.74"/98,43"/118.11"/137.80/157.48"/177.17"/196.85"

Headstock Vertical Travel Y

mm 1 700, 2 000, 2 500, 3 000, 3 500

in 66.93"/78.74" /98.43"/118.11"/137.80"

Longitudinal Travel Z

mm 1 500, 2 000 2 100, 3300

in 59.05/ 78.74 82.68/ 129.92

Extension Spindel Travel W

mm 730 1 000

in 28.74 39.37

Longitudinal Headstock Travel V

(WFT 11R, 13R, 15R)

mm 600

in 23.62

Operating Feed X, Y, Z, V mm.min

-1

| in min 1-8 000 | 0.04-315

W mm.min

-1

| in min 1-6 000 | 0.04-236.2

B RPM 1-1,7

Rapid Traverse X, Y, Z, V mm.min

-1

| in min 12 000, 8000 * 28 000 ** | 474.44/314.91 */1102 **

W mm.min

-1

| in min 10 000, 8000 * | 393.70, 314.91*

B min

-1

2

Max. Table Load kg | lb 15 000, 20 000, 30 000 | 33 069, 44 092, 66 139

Table Dimensions

mm

1200 x1400, T15 1600 x1800, 1800 x2 200,

T20 2 000 x2 400, T25 andT40 see page 43

in

47.24x55.12*, 63.00x70.87**, 70.87x86.61***, 78.74x94.50****,

98.43x98.43, 98.43x118.11

* For Axial Force 40 kN, ** For WFT Linear

T

A

B

L

E

H

B

M

H

O

R

I

Z

O

N

T

K

Y

F

R

Z

K

Y

P

S

L

U

E

N

S

T

V

R

E

F

E

R

E

N

C

E

SEE OUR

MACHINING

VIDEO OF

WFT 13 CNC

16 17

Beds

The longitudinal and transversal

bed of the machine is made of

grey cast iron which is stabilized

through annealing. It was con-

structed in order to absorb the

maximum amount of vibrations

that are created during cutting.

WFT 13 CNC

Rotary Table

Pallet System

The rotary table has outstand-

ing positioning precision (4 arc

i.e. 0,010 mm/ 1 000 mm radius)

and high excentric load as a stand-

ard. There is no slip-sti ck during

the positioning of the table. Due

to simple desing and assembled

components, FERMAT tables re-

quire minimum maintenance and

adjustments during their lifetime.

The rotary table consists of three

main parts slide, bed and rotary

clamping plate. The clamping

plate is ftted to a cross roller taper

bearing that secures high load ca-

pacity with minimal passive resist-

ance.

The rotary movement is secured by

two pinions, each of them having

its own servomotor. The principle

of its operation is often described

as a Master-Slave Function. As a

standard, the rotary table operates

as a continous 4th axis.

The automatic pallet system has

2 to 5 pallets shovel system. For

more details see page 48.

T

A

B

L

E

H

B

M

H

O

R

I

Z

O

N

T

K

Y

F

R

Z

K

Y

P

S

L

U

E

N

S

T

V

R

E

F

E

R

E

N

C

E

Column

The column is made of grey cast

iron. Maximum rigidity and frm-

ness of the column is achieved

through the process of annealing

which also leads to precision and

rigidity in metal-working proce-

dures in production.

18 19

Technical parameters

Metric System | Inch System

WRFT 130

Diameter of Spindle mm | in 130 | 5.12

Taper of Spindle ISO-50, BT-50 | CAT-50

Range of Spindle Speed RPM 10 - 3 000

Rated Power of Main Engine S1/S6 kW | HP 37/56 | 50/75

Travel Table X

mm 2400-6100

in 94.49-240.18

Headstock Vertical Travel Y

mm 2 000, 2 500, 3 000, 3 500, 4000

in 78.74, 98.43, 118.11, 137.80, 157.48

Longitudinal Travel Z

mm 900, 1 200, 2100, 3 300, 3900

in 35.43, 47.24 ,82.68, 129.92, 153.54

Extension Spindel Travel W

mm 730

in 28.74

Ram Travel V mm | in 900 (1000) | 35.43(39.37)

Operating Feed X, Y, Z, W mm | in 1-10 000 | 0.04-394.00

Rapid Traverse X, Y, Z mm.min

-1

| in min 15000 | 590.55

V, W mm.min

-1

| in min 10 000 | 393.70

B min

-1

2

Max. Table Load kg | lb 25 000, 40 000, 50000 | 55 116, 88185, 110231

Table Dimensions

mm

2000 x2000, 2000x2500, 2000x3000,

2500x2500, 2500x3000, 3000x3000

in

78.74x78.74, 78.74x98.43, 78.74x118.11,

98.43x98.43, 98.43x118.11, 118.11x118.11

WRFT 130 CNC

The horizontal milling and boring machines

WRFT represent the newest technology and

concept of large table type horizontal bor-

ers with ram travel and moveable spindle.

WRFT machines are being used mostly dur-

ing powerful machining of big and heavy

workpieces up to 50 tons.

WRFT construction results from the con-

struction of a foor type WRF machine that is

layed out into T placement of the beds with

horizontal table travel (X-Axis), CNC rotary

table (B-Axis) and longitudinal column travel

(Z-Axis). On the guide ways of the column,

the headstock travels vertically (Y-Axis) with

its horizontal ram travel (V-Axis) and move-

able spindle (W-Axis).

Machine confguration:

WRFT 130 CNC

basic machine with spindle diameter

130mm | 5.19 and ram travel 900 mm |

35,43"

WRFT 130 is optionally equipped with the

Automatic Tool Changer (ATC) or the Auto-

matic Pallet Changer System (APC) and with

diferent kinds of Manual or Automatic Mill-

ing Heads.

T

A

B

L

E

H

B

M

H

O

R

I

Z

O

N

T

K

Y

F

R

Z

K

Y

P

S

L

U

E

N

S

T

V

R

E

F

E

R

E

N

C

E

20 21

25

T

A

B

L

E

T

Y

P

E

Beds

The longitudinal and transversal bed of the machine is

made of grey cast iron which is stabilized through annealing.

It was constructed in order to absorb the maximum amount

of vibratons that are created during cut ng.

Table Type - WRFT 130, 150, 160 CNC

Rotary Table

The rotary table has outstanding positoning precision(4 arc sec i.e. 0,010 mm/ 1000 mm

radius) and high excentric load as a standard. There is no slip-stck during the positoning

of the table. Due to simple desing and assembled components, FERMAT tables require

minimum maintenance and adjustments during their life tme.

The table consists of three main parts slide, bed and rotary clamping plate. The

clamping plate is ted onto a cross roller taper bearing that secures high load capacity

with minimal passive resistance.

The rotary movement is securedby twopinions, eachof them having its ownservomotor.

The principle of its operaton is ofen described as a Master-Slave Functon. As a standard,

the rotary table operates as a contnous 4th axis.

25

T

A

B

L

E

T

Y

P

E

Beds

The longitudinal and transversal bed of the machine is

made of grey cast iron which is stabilized through annealing.

It was constructed in order to absorb the maximum amount

of vibratons that are created during cut ng.

Table Type - WRFT 130, 150, 160 CNC

Rotary Table

The rotary table has outstanding positoning precision(4 arc sec i.e. 0,010 mm/ 1000 mm

radius) and high excentric load as a standard. There is no slip-stck during the positoning

of the table. Due to simple desing and assembled components, FERMAT tables require

minimum maintenance and adjustments during their life tme.

The table consists of three main parts slide, bed and rotary clamping plate. The

clamping plate is ted onto a cross roller taper bearing that secures high load capacity

with minimal passive resistance.

The rotary movement is securedby twopinions, eachof them having its ownservomotor.

The principle of its operaton is ofen described as a Master-Slave Functon. As a standard,

the rotary table operates as a contnous 4th axis.

WRFT 130 CNC

Beds

Rotary Table

The longitudinal and transversal

bed of the machine is made of

grey cast iron which is stabilized

through annealing. It was con-

structed in order to absorb the

maximum amount of vibrations

that are created during cutting.

The rotary table has outstanding

positioning precision (4 arc sec i.e.

0,010 mm/ 1000 mm radius). There

is no slip-stick during the position-

ing of the table. Due to simple des-

ing and assembled components,

FERMAT tables require minimum

maintenance and adjustments dur-

ing their life time.

The table consists of three main

parts slide, bed and rotary clamp-

ing plate. The clamping plate is ft-

ted onto a cross roller taper bearing

that secures high load capacity with

minimal passive resistance.

The rotary movement is secured by

two pinions, each of them having

its own servomotor. The principle of

its operation is often described as a

Master-Slave Function. As a stand-

ard, the rotary table operates as a

continous 4th axis.

T

A

B

L

E

H

B

M

H

O

R

I

Z

O

N

T

K

Y

F

R

Z

K

Y

P

S

L

U

E

N

S

T

V

R

E

F

E

R

E

N

C

E

25

T

A

B

L

E

T

Y

P

E

Beds

The longitudinal and transversal bed of the machine is

made of grey cast iron which is stabilized through annealing.

It was constructed in order to absorb the maximum amount

of vibratons that are created during cut ng.

Table Type - WRFT 130, 150, 160 CNC

Rotary Table

The rotary table has outstanding positoning precision(4 arc sec i.e. 0,010 mm/ 1000 mm

radius) and high excentric load as a standard. There is no slip-stck during the positoning

of the table. Due to simple desing and assembled components, FERMAT tables require

minimum maintenance and adjustments during their life tme.

The table consists of three main parts slide, bed and rotary clamping plate. The

clamping plate is ted onto a cross roller taper bearing that secures high load capacity

with minimal passive resistance.

The rotary movement is securedby twopinions, eachof them having its ownservomotor.

The principle of its operaton is ofen described as a Master-Slave Functon. As a standard,

the rotary table operates as a contnous 4th axis.

Column (Y-axis)

FERMAT developed a unique

constructi on of the column (sin-

gle piece design of the column

and the slide, two ball screws

for 130 mm spindle diameter no

counterweight). Maximum rigid-

ity and frmness of such a unison

is achieved through the process

of thermal stabilization, which

ultimately leads to increased pre-

cision and rigidity of the metal-

working procedure.

Ram (V-axis)

To achieve the best features of the

ram ductile iron, a whole complex

of annealing methods have been

applied. Higher accuracy of the

ram axis is achieved by two ball

screws (the so-called Gantry Axis)

and two Linear Positioning Scales.

Thanks to this, maximum safety

with high precision and quality

productions can be consistently

ensured.

22 23

WFC 13 CNC

WFC 13 CNC machine is a horizontal boring

mill with a live spindle of diameter 130|5.12

(optionally 110|3.94 ) and a maximum table

load up to 8000 kg | 17637 lb. The machine

has a sturdy construction allowing demand-

ing machining of cast, steel and cast steel

worpieces.

This machine concept is based on fxed col-

umn which provides absolute frmness nec-

essary for precise machining and two crossed

horizontal beds for table (X and Z axes). Both

beds and column are made of grey cast iron

which is stabilized through annealing to ab-

sorb the maximum of vibrations caused by

cutting.

Machine confguration:

WFC 13 CNC Basic machine with

a spindle diameter of 110mm | 3.94

WFC 13 CNC Basic machine with

a spindle diameter of 130mm | 5.12

T

A

B

L

E

H

B

M

H

O

R

I

Z

O

N

T

K

Y

F

R

Z

K

Y

P

S

L

U

E

N

S

T

V

R

E

F

E

R

E

N

C

E

Technical parameters

Metric System | Inch System

WFC 13

Diameter of Spindle mm | in 110 | 4.33 130 | 5.12

Taper of Spindle ISO-50, BT-50 | CAT-50

Range of Spindle Speed RPM 10-3 100

Rated Power of Main Engine S1/S6 kW | HP 37/56

Travel Table X mm | in 2500 | 98.43"

Headstock Vertical Travel Y

mm 1700, 2000, 2500

in 66.93, 78.74, 98.43

Longitudinal Travel Z mm | in 1600 | 62.99

Extension Spindel Travel W mm | in 730 | 28.74

Operating Feed X, Y, Z, W mm | in 1-10 000 | 0.04- 236.2

Rapid Traverse X, Y, Z mm.min

-1

| in min 10 000 | 393.70

W mm.min

-1

| in min 8 000 | 314.91

B min

-1

2

Max. Table Load kg | lb 8 0000 | 17637

Table Dimensions

mm 1200x1200, 1200x1400, 1400x1600, 1600 x 1600

in 47.24x47.24, 47.24x55.12, 55.12x62.99, 62.99x62.99

Column and Beds

Rotary Table

The concept is based on fxed

column which provides absolute

frmness necessary for precise ma-

chining and two crossed horizon-

tal beds for table (X and Z axes).

Both beds and column are made

of grey cast iron which is stabilized

through annealing to absorb the

maximum of vibrations caused

by cutting. X Axes is supported by

two 45 diagonal supports.

The table consists of slide, bed and

rotary clamping plate. High load

capacity and minimal passive resist-

ance is secured by cross taper roller

bearing under the clamping plate.

Headstock

Headstock of WFC 13 CNC is

equipped with a live spindle of

130 mm in diameter. FERMAT can

optionally provide this machine

with spindle diameter 110 ".

24 25

WFC 10 CNC

The WFC 10 CNC machine is a new model of

horizontal boring mill equipped with a spin-

dle diameter of 100mm |3.94. It is the small-

est horizontal boring machine from the

Fermat production suitable for machining of

not large and lightweight workpieces up to

3000 kg (6614 lb).

WFC 10 CNC is built in a standard confgura-

tion with a fxed column, moveable spindle

and crosswise moveable rotary table. Due

its high reliability, high cutting performance

and an easy operation combined with a

great money value the machine becomes

popular among clients.

WFC 10 CNC is optionally equipped with

the Automatic Tool Changer (ATC), Coolant

Through Spindle, Chip Conveyor or Auto-

matic Pallet Changer System (APC).

Machine confguration:

WFC 10 CNC Basic machine with

a spindle diameter of 100mm | 3.94

Technical parameters

Metric System | Inch System

WFC 10

Diameter of Spindle mm | in 100 | 3.94

Taper of Spindle ISO-50, BT-50, CAT-50

Range of Spindle Speed RPM 10-2000 (3000)*

Rated Power of Main Engine S1/S6 kW | HP 17/25, 22/33 | 23/36, 26/44

Travel Table X

mm 1250, 1600, 2000

in 49.21, 62.99, 78.74

Headstock Vertical Travel Y

mm 1250

in 49.21

Longitudinal Travel Z

mm 1250

in 49.21

Extension Spindel Travel W mm | in 730 | 28.74"

Operating Feed X, Y, Z, W mm | in 4-4000 | 0.18-157.48

Rapid Traverse X, Y, Z, W mm.min

-1

| in min 1-8000 | 0.04-314.96

B min

-1

2

Max. Table Load kg | lb 3000 | 6614

Table Dimensions

mm 1000x1120, 1200x1400

in 39.37x44.09, 47.24x55.12

T

A

B

L

E

H

B

M

H

O

R

I

Z

O

N

T

K

Y

F

R

Z

K

Y

P

S

L

U

E

N

S

T

V

R

E

F

E

R

E

N

C

E

26 27

Floor Type HBM

Our products

One of the main characteristics of the FERMAT foor type horizon-

tal boring and milling machines is their powerful milling and drill-

ing chip removal (even with top Y-axis stroke) and higher preci-

sion than is ofered by other machines available on the market.

Their large variation of selectable parameters is combined with its

broad range of operating functions. Their main feature is a modu-

lar concept that allows great production variability and rapid set-

up through the use of peripheral tools and accessories.

The machine moves in 3 or 4 diferent axes (X, Y, Z and W for bor-

ers). An additional B and/or V-axis is added when the machine is

equipped with the rotary table. Several clamping plates can be

joined together, or in combination with a Rotary Table to achieve

specialized confgurations easily and quickly.

The basic model of the machine comes with Heidenhain, Fanuc or

Siemens controls and drives.

Work pieces can be clamped either on the additional rotary table,

on the clamping plates, or using both these possibilities.

The main working purpose of the machines is chip removal from

spacious and weighty steel, cast steel, or cast iron work pieces. The

machines technology allows its wide utilization in milling, boring,

reaming, and threading processes. FERMAT machines stand out

thanks to their capacity to achieve higher precision than their

competitors.

Horizontal Boring and Milling

Machines Floor Type

H

O

R

I

Z

O

N

T

K

Y

F

R

Z

K

Y

P

S

L

U

E

N

S

T

V

R

E

F

E

R

E

N

C

E

WRF

See page 28

WF

See page 32

WRF portable

See page 33

We have now seen that big boring mill on linear

guideway is works wery vell. Also when working

with spindle and ram out, and the machine is eco-

nomical compare to hydrostatic machines, and

also Fermat machine have long stroke on spindle

1000mm|39.37. We fnd the service well with quick

response as well, and also the technicians in Fer-

mat help us to improve smart solutions where we

save cost. After 2 years of using FERMAT HBMs in

Sby we decided to order a third foor type WRF

boring mill as we got a new order for heavy parts

subcontracting for wind power industry.

Michael Jacobsen,

President of Nordmark Maskinfabrik A/S, Denmark

28 29

Horizontal Boring Machines WRF Series

Technical parameters

Metric System | Inch System

WRF 130 WRF 150 WRF 160

Diameter of Spindle mm | in 130 | 5.12 150 | 5.90 160 | 6.30

Taper of Spindle ISO-50, BT-50 | CAT-50 ISO-50 (60), BT-50(60) | CAT-50 (60)

Range of Spindle Speed RPM 10-3 000 10-2 800 10-2 500

Rated Power of Main Engine S1/S6 kW | HP 37/56 | 40/60 51/77| 68/103 60/80 | 80/107

Travel Table X

mm 2 400-26 900

in 94.49-1059

Longitudinal Travel Z

mm 900 1 000 (1200, 1500)

in 35.43 39.37 (74.24, 59.06)

Extension Spindel Travel W mm | in 730 | 28.74 1 000 | 39.37"

Longitudinal Headstock Travel V

mm 1 200, 2 400, 3 600

in 74.24", 94.49", 141.73"

Operating Feed X, Y, Z, W mm | in 1-10000 | 0.003"-393.70"

V mm | in 1-8000 | 0.04-315

B PRM 0-1.7

Rapid Traverse X mm.min

-1

| in min 1-20 000 | 0.003-787.40

Y, V mm.min

-1

| in min 1-15 000 | 0.003-590.51

Z, W mm.min

-1

| in min 1-12 000 | 0.003-472.44

B PRM 2

Max. Table Load kg | lb 25 00050 000 | 55 11611 0231

Table Dimensions

mm

2000x2000, 2000x2500, 2000x3000, 2500x2500,

2500x3000, 3000x3000, 3500x3500

in

78.74x78.74, 78.74x98.43, 78.74x118.11, 98.43x98.43,

98.43x118.11, 118.11x118.11, 137.80x137.80

H

O

R

I

Z

O

N

T

K

Y

F

R

Z

K

Y

P

S

L

U

E

N

S

T

V

R

E

F

E

R

E

N

C

E

Horizontal Boring Machines WRF are the

biggest representatives of FERMAT boring

mill production. They are used mostly for

precise and powerful machining of big and

heavy work pieces from iron, cast steel and

steel. Our machines are usually intended for

machining of large energy parts, crane or

ship parts, oil and gas equipment and similar

structures.

WRF 130, 150, 160 CNC comes together

with a horizontally and vertically move-

able operators cabin. The machines can be

equipped with number of technological de-

vices that considerably extend the produc-

tivity and functionality of the machine.

Machine confguration:

WFR 130, 150, 160 Basic confguration

WRF 150 TR Machine confguration

with tilting headstock

WRF 130 PORTABLE

WRF 160 H - Machine confguration with

hydrostatic X Axis

WRF 160 H - Machine with box way guided

with travel 1 500 mm | 59,05" and spindle

travel 1000 mm | 39.37"

30 31

Column (Y-axis)

FERMAT developed a unique con-

struction of the column (single

piece design of the column and the

slide, two ball screws for 130 mm

spindle diameter or three for 150

and 160 mm spindle diameter, no

counterweight). Maximum rigid-

ity and frmness of such a unison

is achieved through the process

of thermal stabilization, which

ultimately leads to increased pre-

cision and rigidity of the metal-

working procedure.

Ram (Z-axis)

To achieve the best features of the ram, ductile iron,

a whole complex of annealing methods have been

applied. Higher accuracy of the ram axis is achieved

by two ball screws (the so-called Gantry Axis) and

two Linear Positioning Scales. Thanks to this, maxi-

mum safety with high precision and quality produc-

tions can be consistently ensured.

WRF SERIES WRF 130 CNC Portable

H

O

R

I

Z

O

N

T

K

Y

F

R

Z

K

Y

P

S

L

U

E

N

S

T

V

R

E

F

E

R

E

N

C

E

Headstock

The headstock contains a ram travel

drive, a live spindle and a two-speed

gearbox, which is guided automati-

cally by spindle revolutions. A mod-

ern AC motor is used to control the

fuency of revolutions. The cast is

made from special ductile iron.

Column (Y-axis)

FERMAT developed a unique constructon of the column (single

piece design of the column and the slide, two ball screws for

130 mm spindle diameter or three for 150 and 160 mm spindle

diameter, no counterweight). Maximum rigidity and rmness

of such a unison is achieved through the process of thermal

stabilizaton, which ultmately leads to increased precision and

rigidity of the metal-working procedure.

stabilizaton, which ultmately leads to increased precision and

rigidity of the metal-working procedure.

Floor Type - WRF 130, 150, 160 CNC

Bed

The bed of the machine is made of grey

cast iron, and is stabilized through annealing.

It was constructed in order to absorb the

maximum amount of vibratons which are

created during the cut ng process. It features

heavy duty Schneeberger (INA, THK) linear

guide ways, further contributng to the

precision and rigidity of the machine.

F

L

O

O

R

T

Y

P

E

13

Beds

The bed of the machine is made

of grey cast iron, and is stabilized

through annealing. It was con-

structed in order to absorb the

maximum amount of vibrations

which are created during the cut-

ting process. It features heavy duty

Schneeberger (INA, THK) linear

guide ways, further contributing

to the precision and rigidity of the

machine.

Technical parameters Metric / Inch WRF 130 CNC Portable

Diameter of spindle mm | in 130 | 5.12

Taper of spindle ISO 50, BT 50, CAT 50

Range of spindle speed RPM 10-3000

Rated power of main engine S1/S6 kW | HP 37/56 | 50/75

Horizontal Column Travel X mm | in 2400- 4 300 | 94.49-169,29

Vertical Column Travel Y mm | in 2000-4000 | 78.74-157.48

Ram Travel Z mm | in 900 | 35.43

Spindle Travel W mm | in 730 | 28.74

Operating feet All Axes X,Y,Z,W mm. min

-1

| in min 1-10000 | 0.003- 393.70

Rapid Travel X, Y, Z, W mm. min

-1

| in min

1-10000/1-20000/1-18000/1-12000

393.70/787.40/708.66/472.44

Max. workpiece weight kg | lb 25000 | 55116

Table dimensions mm | in

2000x2000, 3500x3500

78.74x78.74, 137.80x137.80

Portable horizontal boring WRF 130 CNC allows an easy

transfer of the machine outside a permanent basis to

the desired loca-tion. This is used while machining large

parts, which can not be transferred easily, such as parts

for the construction of large energy parts, ships, etc.

Therefore, the column has a supporting/lifting rod at the

top for moving the machine within the plant. The pow-

er cables and coolant water hoses are equipped with

couplings for easy re-connection. Similarly, anchoring

and balancing the machine is designed to facilitate the

alignment geometry in place. WRF 130 comes together

with a horizontally and vertically moveable operators

cabin. Technological possibilities of the machine can

be freely extended by standard accessories as for WRF

130CNC machines.

32 33

WF 13 CNC

Technical parameters

Metric System | Inch System

WF 11 WF 13

Diameter of Spindle mm | in 110 | 4.33 130 | 5.12

Taper of Spindle ISO- 50, BT-50, CAT-50

Range of Spindle Speed RPM 10-3 000

Rated Power of Main Engine S1/S6 kW | HP 37/56 | 50/75

Travel Table X

mm 2 800-6 800 (by 500), 7 800 -22 800 (by 1 000)

in 110.24- 267.72 (by 20), 307.09 - 897.64 (by 39)

Headstock Vertical Travel Y

mm 1700, 2000, 2500, 3000, 3500

in 66.93", 78.74", 98.43", 118.11", 137.80"

Longitudinal Travel Z mm | in 600 | 23.62"

Extension Spindel Travel W mm | in 730 | 28.74"

Operating Feed X, Y, Z, W mm.min -1 /in min 1-8000 | 0.04"-314.96"

W, Z mm.min -1 /in min 1-6 000 | 0.04-236.2

B RPM 1-1.7

Rapid Traverse X, Y, Z, V mm.min -1 /in min 12000, 8000* | 474.44", 314.91"*

W mm.min -1 /in min 10000, 8 000* | 393.70", 314.91"*

B RPM 2

Max. Table Load kg | lb 15000, 20000 | 33069, 44092

Table Dimensions

mm 1600x1800, 1800x2200, 2000x2400

in 63.00"x70.87", 70.87"x86.61", 78.74"x94.50"

* For Axial and Radial Force

A Floor type horizontal boring mill WF type is a

basic CNC machine from FERMAT production.

The machine is designed for precise and high-

ly efcient coordinate boring, drilling, milling,

and cutting of threads of big and heavy work

pieces up to 20 tons (44092 lb) of large and

rugged work pieces from cast iron, cast steel

and steel. The machines can be equipped, in

accordance with the technology needs, with

a part machining area built up from clamping

plates, or with one or more additional tables.

The machine can be equipped with a number

of additional technological devices that con-

siderably widen the possibilities of machine

usage.

H

O

R

I

Z

O

N

T

K

Y

F

R

Z

K

Y

P

S

L

U

E

N

S

T

V

R

E

F

E

R

E

N

C

E

Machine confguration:

WF 13 CNC basic machine with moveable

spindle 130mm/5.12

WF 11 CNC machine with spindle diameter

110mm/4.33

WF 11/13 R machine with ram travel

34 35

WF 11, 13 CNC

Headstock

The headstock of WF 13 CNC is

equipped with a live spindle with trav-

el 730 mm | 28.74" and eather no ram

stroke or 600 mm | 23.62

Beds

The bed of the machine is made

of grey cast iron which is stabi-

lized through annealing. It was

constructed in order to absorb the

maximum amount of vibrations

that are created during cutting.

Guideways are hardened.

Column

The column is made of grey cast

iron. Maximum rigidity and frm-

ness of the column is achieved

through the process of annealing,

which also leads to precision and

rigidity in metal-working proce-

dures in producti on.

F

L

O

O

R

T

Y

P

E

C

O

M

P

O

N

E

N

T

S

O

T

H

E

R

P

R

O

D

U

C

T

S

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

36 37

Universal milling machine FGU (RT) CNC

FGU milling machine is an universal CNC

milling machine for machining parts with

lengths up to 5000 mm (197) and height up

to 3500 mm (138). It is especially suitable for

machining from 5 sides thanks to its build in

automatic micro-positioning 2 axis head.

Rigid machine frame design with weight

over 40 000 kg (88185 lb) guaranties precise

work piece geometry and dimensions after

machining as well as allows productive chip

removal.

As a standard, machine is equipped with mi-

cro positioning head UHA 30mi. Automatic

head transmits 30kW (40HP) output, 1600

Nm and it is rated from 10 to 4000 rpm. It can

be positioned in any angle with increment of

0.001 degree. After positioning the head is

hydraulicaly clamped. FGU can be equipped

with automatic tool changer or robot. Robot

can change the tools not only into a milling

head spindle in vertical position but also in

most of the angular combinations of the

head. This feature brings signifcant time

savings as well. Robot also can handle tools

up 70 kg or even heavier as an option.

Machine is recommended in execution with

CNC rotary table for maximum work piece

load 15 000 or 20 000 kg (33069 or 44092 lb).

For machining of long work pieces can be

equipped with fat table as well.

Precise machining from5 sides and any angles

candecreasethenumber of work piecesetups.

This contributes to productivity and higher

precision. It is ideal for machining parts as hy-

draulic blocks, pumps, molds and dies, etc.

Technical parameters

Metric System | Inch System

FGU FGU RT

Diameter of Spindle ISO- 50, BT-50, CAT-50

Range of Spindle Speed RPM 10 - 3 000 (4 000)

Rated Power of Main Engine S1 kW | HP 30 | 40

Travel Table X mm | in 3 200 | 125.98 1 500-5 000 (by 500) | 59.064" - 196.85" (by 19.69")

Headstock Vertical Travel Y mm | in 1 700, 2 000, 2 500 | 66.93, 78.74, 98.43

Longitudinal Travel Z mm | in 1 600 | 62.99"

Operating Feed X, Y, Z mm.min

-1

/in min 4 - 8000 | 0.18"- 314.96"

B min

-1

1-1.7

Rapid Traverse X mm.min

-1

20 000* | 787.40" 10 000 | 393.70"

Y, Z mm.min

-1

10 000 | 393.70 10 000 | 393.70

B min

-1

1-1.7 2

Max. Table Load kg / lb 10 000 | 22 046 15 000, 20 000 | 33 069, 44 092

Table Dimensions

mm 1 000 x 3 600 1 200x1 400, 1 600x1 800, 1 800x 2 200, 2 000x2 400

in 39.37x141.73

47.24x55.19, 63.00x70.87,

70.87x86.61,78.74x94.50

* linear guide ways

C

O

M

P

O

N

E

N

T

S

O

T

H

E

R

P

R

O

D

U

C

T

S

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

38 39

WRF MILL CNC is similar to the rest of the

WRF line, with the exception of a longer ram

travel, and without a travelling spindle. This

confguration provides a mounting platform

for a variety of attachments such as automat-

ic angle heads, milling heads, or faceplates.

The basic foor plan of WRF MILL CNC ma-

chines is horizontal table travel (X-axis), ver-

tical headstock travel (Y-axis) and horizontal

ram travel of rectangular profle (Z-axis).

Universal milling machine WRF MILL

Technical parameters

Metric System | Inch System

WRF MILL

Ram Dimension mm | in 400 x 500 | 15.75"x19.65"

Taper of Spindle ISO - 50, BT - 50, CAT - 50

Range of spindle Speed RPM 10-4 000

Rated Power of Main Engine S1/S6 kW | HP 37/56 | 50/75

Horizontal Column Travel X mm | in 2 400- 28 100 | 94.49" - 1106"

Vertical Column Travel Y mm | in 2 000 - 6 000 | 78.74" - 236.22"

Ram Travel Z mm | in 1 500 | 59.06

Longitudinal Table Travel V mm | in 1 200, 2 400, 3 600 | 47.24, 94.49, 141.73

Operating Feed X, Y, Z, V mm.min

-1

/ in min 1-10 000 | 0.04"- 393.70"

V min

-1

0-1.7

B mm.min

-1

/ in min 1-8 000 | 0.04" - 314.96"

Rapid Traverse X mm.min

-1

/ in min 1-20 000 | 0.04"-787.40"

Y, V mm.min

-1

/ in min 1-15 000 | 0.04- 590.55

Z min

-1

1-10 000 | 0.04" - 393.70"

V mm.min

-1

/ in min 15 000 | 590.55"

B min

-1

2

Max. Additional Table Load kg / lb 25 000, 40 000, 50 000 | 55 116, 88 185, 110 231

Table Dimensions

mm 2 000x2 000-3 500x3 500

in 78.74x78.74" - 137.76"x137.76"

* linear guide ways

Universal Manual Head

Extending spindle

Universal Automatic Head

Face Plate

C

O

M

P

O

N

E

N

T

S

O

T

H

E

R

P

R

O

D

U

C

T

S

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

40 41

BUC E 63 CNC/BUT E 63 E CNC are fully CNC-controlled centre grinders designed for grinding cylindrical and

conical external surfaces or, with equipment for internal grinding, for grinding of internal surfaces with the

recess or traverse grinding method. Grinding of face surfaces can be performed by the side of the grinding

wheel or its circumferential surface with inclined drive headstock. Series E BUC grinder can be of use particu-

larly in the piece and series production for grinding workpieces weighing up to 3000 kg. This is a precision

machine and allows grinding of diameters to precision of IT 4 tolerance and higher. The standard version of

the machine is equipped with control system Siemens 802D sl, alternatively Siemens 840 D or K51-2C. The

machine meets CE standards and is supplied with basic equipment and a guarantee of 1 year.

The machines are additionally equipped and designed according to specifc needs of the customer and

taking into account the materials grinded or the selected machining technology.

Grinding Machines FERMAT Machine Tool

X

C

Z

C

O

M

P

O

N

E

N

T

S

O

T

H

E

R

P

R

O

D

U

C

T

S

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

Parameters Units BUCE BUB E

Swing mm 630 / 850 / 1000 320 / 400 / 500

Centre-to-centre distance mm 2000 / 3000 / 4000 / 5000 / 6000 1000 / 1500 2000 / 3000

Max. weight of workpiece in centres kg 3000 500

Max. weight of workpiecefying(incl. clamp) kg 300 150

Movement speed X, Z axis m.min-

1

10 10/ 8

Grinding wheel mm 750 x 100 x 305 500 x 80 x 203

Grinding wheel circumferential speed m.s

-1

25 - 45 or 10 - 50

Grinding wheelhead inclination +30/10 +45/-10

Main electric motor power output kW 22 or 17 11

Driving headstock inclination k 0 -90

Cone in drive headstock spindle Morse 6 ISO 296-1991 Morse 65 ISO 296-1991

Drive stock front cone - A 2-6 ISO 702-1-1992 A 1-5 ISO 702-1-1992

Cone in tailstock sleeve - Morse 6 ISO 296-1991 Morse 5 ISO 296-1991

Tailstock cylindricity balancing mm 1

Machine length mm 7626/ 9626/ 11916/ 13916 5500 / 6700 / 7800

Machine width mm 4350 3400

Machine height mm 2888 1950

Machine weight kg 13000/ 15000/ 17100/ 18800 7000 / 7850 / 8900

Control system - Siemens 802D sl / Siemens 840D sl / BaR

Services covering supply, upgrading and

overhaul of the grinding machines within

the framework of the group are provided

since 2007 by FERMAT Machine Tool Ltd.

The company is by virtue of its location in

Prague FERMAT plant indirectly linked to

the long history of world renown produc-

tion of grinding machines in this location.

42 43

The WRF, WRF MILL, WF, WFT, WFC

and WRFT series are equipped with a

standard boring mill live spindle. The

headstock provides an adjustable

mounting platform for a variety of at-

tachments such as CNC angle heads,

manual angle heads, support spindle

sleeves, etc. The headstock is driven

by a servo drive. The two-speed auto-

matic gearbox gives enough torque

for heavy metal chip removal and for

powerful high-speed drilling. FERMAT

machines are also capable of high-

performance manufacturing due to

the spindle axial force of 40,000 Nm.

In WRFT series, two Y-axis ball screws

with two Heidenhain scales control

slide ram defections. The third balls-

crew in the torque position that is con-

stantly pushing the headstock body

upwards is added for 150 and 160 mm

headstock. The upper part features

heavy duty Schneeberger roller linear

guideways, further contributing to the

precision and rigidity of the machine.

WFT machines are equipped with one

ballscrew and counterweight system.

All the tables have outstanding positioning precision (4 arc

i.e. 0.010 mm / 1 000 mm radius) and high excentric load as a

standard. There is no slip-stick during the positioning of the

table. Due to simple design and assembled components, FER-

MAT tables require minimum maintenance and adjustments

during their life ti me.

The rotary table consists of bed, slide, and rotary clamping

plate. The slide enables the rotary clamping plate to move in

the V-axis. The clamping plate is ftted onto a cross roller ta-

Tool Standard SK (ISO)

Tool Standard

ISO

A

B

+/- 0,25

C

+/- 0,25

SK 40 44,45 94,5 88,25

SK 50 69,85 135,60 126,60

SK 60 107,95 201,65 191,65

Tool Standard

CAT

A

J

+/- 0,3

K

+/- 0,3

SK 40 44,45 84,50 79,25

SK 50 69,85 127,00 119,40

SK 60 107,95 199,95 189,45

Tool Standard

CAT

A

B

+/- 0,25

C

+/- 0,25

SK 40 44,45 100,35 93,35

SK 50 69,85 146,75 136,75

SK 60 - - -

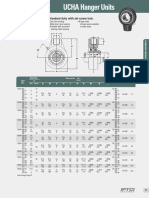

Headstock 100, 110, 120, 130, 150, 160 Rotary Table

Machine components

WFT 13R

per bearing that secures high load capacity with minimal pas-

sive resistance. In order to achieve precision in work pieces,

the rotary table is hydraulically clamped at eight points (T25,

T40, T50) or four points (T15, T20) to avoid rotation during the

working process.

The table is governed by the control system of the machine,

and there is a rotary encoder in the centre of the table that fa-

cilitates the automatic positioning in increments of 0.001. As

a standard, the rotary table operates as a continous 4th axis.

C

O

M

P

O

N

E

N

T

S

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

T15, T20

Clamping Plate Size 1 600x1 800, 1 800x2 200, 2 000x2 400 63.0x70.9, 70.9x86.6; 78.7x94.5 mm in

Maximum Table Load 15 000; 20 000 33,069; 44,092 kg lb

T-Slots Size 20 H8 22 H8

Distance (Middle) 125 (160) 4.9 (6.3) mm in

V-axis Travel 1 500 5 000 59.1 196.8 mm in

Operation Trave V-axis 1 8 000 0.05 315 mm/min in/min

Operation Travel B-axis 0 2 0 2 RPM RPM

Rapid Travel V-axis 10 000 393.7 mm/min in/min

T25, T40, T50

Clamping Plate Size

2 000 x 2 000, 2 000 x 2 500, 2 000 x 3 000,

2 500 x 2 500, 2 500 x 3 000, 3 000 x 3 000

78.7 x 78.7, 78.7x 98.4, 78.7 x 118.1,

98.4 x 98.4, 98.4 x 118.1, 118.1 x 118.1

mm in

Maximum Table Load 25 000 50 000 55,115 110,231 kg lb

T-Slots Size 28 H8 28 H8

Distance (Middle) 160 (250) 6.3 (9.8) mm in

V-axis Travel 1 200 9 500 47.2 374 mm in

Operation Trave V-axis 1 10 000 0.04 393.7 mm/min in/min

Operation Travel B-axis 0 1,7 0 1.7 RPM RPM

Rapid Travel V-axis 20 000 787.4 mm/min in/min

WRF 160

44 45

FERMAT machines are of ered with Heidenhain

iTNC 530, Fanuc 31i, or Siemens Sinumerik 840

D equipped with a 15 LCD display, an operating

panel with a keyboard, and an electronic hand-

wheel. As an option, our machines can be

supplied with Fanuc 0i MD or Heidenhain 620

TNC with 10 LCD display.

The control system coordinates the continuity of

all the axes, and also when peripheral tools are

attached, such as a rotary table or a milling head.

Control System

Control Systems

C

O

M

P

O

N

E

N

T

S

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

HR 410 HR 520 HR 550

Homp I-pendant Standard

inzerce H

46 47

Lubricati on of linear guide ways and ball screws

(X, Y, and Z-axis) is performed by a special

lubricati on unit.

The Central Lubricati on System is designed

with progressive dividers that distribute specifc

amounts of lubricant.

Lubrication Unit

Electrical devices are mostly located in

the switchboard. It includes the basic

unit of the control system, components

for motor drive of the axis and spindle,

and other electrical features made

by renowned manufacturers such

as Schneider, Telemechanique, and

Siemens. The switchboard is being

cooled by a unit built in the door of the

switchboard made by Rittall.

Switchboard

Horizontal movement on X-axis longer than six

meters is secured by a rack with two pinions that

are in a Master-Slave relati onship.

Rack

Guiding surfaces are covered

lenghtwise and crosswise with

telescopic covers.

Telescopic Covers

The X, Y, Z and V axes are equipped with linear scales that

ensure the accuracy of the machine.

The W-axis is measured directly from the servomotor

encoder or opti onally by a Heidenhain linear scale.

Measurement of spindle revoluti ons is performed by the

rotary encoder that allows for the desired positi oning of

the spindle. All f nal positi ons of the parti cular axes are

secured by a limit switch.

Linear Scales Heidenhain

Electrical Components

C

O

M

P

O

N

E

N

T

S

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

Other Components

Roller linear guide ways enable a higher speed

of movement and a smaller force needed for

the machines movement. This results in higher

accuracy of positi oning with smaller energy

consumpti on, and longer operati ng life for

components such as ballscrews, servomotors,

etc. This soluti on requires minimum aintenance

and simplif ed, quicker eventual repairs.

X, Y, Z, and W-axis movement is facilitated by

ballscrews with the favorable characteristic

of very low fricti on. Thanks to the precision

tolerances between the nut and the screw, high

rigidity and accuracy is achieved.

Ballscrews

Linear Guide Ways

An integral part of the machine is a Hydraulic Aggregate used for

clamping and unclamping of a tool from the spindle. On the front

side, there is a liquid level gauge, with a thermometer, for visual

level and temperature checks of oil in the tank.

Hydraulic Aggregate

48 49

Accessories

Automatic Pallet Changer System: Automatic Tool Changer ATC, Robots

APC- Automatic Pallet Changer System

The Automatic Pallet Changer System on the

machine reduces unproductive time during

machining. Machining can be carried out

on one pallet, while the others can be used

for preparation (cleaning of table, set up of

work-piece, etc). The APC system consists of

two or more pallets (according to customer

requirements).

Pallet dimension:

1 600 x 1 800 mm/63.00x70.87

- maximum load 15 t/33069 lb

1 800 x 2 200 mm/70.87x86.61

- maximum load 15 t/33069 lb

1200 x 1200/47.24 x 47.24

- maximum load 5 t/11023 lb*

1200 x 1400/47.24 x 55.12

- maximum load 5 t/11023 lb*

1400 x 1600/55.12 x 63.00

- maximum load 5 t/11023 lb*

*available with 2 to 5 pallets

Description of pallet change

The pallet exchange process is performed in

fve phases:

1. The pallet is unclamped from the X axis.

The shifting slide is connected to the rotati-

on slide on the X-axis by pins inserted into

the lock.

2. The pallet itself is moved by a chain, whe-

re it is pulled by the pin up to the clamping

position

3. The X axis slides moves infront of the next

pallet with the workpiece loaded.

4. The new pallet is shifted to X axis slides,

then the shifting slide retracks.

5. The Pallet is clamped to the X axis.

Automatic Pallet Changer System by Fermat

can save you time and increase the fexibility

of production & business competitiveness.

ROBOTI + FOTO ROBOT

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

Automatic tool change is accomplished by

a chain (for 20, 32, 40, 60 and 90 tools). Tool

changer can exchange tool into the live

spindle as well to automatic head spindle.

Automatic Tool Changer

for 20, 32, 40, 60 or 90 tools

50 51

2 : 380 mm

3 : 555 mm

2 2 5

3 2 5

806

926

430

4 8 5

2 2

5

Universal micro-indexing milling head - UHAmi 30

Spindle Taper SK 50 (DIN, ANSI, MAS)

Hydraulic Tool loosing

Tool clamping force 20 kN

Angle contact High precision bearings mounted on

the tool-holder spindle, trio at the forward side and

couple the back side

Ground gears

Tool cooling, AXIAL through the main spindle

External tool cooling

Rotary encoder at both axes

Taper air-jet

A axis range 180

Speed 10-3000 rpm

Power 30 kW

Torque 1600 Nm

Indexing 0,001

Clamping torque A axis - 3800 Nm C axis - 6500 Nm

Universal Automati c Head UHA 30

automatically attached to the headstock,

automatic positioning, automatic tool clamping

and unclamping.

Revolutions: 3 000 RPM

Maximum Power: 30 kW (40 HP)

Maximum Torque (150 RPM): 1 600 Nm

Tool: ISO 50 DIN 69871

Pull Stud : DIN 69872

Turning: 2,5/ 2,5 (1/ 1)

Coolant Through Spindle: Standard

Right Angle Manual Head PHM 37

- manually attached to the headstock, manual positioning,

automatic tool clamping and unclamping.

Revolutions: 3 000 RPM

Maximum Power: 37 kW (50 HP)

Maximum Torque (150 RPM): 2 000 Nm

Tool: ISO 50 - DIN 69871

Pull Stud: DIN 69872

Turning: any degree (optionally 2,5/1)

Coolant Through Spindle: Option

UHM 30

UHA 30

PHM 37

Milling Heads, Face Plates

Universal Manual Head UHM 30

manually attached to the headstock, manual

positioning, automatic tool clamping and

unclamping.

Revolutions: 3 000 RPM

Maximum Power: 30 kW (40 HP)

Maximum Torque (150 RPM): 1 600 Nm

Tool: ISO 50 DIN 69871

Pull Stud : DIN 69872

Turning: any degree (opti onally 2,5/ 2,5; 1/ 1)

Coolant Through Spindle: Not Possible

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

Right Angle Automati c Head PHA 37

automatically attached to the headstock, automatic

positioning, automatic tool clamping and unclamping.

Revolutions: 3 000 RPM

Maximum Power: 37 kW (50 HP)

Maximum Torque (187 RPM): 2 000 Nm

Tool: ISO 50 DIN 69871

Pull Stud: DIN 69872

Turning: 2,5 (1)

Coolant Through Spindle: Standard

PHA 37

Milling Heads, Face Plates

36

UHA 30

Universal Automatc Head UHA 30 automatcally

atached to the headstock, automatc positoning,

automatc tool clamping and unclamping.

Revolutons: 3 000 RPM

Maximum Power: 30 kW (40 HP)

Maximum Torque (150 RPM): 1 600 Nm

Tool: ISO 50 DIN 69871

Pull Stud : DIN 69872

Turning: 2,5/ 2,5 (1/ 1)

Coolant Through Spindle: Standard

PHM 37

Right Angle Manual Head PHM 37 - manually atached

to the headstock, manual positoning, automatc tool

clamping and unclamping.

Revolutons: 3 000 RPM

Maximum Power: 37 kW (50 HP)

Maximum Torque (150 RPM): 2 000 Nm

Tool: ISO 50 - DIN 69871

Pull Stud: DIN 69872

Turning: any degree

(optonally 2,5/1)

Coolant Through Spindle: Opton

UHM 30

Universal Manual Head UHM 30 manually atached

to the headstock, manual positoning, automatc tool

clamping and unclamping.

Revolutons: 3 000 RPM

Maximum Power: 30 kW (40 HP)

Maximum Torque (150 RPM): 1 600 Nm

Tool: ISO 50 DIN 69871

Pull Stud : DIN 69872

Turning: any degree

(optonally 2,5/ 2,5; 1/ 1)

Coolant Through Spindle: Not Possible

PHA 37

Right Angle Automatc Head PHA 37 - automatcally

atached to the headstock, automatc positoning,

automatc tool clamping and unclamping.

Revolutons: 3 000 RPM

Maximum Power: 37 kW (50 HP)

Maximum Torque (187 RPM): 2 000 Nm

Tool: ISO 50 DIN 69871

Pull Stud: DIN 69872

Turning: 2,5 (1)

Coolant Through Spindle: Standard

Milling Heads, Face Plates

36

UHA 30

Universal Automatc Head UHA 30 automatcally

atached to the headstock, automatc positoning,

automatc tool clamping and unclamping.

Revolutons: 3 000 RPM

Maximum Power: 30 kW (40 HP)

Maximum Torque (150 RPM): 1 600 Nm

Tool: ISO 50 DIN 69871

Pull Stud : DIN 69872

Turning: 2,5/ 2,5 (1/ 1)

Coolant Through Spindle: Standard

PHM 37

Right Angle Manual Head PHM 37 - manually atached

to the headstock, manual positoning, automatc tool

clamping and unclamping.

Revolutons: 3 000 RPM

Maximum Power: 37 kW (50 HP)

Maximum Torque (150 RPM): 2 000 Nm

Tool: ISO 50 - DIN 69871

Pull Stud: DIN 69872

Turning: any degree

(optonally 2,5/1)

Coolant Through Spindle: Opton

UHM 30

Universal Manual Head UHM 30 manually atached

to the headstock, manual positoning, automatc tool

clamping and unclamping.

Revolutons: 3 000 RPM

Maximum Power: 30 kW (40 HP)

Maximum Torque (150 RPM): 1 600 Nm

Tool: ISO 50 DIN 69871

Pull Stud : DIN 69872

Turning: any degree

(optonally 2,5/ 2,5; 1/ 1)

Coolant Through Spindle: Not Possible

PHA 37

Right Angle Automatc Head PHA 37 - automatcally

atached to the headstock, automatc positoning,

automatc tool clamping and unclamping.

Revolutons: 3 000 RPM

Maximum Power: 37 kW (50 HP)

Maximum Torque (187 RPM): 2 000 Nm

Tool: ISO 50 DIN 69871

Pull Stud: DIN 69872

Turning: 2,5 (1)

Coolant Through Spindle: Standard

1 : 250 mm

Spindle Support Sleeves

52 53

381

ma x . 2 2 0

ma x . O1 + 0 0

8 0 0

300

+32

6 5 0

357

270

+32

ma x . 1 7 0

ma x . 1 2 0 0

Two Axis Orthogonal Milling Head

- manual positi oning, manually att ached to the headstock,

manual tool tool clamping and unclamping.

Revolutions: 10 - 1 000 RPM

Maximum Power: 55 kW (74 HP)

Maximum Torque (150 RPM): 2 600 Nm

Tool: ISO 50/60

Turning: 0 - 360

Coolant Through Spindle: Not Possible

IFVW 3B

Orthogonal manual milling head IFVW 3B

2 axis Orthogonal Milling Head with manual turning

ISO 50/60 quick manual tool camping by screw

Max. speed 10 1000 rpm.

Max. Power 55 kW.

Torque 2600 Nm.

Turning range 0- 360

Manual turning by handle

Ratio 1:1

Grease greasing.

Head weight 580 kg

Right angle manual milling head IFVW 2B

Right Angle Milling Head with manual turning

ISO 50/60 quick manual tool camping by screw

Max. speed 10 1000 rpm.

Max. Power 55 kW.

Torque 2600 Nm.

Turning range 0- 360

Manual turning by handle

Ratio 1:1

Grease greasing.

Head weight 300 kg

3 8 0

865

7 5 5

480

2 2 0

Right Angle Milling Head

- manual positi oning, manually att ached to the

headstock, manual tool clamping and unclamping.

Revolutions: 10 - 1 000 RPM

Maximum Power: 55 kW (74 HP)

Maximum Torque (150 RPM): 2 600 Nm

Tool: ISO 50/60

Turning: 0 - 360

Coolant Through Spindle: Not Possible

IFVW 2B

1

5

4

372

460 280

128,57

2

9

4 Right Angle Milling Head

- manual positi oning, manually att ached to the

headstock, manual tool clamping and unclamping.

Revolutions: 10 - 2 000 RPM

Maximum Power: 10 kW (13 HP)

Maximum Torque (150 RPM): 180 Nm

Tool: ISO 40

Turning: 0 - 360

Coolant Through Spindle: Not Possible

IFVW 1B

R

ig

h

t

a

n

g

le

m

illin

g

h

e

a

d

IF

V

W

1

B

R

ight A

ngle M

illing H

ead w

ith m

anual turning

IS

O

40 quick m

anual tool cam

ping by screw

M

ax. speed 10 2000 rpm

.

M

ax. P

ow

er 10 kW

.

T

orque 180 N

m

.

T

urning range 0- 360

H

ead length 600 or 1200 m

m

O

il greasing.

H

ead w

eight 300 kg

manually attached to the headstock,

manual positioning, automatic tool

clamping and unclamping

Right Angle Manual Milling Head

Revolutions: 2000 RPM

Maximum Power: 20kW (27HP)

maximum Torque:

Tool: SK 50 (DIN, MAS, ANSI)

PHM 20

manually attached to the headstock, manual

positioning, automatic tool clamping and

unclamping

Two Axis Orthogonal Manual Milling Head

Revolutions: 2000 RPM

Maximum Power: 20kW (27HP)

maximum Torque:

Tool: SK 50 (DIN, MAS, ANSI)

OHM 20

Milling Heads, Face Plates

A

C

C

E

S

S

O

R

I

E

S

R

E

F

E

R

E

N

C

E

S

625

400

5 6 0

2 0 0

1 2 8 , 5 6

2 1 0

130

2 5 , 4

397

1 8 2

311

280

128,57

3 2 5

3 8 0

865

7 5 5

480

2 2 0

544

2 0 0

4 4 0

300

1 2 8 , 5 7

Plate Diameter: 500 mm (19.68 in)

Positioning: Automatic

Boring Accuracy: 0,01 mm (0.0004 in)

Radial Traverse: 160 mm (6.30 in)

Maximum Boring Diameter: 1 000 mm (3.94 in)

Coolant Through Spindle: Standard

DAndrea Face Plate UT 5-500 S

automatically or manually attached to

the headstock, automatic clamping and

unclamping

Revolutions: 6000 RPM

Maximum Power: 37kW (50HP)

Maximum Torque: 182,5 Nm

Tool: ISO 50 DIN 69871

Coolant Through Spindle: Standard

Outside Coolant: Standard

Speeding Head

UHM 20

manually attached to the headstock,

manual positioning, automatic tool

clamping and unclamping

Two Axis Universal Manual Milling Head

Revolutions: 2000 RPM

Maximum Power: 20kW (27HP)

maximum Torque:

Tool: SK 50 (DIN, MAS, ANSI)

1255

90

1320 450

4 8 5

9 5

Plate Diameter: 650 mm (19.68 in)

Positioning: Automatic

Boring Accuracy: 0,05 mm (0.002 in)

Radial Traverse: 170 mm (6.69 in)

Maximum Boring Diameter: 1 200 mm (47.24 in)

Coolant Through Spindle: Not Possible

Automatic Face plate FH 65/80

54 55

Inside the cabin, there is a main Control Panel