Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Data Sheet

Caricato da

Voicu StaneseDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Data Sheet

Caricato da

Voicu StaneseCopyright:

Formati disponibili

Main dimensions

Flue Gas Flange

Dimensions in accordance with Part 4 of the DIN 24154 Standard

Project number: 147083/2.74 Offer No.: 1168947643-74

DA078

Printing date: 19.06.2012

nominal diameter [DN] 1) [mm] 400 D1 [mm] 484 D2 [mm] 448

Dimension(s) D3 [mm] 392 D4 [mm] 11,5 [] 15 [] 30

Quantity Bores [-] 12

wall thickness [mm] 8

weight [kg] 3,8

The bores are evenly distributed along the periphery. Dimensions with 1 % tolerance; transport weight indication with 4 % tolerance and operating weight indication with 2 % tolerance The exhaust pipe is not pushed through and welded, as in DIN 24154 R4, but rather butted onto the flange and welded!

Page 1 of 1

Load securing device

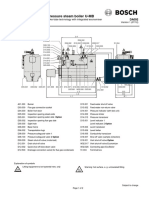

LOGANO SHD815

in three-pass flame-tube smoke-tube technology

Project number: 147083/2.74 Offer No.: 1168947643-74

DA368

Printing date: 19.06.2012

Explanation of symbols Lifting equipment to be fastened here, only

centre of gravity

Lashing equipment

LOGANO SHD815 Nominal output [kg/h] 3500 Mean working gauge pressure [bar] 8 Dimension(s) L1 [mm] 6217 L3 [mm] 3030 Base frame L2 [mm] 3750

1)

Anhngelast Transportation weight [kg] 9521 A1 [kg] 4899 A2 [kg] 4622

L6 [mm] 735

L8 [mm] 100

L9 [mm] 50 centre of gravity

B1 [mm] 2165

H1 1) [mm] 2510

Lashing point requirements H2 L5 [mm] 1000 B4 [mm] 1655

L7 [mm] 425

B2 [mm] 1655

wide flange beam [IPB - HEB - DIN1025] 180

L4 [mm] 1781

B3 [mm] 815

[mm] 1143

The scope of delivery is defined in the order confirmation. Transport the boiler on anti-slip mats (positioned below the boiler feet) with a coefficient of sliding friction of >= 0.6. The entire surface of the base frame must rest on the loading platform. Height to top edge Transportation lugs

Page 1 of 1

Main dimensions

LOGANO SHD815

in three-pass flame-tube smoke-tube technology

Project number: 147083/2.74 Offer No.: 1168947643-74

DA011

Printing date: 19.06.2012

51.004 A01.000 D03.000 D03.002 D04.007 D05.000 D05.001 D05.002 D05.005 D06.000 D06.002 D07.000 D08.000 D08.100 D09.000 D12.001

terminal box Burner Flue gas connection socket Flue gas chamber Reversing chamber door Inspection opening steam-side Inspection opening water side Inspection opening flue gas side Sight hole Base frame Lifting lug Operating platform option Pressure safeguard valve 1 Pressure safeguard valve 2 Steam shut-off valve Drain shut-off valve

D12.002 D12.503 D13.001 D13.002 D14.001 D14.002 D14.005 D14.013 D15.001

Quick shut-off blow down valve Connection for drainage flue gas condensate Feed water shut-off valve Feed water non-return valve Pressure indicator (with test unit) Pressure limiter Shut-off valve Pressure transducer Level indicator 1 Level indicator 2 option

D15.003 D15.006 D16.002 D16.005 D16.006 D19.001

Level transducer Level limiter Desalting shut-off valve Desalting control valve Conductivity transducer option vent shut-off valve option

Explanation of symbols Warning: dangerous voltage

electrical

Lifting equipment to be fastened here, only

Warning: hot surface, e. g. uninsulated fitting

Page 1 of 2

Main dimensions

LOGANO SHD815

in three-pass flame-tube smoke-tube technology

Project number: 147083/2.74 Offer No.: 1168947643-74

DA011

Printing date: 19.06.2012

LOGANO SHD815 Nominal output [kg/h] 3500 Mean working gauge pressure [bar] 8 Transportation weight [kg] 9521 Operating weight [kg] 15269 Maximum weight

3)

Connected load (electrical) [kW] 9,5

[kg] 17359

Dimension(s) L1 [mm] 6217 L 2 1) [mm] 5050 L3 [mm] 4600 B1 [mm] 2439 B 2 1) [mm] 2165 H1 [mm] 2947 H 2 1) 4) [mm] 2510

Flue gas connection B4 [mm] 358 H3 [mm] 623

Base frame L4 [mm] 3750 L5 [mm] 3400 L6 [mm] 600 L7 [mm] 425 L8 [mm] 175 L 9 2) [mm] 225 B3 [mm] 1655 wide flange beam [IPB - HEB - DIN1025] 180

1)

2) 3) 4)

References and defaults to Requirements for the boiler installation room see technical information TI024. Missing dimensions are not contained in scope of delivery. Dimensions with 1 % tolerance; transport weight indication with 4 % tolerance and operating weight indication with 2 % tolerance The indicated transport weight already includes the surcharges for normal sheet metal thickness tolerances, hence difference downwards is possible. Dimensioning insertion opening: Positioning height: addition of at least 100 mm to dimension H1 resp. dimension H2 (mounted / not mounted fittings) Positioning width: addition of at least 200 mm to dimension B1 resp. dimension B2 (mounted / not mounted fittings) Smallest transport dimensions once fittings, burner and terminal box have been removed (without cable ducting; with cable ducting + 75 mm on right). The boiler operating weight must be absorbed by the foundation in the area of the front and rear supports. Maximum weight incl. 100 % filled with water Height to top edge Transportation lugs

Page 2 of 2

Individual dimensions

LOGANO SHD815

in three-pass flame-tube smoke-tube technology

Project number: 147083/2.74 Offer No.: 1168947643-74

DA012

Printing date: 19.06.2012

D03.000 D05.000 D05.001 D05.002 D08.500 D08.600 D09.500 D12.500

Flue gas connection socket Inspection opening steam-side Inspection opening water side Inspection opening flue gas side Connection for Pressure safeguard valve 1 Connection for Pressure safeguard valve 2 Connection for Steam shut-off valve Connection for drain

D12.503 D13.501 D14.500 D15.501

Connection for drainage flue gas condensate Connection for Feed water shut-off valve Connection for manostat pipe Connection for Level indicator 1 Connection for Level indicator 2 option

D16.501 D19.501

Connection for Desalting shut-off valve Connection for vent shut-off valve option

Page 1 of 2

Individual dimensions

LOGANO SHD815

in three-pass flame-tube smoke-tube technology

Project number: 147083/2.74 Offer No.: 1168947643-74

DA012

Printing date: 19.06.2012

LOGANO SHD815 Nominal output [kg/h] 3500 L1 [mm] 5050

Dimension(s) B1 [mm] 2165 H 1 4) [mm] 2510

Nozzle position L3 [mm] L4 [mm] 2250 L5 [mm] 2550 L6 [mm] 1850 L7 [mm] 1500 L8 [mm] 1150 L9 [mm] L 10 [mm] 800

Nozzle position L 12 [mm] L 13 [mm] 420 B3 [mm] 950 H2 [mm] 2415 H3 [mm] 1740 H4 [mm] 1700 H5 [mm] 1215 H8 [mm] 340

Flue gas connection B4 [mm] 358 H6 [mm] 623 L2 [mm] 3750 L 11 [mm] 425 B2 [mm] 1655

Base frame H7 [mm] 190 wide flange beam [IPB - HEB - DIN1025] 180

Connection DN PN [mm] [bar/120C]

D03.000 1) 400 0,1

D08.500 / D08.600 2) 40 40

D09.500 2) 100 16

D12.500 2) 40 40

D12.503 3) 3/4 0,1

Connection DN PN [mm] [bar/120C]

D13.501 2) 40 40

D14.500 2) 20 40

D15.501 2) 25 40

D16.501 2) 25 40

D19.501 2)

1) 2) 3) 4)

References and defaults to Requirements for the boiler installation room see technical information TI024. Missing dimensions are not contained in scope of delivery. Dimensions with 1 % tolerance Nominal diameter for pipe connection according to DIN 24154 part 4 Nominal diameter for flanges according to DIN 2633 / 2634 / 2635 Pipe thread according to DIN 2999 Height to top edge Transportation lugs

Page 2 of 2

Piping diagram

LOGANO SHD615 , LOGANO SHD815

Project number: 147083/2.74 Offer No.: 1168947643-74

DA021

Printing date: 19.06.2012

Position D08.000 D08.100 D09.000 D12.001 D12.002 D12.005 D12.006 D12.007 D13.001 D13.002 D14.001 D14.002 D14.004 D14.005

Designation Pressure safeguard valve Pressure safeguard valve Steam extraction shut-off valve Drain shut-off valve Quick shut-off blow down valve three-way regulator valve (magnetic) Filter valve Shut-off valve Feed water shut-off valve Feed water non-return valve Pressure indicator (with test unit) Pressure limiter pressure regulator Shut-off valve

Position D15.001 D15.003 D15.006 D15.007 D15.008 D15.009 D15.101 D15.109 D16.002 D16.003 D16.004 D16.005 D16.007 D16.010

Designation Level indicator Level controller Level limiter Level limiter level switch Shut-off valve Level indicator option Shut-off valve option Desalting shut-off valve conductivity controller 1) flow rate indicator Desalting control valve (motorized) Shut-off valve Non-return valve

Page 1 of 2

Piping diagram

LOGANO SHD615 , LOGANO SHD815

Project number: 147083/2.74 Offer No.: 1168947643-74

DA021

Printing date: 19.06.2012

Position Piping 08.001 08.002 08.101 09.001 12.001 12.002

1)

Position 12.004 15.001 16.001 16.002 23.001 40.002

Piping Discharge line flue gas condensate water level blowoff pipe boiler water desalting line Water sample extraction pipe Flue gas line Feed water pressure line

Pressure safeguard blowoff line Pressure safeguard drainage line Pressure safeguard blowoff line Steam pipe Drain pipe control line control medium

Depicted equipment is on the basis of EN12953 Part 6 References and defaults to Requirements for the boiler installation room see technical information TI024. The scope of delivery is defined in the order confirmation. The conductivity measuring transducer with shut-off at the limit value is a minimum requirement of EN12953 Part 6.

Page 2 of 2

Main and individual dimensions

Feed pump unit SG

Project number: 147083/2.74 Offer No.: 1168947643-74

DA004

Printing date: 19.06.2012

A37.001 Shut-off valve (throttle cone) A37.002 Non-return valve A37.003 Pressure indicator A37.004 Shut-off valve A37.005 Filter valve A37.008 Pump Feed pump unit Discharge flow [kg/h] 3783 [bar] 10 [mm] 1000 discharge pressure Min. required positive suction head

A37.009 A37.011 A37.019 A37.501 A37.502

Pump engine bracket pressure monitor (minimum pressure) Connection for suction side Connection for pressure side

Transportation weight [kg] 132

Operating weight [kg] 140

Connected load (electrical) [kW] 3

Dimension(s) L1 [mm] 1044 L2 [mm] 732 L3 [mm] 662 Bearing area L4 [mm] 600

1)

B1 [mm] 240

B3 [mm] 110

B4 [mm] 178

H1 [mm] 1232

H2 [mm] 540 Connection for

H3 [mm] 235

H4 [mm] 160

B2 [mm] 60

Surface area [cm] 720 DN 65

A37.501 1) PN 16 DN 32

A37.502 1) PN 40

References and defaults to Requirements for the boiler installation room see technical information TI024. During assembly, please note the specified flow direction Install the consoles onto anti-vibration supports Missing dimensions are not contained in scope of delivery. Dimensions with 1 % tolerance; transport weight indication with 4 % tolerance and operating weight indication with 2 % tolerance Nominal diameter for flanges according to DIN 2633 / 2634 / 2635

Page 1 of 1

Piping diagram

Feed water supply steam boiler

Boiler level control via two-step control

Project number: 147083/2.74 Offer No.: 1168947643-74

DA388

Printing date: 19.06.2012

Depiction of the feed water supply from the tank to the boiler

depiction with 2 feed pumps per boiler Hinweis: Nur eine Speisepumpe im Lieferumfang!

Page 1 of 2

Piping diagram

Feed water supply steam boiler

Boiler level control via two-step control

Project number: 147083/2.74 Offer No.: 1168947643-74

DA388

Printing date: 19.06.2012

Position A37.001 A37.002 A37.003 A37.004 A37.005 Position 30.001 30.010

Designation Shut-off valve (throttle cone) Non-return valve Pressure indicator Shut-off valve Filter valve Piping Feed water suction piping Feed water suction piping

Position A37.008 A37.019 B30.000 D01

Designation Feed pump pressure monitor option Feed water tank steam boiler

Position 40.002

Piping Feed water pressure line

The scope of delivery is defined in the order confirmation.

Page 2 of 2

Individual dimensions

LOGANO SHD815

in three-pass flame-tube smoke-tube technology

Project number: 147083/2.74 Offer No.: 1168947643-74

DA012

Printing date: 19.06.2012

D03.000 D05.000 D05.001 D05.002 D08.500 D08.600 D09.500 D12.500

Flue gas connection socket Inspection opening steam-side Inspection opening water side Inspection opening flue gas side Connection for Pressure safeguard valve 1 Connection for Pressure safeguard valve 2 Connection for Steam shut-off valve Connection for drain

D12.503 D13.501 D14.500 D15.501

Connection for drainage flue gas condensate Connection for Feed water shut-off valve Connection for manostat pipe Connection for Level indicator 1 Connection for Level indicator 2 option

D16.501 D19.501

Connection for Desalting shut-off valve Connection for vent shut-off valve option

Page 1 of 2

Individual dimensions

LOGANO SHD815

in three-pass flame-tube smoke-tube technology

Project number: 147083/2.74 Offer No.: 1168947643-74

DA012

Printing date: 19.06.2012

LOGANO SHD815 Nominal output [kg/h] 3500 L1 [mm] 5050

Dimension(s) B1 [mm] 2165 H 1 4) [mm] 2510

Nozzle position L3 [mm] L4 [mm] 2250 L5 [mm] 2550 L6 [mm] 1850 L7 [mm] 1500 L8 [mm] 1150 L9 [mm] L 10 [mm] 800

Nozzle position L 12 [mm] L 13 [mm] 420 B3 [mm] 950 H2 [mm] 2415 H3 [mm] 1740 H4 [mm] 1700 H5 [mm] 1215 H8 [mm] 340

Flue gas connection B4 [mm] 358 H6 [mm] 623 L2 [mm] 3750 L 11 [mm] 425 B2 [mm] 1655

Base frame H7 [mm] 190 wide flange beam [IPB - HEB - DIN1025] 180

Connection DN PN [mm] [bar/120C]

D03.000 1) 400 0,1

D08.500 / D08.600 2) 40 40

D09.500 2) 100 16

D12.500 2) 40 40

D12.503 3) 3/4 0,1

Connection DN PN [mm] [bar/120C]

D13.501 2) 40 40

D14.500 2) 20 40

D15.501 2) 25 40

D16.501 2) 25 40

D19.501 2)

1) 2) 3) 4)

References and defaults to Requirements for the boiler installation room see technical information TI024. Missing dimensions are not contained in scope of delivery. Dimensions with 1 % tolerance Nominal diameter for pipe connection according to DIN 24154 part 4 Nominal diameter for flanges according to DIN 2633 / 2634 / 2635 Pipe thread according to DIN 2999 Height to top edge Transportation lugs

Page 2 of 2

Main dimensions

Flue Gas Flange

Dimensions in accordance with Part 4 of the DIN 24154 Standard

Project number: 147083/2.74 Offer No.: 1168947643-74

DA078

Printing date: 19.06.2012

nominal diameter [DN] 1) [mm] 500 D1 [mm] 587 D2 [mm] 551

Dimension(s) D3 [mm] 495 D4 [mm] 11,5 [] 15 [] 30

Quantity Bores [-] 12

wall thickness [mm] 8

weight [kg] 4,3

The bores are evenly distributed along the periphery. Dimensions with 1 % tolerance; transport weight indication with 4 % tolerance and operating weight indication with 2 % tolerance The exhaust pipe is not pushed through and welded, as in DIN 24154 R4, but rather butted onto the flange and welded!

Page 1 of 1

Main dimensions

LOGANO S825L

Project number: 147083/2.74 Offer No.: 1168947643-74

DA160

Printing date: 19.06.2012

51.002 51.004

Instrument box option terminal box option

D07.000 D08.000 D08.100 D10.000 D10.002 D11.000 D12.001 D12.503

Operating platform option Pressure safeguard valve 1 Pressure safeguard valve 2 Supply flow Supply flow adapter piece Return flow Drain shut-off valve option Connection for drainage flue gas condensate

A01.000 Burner D03.000 Flue gas connection socket D04.000 Boiler front door D05.002 Inspection opening flue gas side D05.005 Sight hole D06.000 Base frame D06.002 Lifting lug Explanation of symbols Warning: dangerous voltage

electrical

Lifting equipment to be fastened here, only

Warning: hot surface, uninsulated fitting

e.

g.

Page 1 of 2

Main dimensions

LOGANO S825L

Project number: 147083/2.74 Offer No.: 1168947643-74

DA160

Printing date: 19.06.2012

LOGANO S825L Type 3700 Mean working gauge pressure [bar] 5,16 Transportation weight [kg] 5800 Maximum weight 2) [kg] 8500 Connected load (electrical) [kW]

Dimension(s) L1 [mm] 5266 L 2 1) [mm] 4075 L3 [mm] 3820 B 1 1) [mm] 1724 H1 [mm] 2717 H 2 1) [mm] 2100 H3 [mm] 2010

Flue gas connection H4 [mm] 1490 L4 [mm] 3410

Base frame B2 [mm] 1150 H5 [mm] 200

1)

2)

References and defaults to Requirements for the boiler installation room see technical information TI024. Missing dimensions are not contained in scope of delivery. Dimensions with 1 % tolerance; transport weight indication with 4 % tolerance and operating weight indication with 2 % tolerance The indicated transport weight already includes the surcharges for normal sheet metal thickness tolerances, hence difference downwards is possible. Dimensioning insertion opening: Positioning height: addition of at least 100 mm to dimension H1 resp. dimension H2 (mounted / not mounted fittings) Positioning width: addition of at least 200 mm to dimension B1 (mounted / not mounted fittings) Smallest transport dimensions once fittings, burner and terminal box have been removed (without cable ducting; with cable ducting + 75 mm on right). Maximum weight incl. 100 % filled with water

Page 2 of 2

Individual dimensions

LOGANO S825L

Project number: 147083/2.74 Offer No.: 1168947643-74

DA162

Printing date: 19.06.2012

D03.000 Flue gas connection socket D05.002 Inspection opening flue gas side D08.500 Connection for Pressure safeguard valve 1 D08.600 Connection for Pressure safeguard valve 2

D10.500 D11.500 D12.500 D12.503

Connection for Supply flow Connection for Return flow Connection for drain Connection for drainage flue gas condensate

LOGANO S825L L2 Type 3700 [mm] 2490 L3 [mm] 600

Nozzle position L4 [mm] 800 L5 [mm] 300 H1 [mm] 2000 H2 [mm] 1490 D1 [mm] 1700 L1 [mm] 3410

Base frame B1 [mm] 1150 U-Profil [U-DIN 1026] 200

Connection for DN PN [mm] [ bar / 120C ]

D03.000 1) 500 0,1

D08.500 / D08.600 2) 65 16

D10.500 2) 200 16

D11.500 2) 200 16

D12.500 2) 32 40

D12.503 3) 3/4 0,1

1) 2) 3)

References and defaults to Requirements for the boiler installation room see technical information TI024. Missing dimensions are not contained in scope of delivery. Dimensions with 1 % tolerance Nominal diameter for pipe connection according to DIN 24154 part 4 Nominal diameter for flanges according to DIN 2633 / 2634 / 2635 Pipe thread according to DIN 2999

Page 1 of 1

Piping diagram

LOGANO S825L

Project number: 147083/2.74 Offer No.: 1168947643-74

DA111

Printing date: 19.06.2012

Position D08.000 D08.100 D10.003 D10.004 D10.013 D10.014 D11.003 D11.004

Designation Pressure safeguard valve Pressure safeguard valve temperature indicator Temperature limiter flow limiter option temperature controller temperature indicator temperature monitor

Position D12.001 D12.002 D14.001 D14.002 D14.005 D15.004 D15.006

Designation Drain shut-off valve Quick shut-off blow down valve Pressure indicator (with test unit) Pressure limiter Shut-off valve temperature indicator Level limiter

Page 1 of 2

Piping diagram

LOGANO S825L

Project number: 147083/2.74 Offer No.: 1168947643-74

DA111

Printing date: 19.06.2012

Position Piping 08.001 08.002 08.003 08.101 08.102 08.103 Pressure safeguard blowoff line Pressure safeguard drainage line pressure safeguard vapour line Pressure safeguard blowoff line Pressure safeguard drainage line pressure safeguard vapour line

Position 10.001 11.001 12.001 12.004 23.001

Piping hot water supply flow line hot water return flow line Drain pipe Discharge line flue gas condensate Flue gas line

References and defaults to Requirements for the boiler installation room see technical information TI024. The scope of delivery is defined in the order confirmation.

Page 2 of 2

Main and individual dimensions

Supply flow adapter piece

for LOGANO S825L

Project number: 147083/2.74 Offer No.: 1168947643-74

DA131

Printing date: 19.06.2012

D10.004

D10.500

D15.006

D14.001

D14.002

D14.006

D14.005

D10.014

BAR

700

D10.500 B1 B2

D10.013 ~510 L1

D10.004 D10.013 D10.014 D10.500 D14.001

Temperature limiter option flow limiter option temperature controller Connection for Supply flow Pressure indicator (with test unit)

D14.002 D14.005 D14.006 D15.006

Pressure limiter manostat tube - Shut-off valve DN20 Pressure limiter Level limiter option

Supply flow adapter piece Type VZ 200

Transportation weight [kg] 49

Maximum weight [kg] 71

Dimension(s) L1 B1 B2 [mm] [mm] [mm] 305 515 290

nominal diameter D10.500 DN 1) PN 1) 200 16

1) 2)

Dimensions with 1 % tolerance; transport weight indication with 4 % tolerance and operating weight indication with 2 % tolerance Nominal diameter for flanges according to DIN 2633 / 2634 / 2635 Maximum weight incl. 100 % filled with water

Page 1 of 1

System diagram

Single boiler system

with Logamatic boiler control unit with hydraulic decoupling

for hot water generator

Project number: 147083/2.74 Offer No.: 1168947643-74

DA201

Printing date: 19.06.2012

hot water boiler without flue gas heat exchanger

hot water boiler with a flue gas heat exchanger integrated into the boiler circuit Return flow flue gas heat exchanger control element for return flow temperature boosting Supply flow boiler supply flow Supply flow flue gas heat exchanger Hydraulic compensation line (low-loss header)

FK FZ PK R RG RK

boiler water - temperature sensor (inserted in low-loss RWT header) auxiliary sensor for the return flow temperature SR boiler circuit pump V Return flow VK control device Logamatic VWT boiler return flow WH

brief description of the system:

Control of the minimum return flow temperature via a separate control element (SR) in the boiler circuit and a boiler circuit pump as primary circuit pump.

function description of the system:

The return flow temperature is controlled by actuating the three-way valve (SR). The return flow temperature sensor (FZ) measures the boiler return flow temperature. If it falls below the setpoint, the volumetric flow of heating water to the boiler return is continuously throttled by actuating the three-way valve (SR). When the return flow temperature rises above the setpoint, the three-way valve (SR) reopens and the volumetric flow to the heating circuit increases.

Special planning notes:

A low-loss header or alternatively a flow header with bypass and non-return valve must be included when planning. The boiler circuit pump must be switched to continuous operation or with an overrun of 60 minutes. The accompanying temperature sensor built into the boiler supply flow connection socket must not be used for boiler temperature control. For temperature control, use the temperature sensor supplied separately which must be built into the low-loss header. The diagrams show only the control elements necessary for control. The boiler equipment required can be found in the corresponding piping diagrams. The scope of delivery is defined in the order confirmation. The system diagram provides a general guide to the possible configuration without obligation or claims as to its completeness. The practical implementation is subject to currently applicable technical rules. Safety equipment must be installed in accordance with local regulations.

Page 1 of 1

Potrebbero piacerti anche

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Data Sheet Cryogenic Vessel T18V490Documento12 pagineData Sheet Cryogenic Vessel T18V490Silviu Modiga100% (2)

- Weller Ungar Parts CatalogDocumento108 pagineWeller Ungar Parts Catalogelfrich60% (5)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDa EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerValutazione: 5 su 5 stelle5/5 (1)

- Pump Documentation LEWA DOKU - 532316Documento80 paginePump Documentation LEWA DOKU - 532316miltonmontaldoNessuna valutazione finora

- Trelleborg Piping SPEC. REV CDocumento1 paginaTrelleborg Piping SPEC. REV CSIVANessuna valutazione finora

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- Working Guide to Drilling Equipment and OperationsDa EverandWorking Guide to Drilling Equipment and OperationsValutazione: 5 su 5 stelle5/5 (9)

- Sdre14-5 Ral 1-2-Rev17Documento3 pagineSdre14-5 Ral 1-2-Rev17lwin_oo2435Nessuna valutazione finora

- High Flow NAMUR 1/4 & 1/2 valves catalogueDocumento8 pagineHigh Flow NAMUR 1/4 & 1/2 valves catalogueSandi AslanNessuna valutazione finora

- UNIVERSAL High-Pressure Steam Boiler ZFR: in Three-Pass Double-Flue Flame-Tube Smoke Tube TechnologyDocumento2 pagineUNIVERSAL High-Pressure Steam Boiler ZFR: in Three-Pass Double-Flue Flame-Tube Smoke Tube TechnologyJose Ricardo DuranNessuna valutazione finora

- SVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical InformationDocumento5 pagineSVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical Informationhippong niswantoroNessuna valutazione finora

- UNIVERSAL Steam Boiler UL-S: Main DimensionsDocumento3 pagineUNIVERSAL Steam Boiler UL-S: Main DimensionsJose Ricardo Duran0% (1)

- LVH-C: Lowviscosity Housing-CoalescerDocumento5 pagineLVH-C: Lowviscosity Housing-CoalescerAzmi AhmadNessuna valutazione finora

- Datasheet-A Rev No. Sr. No. Description SpecificationDocumento3 pagineDatasheet-A Rev No. Sr. No. Description Specificationinstruman007Nessuna valutazione finora

- Select the Right Gas and Air Filter for Your ApplicationDocumento8 pagineSelect the Right Gas and Air Filter for Your ApplicationJulio OrtegaNessuna valutazione finora

- Technical information on potential-free contacts and load securing for steam boilerDocumento58 pagineTechnical information on potential-free contacts and load securing for steam boilerRamy MahmoudNessuna valutazione finora

- UNIVERSAL High-Pressure Steam Boiler U-MB: Main DimensionsDocumento2 pagineUNIVERSAL High-Pressure Steam Boiler U-MB: Main DimensionsJose Ricardo DuranNessuna valutazione finora

- 4.1psv - CatalogueDocumento96 pagine4.1psv - CatalogueSivareddy InduriNessuna valutazione finora

- Valve Color CodingDocumento4 pagineValve Color Codingesakkiraj1590Nessuna valutazione finora

- UNIVERSAL High-Pressure Steam Boiler ZFRDocumento2 pagineUNIVERSAL High-Pressure Steam Boiler ZFRJose Ricardo DuranNessuna valutazione finora

- 2/2-way valves DN 20 to 50 for air solenoid actuated diaphragm valvesDocumento4 pagine2/2-way valves DN 20 to 50 for air solenoid actuated diaphragm valvesOscar CurimanyaNessuna valutazione finora

- Hydrotechnik Full CatalogueDocumento128 pagineHydrotechnik Full CatalogueEysakaylovasNessuna valutazione finora

- R 175 UkDocumento4 pagineR 175 UkAhmed EldalyNessuna valutazione finora

- WPI-KE-1104-SP141-QM5433 (Datasheet)Documento4 pagineWPI-KE-1104-SP141-QM5433 (Datasheet)Jèfrì PìnémNessuna valutazione finora

- GrundfosliteratureDocumento24 pagineGrundfosliteratureRuxandra Adriana100% (1)

- Flanged Safety Relief Valves - Spring Loaded: Type 447 PTFE-lined Packed Lever H4 Closed Bonnet Bellows DesignDocumento9 pagineFlanged Safety Relief Valves - Spring Loaded: Type 447 PTFE-lined Packed Lever H4 Closed Bonnet Bellows DesignSaleh EttehadiNessuna valutazione finora

- ARI-Strainer technical specificationsDocumento6 pagineARI-Strainer technical specificationsEmnNessuna valutazione finora

- Rosemount 1195 Integral Orifice Primary Element: Product Data SheetDocumento18 pagineRosemount 1195 Integral Orifice Primary Element: Product Data Sheetابزار دقیقNessuna valutazione finora

- Duct & Vent EngineeringDocumento70 pagineDuct & Vent Engineeringtop20202080% (5)

- 01 Excelon FiltersDocumento16 pagine01 Excelon Filtersalex_alfonso9407Nessuna valutazione finora

- Wafer Type Butterfly Valve Z 611-A Wafer Type Butterfly Valve Z 611-ADocumento4 pagineWafer Type Butterfly Valve Z 611-A Wafer Type Butterfly Valve Z 611-ARadu GanciuNessuna valutazione finora

- 40lma PD NewDocumento18 pagine40lma PD Newanoopkumar1231150Nessuna valutazione finora

- Rosemount 1195 Integral Orifice Primary Element: Quick Installation GuideDocumento16 pagineRosemount 1195 Integral Orifice Primary Element: Quick Installation GuideJosé Carlos Batista SilvaNessuna valutazione finora

- XOMOXLinedPlugValvesEMEA TechnicalDataDocumento20 pagineXOMOXLinedPlugValvesEMEA TechnicalDataperoooNessuna valutazione finora

- LouversDocumento11 pagineLouverskarthikraja21Nessuna valutazione finora

- Guth VSR Modulating ValvesDocumento8 pagineGuth VSR Modulating ValvesRaul Guevara TorresNessuna valutazione finora

- AEGNEP Compressed AirDocumento42 pagineAEGNEP Compressed AirDavid HayesNessuna valutazione finora

- CV1 PDFDocumento1 paginaCV1 PDFAditya TapkirNessuna valutazione finora

- Aire Octimizacion TecnicaDocumento28 pagineAire Octimizacion TecnicaWilliam AlvaradoNessuna valutazione finora

- Fcu PDFDocumento12 pagineFcu PDFonspsnonsNessuna valutazione finora

- Jet DiffuserDocumento12 pagineJet DiffuserJoemon JoseNessuna valutazione finora

- Steam Valve Sizing Project with Case StudiesDocumento1 paginaSteam Valve Sizing Project with Case StudiesAditya TapkirNessuna valutazione finora

- Catalog 83 275 800Documento115 pagineCatalog 83 275 800nhojnhojNessuna valutazione finora

- 11 2 Cmb-P-Nu-G1, Nu-Ga1, Nu-Ha1, Nu-Gb1, Nu-Hb1 BC ControllersDocumento34 pagine11 2 Cmb-P-Nu-G1, Nu-Ga1, Nu-Ha1, Nu-Gb1, Nu-Hb1 BC ControllersGeovany Mena VillagraNessuna valutazione finora

- Boiler SpecificationDocumento18 pagineBoiler SpecificationAtul Jain100% (3)

- Butterfly Valve Technical Data SheetDocumento6 pagineButterfly Valve Technical Data SheetMr. ANessuna valutazione finora

- Donaldson AccessoriesDocumento74 pagineDonaldson AccessoriesCentral HydraulicsNessuna valutazione finora

- Solenoid Valve With Isolating Diaphragm: Type 0780Documento6 pagineSolenoid Valve With Isolating Diaphragm: Type 0780Oren WeinsteinNessuna valutazione finora

- 145B9973 - Off Base Piping List of Lines PDFDocumento4 pagine145B9973 - Off Base Piping List of Lines PDFHumayun NawazNessuna valutazione finora

- 3600 - Hi-Lo Pilot SwitchDocumento10 pagine3600 - Hi-Lo Pilot Switchsumesh19778933Nessuna valutazione finora

- TD Pmo 6000 en 080108Documento16 pagineTD Pmo 6000 en 080108Ricardo DávilaNessuna valutazione finora

- DCV03 Directional Valve GuideDocumento12 pagineDCV03 Directional Valve GuideCarlos Antonio SteimmerNessuna valutazione finora

- AGYF Floor Service ManualDocumento22 pagineAGYF Floor Service ManualAmanda Mack100% (1)

- Awm 8121Documento22 pagineAwm 8121borlixNessuna valutazione finora

- DCV Spirax PDFDocumento2 pagineDCV Spirax PDFVaitheeswaran PalaniNessuna valutazione finora

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Da EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Valutazione: 3.5 su 5 stelle3.5/5 (3)

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7Da EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7Nessuna valutazione finora

- Css Cheat SheetDocumento1 paginaCss Cheat SheetIvica DumanovicNessuna valutazione finora

- 2N3906 General Purpose Transistors: PNP SiliconDocumento7 pagine2N3906 General Purpose Transistors: PNP SiliconJose G. Cantillo L.Nessuna valutazione finora

- 2N3906 General Purpose Transistors: PNP SiliconDocumento7 pagine2N3906 General Purpose Transistors: PNP SiliconJose G. Cantillo L.Nessuna valutazione finora

- MpBus 02 eDocumento30 pagineMpBus 02 eVoicu StaneseNessuna valutazione finora

- Fix engine codes and diagnosticsDocumento4 pagineFix engine codes and diagnosticsVitor Roberto MoreiraNessuna valutazione finora

- FastTrack To WirelessSpeedlightsDocumento8 pagineFastTrack To WirelessSpeedlightsVoicu StaneseNessuna valutazione finora

- Dell Studio-1558 Service Manual En-UsDocumento49 pagineDell Studio-1558 Service Manual En-UsVoicu StaneseNessuna valutazione finora

- Analysis of Self Excited Induction GeneratorDocumento7 pagineAnalysis of Self Excited Induction Generatorsajs201100% (1)

- Modbus RtuDocumento8 pagineModbus RtuVoicu StaneseNessuna valutazione finora

- Manufacturer: Model: Year: Registration: Mileage: Job Number: DateDocumento5 pagineManufacturer: Model: Year: Registration: Mileage: Job Number: DateVoicu StaneseNessuna valutazione finora

- MBus 03 eDocumento26 pagineMBus 03 eVoicu StaneseNessuna valutazione finora

- Steinmetz, Charles Proteus - Electric Discharges Waves and ImpulsesDocumento172 pagineSteinmetz, Charles Proteus - Electric Discharges Waves and ImpulsesVoicu StaneseNessuna valutazione finora

- Release NoteDocumento8 pagineRelease NoteVoicu StaneseNessuna valutazione finora

- Building Automation and Control L System Desi GoDocumento52 pagineBuilding Automation and Control L System Desi GoVoicu StaneseNessuna valutazione finora

- Modbus RtuDocumento8 pagineModbus RtuVoicu StaneseNessuna valutazione finora

- Telit Wireless M-Bus User Guide r3Documento37 pagineTelit Wireless M-Bus User Guide r3Voicu StaneseNessuna valutazione finora

- M-Bus 012Documento36 pagineM-Bus 012Voicu StaneseNessuna valutazione finora

- Kalorimetar Data Sheet UH50 - UH106 101kDocumento15 pagineKalorimetar Data Sheet UH50 - UH106 101kbobesponjakockaloneNessuna valutazione finora

- Telit SR Manager Tool User Guide r1Documento72 pagineTelit SR Manager Tool User Guide r1Voicu StaneseNessuna valutazione finora

- Info Iec60870 5 601 Ed1 0 enDocumento7 pagineInfo Iec60870 5 601 Ed1 0 enVoicu StaneseNessuna valutazione finora

- M-Bus 012Documento36 pagineM-Bus 012Voicu StaneseNessuna valutazione finora

- MicroturbineSection 3Documento18 pagineMicroturbineSection 3Voicu StaneseNessuna valutazione finora

- M BusDocumento88 pagineM Busakshay_haridasNessuna valutazione finora

- Williams Microturbine Diary Lagoon 03-3-018Documento8 pagineWilliams Microturbine Diary Lagoon 03-3-018Voicu StaneseNessuna valutazione finora

- The Definitive Guide to the M-Bus ProtocolDocumento91 pagineThe Definitive Guide to the M-Bus ProtocolZoran MilicNessuna valutazione finora

- CSIR Microturbine Research for Distributed Power GenerationDocumento1 paginaCSIR Microturbine Research for Distributed Power GenerationVoicu StaneseNessuna valutazione finora

- MicroturbineSection 3Documento18 pagineMicroturbineSection 3Voicu StaneseNessuna valutazione finora

- A Microturbine For Electric Power Generation - Paper PresentationDocumento8 pagineA Microturbine For Electric Power Generation - Paper Presentationprateekg92Nessuna valutazione finora

- Paper 10: DYNAMICS BEHAVIOR OF A 30 KW CAPSTONE MICROTURBINEDocumento18 paginePaper 10: DYNAMICS BEHAVIOR OF A 30 KW CAPSTONE MICROTURBINEMAT JIBRUD100% (1)

- How To Use Dr. Foster's Essentials: Essential Oils and BlendsDocumento5 pagineHow To Use Dr. Foster's Essentials: Essential Oils and BlendsemanvitoriaNessuna valutazione finora

- Lea 2 PDFDocumento21 pagineLea 2 PDFKY Renz100% (1)

- Water System BOQ 16.12.2023 R0Documento144 pagineWater System BOQ 16.12.2023 R0moinu85Nessuna valutazione finora

- Convection: Example 3.1Documento5 pagineConvection: Example 3.1MChobind RivaldoNessuna valutazione finora

- Boutique Olive Oil Machines Catalogue ENG5Documento33 pagineBoutique Olive Oil Machines Catalogue ENG5Younesse EL BraiNessuna valutazione finora

- RC Design IIDocumento58 pagineRC Design IIvenkatesh19701Nessuna valutazione finora

- The Anglican Digest - Winter 2022Documento64 pagineThe Anglican Digest - Winter 2022The Anglican Digest100% (1)

- Student Pilot GuideDocumento13 pagineStudent Pilot GuideAŞKIN FIRATNessuna valutazione finora

- Personal Care Na Hair GuideDocumento8 paginePersonal Care Na Hair GuideIsabellaNessuna valutazione finora

- Equations 2Documento8 pagineEquations 2Patrick ValdezNessuna valutazione finora

- Gas Exchange in Plants and AnimalsDocumento7 pagineGas Exchange in Plants and AnimalsMarvin MelisNessuna valutazione finora

- 25f8e d64fDocumento6 pagine25f8e d64fapi-233604231Nessuna valutazione finora

- Grade 9 Unit 1 - Part 1: Square RootsDocumento20 pagineGrade 9 Unit 1 - Part 1: Square RootsWilson ZhangNessuna valutazione finora

- 0580 w15 QP 42Documento16 pagine0580 w15 QP 42Shahrizan Noor100% (1)

- GCSE 1MA1 - Algebraic Proof Mark SchemeDocumento13 pagineGCSE 1MA1 - Algebraic Proof Mark SchemeArchit GuptaNessuna valutazione finora

- Technical Data Speedmaster CX 104Documento2 pagineTechnical Data Speedmaster CX 104Vinh Lê HữuNessuna valutazione finora

- داينمك الملزمة كاملةDocumento79 pagineداينمك الملزمة كاملةarno assassin33% (3)

- Pancreatic NekrosisDocumento8 paginePancreatic Nekrosisrisyda_mkhNessuna valutazione finora

- October 14, 2011 Strathmore TimesDocumento28 pagineOctober 14, 2011 Strathmore TimesStrathmore TimesNessuna valutazione finora

- M2030 PA300 Siren Data Sheet 5-2021Documento2 pagineM2030 PA300 Siren Data Sheet 5-2021parak014Nessuna valutazione finora

- Christmas Around the WorldDocumento16 pagineChristmas Around the WorldVioleta Veljanovska100% (1)

- Installation & Testing of Fire Protection SystemsDocumento7 pagineInstallation & Testing of Fire Protection Systemssunny_84tNessuna valutazione finora

- Guía Fallas para Ricoh Aficio 220Documento31 pagineGuía Fallas para Ricoh Aficio 220desechableNessuna valutazione finora

- Da Memorandum Order No 6 Implementation Guidelines of The Kadiwa Ni Ani at Kita ProjectDocumento17 pagineDa Memorandum Order No 6 Implementation Guidelines of The Kadiwa Ni Ani at Kita ProjectMildred VillanuevaNessuna valutazione finora

- SPECIFIC GRAVITY - DENSITY OF HYDRAULIC CEMENT (IS - 4031-Part 11-1988)Documento6 pagineSPECIFIC GRAVITY - DENSITY OF HYDRAULIC CEMENT (IS - 4031-Part 11-1988)Pritha DasNessuna valutazione finora

- Real Possibility of Future ConditionDocumento3 pagineReal Possibility of Future ConditionHusNessuna valutazione finora

- BR A Consumables Catalog ElecDocumento31 pagineBR A Consumables Catalog Elecdweil1552Nessuna valutazione finora

- El DoradoDocumento12 pagineEl Doradoandrewwilliampalileo@yahoocomNessuna valutazione finora

- Perreaux E220 200W Stereo Power Amplifier from 1994Documento2 paginePerreaux E220 200W Stereo Power Amplifier from 1994joaoraffa raffaNessuna valutazione finora