Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Industrial Boiler Product Range

Caricato da

Ram Prasad NannaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Industrial Boiler Product Range

Caricato da

Ram Prasad NannaCopyright:

Formati disponibili

Industrial Boiler Product Range

B&W

Table of Contents

Oil & Gas fired boilers FM Packaged Boiler High Capacity FM (HCFM ) Boiler Power for Industry Boiler ( PFI ) Radiant Boiler ( RB ) Heat Recovery Steam Generator ( HRSG ) Solid fuel fired boilers Atmospheric fluid bed boiler - Underbed fuel feed design (AFBC - UB ) Atmospheric fluid bed boiler - Overbed fuel feed design (AFBC - OB ) Circulating fluid bed boiler ( CFBC ) Traveling grate fired boiler ( TG ) Dumping grate fired boiler ( DG ) Pinhole grate fired boiler ( PG ) Pulverised fuel boiler ( PF ) Accessory equipments Deaerator Renovation & Modernization After Sales Service

2 3 4 5 6

7 8 9 10 11 12 13

14 15 16

Designs and information shown in this booklet are for purposes of illustration only. Equipment designed for specific applications may differ.

FM Packaged Boiler

Membrane Furnace Wall

Steam Drum

Outer Casing

Superheater

Burner

Convention Bank Water Drum

Wind Box

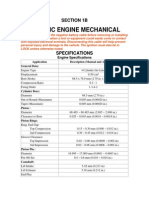

Capacity Range Pressure Temperature Fuel

: 5 TPH to 100 TPH : Upto 74 Kg/cm2g : Upto 4500C : All liquid and gaseous fuels, Waste Fuels, BFG, Tar, Bio-Gas.

Typical Efficiency : 93% ( on LHV ) Design features : Bi-Drum, bottom supported, forced draft, natural circulation boilers.l Special design of drum internals for high steam purity l Membrane / Studded wall water cooled furnace construction l Minimum foundation required l Can be installed outdoor l Fully drainable superheater l Suitable for firing of heavy fuels / lean gases l Fine combustion control & high turndown ratios l Preengineered economiser l Short / attractive delivery 2

High Capacity FM (HCFM/PFM) Boiler

Superheater

Saturated Steam Supply Pipes Steam Drum

Reach wll with header arrangement

Buck Stray

Wind Box Furnace Side Wall

Convention Bank Burner Furnace Wall Base Frame

Capacity Range Pressure Temperature Fuel Design features

: 80 TPH to 272 TPH : Upto 124 Kg/cm2g : Upto 4500C : All liquid and gaseous fuels, Waste Fuels, BFG, Tar, Bio-Gas. : High Capacity FM (HCFM/PFM) boiler completely pre-engineered with modular design for dock or field assembly l Multiple burners for increased capacity. l Special design of drum internals - High steam purity l Membrane / Studded wall water cooled furnace construction l Minimum foundation required l Can be installed outdoor l Fully drainable superheater l Firing of heavy fuels / lean gases possible l Fine combustion control & high turndown ratios l Short / attractive delivery l Over 5000 operating units. 3

Power for Industry Boiler ( PFI )

Capacity Range Pressure Temperature Fuel Design Features

: 45 TPH to 208 TPH : Upto 80 kg/cm2g : Upto 5100C : Liquid and /or gaseous fuels, blast furnace gas, CO gas and high ash liquid fuels : Bi-drum bottom supported, multiple gas pass unit designed specifically to burn liquid and / or gaseous fuels. l Membrane walled water cooled furnace l Combined hot air & gas ducts integral with rear wall casing l Fully drainable bottom supported superheater l Flat superheater temperature v/s load curve l Wash water drains

High Pressure Radiant Boiler ( RB )

Capacity Range Pressure Temperature Fuel

: 80 TPH to 500 TPH : Upto 140 Kg/cm2g : Upto 5400 C : All liquid and gaseous fuels

Design Features : Single Drum, bottom supported, forced draft, natural circulation, 2 pass type boilers. l Furnace & second pass made of totally water-cooled membrane walls l Front wall firing on wide range of liquid & gaseous fuels l Higher operational reliability l Steam drum outside the flue gas path, permitting quick start-up & load chasing l Fully welded construction l Fully drainable, horizontal, convective superheater l Steam cooled superheater support.

Heat Recovery Steam Generator ( HRSG )

Capacity Range Pressure Temperature

: Upto 100 MW : Upto 135 Kg/cm2g : Upto 5600 C

Design Features : Single drum / Bi-boilers with or without supplementary firing on Gas Turbine Exhaust l Supplementary fired / unfired mode l Fresh air firing option l Multiple Pressures (levels) l Natural Circulation l Single drum all welded construction l Low gas side pressure drop l Cold casing insulation l Fully drainable superheater finned tubes l Modular design l Integral Deaerator / makeup water heater option l Low power consumption l High tolerance to Turbine Exhaust Gas flow maldistribution l 99.99 % availability l Lower capital costs l Easy maintenance and accessibility

Atmospheric Fluid Bed Combustion Boiler ( Underbed feed system design )

Capacity Range Pressure Temperature Fuel Design Feature

: Upto 300 TPH : Upto 135 Kg/cm2g : Upto 5400 C : Coal / Lignite / Rice Husk / Pith / Petcoke / Washery Rajects / Char / Oil / Agricultural Waste etc. : Top or bottom supported, Single or Bi-drum design boilers suitable for firing low calorific value fuels. Suspension burning of fuel - higher combustion efficiency l Coal Size 6 mm l Bubbling Bed Ash Coolers l Stainless Steel Fluidizing Nozzles l Boiler bank without Baffles l High Steam Purity l Membrane walled furnace l Start-up by oil / charcoal.

Atmospheric Fluid Bed Combustion Boiler ( Over bed feed system design )

Capacity Range Pressure Temperature Fuel Design Feature

: Upto 300 TPH : Upto 135 Kg/cm2g : Upto 5400 C : Coal / Lignite / Rice Husk / Pith / Spent Coffee Ground / Spent Tea Ground / Washery Rejects / Char / Oil / Gas / Agricultural Waste / Sludge etc. : Top or bottom supported, Single or Bi-drum design boilers suitable for firing low calorific value fuels. Suspension burning of fuel - higher combustion efficiency l Coal Size upto 12 mm accepted l Bubbling Bed Ash Coolers l Stainless Steel Fluidizing Nozzles l Boiler bank without Baffles l High Steam Purity l Membrane walled furnace l Start-up by oil / charcoal.

Circulating Fluidized Bed Combustion Boiler ( CFBC )

Capacity range Fuel

: Upto 500 TPH : Coal, Lignite, Petroleum Coke.

Design Features : Top supported Internal Recirculation CFB with U-Beam Impact Separators available in Single or Bi-drum design Suitable for firing wide range of low calorfic, high ash fuels with less expensive fuel preparations l Lower emissions levels l High availability and lower maintenance l Reduced Boiler building volume l Wide load swings with high turn-down l Low power consumption l Low start up time l Two - stage solids collection for better performance

Travelling Grate Fired Boiler ( TG )

Capacity Range Pressure Temperature Fuel Design Feature

: Upto 140 TPH : Upto 106 Kg/cm2g : Upto 5150 C : Bagasse / Rice husk / Coal / Lignite, Other biomass : Travelling Grate stoker fired, Bi-drum, top or bottom supported, balanced draft, natural circulation boilers l Modulating secondary air system for even distribution of bagasse l Tall furnace for higher residence time l Continuous ash discharge l Compact low operating pressure hydraulic drive l Suspension burning for complete combustion & quick response to load variation l Special design of drum internals - High steam purity l No underground ducting l No air leakage l Flexibility in firing various fuels 10

Dumping Grate Fired Boiler ( DG )

Capacity Range Pressure Temperature Fuel Design Feature

: Upto 100 TPH : Upto 106 Kg/cm2g : Upto 5150 C : Bagasse / Other biomass / Other low ash fuel : Dumping Grate stoker fired, Bi-drum, top or bottom supported, balanced draft, natural circulation, water tube boilers l Modulating secondary air system for even distribution of bagasse on grate l Tall furnace for longer residence time l Suspension burning for complete combustion & quick response to load variation l Special design of drum internals - High steam purity l Flexibility in firing various low ash fuel.

11

Pinhole Grate Fired Boiler ( PG )

Capacity Range Pressure Temperature Fuel Design Feature

: Upto 300 TPH : Upto 106 Kg/cm2g : Upto 5150 C : Bagasse / Other biomass / Other low ash fuel : Pinhole Grate Stoker fired, Bi-drum, top or bottom supported, balanced draft, natural circulation boilers. l Modulating secondary air system for even distribution of bagasse on grate l Tall furnace for longer residence time l Stationary water cooled grate design with no moving parts, avoiding mechanical failures l Steam nozzles for simplified on line ash removal l Suspension burning for complete combustion & quick response to load variation l Special design of drum internals - High steam purity l No underground ducting 12

Pulverised Fuel Boiler ( PF )

Capacity Range Pressure Temperature Fuel

: 150 TPH to 500 TPH : Upto 152 kg/cm2g : Upto 5400C : Coal / Lignite

Design Features : Top-supported, Single or Bi-drum, single gas pass unit l Membrane wall construction l Furnace nose arch, and economizer and / or air heater for economical heat recovery l Higher operational reliability l Steam cooled superheater support

13

Deaerator

Capacity Range Pressure Temperature Design Feature

: 10 TPH to 300 TPH : 0.35 to 7 Kg/cm2g : 105 to 1500 C : Spray & Tray type Deaerators l Fixed spray nozzle - assured performance & fine spray l Multiple levels of perforated trays l Large manhole access for deaerator tower internal inspection l Canopied steam inlet l External vent condenser for ease of maintenance & repair l Special deaerator internals promote intense mixing of water & steam & ensure high oxygen removal.

14

Renovation & Modernization

Babcock & Wilcox, (B&W) USA, has been the pioneer in the field of Industrial, Utility and Supercritical boilers since 1867. B&W has a rich experience in evolving and implementing Engineering solutions to steam generator problems. Thermax Babcock & Wilcox shares this knowledge base on a two-way basis with B&W. The Renovation & Modernization (R&M) Division of TBW implements Remaining Life Assessment Study programs, Plant Improvement Project (PIP) and Replacements-in-Kind (RIK) Solutions to existing boilers. Scores of Industrial and Utility boilers have benefited from TBW's R&M programs. Life Extension Studies l Condition Assessment, Remaining Life Analysis and Life Extension studies for Steam Generators. l Boiler Performance Reviews and System Analysis. Capacity & Efficiency Upgrades Retrofitting modern fuel firing systems and pressure part upgrades to increase capacity of the existing steam generators. l Restoring original capacity of derated boilers. l Enhance steam-generating capacity above original rating. l Improvement in thermal efficiency.

Engineering Studies l Design and performance analysis of operating boilers irrespective of make, age, design or fuel. l Evolution of techno-economic solutions for further implementation. Pressure Part Upgrades Modification of pressure parts by redesigning heat transfer surfaces such as Furnace water walls, Superheaters, Reheaters, Economizers, etc.

Fuel Flexibility Upgrades l Fuel conversion from / to liquid, gaseous or solids in solo or multiple firing mode. l Conversion to fluidized bed combustion. l Conversion from coal to lignite and to biomass firing, such as husk, bagasse, pith etc.

15

After Sales Service

Services on call l Prompt response to any customer call/complaint and deputation of engineer as required Preventive /Predictive Service l Annual Service Contract package comprising of site visits for performance monitoring & optimization, annual shutdown and emergencies Condition Assessment & Remaining Life -Analysis Studies l Review & survey using special testing equipment & patented methods l In-situ examination & analysis of pressure parts for present condition & remaining life l In accordance with Central Boiler Board IBR regulation 391A Boiler Performance Optimization l Studies & engineering solutions to bring back the unit to optimum performance l Fuel conversions, capacity enhancement and technology upgrades Test facilities l In-house test facilities encompass proven NDT & metallurgical testing

16

B&W

Thermax Babcock & Wilcox Limited

Pune - Corporate Office D-1, MIDC, R. D. Aga Road, Chinchwad, Pune: 411 019 Tel: +91-20-4126464 Fax: +91-20-27479200 Website : www.tbwindia.com Mumbai Dhanrajmahal 2nd floor, Chhatrapati Shivaji Maharaj Marg, Near Gateway of India, Colaba, Mumbai 400 039, India. Tel: 91-22-22045391, 22045324, Fax: 91-22-22040859 Delhi 9, Community Centre, Basant Lok, New Delhi 110 057, India. Tel: 91-11-26145319, 26145326, Fax: 91-11-26148679 Chennai Fatima Akthar Court, 3rd floor, 312 Anna Salai, Teynampet, Chennai 600 018, India. Tel: 91-44-24353831, 24353834, Fax: 91-44-24353841 Kolkata Azimganj House, 5th Floor, 7 Camac Street, Kolkata 700 017, India. Tel: 91-33-22826711/2/3, Fax: 91-33-22826796 Hyderabad 6-3-649 Nalanda Complex, Somaji Guda, Hyderabad 500 082 India. Tel: 91-40-23310254, 23312013, 23396820 Fax: 91-40-23312335 Raipur A-301,Golcha Plaza, 3rd Floor, Nalghar Chowk, Raipur (C.G) 492001 Tel.: 0771-5001768 Mobile: 9893021768

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- viết 6Documento7 pagineviết 6Minh Chu XuânNessuna valutazione finora

- Unit 2: Actuation SystemsDocumento10 pagineUnit 2: Actuation SystemsNaga RajanNessuna valutazione finora

- Molybdenum Disulphide-Titanium Low FrictionDocumento12 pagineMolybdenum Disulphide-Titanium Low Frictionyorf1989Nessuna valutazione finora

- FP Diesel BrochureDocumento2 pagineFP Diesel BrochureRajesh SoundararajanNessuna valutazione finora

- Iveco Fault CodesDocumento7 pagineIveco Fault CodesEsam Phlipe67% (3)

- COPT WorkingDocumento9 pagineCOPT WorkingRavindar AnandanNessuna valutazione finora

- Westen Con Dens RangeDocumento4 pagineWesten Con Dens RangeTee RexNessuna valutazione finora

- 1 9 7 6 Volvo 262 264 265: Notice To Owner: Your Volvo Has Been Built To Comply With All North American Safety and AntiDocumento103 pagine1 9 7 6 Volvo 262 264 265: Notice To Owner: Your Volvo Has Been Built To Comply With All North American Safety and AntiJohn DaneNessuna valutazione finora

- PDG 20SDocumento2 paginePDG 20SNAIRASECNessuna valutazione finora

- Ps 20 1 eDocumento8 paginePs 20 1 eRoozbeh PNessuna valutazione finora

- Nissan RB Engine - WikipediaDocumento60 pagineNissan RB Engine - WikipediaZedrick Nell100% (2)

- Normas para Pruebas en Mantenimientos de SubestacionesDocumento4 pagineNormas para Pruebas en Mantenimientos de SubestacionesCristianMedinaNessuna valutazione finora

- Motor Daewod 1.0-1.2l Aveo, Spark, MatizDocumento155 pagineMotor Daewod 1.0-1.2l Aveo, Spark, MatizAndrea Molina LezamaNessuna valutazione finora

- Polyalthia LongifoliaDocumento4 paginePolyalthia LongifoliaeshuNessuna valutazione finora

- Commissioning Procedures WIDocumento10 pagineCommissioning Procedures WITara WilcoxNessuna valutazione finora

- Onan RV GenSet Service ManualDocumento136 pagineOnan RV GenSet Service ManualAlbert A Ghazaleh100% (2)

- Handbook TabsDocumento1 paginaHandbook TabsABPNessuna valutazione finora

- 1031 Fy FXD Duplex Power PumpDocumento2 pagine1031 Fy FXD Duplex Power PumpBahman Matouri100% (1)

- Limit Value 2020 2.50.13 CPU-PDocumento30 pagineLimit Value 2020 2.50.13 CPU-PRaul Montoya100% (3)

- Fuel Supply System in Petrol EnginesDocumento54 pagineFuel Supply System in Petrol EnginesKLUniveristy86% (14)

- LEMA 25 50 E NeuDocumento7 pagineLEMA 25 50 E NeuDarwin Barra TorresNessuna valutazione finora

- DocumentDocumento3 pagineDocumentAfthirah AmiraNessuna valutazione finora

- 2009-06-17 232200 Ism Low Oil Pressure ChartDocumento4 pagine2009-06-17 232200 Ism Low Oil Pressure ChartrowanNessuna valutazione finora

- Biodiesel Production Through Waste Cooking OilDocumento15 pagineBiodiesel Production Through Waste Cooking OilYan's Senora BescoroNessuna valutazione finora

- Combustion TheoryDocumento74 pagineCombustion TheoryRobert Barrett100% (1)

- Gas Turbine EngineDocumento169 pagineGas Turbine Enginebagus2sepdi2sasongko100% (3)

- 70 - 75 - 80 - 90 - 100 - 115 HPDocumento3 pagine70 - 75 - 80 - 90 - 100 - 115 HPLorenzoGabrielSilvaDonosoNessuna valutazione finora

- Atex GuideDocumento44 pagineAtex Guideminah22100% (4)

- Power Stroke Engine: Technician High Pressure Pump Guide For The 7.3Documento8 paginePower Stroke Engine: Technician High Pressure Pump Guide For The 7.3Abysmal67% (3)

- Air Compressor BrosurDocumento6 pagineAir Compressor BrosurFick Ry'sNessuna valutazione finora