Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

BOP-02 - Handling BOP Equpt Nippling Up

Caricato da

Abdul Hameed OmarDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

BOP-02 - Handling BOP Equpt Nippling Up

Caricato da

Abdul Hameed OmarCopyright:

Formati disponibili

BOP

JOB: HANDLING OF B.O.P EQUIPMENT - NIPPLING UP

TOOLS / MATERIALS USED Slings, eyes hooks and shackles POTENTIAL HAZARDS Conditions or Actions Which Could Cause an Injury / Affect Health Injury to fingers with pinch points of slings.

BOP-02

RECOMMENDED SAFE PROCEDURES Personal Protective Devices Special Clothing Procedures

KEY JOB PROCESS STEPS

S/P

RISK

1. Make all necessary arrangements to N/U BOP and check shackles, pick up lines, eyes and hooks

2. N/U pick up lines

Pick up lines, draw works, shackles, eyes hooks

Leave it caught in between Slipping, falling from wellhead. Injury to personnel if caught in loop and keep clear of swing Injury to personnel if slings fail. Injury to personnel if any left tool falls down

3. Pick up BOP stack and center above the well head flange

BOP, slings and trolley

Keep rotary table covered and all tools away from opening (offshore). Be sure that all slings, shackles, eyes are in good condition, inspected, certified and colour coded. Be sure that BOPs are secured clear from obstructions / connections. Use work vest, safety glasses. Be sure pick up lines are hooked up properly. Take the slack back on drum. Take off BOP securing clamps (offshore) Make sure all BOP bolts, spanners are ready. Be sure that safety belts are used. Use work vest, safety glasses. For lifting personnel, use certified appliances Make sure that every one is well away from the BOP area. Maintain proper communication Keep close supervision Make sure that there is no tools left at the top of BOP. Keep all bolts ready. Give proper signals. P/U BOP slowly and equally balanced. Never allow any jerk to the BOP to prevent breaking of slings.

123678271.doc

Mar. 2004

Page 1 of 4

123678271.doc

Mar. 2004

Page 2 of 4

KEY JOB PROCESS STEPS

TOOLS / MATERIALS USED BOP slings, BOP trolley & Sledge hammer

POTENTIAL HAZARDS Conditions or Actions Which Could Cause an Injury / Affect Health Injury to fingers or hands or feet if caught between objects. Injury to hands / fingers / body with sledgehammer. Slip and fall.

S/P

RISK

RECOMMENDED SAFE PROCEDURES Personal Protective Devices Special Clothing Procedures Use safety belt while working at a height Use proper spanner for bolts / secure hand tools. Check bolt hammer and handles. Never put hands or fingers or feet between flanges and at the top of the bolts that have already passed through the holes of the upper flange while the unit is being lowered. Make sure that bolts are tightened with proper torque. Working platform or scaffolding is to be used. Use your PPE. Use safety belt while working on BOP stack. Use air hoist to lift loads.

4. N/U BOP or stack as a whole and tight the flanges properly

5. Connect choke and kill lines, hydraulic hoses Choke and kill lines hydraulic hoses and hammer 6. Test the BOP equipments and N/U rams actuating handles (onshore). BOP handles and air hoist Slip or fall Injury to fingers or hands during hammering. Injury to eyes with flying particles Strains from lifting. Injury to personnel with high pressure leakage Injury to hands / feet if caught between handle and hard object Slip or fall from BOP while installing handles. Injury to fingers with pinch points or cut due to sharp edges during cleaning and handling tools

7. Keep all tools away from cellar deck and at proper place Hammer, tools, slings and shackles

Make sure that everybody is well away from the BOP stack Never stand on BOP during pressure test For pressure test watch the pressure gauge instead of being near the flanges to check leaks (pressure gauge at the drillers sight on rig floor). Make sure that all tools are away from cellar deck. Clean all tools and keep them at proper place

123678271.doc

Mar. 2004

Page 3 of 4

123678271.doc

Mar. 2004

Page 4 of 4

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

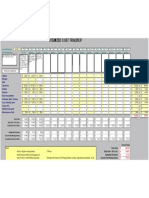

- Mud-Gas Separator Sizing Worksheet: Prerecorded InformationDocumento3 pagineMud-Gas Separator Sizing Worksheet: Prerecorded InformationAbdul Hameed OmarNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Wo Cost TrackerDocumento1 paginaWo Cost TrackerAbdul Hameed OmarNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- New TDS 11 CourseDocumento171 pagineNew TDS 11 CourseAbdul Hameed Omar100% (3)

- Raised Panel WainscotingDocumento6 pagineRaised Panel Wainscotingjlewis43jhuNessuna valutazione finora

- Material Consumption PDFDocumento10 pagineMaterial Consumption PDFShyamontika Choudhury ChakrabartiNessuna valutazione finora

- Steel Plates For Offshore StructuresDocumento8 pagineSteel Plates For Offshore StructuresYiengeChanYeeNessuna valutazione finora

- CBR LabDocumento6 pagineCBR LabKaLeung ChungNessuna valutazione finora

- 39 - Buckling & Wellhead Load After CementingDocumento2 pagine39 - Buckling & Wellhead Load After CementingAbdul Hameed OmarNessuna valutazione finora

- Project ReportDocumento63 pagineProject ReportPramit ChhabraNessuna valutazione finora

- Process Flow Chart of Knitting: A. Stitch LengthDocumento9 pagineProcess Flow Chart of Knitting: A. Stitch LengthAushru HasanNessuna valutazione finora

- Manual Generador ENGGADocumento20 pagineManual Generador ENGGAmanuel100% (2)

- Data Input Sheet: A Worksheet From Well Control TOOLKIT - .Documento4 pagineData Input Sheet: A Worksheet From Well Control TOOLKIT - .Abdul Hameed OmarNessuna valutazione finora

- BlackAndDeckerCircularSaw 7390Documento8 pagineBlackAndDeckerCircularSaw 7390wkinningcNessuna valutazione finora

- Ideal Kick Removal: Drill Hole DataDocumento2 pagineIdeal Kick Removal: Drill Hole DataAbdul Hameed OmarNessuna valutazione finora

- 1260707829bop Test FormDocumento4 pagine1260707829bop Test FormAbdul Hameed Omar100% (1)

- Lab Report TemplateDocumento4 pagineLab Report Templateapi-462603552Nessuna valutazione finora

- Brij - CrodaDocumento4 pagineBrij - Crodafgsdfgsdfg50% (2)

- 1260707780BOP Equipment Failure ReportDocumento1 pagina1260707780BOP Equipment Failure ReportAbdul Hameed OmarNessuna valutazione finora

- Hydraulic Calculations MudpumpDocumento1 paginaHydraulic Calculations MudpumpSudish BhatNessuna valutazione finora

- Adss AustraliaDocumento29 pagineAdss Australiadwas1314Nessuna valutazione finora

- HendrixACS - 4. Restoration GuideDocumento14 pagineHendrixACS - 4. Restoration GuideMarilyn ChimarroNessuna valutazione finora

- ASTM D 86 - 07b PDFDocumento27 pagineASTM D 86 - 07b PDFJulian Felipe Noguera Cruz100% (1)

- Drilling Application: Name of Company: Well Name & Number: DateDocumento1 paginaDrilling Application: Name of Company: Well Name & Number: DateAbdul Hameed OmarNessuna valutazione finora

- 10 - Simple Mud Engineerv1.22Documento22 pagine10 - Simple Mud Engineerv1.22Abdul Hameed OmarNessuna valutazione finora

- Drilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Documento1 paginaDrilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Abdul Hameed OmarNessuna valutazione finora

- Subsea AccumulatorsDocumento4 pagineSubsea AccumulatorsAbdul Hameed OmarNessuna valutazione finora

- Drilling Application: Name of Company: Well Name & Number: DateDocumento1 paginaDrilling Application: Name of Company: Well Name & Number: DateAbdul Hameed OmarNessuna valutazione finora

- Allowable Drilling Torque: Calculations 30,577 4.855 21.733 4.154 0.362 0.2Documento1 paginaAllowable Drilling Torque: Calculations 30,577 4.855 21.733 4.154 0.362 0.2Abdul Hameed OmarNessuna valutazione finora

- 1260709146e - Hydraulics PDFDocumento9 pagine1260709146e - Hydraulics PDFAbdul Hameed OmarNessuna valutazione finora

- TDS-11SA With 2 AC X 400 HP Motors Current Drill Pipe Torque Amps LBS-FTDocumento1 paginaTDS-11SA With 2 AC X 400 HP Motors Current Drill Pipe Torque Amps LBS-FTAbdul Hameed OmarNessuna valutazione finora

- Assortment of Mini ApplicationsDocumento1 paginaAssortment of Mini ApplicationsAbdul Hameed OmarNessuna valutazione finora

- Asset RegisterDocumento101 pagineAsset RegistertothemNessuna valutazione finora

- Vol 6 Report 186-Coatings and Inks For Food Contact Materials PDFDocumento142 pagineVol 6 Report 186-Coatings and Inks For Food Contact Materials PDFvaducNessuna valutazione finora

- MR366X8423A000Documento128 pagineMR366X8423A000Guillermo MV100% (1)

- What Is An Ufer GroundDocumento7 pagineWhat Is An Ufer GroundhendrexNessuna valutazione finora

- M 37Documento1 paginaM 37navneetkpatil8409Nessuna valutazione finora

- Noise and VibrationDocumento5 pagineNoise and VibrationIbrahim LotfyNessuna valutazione finora

- Results and Discussion: Results of Proximate Analysis of Fuel PelletsDocumento6 pagineResults and Discussion: Results of Proximate Analysis of Fuel PelletsBalaji RamaswamyNessuna valutazione finora

- Eml 5233 HWK #6Documento3 pagineEml 5233 HWK #6jack dealerNessuna valutazione finora

- BS en 14303-2009Documento38 pagineBS en 14303-2009Iveel PurevdorjNessuna valutazione finora

- Copper StandardsDocumento3 pagineCopper StandardsSarath KumarNessuna valutazione finora

- United States Patent (19) : Fisher, Both of Chester, All of VaDocumento4 pagineUnited States Patent (19) : Fisher, Both of Chester, All of VaCh PrasadNessuna valutazione finora

- Alati Stuhne Brochure Moulds 2016Documento16 pagineAlati Stuhne Brochure Moulds 2016wardaddyNessuna valutazione finora

- EHB - en - File - 9.7.3 Equivalent ASME EN Materials PDFDocumento3 pagineEHB - en - File - 9.7.3 Equivalent ASME EN Materials PDFks2000n1Nessuna valutazione finora

- Batch-7 Phase - LI FinalDocumento45 pagineBatch-7 Phase - LI Final19TUCV038 SHUHAIL AKTHAR.ANessuna valutazione finora

- Air, Combustion, Fire Fighting-Topic 7 ChemistryDocumento6 pagineAir, Combustion, Fire Fighting-Topic 7 ChemistryAlberto De SafariNessuna valutazione finora

- MSDS - Fuel-Protect, Keep Clean Solution, For Diesel InjectorDocumento5 pagineMSDS - Fuel-Protect, Keep Clean Solution, For Diesel InjectorDaniel OlanoNessuna valutazione finora

- IB HL Chemistry Assessment Statements Topic 7Documento3 pagineIB HL Chemistry Assessment Statements Topic 7AndrewNessuna valutazione finora

- Paraloid K 120ndDocumento7 pagineParaloid K 120ndkishanptlNessuna valutazione finora