Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Eighth Semester B.Tech. Degree Examination, November 2008 (2003 Scheme) Branch: Production 03.804: Machine Tool Design (P)

Caricato da

Jithesh VDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Eighth Semester B.Tech. Degree Examination, November 2008 (2003 Scheme) Branch: Production 03.804: Machine Tool Design (P)

Caricato da

Jithesh VCopyright:

Formati disponibili

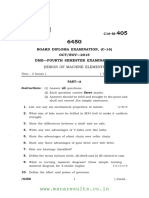

*7116*

Reg. No. : ..................................... Name : ..........................................

(Pages : 3)

7116

Eighth Semester B.Tech. Degree Examination, November 2008 (2003 Scheme) Branch : Production 03.804 : MACHINE TOOL DESIGN (P)

Time : 3 Hours Instructions: 1) 2) 3) 4) Max. Marks : 100 Answer all questions from Part A. Answer one question from each Module in Part B. Use of approved design data book permitted. Assume suitable data wherever necessary. PART A 1. Why geometric progression is used for spindle speeds ? 2. Explain the significance of Petroffs equation in bearing design. 3. What are the factors governing the design of Ball and Roller bearings ? 4. List out the important physical characteristics of a good bearing material. 5. When do we prefer herringbone gears over spur and helical gears ? 6. What are the advantages of helical gears over spur gears ? 7. What is meant by interference in gears ? How it will be overcome ? 8. Why a combination of flat and V type slideways is preferred for machine tools ? 9. What are the basic requirements of a machine tool ? 10. Explain the significance of speed diagrams in machine tool design. (104=40 Marks)

P.T.O.

7116

-2-

*7116*

PART B Module I 11. Design a bearing and journal to support a load of 4500 N at 600 rpm using a hardened steel journal and a bronze backed babbit bearing. An abundance of oil is supplied by means of oiling rings. The oil viscosity is 250 Second saybolt at 37.8C and the specific gravity is 0.90 at 15.6C. The bearing is relieved for 20 degree from the normal to the load line. 20 12. A ball bearing operates on the following work cycle.

Radial load (N) 3000 7000 5000

Element No. 1 2 3

Speed (rpm) Element time (%) 720 1440 900 30 50 20

The dynamic load carrying capacity of the bearing is 16.6 kN. Find a) The average speed of rotation. b) The equivalent radial load and. c) The bearing life. Module II 13. A pair of spur gears is to be used for a sugar crusher. Design the gears for strength. Power transmitted = 25 kW Speed of pinion = 400 rpm Speed reduction ratio = 4:1 Tooth profile = 20 full depth involute Velocity = 6 m/sec (limited). 20 20

*7116*

-3-

7116

14. Design a worm gear drive to transmit 3 KW at 600 rpm. Speed of worm wheel is 40 rpm. Tabulate the results neatly. Module III 15. Explain with sketches the different types of machine tool beds and their design features. 16. a) Give an account about design of slide ways for wear resistance. b) Enumerate the basic procedure associated with Ram-type structures.

20

20 10 10

Potrebbero piacerti anche

- Change Your MotionDocumento4 pagineChange Your MotionreynandcpcNessuna valutazione finora

- Machine Design Elements and AssembliesDa EverandMachine Design Elements and AssembliesValutazione: 3.5 su 5 stelle3.5/5 (2)

- Pivot Interactives Motion Graphing A Dry Ice Puck On A RampDocumento2 paginePivot Interactives Motion Graphing A Dry Ice Puck On A RampSophia0% (1)

- Welding Journal PDFDocumento7 pagineWelding Journal PDFraisalfiansyahNessuna valutazione finora

- Seventh Semester B.Tech. Degree Examination, June 2009 03-703: Design of Machine Elements - Ii (M)Documento3 pagineSeventh Semester B.Tech. Degree Examination, June 2009 03-703: Design of Machine Elements - Ii (M)Harish ChandranNessuna valutazione finora

- 181505-181902-MD - IiDocumento2 pagine181505-181902-MD - IiSiddharth PanchalNessuna valutazione finora

- rr320305 Design of Machine Members IIDocumento8 paginerr320305 Design of Machine Members IISRINIVASA RAO GANTANessuna valutazione finora

- Machine Design - LDocumento2 pagineMachine Design - LNilesh Mistry (Nilesh Sharma)Nessuna valutazione finora

- UPTU 2013-14 Machine Design - II EME 602Documento4 pagineUPTU 2013-14 Machine Design - II EME 602nitin_johriNessuna valutazione finora

- Dmm2 Mar2006Documento8 pagineDmm2 Mar2006Abdul Saleem MohammedNessuna valutazione finora

- 2020-11-10SupplementaryME402ME402-E - Ktu QbankDocumento2 pagine2020-11-10SupplementaryME402ME402-E - Ktu QbankbilalfocusNessuna valutazione finora

- MD II Machine Design AssignmentsDocumento5 pagineMD II Machine Design Assignmentsrishabhk28995Nessuna valutazione finora

- Machine Design II Question PaperDocumento8 pagineMachine Design II Question PaperProf. Avinash MahaleNessuna valutazione finora

- Design of Machine Elements-II Exam QuestionsDocumento9 pagineDesign of Machine Elements-II Exam QuestionsPrasinNessuna valutazione finora

- Gujarat Technological UniversityDocumento3 pagineGujarat Technological Universityrajushamla9927Nessuna valutazione finora

- Lathe DesignDocumento11 pagineLathe DesignShiyas Basheer0% (1)

- Machine Design Exam Questions on Gears, Bearings and Other Mechanical ComponentsDocumento3 pagineMachine Design Exam Questions on Gears, Bearings and Other Mechanical ComponentsNILESH SUTHARNessuna valutazione finora

- Me 7 Sem Subject Design of Mechanical Drives Jun 2017Documento2 pagineMe 7 Sem Subject Design of Mechanical Drives Jun 2017djniksthehearteditorNessuna valutazione finora

- DtsDocumento3 pagineDtsRuby SmithNessuna valutazione finora

- Jeppiaar Institute of Technology: Kunnam, Sunguvarchatram, Sriperumbudur, Chennai - 631 604Documento3 pagineJeppiaar Institute of Technology: Kunnam, Sunguvarchatram, Sriperumbudur, Chennai - 631 604Balu phoenixNessuna valutazione finora

- ME2352 Design of Transmission Question BankDocumento4 pagineME2352 Design of Transmission Question BankKarthik SubramaniNessuna valutazione finora

- Design of Transmission SystemsDocumento3 pagineDesign of Transmission SystemsSaravanan KumarNessuna valutazione finora

- Machine Design-I Exam Guide for University of Pune StudentsDocumento56 pagineMachine Design-I Exam Guide for University of Pune Studentsavinash119870% (1)

- Question Paper Code:: (10×2 20 Marks)Documento3 pagineQuestion Paper Code:: (10×2 20 Marks)PradeepNessuna valutazione finora

- WWW Manaresults Co inDocumento4 pagineWWW Manaresults Co inGod deva123Nessuna valutazione finora

- 2019 May ME402-A - Ktu QbankDocumento3 pagine2019 May ME402-A - Ktu Qbankbilalfocus0% (1)

- Mechatronics exam with questions on control systems and PLC applicationsDocumento62 pagineMechatronics exam with questions on control systems and PLC applicationshaptooorNessuna valutazione finora

- 07a6ec05 Designofmachinemembers IIDocumento11 pagine07a6ec05 Designofmachinemembers IIzahid_polyNessuna valutazione finora

- Makalah GTWDocumento8 pagineMakalah GTWfaisalNessuna valutazione finora

- Me 2352 - DTS Q BankDocumento5 pagineMe 2352 - DTS Q Bankpaul_jaikumarm27530% (1)

- Main Shaft of Two Wheerls Modelling and AnalysisDocumento42 pagineMain Shaft of Two Wheerls Modelling and AnalysisAVINASHNessuna valutazione finora

- Silver Oak College of Engineering & Technology Aditya Silver Oak Institute of TechnologyDocumento2 pagineSilver Oak College of Engineering & Technology Aditya Silver Oak Institute of TechnologyShree PrajapatiNessuna valutazione finora

- Me 7 Sem Design of Mechanical Drives 3560 Summer 2019Documento2 pagineMe 7 Sem Design of Mechanical Drives 3560 Summer 2019djniksthehearteditorNessuna valutazione finora

- 15A03602 Design of Machine Members - IIDocumento2 pagine15A03602 Design of Machine Members - IIJagannath CherkuNessuna valutazione finora

- DTSDocumento7 pagineDTSmithundme659Nessuna valutazione finora

- RR420305 Robotics PDFDocumento9 pagineRR420305 Robotics PDFSarath ChandraNessuna valutazione finora

- DMM Ii (2015)Documento35 pagineDMM Ii (2015)gorijalaNessuna valutazione finora

- Design of Transmission ElementDocumento42 pagineDesign of Transmission ElementVenkatesh MohanNessuna valutazione finora

- Question Paper Code:: (10×2 20 Marks)Documento3 pagineQuestion Paper Code:: (10×2 20 Marks)PradeepNessuna valutazione finora

- DMDDocumento4 pagineDMDSantosh AloneNessuna valutazione finora

- Dts Important Ques 2 16 MarksDocumento5 pagineDts Important Ques 2 16 MarksBas RamuNessuna valutazione finora

- Supp Nov 2009Documento10 pagineSupp Nov 2009prk74Nessuna valutazione finora

- Sathyabama University: Register NumberDocumento3 pagineSathyabama University: Register NumberSecret SecretNessuna valutazione finora

- Design of Transmission System Question PaperDocumento1 paginaDesign of Transmission System Question PapermuthurajaNessuna valutazione finora

- Design of Transmission Systems 3Documento2 pagineDesign of Transmission Systems 3srajapratyNessuna valutazione finora

- DTS Prelim 2022-23Documento4 pagineDTS Prelim 2022-23Prathamesh RaneNessuna valutazione finora

- 2018sme 7 Sem Design of Mechanical Drives Summer 2018Documento2 pagine2018sme 7 Sem Design of Mechanical Drives Summer 2018Komal HingeNessuna valutazione finora

- 15A03602 Design of Machine Members - IIDocumento2 pagine15A03602 Design of Machine Members - IIJagannath CherkuNessuna valutazione finora

- r05320305 Design of Machine Members IIDocumento11 paginer05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- AT8611 Lab QuestionsDocumento9 pagineAT8611 Lab QuestionsChirpiNessuna valutazione finora

- rr320305 Design of Machine Members IIDocumento8 paginerr320305 Design of Machine Members IISrinivasa Rao GNessuna valutazione finora

- 05-04 Machine Design & Cad-II (Me)Documento2 pagine05-04 Machine Design & Cad-II (Me)Abdul AhadNessuna valutazione finora

- r05320305 Design of Machine Members IIDocumento9 paginer05320305 Design of Machine Members IISRINIVASA RAO GANTANessuna valutazione finora

- Machine Design - II: (Also Old Sem-VI Equivalence) (126112)Documento2 pagineMachine Design - II: (Also Old Sem-VI Equivalence) (126112)Harshal DesaleNessuna valutazione finora

- Assignment 1 (Unit 1 and 2)Documento5 pagineAssignment 1 (Unit 1 and 2)Atharva ChoudhariNessuna valutazione finora

- WWW - Manaresults.co - In: (Mechanical Engineering)Documento2 pagineWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailNessuna valutazione finora

- ME 7601 DTS Assessment IIDocumento2 pagineME 7601 DTS Assessment IIraghulNessuna valutazione finora

- Dme KtuDocumento9 pagineDme Ktuhyy5u6Nessuna valutazione finora

- WWW - Manaresults.co - In: Design of Machine Members - IiDocumento2 pagineWWW - Manaresults.co - In: Design of Machine Members - IiXyz AbcNessuna valutazione finora

- DTS 2Documento2 pagineDTS 2Soundaryan PraveenNessuna valutazione finora

- MDDocumento2 pagineMDAbhijeet PramanikNessuna valutazione finora

- Me 1352Documento6 pagineMe 1352arunramakrishnanNessuna valutazione finora

- Laxmi Publications ARUN TNDocumento1 paginaLaxmi Publications ARUN TNJithesh VNessuna valutazione finora

- Management of Training and Employer Relations: Objectives, StrategiesDocumento7 pagineManagement of Training and Employer Relations: Objectives, StrategiesJithesh VNessuna valutazione finora

- Examination Shedule-1Documento1 paginaExamination Shedule-1Jithesh VNessuna valutazione finora

- ME 2009 Unsolved PDFDocumento13 pagineME 2009 Unsolved PDFMushini NagabhushanNessuna valutazione finora

- KERALA PUBLIC SERVICE COMMISSION EXAM ADMISSION TICKETDocumento2 pagineKERALA PUBLIC SERVICE COMMISSION EXAM ADMISSION TICKETJithesh VNessuna valutazione finora

- 5917 Question PaperDocumento16 pagine5917 Question PaperJithesh V0% (1)

- KERALA PUBLIC SERVICE COMMISSION EXAM ADMISSION TICKETDocumento2 pagineKERALA PUBLIC SERVICE COMMISSION EXAM ADMISSION TICKETJithesh VNessuna valutazione finora

- Management of Training and Employer Relations: Objectives, StrategiesDocumento7 pagineManagement of Training and Employer Relations: Objectives, StrategiesJithesh VNessuna valutazione finora

- KERALA PUBLIC SERVICE COMMISSION EXAM ADMISSION TICKETDocumento2 pagineKERALA PUBLIC SERVICE COMMISSION EXAM ADMISSION TICKETJithesh VNessuna valutazione finora

- KERALA PUBLIC SERVICE COMMISSION EXAM ADMISSION TICKETDocumento2 pagineKERALA PUBLIC SERVICE COMMISSION EXAM ADMISSION TICKETJithesh VNessuna valutazione finora

- What Is ManagementDocumento2 pagineWhat Is ManagementJithesh VNessuna valutazione finora

- Probation DeclarationDocumento1 paginaProbation DeclarationJithesh VNessuna valutazione finora

- Fkey 53 16Documento1 paginaFkey 53 16Jithesh VNessuna valutazione finora

- Lbs College of Engineering, KasaragodDocumento2 pagineLbs College of Engineering, KasaragodJithesh VNessuna valutazione finora

- SBI Cash Voucher TitleDocumento1 paginaSBI Cash Voucher TitleJithesh VNessuna valutazione finora

- Pump Operator1Documento1 paginaPump Operator1Jithesh VNessuna valutazione finora

- IIST Faculty RecruitmentDocumento1 paginaIIST Faculty RecruitmentTrinath31Nessuna valutazione finora

- An Experimental Investigation of Dissimilar Metal Welding of Mild Steel and Stainless SteelDocumento1 paginaAn Experimental Investigation of Dissimilar Metal Welding of Mild Steel and Stainless SteelJithesh VNessuna valutazione finora

- PGCET-2014 Allotment Status For Higher Option - Cut Off Rank For First RoundDocumento1 paginaPGCET-2014 Allotment Status For Higher Option - Cut Off Rank For First RoundJithesh VNessuna valutazione finora

- Indian Space Research Organisation (Isro) Bangalore, India: Application FormDocumento2 pagineIndian Space Research Organisation (Isro) Bangalore, India: Application FormJithesh VNessuna valutazione finora

- 13-1007311919 Asif Chowdhury Bank SlipDocumento1 pagina13-1007311919 Asif Chowdhury Bank SlipArthur SandersNessuna valutazione finora

- Sbi Booklet For ExamsDocumento11 pagineSbi Booklet For Examsravi98195Nessuna valutazione finora

- Rising PopulationsDocumento34 pagineRising PopulationsJithesh VNessuna valutazione finora

- PGCET-2014 Allotment Status For Higher Option - Cut Off Rank For First RoundDocumento1 paginaPGCET-2014 Allotment Status For Higher Option - Cut Off Rank For First RoundJithesh VNessuna valutazione finora

- Unit1 L1 RVRDocumento7 pagineUnit1 L1 RVRJithesh VNessuna valutazione finora

- CBS Challan For Clerical CadreDocumento1 paginaCBS Challan For Clerical Cadregupta123Nessuna valutazione finora

- Indian Space Research Organisation (Isro) Bangalore, India: Application FormDocumento2 pagineIndian Space Research Organisation (Isro) Bangalore, India: Application FormJithesh VNessuna valutazione finora

- Rising PopulationsDocumento34 pagineRising PopulationsJithesh VNessuna valutazione finora

- Harmonising Industrialisation and Environment ConservationDocumento11 pagineHarmonising Industrialisation and Environment ConservationJithesh VNessuna valutazione finora

- Fourier's Law of Heat ConductionDocumento14 pagineFourier's Law of Heat Conductionhasib100% (1)

- Ferroresonance During Single-Phase Switching of Distribution TransformersDocumento6 pagineFerroresonance During Single-Phase Switching of Distribution TransformersDiego Betancourt MejiaNessuna valutazione finora

- Stress Analysis of Flat Plates With Attached NozzlesDocumento125 pagineStress Analysis of Flat Plates With Attached NozzlesZarra FaktNessuna valutazione finora

- April 2015-Vacuum Drying Chem Eng PDFDocumento9 pagineApril 2015-Vacuum Drying Chem Eng PDFAlvaro BarbozaNessuna valutazione finora

- IS 516 (Part-2) Sec-1 - 2018Documento16 pagineIS 516 (Part-2) Sec-1 - 2018Sai Pavan100% (9)

- cO2CH4 Permselective GassensorDocumento5 paginecO2CH4 Permselective GassensorKartik RamasubramanianNessuna valutazione finora

- EE221 Solution Problem Set2Documento10 pagineEE221 Solution Problem Set2srinivasanNessuna valutazione finora

- Fourier Transform and Its Medical ApplicationDocumento55 pagineFourier Transform and Its Medical Applicationadriveros100% (1)

- LM 08Documento38 pagineLM 08Tôi Là Đăng TèoNessuna valutazione finora

- Problems On Beams PDFDocumento16 pagineProblems On Beams PDFC j50% (6)

- MFIX On of Discrete Element MethodDocumento30 pagineMFIX On of Discrete Element MethodkamranianNessuna valutazione finora

- 1117 1 M-Ary Signals PART 1Documento11 pagine1117 1 M-Ary Signals PART 1PARKSANGWOOKNessuna valutazione finora

- 2 B.tech Biotechnology 27 38Documento38 pagine2 B.tech Biotechnology 27 38Anju GuptaNessuna valutazione finora

- Latent Print DevelopmentDocumento20 pagineLatent Print Developmentapi-272036460100% (1)

- Overview Aerodynamics 2017Documento10 pagineOverview Aerodynamics 2017marcoNessuna valutazione finora

- Improve Steel Quality with Electromagnetic StirrersDocumento4 pagineImprove Steel Quality with Electromagnetic Stirrerst_pradipNessuna valutazione finora

- Kinematics of Machinery: Motion and AnalysisDocumento29 pagineKinematics of Machinery: Motion and AnalysisShashank SinghNessuna valutazione finora

- Lift EstimationDocumento5 pagineLift EstimationAvinash SinghNessuna valutazione finora

- SABIC Innovative Plastics Lexan® 940 PC Data SheetDocumento3 pagineSABIC Innovative Plastics Lexan® 940 PC Data SheetMRC RailNessuna valutazione finora

- Modelling Urban Areas in Dam-Break Flood-Wave Numerical SimulationsDocumento14 pagineModelling Urban Areas in Dam-Break Flood-Wave Numerical SimulationsDaru Nurisma PramuktiNessuna valutazione finora

- Stiffness of Cable-Based Parallel Manipulators With Application To Stability AnalysisDocumento8 pagineStiffness of Cable-Based Parallel Manipulators With Application To Stability AnalysisNhật MinhNessuna valutazione finora

- Air Preheater Technical PaperDocumento21 pagineAir Preheater Technical Paperchekoti koushikNessuna valutazione finora

- Optimum Penstocks For Low Head Microhydro Schemes - Alexander, Giddens - 2008Documento13 pagineOptimum Penstocks For Low Head Microhydro Schemes - Alexander, Giddens - 2008cbarajNessuna valutazione finora

- PAP NAV Energie Savings in Twin Propellers DesignDocumento14 paginePAP NAV Energie Savings in Twin Propellers Designyannickjan2005Nessuna valutazione finora

- Daftar PustakaDocumento5 pagineDaftar PustakamaisyaraaaahNessuna valutazione finora

- Acceleration (Inclined Plane)Documento5 pagineAcceleration (Inclined Plane)jambunaNessuna valutazione finora

- Led t5 Eco Batten - 93044476 - Lbte 4 5 WW 1ft Eco - 221864 - EmeaDocumento3 pagineLed t5 Eco Batten - 93044476 - Lbte 4 5 WW 1ft Eco - 221864 - EmeaNailza BizerraNessuna valutazione finora

- XI Maths - I Terminal ExamDocumento2 pagineXI Maths - I Terminal ExamPurisai Rajamani KumarNessuna valutazione finora