Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

BOP-01 - Handling BOP Equipment Nippling Down

Caricato da

Abdul Hameed OmarDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

BOP-01 - Handling BOP Equipment Nippling Down

Caricato da

Abdul Hameed OmarCopyright:

Formati disponibili

BOP

JOB: HANDLING OF B.O.P EQUIPMENT - NIPPLING DOWN

TOOLS / MATERIALS USED POTENTIAL HAZARDS Conditions or Actions Which Could Cause an Injury / Affect Health

BOP-01

RECOMMENDED SAFE PROCEDURES Personal Protective Devices Special Clothing Procedures

KEY JOB PROCESS STEPS

S/P

RISK

1. Check all pick up lines, eyes and Slings, eyes Injury to fingers with pinch shackles and secure BOP and shackles points of slings. Slip, fall from BOP stack.

Be sure BOP stack is cleaned from mud. Be sure that all slings, eyes and shackles are in good conditions, inspected, certified and colour coded. Use PPE (safety belt). Be sure that BOP is secured properly with the pick up lines. Use work vest, safety glasses. Make sure that all hydraulic lines pressure is bled off to zero pressure. Stay well away from hydraulic lines. Use PPE. Open hydraulic lines slowly and let the fluid come out. Collect in bucket to avoid pollution. Disconnect lines. Always use safety belt while working on BOP stack. Use PPE such as goggles, hand gloves, work vest Working platform or scaffolding is to be used (Offshore)

2. Bleed off all hydraulic lines Hydraulic lines pressure to zero before hammering

Slip and fall Whipping action from the hose.

3. Open all hydraulic lines from BOP, hoses Slip and fall BOPs hammer Injury to eyes with fluid. Injury to fingers or hands with hammer

4. Disconnect the rams actuating Rams handles Injury to hands or feet. handles from BOP and air hoist Injury to fingers with pinch point

Disconnect all the handles and lay down carefully. Never stand under the handles. Use air hoist for N/D handles.

123537415.doc

Jan 2003

Page 1 of 3

123537415.doc

Jan 2003

Page 2 of 3

KEY JOB PROCESS STEPS

TOOLS / MATERIALS USED

POTENTIAL HAZARDS Conditions or Actions Which Could Cause an Injury / Affect Health Burn with drilling fluid. Injury to eyes if drilling fluid goes into it.

Slip and fall if pipe wrench slips.

S/P

RISK

RECOMMENDED SAFE PROCEDURES Personal Protective Devices Special Clothing Procedures

5. Drain out drilling fluid column Drilling fluid above well head flange

Make sure that everyone is away from mud. Open the valve with proper handle. Never open the valve with pipe wrench. Use PPE.

6. Open BOP bolts from flanges BOP winch / Injuries to finger or hand and L/D BOP Trolley or Draw with sledge hammer. works Crane Slip and fall if spanner slips. and BOP Injury to personnel if caught between BOP and equipment. Falling object from top of BOP / RT Flying metallic chips. 7. L/D pick up lines, shackles and Pick up lines, Slip and fall. keep at proper place Shackles and Injury to fingers or feet if Tools caught between object.

Use proper spanner for bolts. Check hammer. Make sure that all bolts are opened and removed from flanges. Make sure no tool is left on BOP flanges. Make sure that everyone is well away from BOP. Give proper signals. Pick up slowly and N/D BOP carefully. Use PPE. Be sure that pick up lines are not damaged. Use PPE. Keep all tools away from well head. Cover the rotary table.

8. Stack and clean BOP, BOP, Water Injury to eyes with particles. equipments, at proper place Hose and Fire Slip and fall while cleaning Brush with water

Make sure that BOP stack is well secured. Make sure all PPE is worn for cleaning BOPs Ensure that BOP area is clean.

123537415.doc

Jan 2003

Page 3 of 3

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- New TDS 11 CourseDocumento171 pagineNew TDS 11 CourseAbdul Hameed Omar100% (3)

- Occupational Health and SafetyDocumento23 pagineOccupational Health and SafetyElena Hernandez100% (6)

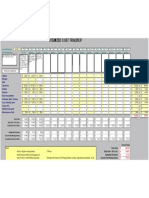

- 10 - Simple Mud Engineerv1.22Documento2 pagine10 - Simple Mud Engineerv1.22Abdul Hameed OmarNessuna valutazione finora

- 10 - Simple Mud Engineerv1.22Documento22 pagine10 - Simple Mud Engineerv1.22Abdul Hameed OmarNessuna valutazione finora

- 08 - BASIC MUD REPORTv1.5Documento21 pagine08 - BASIC MUD REPORTv1.5Abdul Hameed OmarNessuna valutazione finora

- Wo Cost TrackerDocumento1 paginaWo Cost TrackerAbdul Hameed OmarNessuna valutazione finora

- 39 - Buckling & Wellhead Load After CementingDocumento2 pagine39 - Buckling & Wellhead Load After CementingAbdul Hameed OmarNessuna valutazione finora

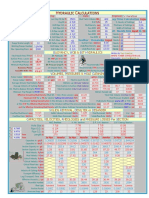

- Hydraulic Calculations MudpumpDocumento1 paginaHydraulic Calculations MudpumpSudish BhatNessuna valutazione finora

- Assortment of Mini ApplicationsDocumento1 paginaAssortment of Mini ApplicationsAbdul Hameed OmarNessuna valutazione finora

- 29 - Well Control Data Sheet For Directional Wells Wt. & Wt. MethodDocumento2 pagine29 - Well Control Data Sheet For Directional Wells Wt. & Wt. MethodAbdul Hameed OmarNessuna valutazione finora

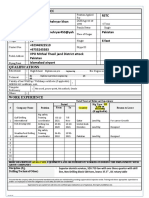

- Drilling Application: Name of Company: Well Name & Number: DateDocumento1 paginaDrilling Application: Name of Company: Well Name & Number: DateAbdul Hameed OmarNessuna valutazione finora

- Data Input Sheet: A Worksheet From Well Control TOOLKIT - .Documento4 pagineData Input Sheet: A Worksheet From Well Control TOOLKIT - .Abdul Hameed OmarNessuna valutazione finora

- 1260709465flow Back Test RecordDocumento2 pagine1260709465flow Back Test RecordAbdul Hameed OmarNessuna valutazione finora

- 16dti (EDocFind - Com)Documento2 pagine16dti (EDocFind - Com)Abdul Hameed OmarNessuna valutazione finora

- Well Control Kill Sheet (Low Angle Wells) : Drillstring Volume Annular Volume (BBLS) (BBLS)Documento2 pagineWell Control Kill Sheet (Low Angle Wells) : Drillstring Volume Annular Volume (BBLS) (BBLS)khaledNessuna valutazione finora

- Subsea AccumulatorsDocumento4 pagineSubsea AccumulatorsAbdul Hameed OmarNessuna valutazione finora

- Ideal Kick Removal: Drill Hole DataDocumento2 pagineIdeal Kick Removal: Drill Hole DataAbdul Hameed OmarNessuna valutazione finora

- 1260707780BOP Equipment Failure ReportDocumento1 pagina1260707780BOP Equipment Failure ReportAbdul Hameed OmarNessuna valutazione finora

- 21 Volumetric MethodDocumento1 pagina21 Volumetric MethodAbdul Hameed OmarNessuna valutazione finora

- Mud-Gas Separator Sizing Worksheet: Prerecorded InformationDocumento3 pagineMud-Gas Separator Sizing Worksheet: Prerecorded InformationAbdul Hameed OmarNessuna valutazione finora

- Maximum Casing Pressure and Pit GainDocumento1 paginaMaximum Casing Pressure and Pit GainstevebeardsleyNessuna valutazione finora

- Drilling Application: Name of Company: Well Name & Number: DateDocumento1 paginaDrilling Application: Name of Company: Well Name & Number: DateAbdul Hameed OmarNessuna valutazione finora

- Drilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Documento1 paginaDrilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Abdul Hameed OmarNessuna valutazione finora

- Mud-Gas Separator Sizing Worksheet: Prerecorded InformationDocumento3 pagineMud-Gas Separator Sizing Worksheet: Prerecorded InformationAbdul Hameed OmarNessuna valutazione finora

- Formation TemperatureDocumento2 pagineFormation TemperatureAbdul Hameed OmarNessuna valutazione finora

- 1260707829bop Test FormDocumento4 pagine1260707829bop Test FormAbdul Hameed Omar100% (1)

- 2009 Separator CalcsDocumento18 pagine2009 Separator CalcsneelNessuna valutazione finora

- 1260709146e - Hydraulics PDFDocumento9 pagine1260709146e - Hydraulics PDFAbdul Hameed OmarNessuna valutazione finora

- TDS-11SA With 2 AC X 400 HP Motors Current Drill Pipe Torque Amps LBS-FTDocumento1 paginaTDS-11SA With 2 AC X 400 HP Motors Current Drill Pipe Torque Amps LBS-FTAbdul Hameed OmarNessuna valutazione finora

- Over PullDocumento1 paginaOver PullAbdul Hameed OmarNessuna valutazione finora

- TDS-11SA Lubrication and Maintenance GuidelinesDocumento1 paginaTDS-11SA Lubrication and Maintenance GuidelinesEduardo Vilela RomeroNessuna valutazione finora

- Confined Space Entry AwarenessDocumento29 pagineConfined Space Entry AwarenessAshishNessuna valutazione finora

- Muhammad Wiji Utomo: Occupational Health and SafetyDocumento1 paginaMuhammad Wiji Utomo: Occupational Health and SafetywijitomoNessuna valutazione finora

- Foxconn HR ProblemsDocumento21 pagineFoxconn HR ProblemsvothongtuNessuna valutazione finora

- Our People Make Southwest Airlines One of The World's Most Admired CompaniesDocumento39 pagineOur People Make Southwest Airlines One of The World's Most Admired CompaniesDimas Radhitya Wahyu PratamaNessuna valutazione finora

- PDF My FilesDocumento8 paginePDF My FilesGerandy SyNessuna valutazione finora

- Lifting EquipmentDocumento82 pagineLifting Equipmentchandrahas reddyNessuna valutazione finora

- Hit Hy-150 PDFDocumento16 pagineHit Hy-150 PDFEduardo Antonio Duran SepulvedaNessuna valutazione finora

- Ed Temporary Refuge IntegrityDocumento27 pagineEd Temporary Refuge Integrityliamo88880Nessuna valutazione finora

- Workplace HousekeepingDocumento9 pagineWorkplace HousekeepingKeith Tanaka MagakaNessuna valutazione finora

- Pre Employment Health DeclarationDocumento4 paginePre Employment Health DeclarationPooja AroraNessuna valutazione finora

- Industrial Safety and Health ManagementDocumento5 pagineIndustrial Safety and Health ManagementAssignmentLab.comNessuna valutazione finora

- L1b - Hazard Identification, Risk Assessment and Risk ControlDocumento26 pagineL1b - Hazard Identification, Risk Assessment and Risk ControlKillua AzNessuna valutazione finora

- Lifting Operations 2.034Documento10 pagineLifting Operations 2.034svdnolen0% (1)

- Ladder Safety ChecklistDocumento3 pagineLadder Safety ChecklistzulfactNessuna valutazione finora

- MSDS Contact CementDocumento6 pagineMSDS Contact CementfaridanurroNessuna valutazione finora

- How To Make A Bow Tie An Introduction To Process SafetyDocumento55 pagineHow To Make A Bow Tie An Introduction To Process SafetyPriyo DjatmikoNessuna valutazione finora

- OHSE Management Plan SafetyDocumento45 pagineOHSE Management Plan SafetyLegend Anbu100% (1)

- Method Statement For Cable Conduit & Tray Installation PDFDocumento5 pagineMethod Statement For Cable Conduit & Tray Installation PDFUtku Can Kılıç100% (1)

- Ergo WhitepaperDocumento16 pagineErgo WhitepaperNelly PaniaguaNessuna valutazione finora

- Hazard Assessment FormDocumento4 pagineHazard Assessment FormБаясааАхNessuna valutazione finora

- Hammer MillDocumento2 pagineHammer MillIfa FafaNessuna valutazione finora

- ADC Fact Sheet 4Documento3 pagineADC Fact Sheet 4Muhammad shehryar KhanNessuna valutazione finora

- OSH Requirement ChecklistDocumento6 pagineOSH Requirement Checklistjett teejNessuna valutazione finora

- 1.2 - Lead Exposure Management v3.1 EnglishDocumento18 pagine1.2 - Lead Exposure Management v3.1 EnglishShuhaib MDNessuna valutazione finora

- Sun Coast Remediation Research-RevisedDocumento5 pagineSun Coast Remediation Research-RevisedHarvard Tutor100% (2)

- Posture and Ergonomic Workstation Setup GuideDocumento24 paginePosture and Ergonomic Workstation Setup GuideBackHealthNessuna valutazione finora

- Praxair Material Safety Data Sheet: Product: Carbon Dioxide, Refrigerated Liquid P-4573-D Date: December 2009Documento10 paginePraxair Material Safety Data Sheet: Product: Carbon Dioxide, Refrigerated Liquid P-4573-D Date: December 2009prasad5034Nessuna valutazione finora

- Safe Operating Procedure: (Revised 5/18) Personal Protective Equipment (Ppe) - Foot Protection Evaluation and ChecklistDocumento7 pagineSafe Operating Procedure: (Revised 5/18) Personal Protective Equipment (Ppe) - Foot Protection Evaluation and ChecklistMohd Zubaidi Bin OthmanNessuna valutazione finora

- Guidance On The Use of Excavator Quick HitchesDocumento2 pagineGuidance On The Use of Excavator Quick Hitchesargon39Nessuna valutazione finora