Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Span Limits For Elevated Temperature Piping

Caricato da

Dushyant VarshneyDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Span Limits For Elevated Temperature Piping

Caricato da

Dushyant VarshneyCopyright:

Formati disponibili

Charles Becht IV Yaofeng Chen

Becht Engineering Company, 22 Church Street, Liberty Corner, NJ 07938

Span Limits for Elevated Temperature Piping

Pipe deection due to self-weight quite often governs in the determination of the spacing between supports. Methods are readily available for calculation of elastic deection of the pipe. However, such methods are not available for calculation of long-term deection due to creep, which can be many times the initial elastic deection for pipe operating in the creep regime of the material. Closed-form solutions for simple span conditions are presented which can be used by the analyst to develop charts for specic applications. These solutions provide insights into the problem of establishing span limits for elevated temperature pipe. S0094-9930 00 01101-X

Introduction

While pipe deection is not limited by ASME B31.1 or B31.3, it quite often governs support spacing of pipe. While the pipe may be strong enough to span between supports, excessive sag is generally considered undesirable for several reasons, including the fact that personnel tend to lose condence in the design of piping exhibiting large deection. A general rule of thumb in design of process piping is to limit the deection to 1/2 in. 13 mm . While calculating the deection of piping that behaves elastically is relatively trivial, determining the deection of pipe operating well into the creep regime for the material of construction poses problems for the designer. Span tables, piping stress analysis programs, and generally available design methods only consider the elastic deection of pipe. While creep deection, over time, can be dramatically more than the initial elastic deection, simplied methods to determine the development of the pipe sag over time are not available. Various approaches have been considered, such as limiting the allowable sustained longitudinal stress at elevated temperatures to something less than the code allowable stress. Note that this is essential to prevent excessive creep deection at very high temperatures. In developing the design basis for stainless steel pipe to operate at temperatures up to 1800F 980C for the Marble Hill Nuclear Reactor Pressure Vessel Annealing Demonstration Project, it was apparent that accumulation of creep deection required consideration in establishing the maximum permissible span between pipe supports. To establish these limits, closed-form integrals to calculate creep deection of pipe spans were developed, which could readily be solved on available math software, such as MathCad. These integrals, and their derivation, are provided in the Appendix. They are based on a steady-state creep law, Norton, where creep strain rate is equal to a constant times stress to the power of n. The exponent n depends on material and temperature, but a value of about 6 can be expected for high-temperature austenitic stainless steel.

(1)

The stress in a beam section redistributes due to creep because of the sensitivity of creep rate to stress. The stress on the outer ber of a beam under steady-state creep condition may be calculated as follows:

y1

Mh 2I c

(2)

The outer ber strain in a beam is proportional to the radius of curvature, as follows: y1

y1

(3)

Combining Eqs. 1 , 2 , and 3 , results in the following equation: Mh 2I c

n

y1 Bt

(4)

The inverse of the radius of curvature can be replaced with the second derivative of deection, d 2 y/dx 2 . The resulting equation is integrated twice to calculate deection, with appropriate inclusion of constants of integration and due consideration to changes in direction of curvature. Equations are provided in the Appendix for three conditions: simply supported beam, cantilever beam, and beam with xed ends.

Discussion

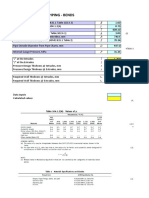

The evaluations provided insights into the problem of establishing allowable spans for high-temperature piping. One very interesting nding at very high temperatures was that the allowable span was relatively insensitive to the allowable deection and the constant B in the creep equation, within reasonable limits. It is the sensitivity of creep rate to stress, and, in turn, the sensitivity of stress to span length, that dominates the creep deection problem. Considering that stress is proportional to the span length to the second power, and assuming that creep strain rate is proportional to stress to, say, the sixth power, knowing that deection is proportional to strain, we nd that creep deection rate is highly sensitive to span length. Creep deection goes up exponentially with span length, so that beyond a given length, at least at relatively high temperatures, deection is unacceptable, and below that length, deection is not particularly signicant. Figure 1 shows the creep deection of a simply supported Schedule 10S 304L stainless steel line, assuming 30 lb/ft. 44 kg/m steel and insulation weight with vapor as the contents, as a function of length at 1500F 815C and for a duration of 1000 h. One can see that, between span lengths of 17 MAY 2000, Vol. 122 121

Creep Deection Equations

Creep deection under bending was calculated per Finnie and Heller 1 as follows. The same basic assumptions as in elastic beam analysis were made e.g., shear deformation neglected, plane sections remain plane, and small displacement . It is also assumed that the creep rate in tension and compression, at the same stress level, is the same. The Norton creep equation is assumed, as follows:

Contributed by the Pressure Vessels and Piping Division and presented at the Pressure Vessels and Piping Conference, Orlando, Florida, July 2731, 1997, of THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS. Manuscript received by the PVP Division, August 20, 1997; revised manuscript received October 11, 1999. Associate Technical Editor: M. B. Ruggles.

Journal of Pressure Vessel Technology

Copyright 2000 by ASME

Fig. 1 Creep deection of simply supported beam at 1000 h versus span 1500F

Fig. 2 Creep deection versus span length at 1000 h for different restraint conditions 1600F

122 Vol. 122, MAY 2000

Transactions of the ASME

Fig. 3 Comparison of creep and elastic deection of beams at 100,000 h versus span length for pinned and xed restraint 1500F

and 18 ft 5.2 and 5.5 m , the deection increases from 1/2 in. 13 mm to over 1 in. 25 mm . At 16 ft 4.9 m , the deection is about 0.2 in. 5 mm . Material properties for 304L are from Swindeman 2,3 . Figure 2 shows deection as a function of span length, temperature, and end restraint condition. These curves are based on 304L material. The duration for the charts is 1000 h and the temperature is 1600F 870C . They are for a specic application; they are provided to illustrate the effect of span length and support condition on deection. The project for which this work was done used dual stamped material, so that the L-grade material properties were appropriate to evaluate the elevated temperature material properties of the material. Figure 3 shows a chart for 304L Schedule 20S pipe with 20 lb/ft 29 kg/m insulation and a duration of 100,000 h, about 10 yr, for elastic and creep deection as well as for elastic deection only. Included on the chart are results based on simply supported and xed supports. Note that the allowable span length based on allowable stress considerations only, per ASME B31.3, is about 16 ft 4.9 m for simply supported and 23 ft 7 m for xed supports. The allowable span length, based on 1/2 in. 13 mm permissible elastic deection and a simply supported condition, would be 31 ft 9.4 m . It is obvious that these span lengths based on these conventional criteria would result in excessive long-term deection for this elevated temperature pipe.

Nomenclature

B h I Ic K L M n ro ri t w x y y0 y1 yf yf

c y1

y1

constant in creep equation outside diameter of pipe moment of inertia of pipe ctitious moment of inertia used to calculate outer ber stress for creeping beam constant beam length bending moment stress exponent in creep equation outside radius of pipe inside radius of pipe time weight of pipe and contents per unit length dimension along beam length beam deection end slope of deected beam extreme ber distance from neutral axis beam deection at inection point slope of deection at inection point creep strain outer ber strain gamma function radius of curvature of beam stress outer ber stress in beam

Conclusion

Creep deection must be considered in determining allowable span lengths for elevated temperature piping. Equations are provided herein with which span tables can be developed for specic applications. Journal of Pressure Vessel Technology

Appendix

The equations for calculating creep deection of pipe, based on simply supported, cantilever, and xed-end conditions, follow: MAY 2000, Vol. 122 123

I c I 3

8 1 n

1 1

ri ro

3 1/n

ri ro

1 2n 1 1.5 2n 1

n

y Fix End Beam

h 2Bt h 2I c

L2 wL 2 n 2 2 n 1

slope at inection point

s

from Finnie and Heller 1 for hollow cylinder K Simply Supported slope at support

L/2

h 2Bt h 2I c

w 2

yf

K

0

6Lx L 2 6x 2

dx

deection at inection point

s x

yf

0

yf

K

0

6LX L 2 6X 2

dX dx

y 0 K

0 L/2 x

Lx x 2

dx

n

deection at midspan

L/2 x

y

0

y 0 K

0

XL X 2

dX dx

yf

s

yf

K

s

6LX L 2 6X 2

dX dx

Cantilever end slope

L

References

y 0 K

0

2 n

dx

closed-form solution

1 Finnie, I., and Heller, W. R., 1959, Creep of Engineering Materials, McGrawHill, New York, NY. 2 Swindeman, R. W., 1995, Compilation of Materials Data Base for Very High Temperature, PVRC 94-07, 1/18/95 draft report. 3 Swindeman, R. W., 1996, personal communication with Dr. Swindeman; additional plots from reference database.

124 Vol. 122, MAY 2000

Transactions of the ASME

Potrebbero piacerti anche

- Ligament Pressure Vessel AnalysisDocumento8 pagineLigament Pressure Vessel AnalysisAnnie HillNessuna valutazione finora

- FRP Flange DesignDocumento29 pagineFRP Flange DesignSubhadip RoyNessuna valutazione finora

- Minimze Leakage in HX Grith Flange PDFDocumento5 pagineMinimze Leakage in HX Grith Flange PDFRajesh KumarNessuna valutazione finora

- TH10 - Pipe Loop or Expansion Joints PDFDocumento3 pagineTH10 - Pipe Loop or Expansion Joints PDFEdward JulianNessuna valutazione finora

- Improved Analysis of External Loads On Flanged JointsDocumento1 paginaImproved Analysis of External Loads On Flanged JointsTiHoRNessuna valutazione finora

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionDa EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNessuna valutazione finora

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988Da EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNessuna valutazione finora

- Piping Stress Analysis Is The Most Important Activity in Piping DesignDocumento10 paginePiping Stress Analysis Is The Most Important Activity in Piping DesignShreesanth SreenivasanNessuna valutazione finora

- Improve Evaluation of Brittle-Fracture Resistance For VesselsDocumento6 pagineImprove Evaluation of Brittle-Fracture Resistance For VesselsHieuNessuna valutazione finora

- Determine-The-Optimal-Span-Between-Pipe Supports-For-Thin-Walled-Piping-Systems PDFDocumento10 pagineDetermine-The-Optimal-Span-Between-Pipe Supports-For-Thin-Walled-Piping-Systems PDFLuis Pereira PeñaNessuna valutazione finora

- Shell Thickness CalcDocumento1 paginaShell Thickness CalcDidi KurniadiNessuna valutazione finora

- Piping Flexibility - A Detailed ApproachDocumento5 paginePiping Flexibility - A Detailed ApproachRUDHRA DHANASEKARNessuna valutazione finora

- Slug Flow Analysis Using Dynamic Spectrum Method in Caesar II Part 2 of 2Documento4 pagineSlug Flow Analysis Using Dynamic Spectrum Method in Caesar II Part 2 of 2Romner Cordova100% (2)

- Water HammerDocumento12 pagineWater Hammerkanbouch100% (1)

- Barry Dooley Introducton-to-ACC-FAC-and-Cycle-ChemistryDocumento37 pagineBarry Dooley Introducton-to-ACC-FAC-and-Cycle-Chemistrychemicalchouhan9303Nessuna valutazione finora

- Flange Leakage Check: Equivalent Pressure / Kellogg MethodDocumento3 pagineFlange Leakage Check: Equivalent Pressure / Kellogg Methodtom hNessuna valutazione finora

- Pyrogel XTE DatasheetDocumento2 paginePyrogel XTE DatasheetLe Thanh HaiNessuna valutazione finora

- Jacketed PipingDocumento4 pagineJacketed Pipingbinukumar100Nessuna valutazione finora

- Piping & Bending and Straight Pipe - Required Minumum Wall Thickness Calculations (ASME B31.1 Power Piping 2010)Documento40 paginePiping & Bending and Straight Pipe - Required Minumum Wall Thickness Calculations (ASME B31.1 Power Piping 2010)Ahmet OVENNessuna valutazione finora

- Thermal Design Considerations For Centrifugal Compressor Piping SystemsDocumento5 pagineThermal Design Considerations For Centrifugal Compressor Piping SystemsSerge Rinaudo100% (1)

- Lockhart&Martinelli ImprovedDocumento12 pagineLockhart&Martinelli Improvedrui_filho_12Nessuna valutazione finora

- Design Considerations For Compact Heat ExchangersDocumento16 pagineDesign Considerations For Compact Heat ExchangersHaunted HunterNessuna valutazione finora

- A Literature On "Cold Springing (Cold Pull) in Piping Systems"Documento5 pagineA Literature On "Cold Springing (Cold Pull) in Piping Systems"iaftNessuna valutazione finora

- TES-ME-STRTN-GL Design and Fabrication of Butt-Welded Transition Joints Specification (CAN-US-MEX)Documento19 pagineTES-ME-STRTN-GL Design and Fabrication of Butt-Welded Transition Joints Specification (CAN-US-MEX)BetoCostaNessuna valutazione finora

- SIF Pipe Stress Checklist PDFDocumento2 pagineSIF Pipe Stress Checklist PDFEsapermana RiyanNessuna valutazione finora

- Elimination of Bowing Distortion in Welded StiffenersDocumento8 pagineElimination of Bowing Distortion in Welded StiffenersHaris HartantoNessuna valutazione finora

- Diaphragm Elimination Using Taper-Lok - NPRADocumento11 pagineDiaphragm Elimination Using Taper-Lok - NPRAN. S. PanditNessuna valutazione finora

- Piping Code Paradoxes B31 3 Appen PDocumento16 paginePiping Code Paradoxes B31 3 Appen Psammar_10Nessuna valutazione finora

- Pipe Expansion & FlexibilityDocumento92 paginePipe Expansion & Flexibilityfileseeker100% (1)

- 1 4945413584441049168Documento17 pagine1 4945413584441049168MohsenNessuna valutazione finora

- Thermal BowingDocumento8 pagineThermal BowingA. VenugopalNessuna valutazione finora

- Heat Loss in Pipe Support PDFDocumento60 pagineHeat Loss in Pipe Support PDFThaku KishorNessuna valutazione finora

- Pipe Work Damper Sept 02Documento7 paginePipe Work Damper Sept 02Manel MontesinosNessuna valutazione finora

- High-Temperature Characteristics of Stainless Steels: A Designers' Handbook Series N 9004Documento47 pagineHigh-Temperature Characteristics of Stainless Steels: A Designers' Handbook Series N 9004aemis2010Nessuna valutazione finora

- ASME Ch17 p001-068 1 9-5-08 PDFDocumento68 pagineASME Ch17 p001-068 1 9-5-08 PDFJames RobsonNessuna valutazione finora

- Vessels For High Pressure Dust CollectorsDocumento4 pagineVessels For High Pressure Dust CollectorsWade ColemanNessuna valutazione finora

- Stress DesignDocumento158 pagineStress DesignOz2iaZNessuna valutazione finora

- 5.00 A Conundrum The Difficulties of Pipe Stress Analysis For Cold PipesDocumento17 pagine5.00 A Conundrum The Difficulties of Pipe Stress Analysis For Cold Pipesprabu2001Nessuna valutazione finora

- Pipe Wall THK Calc For External PressureDocumento2 paginePipe Wall THK Calc For External PressurektejankarNessuna valutazione finora

- Flange Leakage PDFDocumento48 pagineFlange Leakage PDFGaurav TripathiNessuna valutazione finora

- Ower Iping: Charles Becht IVDocumento52 pagineOwer Iping: Charles Becht IVmiguel medina100% (1)

- ClydeBergemannSootblowers PrinceGeorge06Documento36 pagineClydeBergemannSootblowers PrinceGeorge06Arun YogaNessuna valutazione finora

- Spring - Hanger - Basic PSA Inc PDFDocumento26 pagineSpring - Hanger - Basic PSA Inc PDFViji SvrNessuna valutazione finora

- Auto-Refrigeration / Brittle Fracture: Prevention and Process Safety MitigationDocumento2 pagineAuto-Refrigeration / Brittle Fracture: Prevention and Process Safety MitigationAli VarmazyarNessuna valutazione finora

- CAESARII Assorted TopicsDocumento21 pagineCAESARII Assorted TopicsromlibNessuna valutazione finora

- Requirement For Branch Connection at Flare HeaderDocumento3 pagineRequirement For Branch Connection at Flare Headergpskumar22Nessuna valutazione finora

- Dynamic Load in Piping SystemDocumento3 pagineDynamic Load in Piping SystemAMITDEWANGAN1991100% (1)

- A Comparison Between ASME B31.1 and ASME B31.3 On Some TopicsDocumento4 pagineA Comparison Between ASME B31.1 and ASME B31.3 On Some TopicsPranpath Narupantawart100% (1)

- Fatigue Life For ASME VII-DIV2Documento23 pagineFatigue Life For ASME VII-DIV2Muhammad Abd El KawyNessuna valutazione finora

- Piping TheoryDocumento22 paginePiping TheoryDilip YadavNessuna valutazione finora

- AISC - Buckling DesignDocumento9 pagineAISC - Buckling Designmelvin_leongNessuna valutazione finora

- Pipe Support SpansDocumento4 paginePipe Support SpansMitchellgranyNessuna valutazione finora

- Detail Engineering MethodologyDocumento11 pagineDetail Engineering MethodologyKumarJR86100% (1)

- Stress Analysis Methods For Underground Pipe Lines Part 1 - Basic CalculationsDocumento5 pagineStress Analysis Methods For Underground Pipe Lines Part 1 - Basic Calculationskumaran__k100% (3)

- Above Ground Pipeline DesignDocumento15 pagineAbove Ground Pipeline DesigndilimgeNessuna valutazione finora

- Imperfection, Residual Stress and Yield Slenderness Limit of Very High Strength (VHS) Circular Steel Tubes, 2003 (H Jiao, X.-L Zhao)Documento17 pagineImperfection, Residual Stress and Yield Slenderness Limit of Very High Strength (VHS) Circular Steel Tubes, 2003 (H Jiao, X.-L Zhao)Phan Đào Hoàng HiệpNessuna valutazione finora

- Piping Stress Handbook, 2nd Edition, Victor Helguero M.,: H. Saunders Scotia, N. Y. 12302Documento2 paginePiping Stress Handbook, 2nd Edition, Victor Helguero M.,: H. Saunders Scotia, N. Y. 12302bashirNessuna valutazione finora

- Design of Pipe RacksDocumento23 pagineDesign of Pipe RacksDushyant Varshney100% (1)

- Selection of Pipe SupportDocumento77 pagineSelection of Pipe SupportRobert Nixon86% (7)

- Design of Piping SystemsDocumento115 pagineDesign of Piping SystemsDushyant Varshney100% (2)

- Structural Analysis of Pipeline and Piping SystemsDocumento58 pagineStructural Analysis of Pipeline and Piping SystemsDushyant VarshneyNessuna valutazione finora

- Evaluation of Model Combination Methods For Seismic Response Spectrum AnalysisDocumento11 pagineEvaluation of Model Combination Methods For Seismic Response Spectrum AnalysisDushyant VarshneyNessuna valutazione finora

- Nozzle Loads Piping Stresses and The Effect of Piping On EquipmentDocumento40 pagineNozzle Loads Piping Stresses and The Effect of Piping On Equipmentcaesar00100% (6)

- External Loads On Nozzles and Piping Intersections Paulin Webinar Part 2 W044Rev1Documento41 pagineExternal Loads On Nozzles and Piping Intersections Paulin Webinar Part 2 W044Rev1Nabil Al-Khirdaji100% (1)

- Pipe On SupportsDocumento8 paginePipe On SupportsMahesh KoiladaNessuna valutazione finora

- Analytical Considerations The Code Qualification Piping SystemsDocumento17 pagineAnalytical Considerations The Code Qualification Piping SystemsMahendra RathoreNessuna valutazione finora

- Analytical Considerations The Code Qualification Piping SystemsDocumento17 pagineAnalytical Considerations The Code Qualification Piping SystemsMahendra RathoreNessuna valutazione finora

- Eliminating Conservatism in The Piping System Analysis Process Through Application of A Suite of Locally Appropriate Seismic Input MotionsDocumento7 pagineEliminating Conservatism in The Piping System Analysis Process Through Application of A Suite of Locally Appropriate Seismic Input MotionsDushyant VarshneyNessuna valutazione finora

- Dynamic Analysis of Reciprocating Compressors On FPSO Topside ModulesDocumento9 pagineDynamic Analysis of Reciprocating Compressors On FPSO Topside ModulesDushyant Varshney100% (1)

- Design and Analysis of High Speed Milling Spindle For Minimum DeflectionDocumento8 pagineDesign and Analysis of High Speed Milling Spindle For Minimum DeflectionPAVANNessuna valutazione finora

- Mcnichols Master CatalogDocumento60 pagineMcnichols Master Catalogswoo323Nessuna valutazione finora

- Direct Design Method For QuizDocumento142 pagineDirect Design Method For QuizPavan PsNessuna valutazione finora

- 1600 Wall Sys3 - ADocumento24 pagine1600 Wall Sys3 - ABlack DiscipleNessuna valutazione finora

- PLI (Pounds Per Linear Foot)Documento5 paginePLI (Pounds Per Linear Foot)ccorp00890% (1)

- MBS 2179Documento8 pagineMBS 2179ranjitNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento21 pagineDisclosure To Promote The Right To InformationBrijeshNessuna valutazione finora

- Ref For Deflection Criteria StructureDocumento5 pagineRef For Deflection Criteria StructurePutu RustikaNessuna valutazione finora

- Beam Column Sample LectureDocumento9 pagineBeam Column Sample LectureCan RapsNessuna valutazione finora

- Reinforced C Vol IDocumento11 pagineReinforced C Vol Ifriend foreverNessuna valutazione finora

- Caltrans Bridge SpecificationDocumento29 pagineCaltrans Bridge SpecificationsamratkadamNessuna valutazione finora

- Accuracy of First - and Second-Order Tetrahedral ElementsDocumento8 pagineAccuracy of First - and Second-Order Tetrahedral ElementsKillgusNessuna valutazione finora

- Suspension BridgeDocumento56 pagineSuspension Bridgeritesh chauhanNessuna valutazione finora

- Rules of ThumbDocumento10 pagineRules of ThumbYazuraPoyoNessuna valutazione finora

- Bridge-Ch-5-Example On Slab Bridge EDITEDFINALDocumento15 pagineBridge-Ch-5-Example On Slab Bridge EDITEDFINALkassahun kebede100% (1)

- Truss DeflectionDocumento5 pagineTruss DeflectionArchieNessuna valutazione finora

- A Distribution Procedure For The Analysis of Slabs Continuous Over Flexible Beams Newmark, N.M.Documento126 pagineA Distribution Procedure For The Analysis of Slabs Continuous Over Flexible Beams Newmark, N.M.Marimari MinteaNessuna valutazione finora

- Physics Lab 2Documento3 paginePhysics Lab 2Rana BusNessuna valutazione finora

- Compliant Folded Beam Suspension MechanismDocumento18 pagineCompliant Folded Beam Suspension Mechanismomer elaminNessuna valutazione finora

- Thirty Years of Fibre Reinforced Concrete Research at The University ofDocumento10 pagineThirty Years of Fibre Reinforced Concrete Research at The University ofjayanthNessuna valutazione finora

- Plinth Beam Design CalculationDocumento4 paginePlinth Beam Design CalculationVinod NairNessuna valutazione finora

- SEMA General Guidance Notes For AssessingDocumento6 pagineSEMA General Guidance Notes For AssessingFarhan GoharNessuna valutazione finora

- Catálogo GALVAMETDocumento16 pagineCatálogo GALVAMETMichael Gutiérrez EscobarNessuna valutazione finora

- Practice Exam 3 AM (C) SolutionsDocumento31 paginePractice Exam 3 AM (C) SolutionsvijaykumarzNessuna valutazione finora

- Recycled AggregateDocumento22 pagineRecycled AggregateThulasirajan KrishnanNessuna valutazione finora

- Department of Mechanical Engineering: Jawaharlal Nehru Technological University Kakinada KAKINADA - 533 003Documento2 pagineDepartment of Mechanical Engineering: Jawaharlal Nehru Technological University Kakinada KAKINADA - 533 003rameshNessuna valutazione finora

- Mem-402-Mos Final QB-2015Documento9 pagineMem-402-Mos Final QB-2015Rohit DiwakarNessuna valutazione finora

- 92 411: Machine Design I Project: Faisal SIDDIQUIDocumento12 pagine92 411: Machine Design I Project: Faisal SIDDIQUIcfellow100% (1)

- A241247 PDFDocumento140 pagineA241247 PDFtim_lim12Nessuna valutazione finora

- T1 - Universal BeamDocumento8 pagineT1 - Universal BeamhussamNessuna valutazione finora