Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DPO

Caricato da

Khristina StefanovaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DPO

Caricato da

Khristina StefanovaCopyright:

Formati disponibili

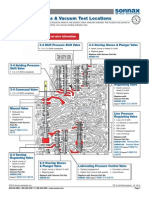

I n s t r u c t i o n D a t a S h e e t

Renault DPO, Citron AL-4

PART NUMBER 120940-01K, F-120940-TL

TOOL

Oversized Pressure Regulator Valve Repair Kit

120940-01K

R

1 Oversized PR Valve 1 Oversized Plunger Valve 1 Custom Pressure Regulator Spring

EQ

UIRE

F-120940-TL

2 Reamers 2 Reamer Guides 1 Guide Pin

More technical information

is available at www.sonnax.com. Type in this part number under Part Finder.

Oversized Plunger Valve

Oversized Pressure Regulator Valve

Custom Pressure Regulator Spring

Tool Kit F-120940-TL

Plastic Plug

Notes or Cautions: If you are exchanging valve body cores, you must match the separator plate code to the original separator plate. There are at least four (4) variations. Each valve body has four (4) or five (5) threaded end plugs. Each plug has a specific calibration. The PR bore threaded end plug must be removed to ream the bore and install the Sonnax oversize PR valve. It is critical to observe, mark and record the position and depth of the PR end plug adjuster prior to disturbing the OE setting. The PR end plug adjuster affects base line pressure, pressure sensor reading and shift quality. Removing the other threaded end plugs is not required. However, removal is suggested to avoid reaming debris contamination of the other valve bores. It is critical to observe, mark and record the position and depth of any end plug adjuster prior to disturbing the OE setting. More information about the Dissasembly of the AL4/DPO Valve Body is available on-line at http://www.sonnax.com/tech/12094001K-TECH.pdf

Disassembly Steps: 1. Place a punch mark on the casting aligned with the index molded into the plastic plug (see Figure 1). 2. Measure and record the depth or height of the plug. Some protrude outward, some are recessed. Count and record the number of rotations needed to remove the plugs. 3. Unscrew the end plug and remove the other valve train components. Keep the end plug for reuse. Discard the two OE valves and the OE PR spring. 4. Clean the PR and Plunger bores to remove any debris or grit.

Figure 1

2009 Sonnax Industries, Inc.

120940-01K Rev:-, 120940-01K-IN

02-11-09

800-843-2600 802-463-9722 F: 802-463-4059 www.sonnax.com info@sonnax.com

Renault DPO, Citron AL-4

PART NUMBER 120940-01K, F-120940-TL

Oversized Pressure Regulator Valve Repair Kit

Important Notes: The plunger valve bore MUST be reamed BEFORE the P.R. Bore. Clean the bore thoroughly in a solvent tank. Generously lubricate the bore and reamer with cutting fluid (i.e. Mobilmet S-122, Lubegard Bio-Tap, Tap Magic, etc). For best results, provide a continuous flow of water-soluble cutting fluid (i.e. Mobilmet S-122) during the reaming process.

The reamers should be turned using a low rpm, high torque air drill regulated to a maximum of 200 rpm. Manually turning the reamer in this application is not recommended. Examine the bore after cleaning for surface finish, debris, and burrs. Flashing and burrs on the exit side of lands and bores must be carefully removed. A small piece of Scotchbrite material attached to a wire and powered with a drill motor is ideal for the task.

1.

2.

3.

Insert the reamer jig.

Insert the reamer.

Use a loose fitting reamer socket, a wobble adapter and a regulated air drill.

4.

5.

6.

Use a continuous supply of cutting fluid and little or no inward force.

Insert the reamer jig.

Align the guide pin and valve body.

7.

8.

NO

YES

9.

NO

DRA G

NO DRA G

Tighten the clamp. Guide pin must move freely.

Do not clamp over bore. Leave gap.

Tighten wing nuts. Guide pin must move freely.

10.

11.

12.

Remove guide pin. Do not loosen Clamp or wing nuts. Installation / Assembly Steps:

Insert the Reamer.

Use a continuous supply of cutting fluid and little or no inward force.

1. Lubricate and install the SONNAX Plunger valve, PR valve and Spring. Position and orient the valve train components as shown in the main photo. 2. Install the threaded end plug adjuster into the PR bore and return it to the OE position recorded prior to disassembly.

2009 Sonnax Ind. Inc. 120940-01K-IN

02-11-09

8 0 0 - 8 4 3 - 2 6 0 0 w w w. s o n n a x . c o m

Final Verification Steps: In-vehicle Pressure Testing: 1. Locate the line pressure port next to the line pressure transducer. 2. Verify and adjust main line pressure to the following specification: Cold, Idle and Park: Line pressure should be 39.2 psi (2.7 bar) 3. If pressure is too high: harsh engagements will result. To reduce pressure turn the PR end plug adjuster anti-clockwise. 4. If pressure is too low: neutral at idle or loss of hill hold results. To increase pressure turn the PR end plug adjuster clockwise. 2

Potrebbero piacerti anche

- AL4 DPO Peugeot, Renault, Citroen Overhaul AL4 DPO Valve Body TECH Line Pressure Problem and Transmission Overheating.Documento2 pagineAL4 DPO Peugeot, Renault, Citroen Overhaul AL4 DPO Valve Body TECH Line Pressure Problem and Transmission Overheating.Leonard100% (10)

- Al4 Oil LeakDocumento2 pagineAl4 Oil LeakmiguelNessuna valutazione finora

- AL4 Pressure Regulation FaultDocumento3 pagineAL4 Pressure Regulation FaultHenk Veen100% (2)

- Gearbox Auto Adaptive Automatic Gearbox AL4 Hydraulic Block Solenoid Valves RemovalDocumento7 pagineGearbox Auto Adaptive Automatic Gearbox AL4 Hydraulic Block Solenoid Valves RemovalMike BeckNessuna valutazione finora

- AL4 SolenoidsDocumento4 pagineAL4 SolenoidsNinjabdsm Bd50% (2)

- AL4 Automatic TransmissionDocumento78 pagineAL4 Automatic TransmissionAndré Gomes100% (2)

- MPS6Documento4 pagineMPS6noe dela vega50% (2)

- AL4 & DPO Technical NoteDocumento18 pagineAL4 & DPO Technical Notepetrulp0% (1)

- DPO Repair ManualDocumento72 pagineDPO Repair ManualHugo Ramos Trejo100% (9)

- U140E U241E Vac LocationsDocumento5 pagineU140E U241E Vac LocationsPedroMecanicoNessuna valutazione finora

- Af-40 VB DiagDocumento4 pagineAf-40 VB Diagsanya72100% (2)

- AL4 DPO Technical NoteDocumento8 pagineAL4 DPO Technical Notedejanflojd100% (1)

- DP0, Al4Documento2 pagineDP0, Al4Marcelo Nascimento100% (1)

- Zf6 6r60 Zip BookletDocumento8 pagineZf6 6r60 Zip BookletAlitar Hersongolls100% (1)

- P2716Documento4 pagineP2716David RosadoNessuna valutazione finora

- Jatco6speed Intro PDFDocumento49 pagineJatco6speed Intro PDFleeroy381100% (1)

- dps6 Internal OperationDocumento40 paginedps6 Internal Operationrodrivalent75% (4)

- AW-6 Linear Solenoid Installation Guide: TF-80 (AF40) and TF-81 (AF21) SeriesDocumento2 pagineAW-6 Linear Solenoid Installation Guide: TF-80 (AF40) and TF-81 (AF21) Seriestejonmx100% (1)

- Sonnax AW 6-Speed FWDDocumento37 pagineSonnax AW 6-Speed FWDhornet22Nessuna valutazione finora

- VW Audi 09G VacTestDocumento7 pagineVW Audi 09G VacTestFernando Arias BarriosNessuna valutazione finora

- Ob 5Documento4 pagineOb 5AdamCzulewicz100% (1)

- Mercedes 722 6Documento1 paginaMercedes 722 6Mauricio Exequiel Chavez100% (2)

- 5L40 eDocumento1 pagina5L40 ePedroMecanicoNessuna valutazione finora

- Tools TF 80scDocumento3 pagineTools TF 80scsuattosunNessuna valutazione finora

- Clutch Slip Monitoring Signal Too LargeDocumento4 pagineClutch Slip Monitoring Signal Too LargeDonovan Cameron60% (5)

- 5HP-19-PR: I.D. The Valve Body First!Documento1 pagina5HP-19-PR: I.D. The Valve Body First!Esther KoltermanNessuna valutazione finora

- Af40 TF80 09G PDFDocumento5 pagineAf40 TF80 09G PDFtambache69Nessuna valutazione finora

- Aw60 41sn Zip BookDocumento8 pagineAw60 41sn Zip BookRiki Nurzaman100% (3)

- Erori dq200Documento4 pagineErori dq200Sigismund BeriaNessuna valutazione finora

- Pdf35 Aw Tf80sc PDFDocumento5 paginePdf35 Aw Tf80sc PDFAlfredoNessuna valutazione finora

- 09g SolenoidDocumento3 pagine09g SolenoidKarim AbbasNessuna valutazione finora

- Repair Manual: ZF Getriebe GMBH SaarbrückenDocumento104 pagineRepair Manual: ZF Getriebe GMBH SaarbrückenVIDAL ALEJANDRO GARCIAVARGASNessuna valutazione finora

- 722 6 VacTestLocationsDocumento4 pagine722 6 VacTestLocationsUrszula WalczewskaNessuna valutazione finora

- Manual Caja Citroen Al4Documento59 pagineManual Caja Citroen Al4JcMarquez100% (1)

- Aw5550SnZip 1580008475 PDFDocumento10 pagineAw5550SnZip 1580008475 PDFyhovany100% (1)

- 6R60Documento1 pagina6R60PedroMecanico50% (2)

- 5r55e Valve Body SonnaxDocumento8 pagine5r55e Valve Body SonnaxjoshetoNessuna valutazione finora

- Oversized Pressure Regulator Valve Kit: Renault/Peugot AL-4, DPODocumento2 pagineOversized Pressure Regulator Valve Kit: Renault/Peugot AL-4, DPOEko hari PrasetyoNessuna valutazione finora

- Sonnax1 PDFDocumento2 pagineSonnax1 PDFEko hari PrasetyoNessuna valutazione finora

- Dynaco c101 c102 Dump Pump PDFDocumento7 pagineDynaco c101 c102 Dump Pump PDFnbgearsNessuna valutazione finora

- 722,9 Valve BodyDocumento1 pagina722,9 Valve BodyMothana HusbanNessuna valutazione finora

- Jatco O9a TransmissionDocumento2 pagineJatco O9a TransmissionDusko IvanNessuna valutazione finora

- Installation ManualDocumento6 pagineInstallation ManualBEARNessuna valutazione finora

- 4r44e 5r55e Zip BookletDocumento8 pagine4r44e 5r55e Zip BookletDaniel BernardNessuna valutazione finora

- Oversized C2 Clutch Control Valve Kit: Aisin AW TF-80SC, TF-81SCDocumento2 pagineOversized C2 Clutch Control Valve Kit: Aisin AW TF-80SC, TF-81SCossoskiNessuna valutazione finora

- "A" Pilotair Valve Block Type and Panel MountedDocumento24 pagine"A" Pilotair Valve Block Type and Panel MountedJairoHernanLoperaNessuna valutazione finora

- Bomba Primaria e CombustibleDocumento8 pagineBomba Primaria e CombustibleoscarNessuna valutazione finora

- Manual SSW10Documento31 pagineManual SSW10Victor RodriguezNessuna valutazione finora

- 8011 289-302 FORD "ACTION PLUS" Intake Manifold Installation InstructionsDocumento2 pagine8011 289-302 FORD "ACTION PLUS" Intake Manifold Installation InstructionsFabio Luis ArgentaNessuna valutazione finora

- Aw60 40le Zip inDocumento10 pagineAw60 40le Zip inMarko PavlovicNessuna valutazione finora

- Oil Filter Installation & ServiceDocumento16 pagineOil Filter Installation & ServicemdhelicoptersNessuna valutazione finora

- Re5Ro5A: A or B Pilot Valve KitDocumento2 pagineRe5Ro5A: A or B Pilot Valve KitvaskaservNessuna valutazione finora

- Technical Information: Recall ACE System Pipe LeakDocumento9 pagineTechnical Information: Recall ACE System Pipe LeakturbojoNessuna valutazione finora

- Fabio Air SpringsDocumento376 pagineFabio Air SpringsАлексей ПобережнюкNessuna valutazione finora

- Aw60 40le Zip BookDocumento8 pagineAw60 40le Zip BookMohamd Fadel Hassan80% (5)

- Tapco Pro 3 ManualDocumento16 pagineTapco Pro 3 Manualacsscruf33% (3)

- 390 InstructionsDocumento48 pagine390 InstructionsemaanazeemNessuna valutazione finora

- Sure Cure Kit: Chrysler 41TE (A604), 42LE (A606)Documento10 pagineSure Cure Kit: Chrysler 41TE (A604), 42LE (A606)carloaex23Nessuna valutazione finora

- 4756 Civic 96-2000 D16y8 Performer XDocumento3 pagine4756 Civic 96-2000 D16y8 Performer XRafael Isaac Lòpez Vargas100% (1)

- Clio Sport Manual 3286aDocumento149 pagineClio Sport Manual 3286aOctavio LópezNessuna valutazione finora

- Getting A Better Look at The Toyota A340E Valve Body: SmartDocumento4 pagineGetting A Better Look at The Toyota A340E Valve Body: SmartKhristina Stefanova100% (6)

- AC Product Update December 2015Documento1 paginaAC Product Update December 2015Khristina StefanovaNessuna valutazione finora

- Friction Plate Usage Chart Mercedes 722.6Documento0 pagineFriction Plate Usage Chart Mercedes 722.6Eduardo Yagüe GomezNessuna valutazione finora

- TenderDocumento39 pagineTenderKhristina StefanovaNessuna valutazione finora

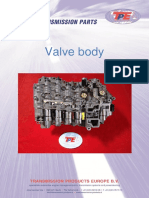

- Valvebody CatalogusDocumento9 pagineValvebody CatalogusKhristina Stefanova100% (1)

- Friction Plate Usage Chart Mercedes 722.6Documento0 pagineFriction Plate Usage Chart Mercedes 722.6Eduardo Yagüe GomezNessuna valutazione finora

- 2003 Sorento Rear Differential Fluid Capacity - 37112Documento1 pagina2003 Sorento Rear Differential Fluid Capacity - 37112Khristina StefanovaNessuna valutazione finora

- Type 300 SEDocumento6 pagineType 300 SEKhristina StefanovaNessuna valutazione finora

- DIY: DSG (02E) Transmission - 40,000 Miles Maintenance ServiceDocumento11 pagineDIY: DSG (02E) Transmission - 40,000 Miles Maintenance ServiceJ.K.jr.bad.100% (4)

- 2015 March Oil Lists BMWDocumento3 pagine2015 March Oil Lists BMWKhristina StefanovaNessuna valutazione finora

- 2003 Sorento Rear Differential Fluid Capacity - 37112Documento1 pagina2003 Sorento Rear Differential Fluid Capacity - 37112Khristina StefanovaNessuna valutazione finora

- Lien WaiverDocumento1 paginaLien WaiverKhristina StefanovaNessuna valutazione finora

- ZF8HP RebuildDocumento62 pagineZF8HP RebuildKhristina Stefanova94% (17)

- Sonnax Tool Kits VB FIX VisualDocumento1 paginaSonnax Tool Kits VB FIX VisualKhristina StefanovaNessuna valutazione finora

- CVC Mercedes Torque ConvertersDocumento7 pagineCVC Mercedes Torque ConvertersKhristina StefanovaNessuna valutazione finora

- AC Product Update February 2015Documento1 paginaAC Product Update February 2015Khristina StefanovaNessuna valutazione finora

- Softelectronic PresentationDocumento18 pagineSoftelectronic PresentationKhristina Stefanova100% (1)

- AC Product Update November 2014Documento1 paginaAC Product Update November 2014Khristina StefanovaNessuna valutazione finora

- Suzuki 3 Speed Wagon R Mazda Carol Suzuki 2 Speed Suzuki A210 Suzuki 4 Speed JimnyDocumento1 paginaSuzuki 3 Speed Wagon R Mazda Carol Suzuki 2 Speed Suzuki A210 Suzuki 4 Speed JimnyKhristina StefanovaNessuna valutazione finora

- Homestead SGL NVDocumento3 pagineHomestead SGL NVKhristina StefanovaNessuna valutazione finora

- Friends & Family Telephone Service Guide: InstructionsDocumento2 pagineFriends & Family Telephone Service Guide: InstructionsKhristina StefanovaNessuna valutazione finora

- Residential LeaseDocumento3 pagineResidential LeaseKhristina Stefanova100% (2)

- Textar Fitting Instructions enDocumento8 pagineTextar Fitting Instructions enKhristina StefanovaNessuna valutazione finora

- Military Declaration FormDocumento1 paginaMilitary Declaration FormKhristina StefanovaNessuna valutazione finora

- Product Update May 2012Documento1 paginaProduct Update May 2012Khristina StefanovaNessuna valutazione finora

- Product Update November 2012Documento1 paginaProduct Update November 2012Khristina StefanovaNessuna valutazione finora

- AW55 50 Solenoid Adjustment Chart v2Documento1 paginaAW55 50 Solenoid Adjustment Chart v2María Martz De García50% (2)

- Product Update December 2011Documento1 paginaProduct Update December 2011Khristina StefanovaNessuna valutazione finora

- Adsit CatalogDocumento100 pagineAdsit CatalogKhristina Stefanova100% (1)

- Multi Spindl Drilling MachineDocumento38 pagineMulti Spindl Drilling MachineBoopathi KalaiNessuna valutazione finora

- Bowen-Lebus Anchor Washpipe Spears: Instruction Manual 2900Documento16 pagineBowen-Lebus Anchor Washpipe Spears: Instruction Manual 2900Foros IscNessuna valutazione finora

- Met PDFDocumento1.197 pagineMet PDFDylan Gaydosh91% (23)

- Workshop VivaDocumento14 pagineWorkshop VivaharoldjoysonNessuna valutazione finora

- Drills: J1 To J89Documento89 pagineDrills: J1 To J89LefialgaNessuna valutazione finora

- MCQ On Press Tool Design - Amit MahtoDocumento3 pagineMCQ On Press Tool Design - Amit MahtoPrashant SinghNessuna valutazione finora

- Sen00190 13 PDFDocumento36 pagineSen00190 13 PDFValter Leiriao100% (1)

- HDD Technical Instruction - External DistributionDocumento24 pagineHDD Technical Instruction - External DistributionMOHD SYAZWAN LOKMAN HAKIM100% (4)

- Week 4 - MachiningDocumento113 pagineWeek 4 - MachiningFattihi EkhmalNessuna valutazione finora

- Sop-11 HDDDocumento15 pagineSop-11 HDDVineet AgrawalNessuna valutazione finora

- SF99 Servo Bore Repair System:: Northland Transmission IncDocumento4 pagineSF99 Servo Bore Repair System:: Northland Transmission IncFrancisco Javier Hernandez LanderoNessuna valutazione finora

- Solid Carbide Tools: Catalogue CDMR 06Documento100 pagineSolid Carbide Tools: Catalogue CDMR 06ranjithjoyNessuna valutazione finora

- MAPAL Competence ISO enDocumento206 pagineMAPAL Competence ISO enMarcio ParrachoNessuna valutazione finora

- Pinnacle Surgical Technique - 0Documento36 paginePinnacle Surgical Technique - 0Rigid EndoscopyNessuna valutazione finora

- Sutherland S Handbook For Bicycle Mechanics 6th EditionDocumento593 pagineSutherland S Handbook For Bicycle Mechanics 6th Editionstarengineer3473100% (7)

- Machine Shop NotesDocumento40 pagineMachine Shop Notesga3006100% (1)

- Sinodrills General Catalogue 2Documento12 pagineSinodrills General Catalogue 2JackChanNessuna valutazione finora

- Introduction To Exploration Drilling Methods IDocumento30 pagineIntroduction To Exploration Drilling Methods Itshepo hlakudi100% (1)

- M 7 Bank High LightedDocumento85 pagineM 7 Bank High LightedMaryam SaeedNessuna valutazione finora

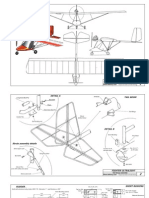

- Fighter Ultralight PlansDocumento24 pagineFighter Ultralight PlansMaps98% (46)

- ADE6698 PT Motor Tech DataDocumento8 pagineADE6698 PT Motor Tech DataberkahharianNessuna valutazione finora

- Evolution of Radial Drilling MachineDocumento52 pagineEvolution of Radial Drilling MachineHari Krishna75% (4)

- Chamber Reamers The Easy WayDocumento7 pagineChamber Reamers The Easy WayMika80% (20)

- BOT 02 2526.slimhole - BroDocumento4 pagineBOT 02 2526.slimhole - Brorake1981Nessuna valutazione finora

- Plans For Steam Marine EngineDocumento5 paginePlans For Steam Marine EngineGeorge LunguNessuna valutazione finora

- Wsdot 6-03.3Documento3 pagineWsdot 6-03.3Dave MulvihillNessuna valutazione finora

- Best Practices.Documento46 pagineBest Practices.eng20072007100% (1)

- AIPS 01-02-016 - Issue 4 - Installation of Rivetless NutplatesDocumento13 pagineAIPS 01-02-016 - Issue 4 - Installation of Rivetless NutplatesjulianocasNessuna valutazione finora

- MDN Femoral Interlocking Recon Nail Intramedullary Fixation Metal Guide Surgical Technique 97-2252-005-01 Rev3!09!2011Documento28 pagineMDN Femoral Interlocking Recon Nail Intramedullary Fixation Metal Guide Surgical Technique 97-2252-005-01 Rev3!09!2011cukiNessuna valutazione finora

- Milling Process, Defects, EquipmentDocumento6 pagineMilling Process, Defects, Equipmentdeuvyn bautistaNessuna valutazione finora