Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Isarc2006-00111 200608141302

Caricato da

doc4printDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Isarc2006-00111 200608141302

Caricato da

doc4printCopyright:

Formati disponibili

ISARC2006

CONSTRUCTION PROJECT BUFFER MANAGEMENT IN SCHEDULING PLANNING AND CONTROL

Jan, Shu-Hui

Ph.D. Student Construction Engineering & Management Program Department of Civil Engineering National Taiwan University No.1, Sec. 4, Roosevelt Road, Taipei, Taiwan d94521007@ntu.edu.tw

Ho, S. Ping

Assistant professor Construction Engineering & Management Program Department of Civil Engineering National Taiwan University No.1, Sec. 4, Roosevelt Road, Taipei, Taiwan spingho@ntu.edu.tw

Abstract: In construction projects, one of the main problems in the schedule planning and control is the determination of the project schedule, especially, when the resources required are limited. Project managers or schedulers have used an estimated time to assure the completion time of either an activity or a project. However, this traditional schedule estimate, often fails in optimizing the project schedule performance, resulting in unnecessary time wastage. Dr. Goldratt proposed the Theory of Constraints (TOC) and Critical Chain, which provide the concepts for achieving effective activity duration control. Literatures show that the TOC and Critical Chain concepts are increasingly being accepted and applied in industries. The purpose of this study is to apply TOC and Critical Chain concepts in construction to manage buffers effectively in scheduling planning and control. Buffer management aims to generate a rigorous construction plan that protects against uncertainties and reduces the potential impact of construction changes. The usage of buffer management in construction schedule is to complete activities without wasting time. Finally, the study illustrates the application of Critical Chain and buffers, especially in construction scheduling planning and control to achieve shorter project duration. Keywords: Buffer Management, Theory of Constraints, Critical Chain, Scheduling and Control 1. INTRODUCTION With the increasing complexity of construction projects, proper planning and control of project activities now represent key issues in the construction scheduling management. Generally, one objective of the construction schedule planning and control is to make successful on-time completion of each activity in project. Goldratt (1990) outlines how the Theory of Constraints (TOC) can be applied to projects to improve performance. Furthermore, the TOC approach focuses on successful on-time completion of the entire project. According to TOC, the main constraint in any project is the time taken for completion of the critical activities. Therefore emphasis is laid on completing activities in the critical path without wasting any time. In 1997, Goldratt introduce a new approach for project management, Critical Chain. The new concept is widely known and applied in practice. Critical chain in a project is defined as the longest sequence of activities from several different paths, connected by activities performed by common resources. The safety time in the Critical Chain is removed from individual activities and is utilized to create the project buffer. The project is to be guarded against delays by providing time buffers. Hence, cutting safety time from critical activities eliminates the major cause of time wastage, thereby removing the constraint. These buffers provide the necessary cushions to individual activities to enable them to accomplish the final goal of completing the critical chain in the least possible time. Horman et al (2003) explored the implementation of buffer management techniques for the planning and execution of the renovation of the Pentagon. Chua et al (2003) proposed an important methodology with work buffer management to integrate with constraints to RI availabilities. Also, Chua et al present methodology that augments the traditional critical chain method with RI availability constraints to analyze the causes of delay in buffer management [1]. Critical chain activities, which take less than the median time for completion, partially compensate for activities, which take longer than median time [6]. However, this does not mean that the project is to be left unprotected against any unforeseen delays in any individual activity [3]. However, the critical chain approach is not suitable especially on the estimation of buffers to absorb d elays in construction projects. In order to enhance the usage and application of the Critical Chain approach in construction, the proposed buffers estimation is proposed in this study to enhance the practicability of application in construction scheduling. This study further discusses the main procedures and difficulties of Critical Chain approach in construction scheduling.

-858-

ISARC2006

2. PROBLEM STATEMENTS

The CPM Network scheduling approaches have been extensively applied in construction to identify necessary activities and determine activity start and finish times. The basic CPM approach has the problem in the ability of dealing with non-precedence constraints although CPM approach is simple to use and solve sophisticated problems. However, many constraints exist in practice regard to construction project. Those constraints should be managed effectively in view of construction schedule planning and control. Most available methodologies to solve the non-precedence constraints include heuristic approach, optimal solutions, and simulation approaches [2]. These methodologies can find optimal or near-optimal solutions regard to the constrained resource and overcome the CPM problems. Another solution for solving the same problem is new methodology-Critical chain [11]. Critical chain is new methodology that applied the TOC to project management in order to complete projects faster. The following is main problems addresses by the Critical Chain: 1. Estimating Safety Time: When engineers make or calculate the duration estimations based their experience, most of engineers tend to add hidden safety duration into their estimations for any uncertainties. Although adding safety duration in activity duration estimate is not wrong, it is necessary to understand the implication of safety duration regard to actual performance [8]. 2. Students Syndrome: Similar to when students are given assignments, they usually start assignments at the last minute even the length of time are enough. Therefore, the extra safety duration becomes a kind of waste because activity leads to late starts [8]. 3. Parkinsons law: People will simply adjust the level of effort to keep busy for the entire activity schedule. If an activity is estimated to take planned duration, it usually does not take less. Usually, people do not promote be early even they can finish the work ahead of schedule [8]. 4. Multi-tasking: the effect of multitasking should be considered because that fragmentation of resource and equipments set up time would cause tasks to delay due to loss of concentration [11]. Although the above problems are commonly happening in construction projects, the traditional CPM approach can not solve these problems. 3. RESEARCH OBJECTIVES The basic assumption of the CPM is that resources required by activities are unlimited. In most construction projects in practice, resources usually and always are limited in practice. Therefore, schedule without considering resource limitations may become an untrustworthy schedule because the start time of activities is usually affected by resource availability. According to the theory

of constraints (TOC) [3], any project is possible to be restricted by one or a few constraints. Furthermore, the capacity of the constraint in activities effect the whole project durations. In order to finish the project ahead of planned schedule against limited resources, the application of buffers in the Critical Chain is utilized to solve the above mentioned problems. There are three types of buffers in Critical Chain include project buffer, feeding buffer, and resource buffer. To facilitate traditional CPM approach, those buffers will be utilized and integrated CPM approach to improve feasible arrangement in schedule through removing constraints in advance and decrease the impact for uncertainties. Furthermore, the problems and solutions using Critical Chain approach in the construction industry may be discussed in this paper. 4. METHODOLOGY 4.1 Theory of Constraints Theory of Constraints (TOC) is a common-sense way to enhance system improvement [3]. Any system usually at least have a constraint that limits its output. The constraint likes that weakest part of the system. The system only becomes stronger until you improve the strength of the weakest part [3]. Goldratt propose a five -step process to achieve continual improvement and to get the most of overcome. Fig. 1 illustrates the sequence of the five steps [4].

Step 1

Identify the systems constraints

Step 2

Decide how to exploit the systems constraints

Step 3

Subordinate everything else to the above decision

Step 4

Does a new constraint limit throughput

Step 5

Do not allow inertia to cause a system constraint

Fig. 1. The Five Steps Represent The TOC Approach [8]

-859-

ISARC2006

4.2 Critical Chain Project Management Goldratt propose a Critical Chain Project Management (CCPM) method to overcome some of the problems inherent in the traditional CPM method [5]. The critical chain method, apply the Theory of Constraints to offers an enhanced approach to manage the associated risk and uncertainty in the project to achieve performance in project schedule management.

4.4 Buffer Estimation Integrated PERT Approach With uncertainly be demonstrated to have an effect on the project, one of the well-known techniques for quantifying the impact of such uncertainty is Program Evaluation and Review Technique (PERT). The PERT approach was developed by the late 1950s [12]. To represent the uncertainty in duration estimates, the PERT technique recognizes the probabilistic, rather than deterministic, nature of the operations involved in high-risk activities. Accordingly, the PERT technique incorporates three durations for each activity into its methodology. The three duration estimates are [12]: Optimistic duration (a): estimate time of executing the activity under very favorable working conditions. Pessimistic duration (b): estimate time of executing the activity under very unfavorable working conditions. Most likely duration (c): estimate time of executing the activity that is closed to the actual duration. This estimates lies in between the above two extremes. 5. BUFFER MANAGEMENT IN CONSTRUCTION In order to manage uncertainty in construction projects, buffer management is utilized to make assessment of the consumption and replenishment of buffers regard to activities and project. Buffer management may provide a clear view of the cumulative risk impact to the project performance. Compare with CPM approach, critical chain includes the consideration about resource constraint and focus o n cause uncertainty management. The study focuses on the usage of buffer management in construction schedule without wasting time. Furthermore, the study finds out the problems to applying critical chain project management in construction.

4.3 Buffer Management There are three kinds of uncertainties in project planning and scheduling namely, activity time uncertainty, path time uncertainty, and resource uncertainties [8]. In order to reduce those uncertainties, buffers are utilized and applied in the critical chain project management. In the critical chain, buffers are added durations and applied to a project schedule to protect what is important to the success of that project [8]. The buffers using in the critical chain include project buffer, feeding buffer, and resource buffer. The function of project buffer is to protect the promised due date from variation in the critical chain. The function of feeding buffers is to protect the critical chain to maintain its relay race performance by buffering the activities in non-critical chains and critical chains where they merge with activities in critical chain. With a properly feeding buffer durations inserted, the activity in critical chain that relies inputs from that non-critical chain has an improved chance of being able to start as soon as it predecessor activity in critical chain is complete. The function of resource buffer is an information signal to resources planned to work on the project critical chain that the project task is coming up for work. Resource buffers are unlike the other buffers, as they do not directly influence the scheduling of the project.

Feeding Buffer E F Noncritical Chain Project Buffer A B C D PB FB

Critical Chain

Fig. 2. The Application of Buffer in Critical Chain

-860-

ISARC2006

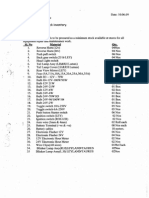

The following is the brief illustration to the application of critical chain project management in construction. As same as the previous description, three estimated buffers are integrated with CPM approach. All procedures are shown in Fig. 2. The project buffer is placed at the end of the project after the last critical chain activity to protect schedule against overruns. The feeding buffer is placed at the intersection between noncritical chain and critical chain to protect the critical chain against overruns on these feeding chains. Resource buffer is placed at the critical chain to ensure that resources are available when needed to protect the critical chain schedule. Resource buffer helps insurance of resource availability, and does not add time to the critical chain. In CCPM, Goldratt proposed that when making plan and schedule, the planner assumes that each activity may completes his work at the mean time without any impact of uncertainty. All the safety times in activities should be removed unnecessary wasting time. Furthermore, Goldratt suggests the size of buffer is 50-50 estimated duration [8]. However, the 50% estimation is too arbitrary and difficult to apply in construction real world. Also, the above approach is unsuitable in construction schedule plan. In order to improve the above problem, a modified approach is proposed to estate buffer more reliable. In construction, the duration estimation of each activity is usually estimated based on planner experience or calculated by average work production rate. However, the estimation usually is longer than the average time because planers always add safety time into the activity for any uncertainty. Usually, most of work estimates can not make sure 100% effort on the activity. If the activity estimation is not 100% effort or people work in the lax attitude, activity duration will be reduced and remove the safety time. In order to solve above problems, the two questions will be used and asked for each activity from participating engineers. First question is How long could you perform this activity based on your previous experience? Another question is How quickly could you perform this activity if everything goes through well and you had all the inputs you needed at the start? After you get the initial protective estimates from first question and obtain reasonable estimates according to question two. However, the engineers need to explain the reasons if the protective and reasonable estimations are same based on question one and two. After obtain the protective and reasonable estimations, the chief engineer may judge and determine the final estimating duration for each activity. Therefore, the safety time of each activity is protective estimation minus reasonable estimation. When buffer is increasing, it means that project may be finish ahead of schedule. On the contrary, it implies that the project will be possible to be delay if buffer is decreasing. The following is the main process applying buffers in construction projects. Step1. Plan the construction schedule using CPM approach.

Step2. Identify and determine the protective estimation for each activity. Step3. Identify and determine the reasonable estimation for each activity. Step4. Remove the safety estimation for each activity based on Step 2 and Step 3. Step5. Identify the critical chain as the longest chain of dependent events for the feasible schedule that was identified in Step 4. Step6. Add the project buffer to the end of the critical chain. Step7. Add the feeding buffers in a noncritical chain merging into critical chain. Step8. Add the resource buffers to ensure the activity to resource availability. Step 9 Return the Step 5 to check critical chain. According to above procedures, the example is illustrated to explain the result. The total durations of schedule are 410 days based on the CPM approach and the total durations of revised schedule are 373.5 days using buffer management approach (see Fig. 3). Therefore, construction project planning is to be enhanced by the buffer management approach. Furthermore, those buffers can be utilized effectively in construction project for planning and controlling. In tradition project management, the critical path changes as activities are completed ahead of or fall behind schedule. With buffer management approach, buffers prevent the critical chain from changing during project execution. Briefly, the critical chain project management provides a rigorous plan and simplifies project control and utilizes buffers reduce the risk of a delay in construction. 6. CONCLUSIONS The basic CPM/PERT approaches do not deal with the hidden constraints. Dr. Goldratt proposed the Theory of Constraints (TOC) and Critical Chain, which provide the concepts for achieving effective remove those constraints. The usage of buffer in TOC and Critical Chain emphasis is laid on completing activities without wasting time by using buffers. The buffers introduced in the critical chain scheduling methodology serve to protect project promises in a static manner. When activities take longer than the schedule anticipates, buffers are consumed. When they take less time, those buffers are replenished. Awareness of project buffer consumption relative to the completion of the critical chain provides an important forward-looking solution. Furthermore, removing safety time from individual activities can eliminate the major cause of time wastage and mitigate the impacts of constraints. According to the study, the application of buffers in project scheduling will improve the effectiveness specifically in the construction plan phase. In the CCPM, the 50 % estimates are too arbitrary and do not apply in the real word regard to construction industry. In order to apply the Critical Chain in construction project,

-861-

ISARC2006

the new buffer estimation is integrated with CPM approach for buffer management in the paper. In the safety time for each activity, two estimations are used in this study. The proposed two estimations for buffers are suitable and applying for construction project management in practice. According to the result from face-face interviews, ratio to safety estimation in practice may be around between 0.1 and 0.2. More details for safety estimations are suggested for further study. Briefly, buffer management can make a steady plan to protect against uncertainties and reduces the potential impact of construction changes. This study illustrates the application of Critical Chain and buffer management can be well applied in construction projects to achieve shorter project duration without driving up costs.

7. SUGGESTIONS FOR FURTHER STUDY An important area for further study is analyzing buffer consumption rates special for construction projects and recommending improved methods for buffer management in construction. The main reason is buffer estimations vary from activity to activity and project to project. It is recommended that buffer estimations versus work types are studied for numerous projects. A second suggestion for further implementation study is with larger and more complex construction projects. It is necessary to study the application of buffer management and critical chain project management in construction larger and complex projects to track the progress of the results through completion and continue to provide lessons learned.

6d 3d

60d

24d

16d

30d

9d

120d 90d

80d

20d 20d

100d 100d 54d 27d 64d 96d 81d 80d 80d Critical Chain

36.5d 12.5d

Feeding Buffer

Project Buffer

36.5d

Fig. 3. The Application of Buffer Management Integrated with CPM Approach in Construction

-862-

ISARC2006

REFERENCES [1] Chua, D. H. K. and Shen, L. J. (2005). Key Constraints Analysis with Integrated Production Scheduler. J. Constr. Eng. Manage., 131 (7), 753764. [2] Chua, D. H. K., Shen, L. J., and Bok, S. H. (2003). Constraint-based planning with Integrated Production Scheduler over Internet. J. Constr. Eng. Manage., 129 (3), 293301. [3] Goldratt, E. (1990). Theory of constraints, North River Press. [4] Goldratt, E. (1992). The goal, North River Press. [5] Goldratt, E. (1997). Critical chain, North River Press, Great Barrington, Mass. [6] Horman, M., and Kenley, R. (1998). Process dynamics: Identifying a strategy for the deployment of buffers in building projects. Int. J. Logistics: Res. Appl., 1 (3), 221237. [7] Horman, M., Messner, J., Riley, D., and Pulaski, M. (2003). Using buffers to manage production: A case study of the pentagon renovation project. International Group of Lean Construction 11th Annual Conf. [8] Leach L. P., Critical Chain Project Management, Artech House Inc, Boston, 2000. [9] Park, M., and Pena-Mora, F. (2004). Reliability buffering for construction projects. J. Constr. Eng. Manage., 130 (5), 626637. [10] Sakamoto, M., Horman, M., and Randolph, T. (2002). A study of the relationship between buffers and performance in construction. International Group of Lean Construction 10th Annual Conf. [11] Tarek Hegazy (2002), Computer-based Construction Project Management, Prentice Hall. [12] Brain Cooke and Williams (1998), Construction Planning, Programming and Control, Macmillan Press.

-863-

Potrebbero piacerti anche

- Critical Chain - Book Review OPSDocumento10 pagineCritical Chain - Book Review OPSekta_singh_5Nessuna valutazione finora

- Tutorial 8 WithSolutionDocumento5 pagineTutorial 8 WithSolutionعهد الغلاNessuna valutazione finora

- Critical Chain Method in Traditional Project and Portfolio Management SituationsDocumento17 pagineCritical Chain Method in Traditional Project and Portfolio Management SituationsnouraNessuna valutazione finora

- Electronic Modular Control Panel II Paralleling Emcp II P Systems Operation Troubleshooting Testing and Adjusting CaterpillarDocumento200 pagineElectronic Modular Control Panel II Paralleling Emcp II P Systems Operation Troubleshooting Testing and Adjusting CaterpillarAbdo MalkiNessuna valutazione finora

- Discover Haxeflixel FullDocumento182 pagineDiscover Haxeflixel FullKristian Macanga100% (3)

- Construction Project Buffer Management in ScheduliDocumento7 pagineConstruction Project Buffer Management in ScheduliANYPATYGATITOSNessuna valutazione finora

- Shen and Chua 2008 - An Investigation of Critical Chain and Lean Project SchedulingDocumento12 pagineShen and Chua 2008 - An Investigation of Critical Chain and Lean Project SchedulingJuanTulichNessuna valutazione finora

- Construction Scheduling Using Constraint Satisfaction Problem MethodDocumento23 pagineConstruction Scheduling Using Constraint Satisfaction Problem MethodRaneesh MohamedNessuna valutazione finora

- Beyond Critical Chain - Steyn 2002Documento7 pagineBeyond Critical Chain - Steyn 2002LorranaNessuna valutazione finora

- Toc SimulationDocumento15 pagineToc SimulationTalha SiddiquiNessuna valutazione finora

- Critical Chain Scheduling: Page 1 of 10Documento10 pagineCritical Chain Scheduling: Page 1 of 10Zulkarnain DahalanNessuna valutazione finora

- The Significance of Lean Principles To Achieve Rapid ConstructionDocumento11 pagineThe Significance of Lean Principles To Achieve Rapid ConstructionnfarahNessuna valutazione finora

- Crashing Time Scheduling ProblemDocumento9 pagineCrashing Time Scheduling ProblemeragornNessuna valutazione finora

- Time Management Practices in Large Construction ProjectsDocumento5 pagineTime Management Practices in Large Construction ProjectsJustice tadiosNessuna valutazione finora

- WP1050 Critical Chain PDFDocumento5 pagineWP1050 Critical Chain PDFzandra mae velascoNessuna valutazione finora

- Ijer 2014 309Documento6 pagineIjer 2014 309Innovative Research PublicationsNessuna valutazione finora

- AReviewofTimeCostTrade Offinconstructionproject FormatDocumento13 pagineAReviewofTimeCostTrade Offinconstructionproject FormatCrisma Eclarino CaamudNessuna valutazione finora

- Critical Chain Project Management Improves Project PerformanceDocumento13 pagineCritical Chain Project Management Improves Project PerformanceRodrigo GiorgiNessuna valutazione finora

- Evaluation of Critical Chain Buffer Sizing Techniques: December 2016Documento11 pagineEvaluation of Critical Chain Buffer Sizing Techniques: December 2016Sovan SahooNessuna valutazione finora

- A State of Art Review On Time Cost Trade Off Problems in Project SchedulingDocumento8 pagineA State of Art Review On Time Cost Trade Off Problems in Project SchedulingInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- 1.1 General: Chapter 1: IntroductionDocumento4 pagine1.1 General: Chapter 1: IntroductionSanjay TiwariNessuna valutazione finora

- Measuring The Efficiency of Project Control Using Fictitious and Empirical Project DataDocumento12 pagineMeasuring The Efficiency of Project Control Using Fictitious and Empirical Project DataBenyamin SadiraNessuna valutazione finora

- Lecture 5 - Unit4Documento10 pagineLecture 5 - Unit4Jamila GhazalNessuna valutazione finora

- The Use of Project Time Management Processes and T PDFDocumento11 pagineThe Use of Project Time Management Processes and T PDFPhumeza Nikiwe MtyaNessuna valutazione finora

- Time Management PracticesDocumento5 pagineTime Management PracticesPriyanth GnanasekaranNessuna valutazione finora

- Time Management Practices in Large Const PDFDocumento5 pagineTime Management Practices in Large Const PDFCassio ManoelNessuna valutazione finora

- The Use of The Critical Path and Critical Chain Methods in The South African Construction IndustryDocumento23 pagineThe Use of The Critical Path and Critical Chain Methods in The South African Construction IndustryGeorgette BalcitaNessuna valutazione finora

- 09 ICED09 Wynn Simulation and SelectionDocumento12 pagine09 ICED09 Wynn Simulation and SelectionMame WoldaNessuna valutazione finora

- Determine The Overall Project Duration and The Activities' Float Times. Such Data Provide ImportantDocumento1 paginaDetermine The Overall Project Duration and The Activities' Float Times. Such Data Provide ImportantSanjay TiwariNessuna valutazione finora

- Critical Chain: by Eliyahu M. GoldrattDocumento33 pagineCritical Chain: by Eliyahu M. GoldrattMuhammad BilalNessuna valutazione finora

- Fast Track ConstructionDocumento5 pagineFast Track ConstructionGOPINATH JNessuna valutazione finora

- Chapter 11 Project Management: Notes:-Facility Planning 6th SemDocumento18 pagineChapter 11 Project Management: Notes:-Facility Planning 6th SemmanipaldhakreyNessuna valutazione finora

- "Phases of Project": Assignment - 1Documento19 pagine"Phases of Project": Assignment - 1Pardeep KapilNessuna valutazione finora

- Critical Chain Project Management - Estimating and SchedulingDocumento4 pagineCritical Chain Project Management - Estimating and SchedulingMohammad IqbalNessuna valutazione finora

- 08 Geekie Steyn Buffer Sizing 1Documento17 pagine08 Geekie Steyn Buffer Sizing 1dreamtheater666Nessuna valutazione finora

- Assessing Project Success Moving Beyond The Triple Constraint - Critique PaperDocumento4 pagineAssessing Project Success Moving Beyond The Triple Constraint - Critique PaperRommel TupigNessuna valutazione finora

- Literature Review (CPM)Documento3 pagineLiterature Review (CPM)SyEd Amir Syahmi100% (1)

- Using Combinations of Heuristics To Schedule Activities of Constrained Multiple Resource ProjectsDocumento8 pagineUsing Combinations of Heuristics To Schedule Activities of Constrained Multiple Resource ProjectsJohn McIntoshNessuna valutazione finora

- Formatted Thesis For PDFDocumento85 pagineFormatted Thesis For PDFSanjay TiwariNessuna valutazione finora

- Vanhoucke Cooperetal PMJ2019Documento13 pagineVanhoucke Cooperetal PMJ2019rorrito33Nessuna valutazione finora

- Unit No. 03Documento43 pagineUnit No. 03rpkodamNessuna valutazione finora

- PM 21a IIEBM 2021 22 Critical Chain Project ManagementDocumento35 paginePM 21a IIEBM 2021 22 Critical Chain Project ManagementRohan SodaNessuna valutazione finora

- Tugas MPI UASDocumento23 pagineTugas MPI UASdilaNessuna valutazione finora

- 5.3 Critical Path Method (CPM) and Program Evaluation & Review Technique (Pert)Documento6 pagine5.3 Critical Path Method (CPM) and Program Evaluation & Review Technique (Pert)Charles VeranoNessuna valutazione finora

- Project Management: Resource AllocationDocumento24 pagineProject Management: Resource Allocationsawaira maniNessuna valutazione finora

- Tools and Techniques of Project ManagementDocumento4 pagineTools and Techniques of Project Managementsimmi33Nessuna valutazione finora

- Pert-And-Cpm-Techniques n67 MustDocumento67 paginePert-And-Cpm-Techniques n67 MustWasim QuraishiNessuna valutazione finora

- PMDocumento16 paginePMSai Ashok Kumar ReddyNessuna valutazione finora

- WP1050 Critical ChainDocumento5 pagineWP1050 Critical ChainRahul SenNessuna valutazione finora

- Activity Overlapping Technique For Early Completion of Construction ProjectDocumento11 pagineActivity Overlapping Technique For Early Completion of Construction ProjectIJRASETPublicationsNessuna valutazione finora

- 2929 - 12th Session PPSDocumento23 pagine2929 - 12th Session PPSAzamkhanNessuna valutazione finora

- Emblems of Success of Critical Chain Project Management: A ReviewDocumento7 pagineEmblems of Success of Critical Chain Project Management: A ReviewTiago HorstmannNessuna valutazione finora

- Application of Project Evaluation, Review Technique and Critical Path Method (PERT-CPM) Model in Monitoring Building ConstructionDocumento14 pagineApplication of Project Evaluation, Review Technique and Critical Path Method (PERT-CPM) Model in Monitoring Building Constructiondinosaur x-drakeNessuna valutazione finora

- Management of Empirical Research On The Success of Production Control in Recent Construction WorksDocumento29 pagineManagement of Empirical Research On The Success of Production Control in Recent Construction WorksGateway Computer EducationNessuna valutazione finora

- Theory of Constraints Approach To Project ManagementDocumento6 pagineTheory of Constraints Approach To Project ManagementAnkit KalraNessuna valutazione finora

- Week 4 Discussion - Quality AssuranceDocumento3 pagineWeek 4 Discussion - Quality AssuranceWilsonbvNessuna valutazione finora

- Critical Chain Project Management CCPMDocumento1 paginaCritical Chain Project Management CCPMMadan YadavNessuna valutazione finora

- Uncertainty in Project Scheduling PDFDocumento6 pagineUncertainty in Project Scheduling PDFecaripasNessuna valutazione finora

- Optimum Activity Overlapping Strategy For Construction Management Using Analytical ApproachDocumento9 pagineOptimum Activity Overlapping Strategy For Construction Management Using Analytical ApproachIJRASETPublicationsNessuna valutazione finora

- What Is The Critical Path Method?Documento9 pagineWhat Is The Critical Path Method?Thjnn ErrNessuna valutazione finora

- Critical Chain Project Management: A Concept Used By The Great Military and Aerospace Companies of The World.Da EverandCritical Chain Project Management: A Concept Used By The Great Military and Aerospace Companies of The World.Nessuna valutazione finora

- Consumable Spares PDFDocumento22 pagineConsumable Spares PDFdoc4printNessuna valutazione finora

- Technical Bid Volume 1 of 2Documento285 pagineTechnical Bid Volume 1 of 2doc4printNessuna valutazione finora

- Types of FormworkDocumento2 pagineTypes of Formworkdoc4printNessuna valutazione finora

- 2010 10 18 Windlasten An Klettersystemen Langfassung enDocumento19 pagine2010 10 18 Windlasten An Klettersystemen Langfassung endoc4printNessuna valutazione finora

- Planning and Scheduling Consideration and Constraints in Automated Construction EnvironmentDocumento8 paginePlanning and Scheduling Consideration and Constraints in Automated Construction Environmentdoc4printNessuna valutazione finora

- 1SC0 2PF Exam-Paper 20180616Documento20 pagine1SC0 2PF Exam-Paper 20180616Thasanya AlgamaNessuna valutazione finora

- IC Project Report Dashboard 10673 0Documento6 pagineIC Project Report Dashboard 10673 0Anonymous Sls6WCF100% (2)

- Codigo Ficheros PHPDocumento33 pagineCodigo Ficheros PHPm_montielNessuna valutazione finora

- R172 NTG4.5 EngineeringMenuDocumento5 pagineR172 NTG4.5 EngineeringMenualeksandar_tudzarovNessuna valutazione finora

- NDT VTL-3-3Documento2 pagineNDT VTL-3-3Priyesh MauryaNessuna valutazione finora

- Science 3 PDFDocumento12 pagineScience 3 PDFJelyn CandoNessuna valutazione finora

- 7 - Introduction To Intelligent ControlDocumento21 pagine7 - Introduction To Intelligent ControlIsmael Espinoza100% (1)

- LAB 7 - Getting Started With Google BigQueryDocumento10 pagineLAB 7 - Getting Started With Google BigQueryRama VNessuna valutazione finora

- Evaluating Capital ProjectsDocumento254 pagineEvaluating Capital Projectsariff_sodriNessuna valutazione finora

- Vector AlgebraDocumento7 pagineVector AlgebraDeeeNessuna valutazione finora

- Cobol Language Fundamentals: Structured COBOL Programming, Stern & Stern, 9th Ed ItionDocumento53 pagineCobol Language Fundamentals: Structured COBOL Programming, Stern & Stern, 9th Ed ItionAsk NameNessuna valutazione finora

- XML SerializationDocumento4 pagineXML Serializationapi-3748960Nessuna valutazione finora

- 808D ADV Commiss Man 1218 en-USDocumento480 pagine808D ADV Commiss Man 1218 en-USBaldev SinghNessuna valutazione finora

- AMC2019 StudentsResults Indonesia 8JDocumento4 pagineAMC2019 StudentsResults Indonesia 8JWinety Kristiana DewiNessuna valutazione finora

- Battery SubsystemDocumento7 pagineBattery SubsystemahmaborashedNessuna valutazione finora

- Pseudocode Is A Technique Used To Describe The Distinct Steps of An Algorithm in ADocumento3 paginePseudocode Is A Technique Used To Describe The Distinct Steps of An Algorithm in AChristian Doson EstilloreNessuna valutazione finora

- Precima Frenos FDW ATEX Operating InstructionsDocumento6 paginePrecima Frenos FDW ATEX Operating InstructionsToni RenedoNessuna valutazione finora

- 3DC Real Light 24HDRi Vol03Documento27 pagine3DC Real Light 24HDRi Vol03AntezanaFernandoNessuna valutazione finora

- DPP 01 Periodic Table JH Sir-3576 PDFDocumento5 pagineDPP 01 Periodic Table JH Sir-3576 PDFChessNessuna valutazione finora

- Mha Mca Cet SyllabusDocumento20 pagineMha Mca Cet Syllabusm kumarNessuna valutazione finora

- LC08 L1TP 120065 20180318 20180403 01 T1 MTLDocumento4 pagineLC08 L1TP 120065 20180318 20180403 01 T1 MTLrendy aswinNessuna valutazione finora

- Active Mathematics PDFDocumento22 pagineActive Mathematics PDFgoingforward77Nessuna valutazione finora

- COA LAb File-ShubhiDocumento28 pagineCOA LAb File-ShubhiKrishan Kant ShuklaNessuna valutazione finora

- Abhilash Betanamudi: AchievementsDocumento3 pagineAbhilash Betanamudi: AchievementsAbhilashBetanamudiNessuna valutazione finora

- Evaluation of Professional Bra Fitting Criteria For Bra Selection and Fitting in The UKDocumento9 pagineEvaluation of Professional Bra Fitting Criteria For Bra Selection and Fitting in The UKaqsa imranNessuna valutazione finora

- CoolebrookDocumento31 pagineCoolebrookloganatahnNessuna valutazione finora

- The Effect of Axial Flow Velocity On Annular Gap Windage Power LossDocumento12 pagineThe Effect of Axial Flow Velocity On Annular Gap Windage Power Losskien nguyenNessuna valutazione finora

- Programming: Simon ScheideggerDocumento90 pagineProgramming: Simon ScheideggerRuben KempterNessuna valutazione finora