Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Compact vs. Non-Compact vs. Slender Sections

Caricato da

yhszaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Compact vs. Non-Compact vs. Slender Sections

Caricato da

yhszaCopyright:

Formati disponibili

Compact vs. Non-Compact vs.

Slender Sections

To put your mind at ease, this section is not on weight loss (as a fellow engineer I understand how that could be worrisome to many). In addition to that, the vast majority of sections out there are compact, which is what you want. Discovering whether or not you have a compact, non-compact, or slender section all depends on the shape of the beam. Table B4.1 in the AISC 360 specs provides all the limits you need to determine which zone your section shape falls into (this will be explained in greater detail below). When you have a compact section there is no possibility of local flange or web bucking to prevent attainment of the full sections yield strength. In common terms, the beam will not have a local failure (i.e. your web buckles) before the beam has global failure. With a non-compact section one or more of the elements in the beam (e.g. in an I-beam which will be detailed below, those elements are the web and the flange) have the possibility of buckling before the beam is able to attain section plasticity. A slender section is almost always avoided. But sometimes it is important to check this type of section. Understand a slender section is even more extreme than a non-compact section. If:

p (the section is compact) p < r (the section is non-compact) r < (the section is slender)

where: = Width to thickness ratio (dependent on section type and element) p = Limiting ratio to see if a section is compact r = Limiting ratio to see if a section is non-compact Note: All current ASTM W, S, M, C, & MC shapes have compact flanges except W21x48, W14x99, W14x90, W12x65, W10x12, W8x31, W8x10, W6x15, W6x9, W6x8.5, & M4x6 (for F y = 50 ksi). All current ASTM W, S, M, HP, C, & MC shapes have compact webs for Fy 65 ksi.

How to find if a rolled doubly symmetric I shaped sections is compact?

This example has been taken from Table B4.1 in the AISC 360 specs

[1]

Table 1: Is a Rolled I-shaped Section or Channels compact?

Description of Element Width Thickness Ratio ()

tb

Flexure in flanges of rolled I-shaped sections & channels Flexure in webs of rolled I-shaped sections & channels

0 38 3 76

E Fy E Fy

10 5 70

E Fy E Fy

htw

where: b = the base of the I-shape or channel's flange t = the thickness of the flange h = the height of the web (does not include the flange thickness) tw = the thickness of the web E = the modulus of elasticity of steel (29,000 ksi) Fy = the yield strength of the steel (e.g. 36 ksi, 50 ksi, 65 ksi, etc.)

Potrebbero piacerti anche

- Compact Vs NON Compact Steel SectionDocumento2 pagineCompact Vs NON Compact Steel Sectionntah84Nessuna valutazione finora

- Steel Corbel Design Based On AISC-ASD 9th, Appendix F Design CriteriaDocumento3 pagineSteel Corbel Design Based On AISC-ASD 9th, Appendix F Design CriteriaPrayas SubediNessuna valutazione finora

- Design and Analysis of Tension MemberDocumento29 pagineDesign and Analysis of Tension MemberJhianne Dulpina RoqueNessuna valutazione finora

- Section Modulus Equations and Calculators Common Shapes: Got It!Documento4 pagineSection Modulus Equations and Calculators Common Shapes: Got It!Fatih AdamNessuna valutazione finora

- Mathcad - Tank Foundation Design Actions - 2611-501 & 502 - Rougher WMS Feed Tank 1 & 2Documento15 pagineMathcad - Tank Foundation Design Actions - 2611-501 & 502 - Rougher WMS Feed Tank 1 & 2shashank sharmaNessuna valutazione finora

- Formula Sheet 3-Steel DesignDocumento7 pagineFormula Sheet 3-Steel DesignAddrien DanielNessuna valutazione finora

- Cap PlateDocumento18 pagineCap PlateVinoth KumarNessuna valutazione finora

- P13 Connection DetailDocumento1 paginaP13 Connection DetailreyhanNessuna valutazione finora

- Canopy Wind Load CalculationDocumento4 pagineCanopy Wind Load CalculationManinder ChaudharyNessuna valutazione finora

- Elastic and Plastic Section Moduli of Steel Angles About Principal Axes PDFDocumento8 pagineElastic and Plastic Section Moduli of Steel Angles About Principal Axes PDFSanket MistryNessuna valutazione finora

- Design of Continuous Footing-1 PDFDocumento8 pagineDesign of Continuous Footing-1 PDFSamuel Antobam100% (2)

- PCA Notes On ACI 318-08 - Chapter 22 - FootingsDocumento22 paginePCA Notes On ACI 318-08 - Chapter 22 - FootingsJeyson GuerraNessuna valutazione finora

- Strength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsDocumento6 pagineStrength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsValdemir ColaresNessuna valutazione finora

- Bolt Design For Steel Connections As Per AISCDocumento24 pagineBolt Design For Steel Connections As Per AISCJayachandra PelluruNessuna valutazione finora

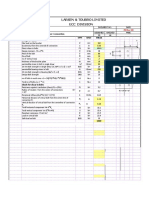

- Larsen & Toubro Limited Ecc Division: Description SYM Unit Value Design of BoltsDocumento6 pagineLarsen & Toubro Limited Ecc Division: Description SYM Unit Value Design of BoltsSrishti Project ConsultantsNessuna valutazione finora

- Warn OK OK OK: ACI 318M-14 PIP STE05121 AISC Design Guide 1Documento11 pagineWarn OK OK OK: ACI 318M-14 PIP STE05121 AISC Design Guide 1hemantcabhaleNessuna valutazione finora

- Part 6 Analysis and Design of Purlins W PDFDocumento17 paginePart 6 Analysis and Design of Purlins W PDFCalvin TehNessuna valutazione finora

- Manual PDFDocumento932 pagineManual PDFSyed Baqir Hussain0% (1)

- Slender-Concrete-Columns-Non-Sway-Frame-Moment-Magnification-ACI 318-19Documento21 pagineSlender-Concrete-Columns-Non-Sway-Frame-Moment-Magnification-ACI 318-19Thadarth NaNessuna valutazione finora

- Assignment 1 GRAD 2019Documento4 pagineAssignment 1 GRAD 2019RamonErnestoICNessuna valutazione finora

- How To Fix STAAD Warning WWW - UniquecivilDocumento5 pagineHow To Fix STAAD Warning WWW - UniquecivilMohdDanishNessuna valutazione finora

- Axially Loaded Columns - Base Plate DesignDocumento2 pagineAxially Loaded Columns - Base Plate DesignaomareltayebNessuna valutazione finora

- Splice DesignDocumento5 pagineSplice DesignBunkun15Nessuna valutazione finora

- The Flexure and Shear Design of Corbel (Bracket)Documento12 pagineThe Flexure and Shear Design of Corbel (Bracket)Girum MindayeNessuna valutazione finora

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearDocumento4 pagineConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearVenu GopalNessuna valutazione finora

- Time Period Calculation in ETABS As Per IS 1893 Part 1Documento2 pagineTime Period Calculation in ETABS As Per IS 1893 Part 1NAYAN RANPURA100% (1)

- Checklist For Concrete Shear Wall (ACI 318-14)Documento5 pagineChecklist For Concrete Shear Wall (ACI 318-14)renzo1221Nessuna valutazione finora

- Anchor Bolt Design For Portal and Connecting BridgeDocumento2 pagineAnchor Bolt Design For Portal and Connecting BridgeAbhinav YadavNessuna valutazione finora

- TR12 PDFDocumento24 pagineTR12 PDFramorusoNessuna valutazione finora

- Design of Steel HangerDocumento2 pagineDesign of Steel HangerMostafa Saleh100% (1)

- Indian Codes - Steel Design Per IS 800:2007Documento3 pagineIndian Codes - Steel Design Per IS 800:2007dineshNessuna valutazione finora

- Fast Check For Block ShearDocumento7 pagineFast Check For Block ShearSergioAlcantaraNessuna valutazione finora

- Wind Calculations UBC and ECPDocumento3 pagineWind Calculations UBC and ECPOmar RubioNessuna valutazione finora

- Software Verification: AISC-360-05 Example 001Documento8 pagineSoftware Verification: AISC-360-05 Example 001Zakir KhanNessuna valutazione finora

- End Plate ConnectionDocumento3 pagineEnd Plate ConnectionibrahimNessuna valutazione finora

- Chapter 5 Flexural MembersDocumento40 pagineChapter 5 Flexural MembersAriel Dela CruzNessuna valutazione finora

- Design of Steel BeamDocumento19 pagineDesign of Steel BeamAnonymous tBhJoH5wgMNessuna valutazione finora

- Water Tank Design (Aci 318-05)Documento8 pagineWater Tank Design (Aci 318-05)arnoldNessuna valutazione finora

- Portal FrameDocumento2 paginePortal FramemaheshbandhamNessuna valutazione finora

- Steel Member Analysis & Design - Sample Calculation (As 4100)Documento9 pagineSteel Member Analysis & Design - Sample Calculation (As 4100)Tiam MarapeNessuna valutazione finora

- ASCE 7-22 CH 32 - For PC - SouDocumento49 pagineASCE 7-22 CH 32 - For PC - SousharethefilesNessuna valutazione finora

- Moment of Resistance For Doubly Reinforced SectionsDocumento32 pagineMoment of Resistance For Doubly Reinforced SectionsWanda Beasley100% (3)

- Tubular Truss ExampleDocumento12 pagineTubular Truss ExampleMock Khang Hi100% (1)

- Design and Detailing For Earthquake Loads: IS 800: 2007 SECTION 12Documento21 pagineDesign and Detailing For Earthquake Loads: IS 800: 2007 SECTION 12Anshul SoniNessuna valutazione finora

- Multi-Tiered Braced Frame Design Based On AISC 341-16: Project: Client: Design By: Job No.: Date: Review byDocumento2 pagineMulti-Tiered Braced Frame Design Based On AISC 341-16: Project: Client: Design By: Job No.: Date: Review byRidho ZiskaNessuna valutazione finora

- Reference For Shear ConnectionDocumento7 pagineReference For Shear ConnectionmaheshbandhamNessuna valutazione finora

- Duopitch Roof ExampleDocumento6 pagineDuopitch Roof ExampleMallesh Nenkat100% (1)

- Example 1 ': σ σ on faces near water face) on faces away σ water faceDocumento4 pagineExample 1 ': σ σ on faces near water face) on faces away σ water faceyenebeb tarikuNessuna valutazione finora

- Chapter-5 Design of Steel BeamDocumento36 pagineChapter-5 Design of Steel Beamzakai zakiNessuna valutazione finora

- Ibc 2003 - Poles Footings DesignDocumento4 pagineIbc 2003 - Poles Footings DesignAhmed ALiNessuna valutazione finora

- Wind Load Design NSCP 2015 PDFDocumento6 pagineWind Load Design NSCP 2015 PDF'Julius OrpiaNessuna valutazione finora

- Is 13920 DetailingDocumento3 pagineIs 13920 Detailingasingh400Nessuna valutazione finora

- CB Value Significance PDFDocumento5 pagineCB Value Significance PDFArchitjNessuna valutazione finora

- Steel Structure ConnectionDocumento6 pagineSteel Structure Connectionntah84Nessuna valutazione finora

- Chequered Plate DesignDocumento2 pagineChequered Plate Designraj vaddiNessuna valutazione finora

- 6.0 Column: VerticallyDocumento27 pagine6.0 Column: VerticallyWah KhaingNessuna valutazione finora

- Chapter 4-stdDocumento102 pagineChapter 4-stdBelkacem AchourNessuna valutazione finora

- Design of Steel Beams To AISC - LRFDDocumento52 pagineDesign of Steel Beams To AISC - LRFDsony setyawan100% (1)

- (Kiot) : Design of Steel and Timber StructureDocumento53 pagine(Kiot) : Design of Steel and Timber Structurebini1221Nessuna valutazione finora

- Reinforced Concrete Buildings: Behavior and DesignDa EverandReinforced Concrete Buildings: Behavior and DesignValutazione: 5 su 5 stelle5/5 (1)

- Mabey UniversalDocumento11 pagineMabey UniversalyhszaNessuna valutazione finora

- Behavior and Design of Selected Elastomeric Bearing Pads PDFDocumento20 pagineBehavior and Design of Selected Elastomeric Bearing Pads PDFyhszaNessuna valutazione finora

- Gleitfolien enDocumento36 pagineGleitfolien enyhszaNessuna valutazione finora

- Catalogo E Link 0010ENG Rev09 PDFDocumento33 pagineCatalogo E Link 0010ENG Rev09 PDFyhszaNessuna valutazione finora

- B02 ELASTOFIP-engDocumento12 pagineB02 ELASTOFIP-engyhszaNessuna valutazione finora

- MK4 Elastomeric BearingsDocumento12 pagineMK4 Elastomeric BearingsyhszaNessuna valutazione finora

- Catalogo E Link 0010ENG Rev09 PDFDocumento33 pagineCatalogo E Link 0010ENG Rev09 PDFyhszaNessuna valutazione finora

- NCHRP RPT 248Documento93 pagineNCHRP RPT 248AvinashRaiNessuna valutazione finora

- Mechanics and Strength of Materials DR TalibDocumento31 pagineMechanics and Strength of Materials DR TalibyhszaNessuna valutazione finora

- FE Review-Steel Design 2015-2Documento23 pagineFE Review-Steel Design 2015-2yhszaNessuna valutazione finora

- Slab-Steel Beam BridgesDocumento103 pagineSlab-Steel Beam BridgesyhszaNessuna valutazione finora

- Grillage Method of Superstructure Analysis: Dr. Shahzad Rahman NWFP University of Engg & Technology, PeshawarDocumento59 pagineGrillage Method of Superstructure Analysis: Dr. Shahzad Rahman NWFP University of Engg & Technology, PeshawarpotharajudvnagaNessuna valutazione finora

- LRFD SteelDocumento280 pagineLRFD SteelKhalid YousafNessuna valutazione finora

- XrsanaDocumento20 pagineXrsanayhszaNessuna valutazione finora

- Effect of Bridges' Width On Optimum Design of Steel Bridges: Firas Ismael Salman, Abdul Muttalib Issa SaidDocumento7 pagineEffect of Bridges' Width On Optimum Design of Steel Bridges: Firas Ismael Salman, Abdul Muttalib Issa SaidyhszaNessuna valutazione finora

- 412 ch1Documento20 pagine412 ch1yhszaNessuna valutazione finora

- Structural Steel Properties & Design Charts BookDocumento44 pagineStructural Steel Properties & Design Charts BookEriellynn LizaNessuna valutazione finora

- 11 - (4th Civil) (R.C. Bridges) Slab Type - Girder Type Bridges PDFDocumento74 pagine11 - (4th Civil) (R.C. Bridges) Slab Type - Girder Type Bridges PDFyhszaNessuna valutazione finora

- Allpile Manual PDFDocumento102 pagineAllpile Manual PDFAhmedMahmoudNessuna valutazione finora

- Handbook 4 BridgeDocumento174 pagineHandbook 4 BridgeVlad MihaiNessuna valutazione finora

- Road Bridges: (Loadings) 1 MLDocumento13 pagineRoad Bridges: (Loadings) 1 MLyhszaNessuna valutazione finora

- "How To Design RF Circuits" - OscillatorsDocumento7 pagine"How To Design RF Circuits" - OscillatorsAbbas Bagherifar100% (8)

- EN1991 8 CalgaroDocumento38 pagineEN1991 8 CalgaroNicu LucanNessuna valutazione finora

- Fhwa Hi 98 032 PDFDocumento593 pagineFhwa Hi 98 032 PDFyhsza100% (1)

- VCODocumento49 pagineVCOyhszaNessuna valutazione finora

- Lecture04 - LRFD and AASHTO CodeDocumento20 pagineLecture04 - LRFD and AASHTO CodeyhszaNessuna valutazione finora

- Guidebook-2 Design of BridgesDocumento232 pagineGuidebook-2 Design of BridgesVERUSH13100% (2)

- 11 - (4th Civil) (R.C. Bridges) Slab Type - Girder Type Bridges PDFDocumento74 pagine11 - (4th Civil) (R.C. Bridges) Slab Type - Girder Type Bridges PDFyhszaNessuna valutazione finora

- Egyptian Code For Loads - 2012 PDFDocumento230 pagineEgyptian Code For Loads - 2012 PDFMicron MacronNessuna valutazione finora

- AHU ParametersDocumento2 pagineAHU Parametersvamsikrishnareddy MadireddyNessuna valutazione finora

- Anvil Specifications v3Documento40 pagineAnvil Specifications v3EnriqueNessuna valutazione finora

- Isovent N 2018 03 en PDFDocumento1 paginaIsovent N 2018 03 en PDFstarykNessuna valutazione finora

- EPC Best Practice Guidelines V1.0Documento104 pagineEPC Best Practice Guidelines V1.0Thomas Dwi Putra SalimNessuna valutazione finora

- Shear Strength of Brazed and Soldered JointsDocumento5 pagineShear Strength of Brazed and Soldered JointsseenudesignNessuna valutazione finora

- Saep 309Documento22 pagineSaep 309brecht1980Nessuna valutazione finora

- Kasiglahan Village National High SchoolDocumento4 pagineKasiglahan Village National High SchoolMichael AnoraNessuna valutazione finora

- AP - (Standarisasi Sparepart Sesuai Dengan Policy Maintenance (Target 15 Item) )Documento3 pagineAP - (Standarisasi Sparepart Sesuai Dengan Policy Maintenance (Target 15 Item) )Muhammad FatahillahNessuna valutazione finora

- New Alternatives For Continuity Plates in I-Beam To Box ColumnsDocumento15 pagineNew Alternatives For Continuity Plates in I-Beam To Box ColumnstaosyeNessuna valutazione finora

- Analysis and Design of Inclined ColumnsDocumento77 pagineAnalysis and Design of Inclined ColumnsAnonymous ciKyr0t70% (10)

- Diaph Design For HCS - Ver 1Documento5 pagineDiaph Design For HCS - Ver 1Shamim Ahsan ZuberyNessuna valutazione finora

- Failure Assessment Diagram PDFDocumento2 pagineFailure Assessment Diagram PDFBrandyNessuna valutazione finora

- ComplaintDocumento19 pagineComplaintJagannath DashNessuna valutazione finora

- European Steel and Alloy GradesDocumento3 pagineEuropean Steel and Alloy Gradesfarshid KarpasandNessuna valutazione finora

- Jkr-Shah AlamDocumento42 pagineJkr-Shah AlamfarahazuraNessuna valutazione finora

- Epoxy-Coated Reinforcement in Highway StructuresDocumento70 pagineEpoxy-Coated Reinforcement in Highway StructuresMehdi BakhshiNessuna valutazione finora

- QA QC PlanDocumento103 pagineQA QC Planrafiullah amireeNessuna valutazione finora

- LinPro Printing PDFDocumento15 pagineLinPro Printing PDFNicoleta ElenaNessuna valutazione finora

- Republic of The Philippines AJ: (0 - U - .zJJ1'rDocumento2 pagineRepublic of The Philippines AJ: (0 - U - .zJJ1'rChesterMercadoNessuna valutazione finora

- SP-1208 - Pipeline Construction Specification (Appendix F) (Formerly PCS-01)Documento94 pagineSP-1208 - Pipeline Construction Specification (Appendix F) (Formerly PCS-01)Rjeb mohamed100% (1)

- LG 14K BTU Portable Air Conditioner LP1411SHR Owner's ManualDocumento48 pagineLG 14K BTU Portable Air Conditioner LP1411SHR Owner's Manualnhutn_15Nessuna valutazione finora

- Chapter 8Documento38 pagineChapter 8غفران عبد الرسول حسن خميطNessuna valutazione finora

- DSRDocumento255 pagineDSRPravanjan SahooNessuna valutazione finora

- SFD Ec 3 2005Documento137 pagineSFD Ec 3 2005Fatih ÇELİKERNessuna valutazione finora

- Shopee E-Commerce Hub-Bogor Project: Inspection and Test PlanDocumento5 pagineShopee E-Commerce Hub-Bogor Project: Inspection and Test PlanANWAR PERANGINANGINNessuna valutazione finora

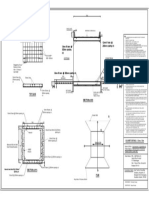

- Culvert 1.5m X 1.5mDocumento1 paginaCulvert 1.5m X 1.5mNISHIMON0% (1)

- Masteremaco S 348Documento2 pagineMasteremaco S 348shahzadNessuna valutazione finora

- Final Weld Strength CalnsDocumento3 pagineFinal Weld Strength CalnsSajal KulshresthaNessuna valutazione finora

- CESMM4.pdf MeasurementDocumento43 pagineCESMM4.pdf MeasurementEmmanuel NamkumbeNessuna valutazione finora

- Foundations Underpinning (Post Graduate Presentation)Documento16 pagineFoundations Underpinning (Post Graduate Presentation)adnan-651358Nessuna valutazione finora