Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hazen Williams Roughnes Constant

Caricato da

Anonymous ynJByUsDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hazen Williams Roughnes Constant

Caricato da

Anonymous ynJByUsCopyright:

Formati disponibili

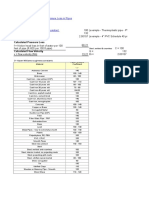

HAZZEN-WILLIAM EQUATION

The Darcy-Weisbach equation with the Moody diagram are considered to be the most accurate model for estimating frictional head loss in steady pipe flow. Since the approach requires a not so efficient trial and error iteration an alternative empirical head loss calculation like the Hazen-Williams equation may be preferred: f = 0.2083 (100/c) 1.852 q1.852 / dh4.8655 where f = friction head loss in feet of water per 100 feet of pipe (fth20/100 ft pipe) c = Hazen-Williams roughness constant q = volume flow (gal/min) dh = inside hydraulic diameter (inches) Note that the Hazen-Williams formula is empirical and lacks a theoretical basis. Be aware that the roughness constants are based on "normal" condition with approximately 1 m/s (3 ft/sec). (1)

Hazen-Williams coefficients are used in the Hazen-Williams equation for friction loss calculation in ducts and pipes. Coefficients for some common materials used in ducts and pipes can be found in the table below:

Material

Hazen-Williams Coefficient -c-

ABS - Acrylonite Butadiene Styrene

130

Aluminum Asbestos Cement

130 - 150 140

Asphalt Lining

130 - 140

Brass

130 - 140

Brick sewer

90 - 100

Cast-Iron - new unlined (CIP)

130

Cast-Iron 10 years old Cast-Iron 20 years old

107 - 113 89 - 100

Cast-Iron 30 years old

75 - 90

Cast-Iron 40 years old

64-83

Cast-Iron, asphalt coated

100

Material

Hazen-Williams Coefficient -c-

Cast-Iron, cement lined

140

Cast-Iron, bituminous lined

140

Cast-Iron, sea-coated

120

Cast-Iron, wrought plain Cement lining

100 130 - 140

Concrete

100 - 140

Concrete lined, steel forms

140

Concrete lined, wooden forms

120

Concrete, old Copper

100 - 110 130 - 140

Corrugated Metal

60

Ductile Iron Pipe (DIP)

140

Ductile Iron, cement lined

120

Fiber

140

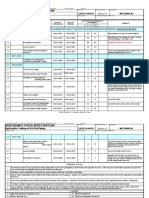

Material

Hazen-Williams Coefficient -c-

Fiber Glass Pipe - FRP

150

Galvanized iron

120

Glass

130

Lead Metal Pipes - Very to extremely smooth

130 - 140 130 - 140

Plastic

130 - 150

Polyethylene, PE, PEH

140

Polyvinyl chloride, PVC, CPVC

150

Smooth Pipes Steel new unlined

140 140 - 150

Steel, corrugated

60

Steel, welded and seamless

100

Steel, interior riveted, no projecting rivets

110

Steel, projecting girth and horizontal rivets

100

Material

Hazen-Williams Coefficient -c-

Steel, vitrified, spiral-riveted

90 - 110

Steel, welded and seamless

100

Tin

130

Vitrified Clay Wrought iron, plain

110 100

Wooden or Masonry Pipe - Smooth

120

Wood Stave

110 - 120

Potrebbero piacerti anche

- Example of Safety Health and Environment Management Plan RKDocumento53 pagineExample of Safety Health and Environment Management Plan RKrakeshkhanna78100% (12)

- FreetDocumento32 pagineFreetHamed GeramiNessuna valutazione finora

- Aeration PaperDocumento11 pagineAeration PapersehonoNessuna valutazione finora

- Estimation Man HourDocumento241 pagineEstimation Man HourAnonymous ynJByUs52% (42)

- Refrigerant-Piping Design Guide-McquayDocumento91 pagineRefrigerant-Piping Design Guide-Mcquayapi-19789368100% (4)

- Lusail Building Permit Application ProcedureesDocumento8 pagineLusail Building Permit Application ProcedureesramtsanNessuna valutazione finora

- Hazen-William Pipe Losses CalculatorDocumento9 pagineHazen-William Pipe Losses CalculatorSing Kho Fibonacci KuanNessuna valutazione finora

- Resistance and Equivalent Length of FittingsDocumento5 pagineResistance and Equivalent Length of FittingsGlishna Peushan WidanapathiranaNessuna valutazione finora

- Hazen Williams EquationDocumento5 pagineHazen Williams EquationAnonymous BJ9omONessuna valutazione finora

- Hazen-Williams EquationDocumento4 pagineHazen-Williams EquationmvooNessuna valutazione finora

- Concentrations and Emissions of Ammonia in Livestock Buildings in Northern EuropeDocumento17 pagineConcentrations and Emissions of Ammonia in Livestock Buildings in Northern Europelg2fNessuna valutazione finora

- 018 10Documento3 pagine018 10ilkerkozturkNessuna valutazione finora

- Biogas Calculator TemplateDocumento26 pagineBiogas Calculator TemplateRana BiswasNessuna valutazione finora

- SprinkCALC III ReportDocumento17 pagineSprinkCALC III ReportKhronos TempusNessuna valutazione finora

- MCPP Series: Centrifugal Process PumpDocumento8 pagineMCPP Series: Centrifugal Process PumpOmar SunasaraNessuna valutazione finora

- The Outlook For The PAL ProcessDocumento14 pagineThe Outlook For The PAL ProcessGeorgi SavovNessuna valutazione finora

- EvapPond SizingDocumento2 pagineEvapPond Sizingtpgovind100% (1)

- Principal Types of Atmospheric Storage TanksDocumento9 paginePrincipal Types of Atmospheric Storage Tanksmohsen ranjbarNessuna valutazione finora

- Enhanced Gravity OWS Sizing SpreadsheetDocumento1 paginaEnhanced Gravity OWS Sizing Spreadsheetdeion29Nessuna valutazione finora

- Condensate Recovery and Return Systems Sdi / SDS: Data SheetDocumento4 pagineCondensate Recovery and Return Systems Sdi / SDS: Data Sheetqdod_waffiNessuna valutazione finora

- Emptying A TankDocumento8 pagineEmptying A Tanksydney augustNessuna valutazione finora

- NMDTM PhosphoricAcidDocumento10 pagineNMDTM PhosphoricAcidacas35Nessuna valutazione finora

- Brochure SuperSettlerDocumento8 pagineBrochure SuperSettlerJesús RiberaNessuna valutazione finora

- PumpingAndMixingSpecialistsForTheCPI en E10272Documento24 paginePumpingAndMixingSpecialistsForTheCPI en E10272Michael PiñaNessuna valutazione finora

- CHAPTER 8 Sizing and CostingDocumento20 pagineCHAPTER 8 Sizing and CostingNurul Amelia Mustaffa0% (1)

- Alfalaval Cip1800l and Cip2800l Pps00064enDocumento2 pagineAlfalaval Cip1800l and Cip2800l Pps00064engmatweakNessuna valutazione finora

- Design Calculations: Design Calculation For 97.5 M /HR WTP 1Documento6 pagineDesign Calculations: Design Calculation For 97.5 M /HR WTP 1JASON SANJAYNessuna valutazione finora

- Flow Characteristics:: B. Pressure Loss (Head Loss, PressureDocumento4 pagineFlow Characteristics:: B. Pressure Loss (Head Loss, PressureLily NurdianaNessuna valutazione finora

- Vetrolux Din 11851Documento1 paginaVetrolux Din 11851uptc1985Nessuna valutazione finora

- Steam Tracing 101Documento2 pagineSteam Tracing 101fawmer61100% (1)

- Lakasa Sand InterceptorDocumento1 paginaLakasa Sand InterceptorIswadi Bin ZulkarnainNessuna valutazione finora

- Guidelines For Sulfide Generation PDFDocumento24 pagineGuidelines For Sulfide Generation PDFnawajhaNessuna valutazione finora

- Book-Condensed Hydraulic PDFDocumento66 pagineBook-Condensed Hydraulic PDFbratkpNessuna valutazione finora

- Bernoulli Cyclon SeparatorDocumento4 pagineBernoulli Cyclon SeparatorMonk KongNessuna valutazione finora

- Sodium Bicarbonate For Flue Gas TreatmentDocumento12 pagineSodium Bicarbonate For Flue Gas Treatmentblabla21Nessuna valutazione finora

- Replacement Boiler Sizing Chart: Standing RadiationDocumento4 pagineReplacement Boiler Sizing Chart: Standing Radiationvivek mishraNessuna valutazione finora

- Deaeration Technique DT199505 - A01Documento3 pagineDeaeration Technique DT199505 - A01smallik3Nessuna valutazione finora

- Iso 13679 Connection Testing: Test DatasheetDocumento2 pagineIso 13679 Connection Testing: Test DatasheetMostafa HashemiNessuna valutazione finora

- Phosphate Hideout PDFDocumento4 paginePhosphate Hideout PDFAHMAD DZAKYNessuna valutazione finora

- Surge TankDocumento2 pagineSurge TankBilel MarkosNessuna valutazione finora

- PlumbingDocumento62 paginePlumbingAnonymous iTzCnMNessuna valutazione finora

- NorsonDocumento11 pagineNorsonPiyush A Joshi0% (1)

- New Microsoft PowerPoint PresentationDocumento19 pagineNew Microsoft PowerPoint PresentationYaSsin Saad100% (1)

- Cold Water Connection Point - 2Documento5 pagineCold Water Connection Point - 2Satya N.G100% (1)

- Cobriza S Cu Tailings Surface Stacking 1 (1) ..Documento19 pagineCobriza S Cu Tailings Surface Stacking 1 (1) ..julmaytaNessuna valutazione finora

- Advanced Engineering, Worldwide Facilities & Comprehensive Technical SupportDocumento12 pagineAdvanced Engineering, Worldwide Facilities & Comprehensive Technical SupportCenon MalabananNessuna valutazione finora

- Article Low Cost and Reliable Sulphur Recovery PDFDocumento4 pagineArticle Low Cost and Reliable Sulphur Recovery PDFpsnmurthy333Nessuna valutazione finora

- PumpLab Book 1 PreviewDocumento11 paginePumpLab Book 1 Previewcorey6Nessuna valutazione finora

- How To Prevent Caking in NPK Fertilizer Production ProcessDocumento2 pagineHow To Prevent Caking in NPK Fertilizer Production Processluna leNessuna valutazione finora

- Philippine National Standard For Petroleum Products & Other Fuel Related ProductsDocumento1 paginaPhilippine National Standard For Petroleum Products & Other Fuel Related ProductsRay RomeyNessuna valutazione finora

- Sodium Hypochlorite - Storage: Please Consult Our Safety Data SheetDocumento4 pagineSodium Hypochlorite - Storage: Please Consult Our Safety Data SheetIoana PopescuNessuna valutazione finora

- Torque Requirement For High Solid Centrifugal Sludge DewateringDocumento5 pagineTorque Requirement For High Solid Centrifugal Sludge DewateringArdyanto WijayaNessuna valutazione finora

- ALFA LAVAL - Spiral PDFDocumento8 pagineALFA LAVAL - Spiral PDFlaquetengoNessuna valutazione finora

- LASTlifting Pump PDSDocumento3 pagineLASTlifting Pump PDSsunii19847908Nessuna valutazione finora

- Sulfur Tank Case StudyDocumento18 pagineSulfur Tank Case StudyMajdi BelguithNessuna valutazione finora

- HazenDocumento4 pagineHazenAnthony MorganNessuna valutazione finora

- Hazen-Williams Equation - Calculating Head Loss in Water PipesDocumento8 pagineHazen-Williams Equation - Calculating Head Loss in Water PipesJonnah Faye MojaresNessuna valutazione finora

- My CalculationsDocumento39 pagineMy CalculationsWaqas Khan ChannarNessuna valutazione finora

- Hazen Williams FormulaDocumento1 paginaHazen Williams FormulaJR ZunigaNessuna valutazione finora

- Liquid Pipeline Hydraulics 24 PDFDocumento1 paginaLiquid Pipeline Hydraulics 24 PDFDaniel WigginsNessuna valutazione finora

- Hazen-Williams Equation: General Form Pipe EquationDocumento4 pagineHazen-Williams Equation: General Form Pipe EquationatokkuNessuna valutazione finora

- Minimum Pipe DiameterDocumento4 pagineMinimum Pipe DiameterNoor A QasimNessuna valutazione finora

- C ValueDocumento2 pagineC ValuePadmanabh Shetty0% (1)

- Hazen - Williams EquationDocumento3 pagineHazen - Williams EquationalisobohNessuna valutazione finora

- A Hee A HandbookDocumento140 pagineA Hee A HandbookAnonymous kkv6l965Nessuna valutazione finora

- Inverter Ducted UnitsDocumento2 pagineInverter Ducted UnitsAnonymous ynJByUsNessuna valutazione finora

- Kitchen Exhaust SchematicDocumento14 pagineKitchen Exhaust SchematiclkakeanNessuna valutazione finora

- Control Philisophy: 1. Ahu (Air Handling Unit)Documento2 pagineControl Philisophy: 1. Ahu (Air Handling Unit)Anonymous ynJByUsNessuna valutazione finora

- User's Handbook On Solar Water HeatersDocumento36 pagineUser's Handbook On Solar Water Heatersjose_alberto2Nessuna valutazione finora

- Heating Systems in Buildings - EnglishDocumento1 paginaHeating Systems in Buildings - EnglishAnonymous ynJByUsNessuna valutazione finora

- Fire Protection Engineering For BuildingsDocumento46 pagineFire Protection Engineering For BuildingsAnonymous ynJByUsNessuna valutazione finora

- Boiler Energy Audit ManualDocumento29 pagineBoiler Energy Audit ManualAnubhav100% (11)

- EMSDocumento169 pagineEMSAnonymous ynJByUsNessuna valutazione finora

- Wellness 01 2014 PDFDocumento29 pagineWellness 01 2014 PDFAnonymous ynJByUsNessuna valutazione finora

- Childers Insulation Products Selection GuideDocumento8 pagineChilders Insulation Products Selection GuideAnonymous ynJByUs0% (1)

- Calculate Swimming Pool Water Pump NeedsDocumento2 pagineCalculate Swimming Pool Water Pump NeedsAnonymous ynJByUsNessuna valutazione finora

- Epa Bum FullDocumento265 pagineEpa Bum FullAutif SayyedNessuna valutazione finora

- FCU Tag ListDocumento4 pagineFCU Tag ListAnonymous ynJByUsNessuna valutazione finora

- Dry & Wet Riser SystemsDocumento2 pagineDry & Wet Riser SystemsAnonymous ynJByUs100% (1)

- Man HourDocumento10 pagineMan HourAnonymous ynJByUsNessuna valutazione finora

- Fluid Power FormulasDocumento5 pagineFluid Power Formulassrinivas1973Nessuna valutazione finora

- BearingsDocumento33 pagineBearingsBrajendra Kumar100% (1)

- TU-91 2009 Accounting BasicsDocumento38 pagineTU-91 2009 Accounting BasicsGururaj NasaliNessuna valutazione finora

- How Do Sprinkler Heads WorkingDocumento7 pagineHow Do Sprinkler Heads WorkingAnonymous ynJByUsNessuna valutazione finora

- ASPEDocumento20 pagineASPEAnonymous ynJByUs100% (1)

- Man HourDocumento10 pagineMan HourAnonymous ynJByUsNessuna valutazione finora

- Safety Standards Eye ProtectionDocumento2 pagineSafety Standards Eye ProtectionAnonymous ynJByUsNessuna valutazione finora

- ConversionsDocumento1 paginaConversionsAnonymous ynJByUsNessuna valutazione finora

- Drip - IrrigationDocumento28 pagineDrip - IrrigationAnonymous ynJByUsNessuna valutazione finora

- Calgonpump@Hydropneumatic Tank SizingDocumento4 pagineCalgonpump@Hydropneumatic Tank Sizingcyong7788Nessuna valutazione finora

- Centrifugal PumpDocumento1 paginaCentrifugal PumpAnonymous ynJByUsNessuna valutazione finora

- Electrical Symbols Legend Abbreviations Legend: P U o R GDocumento5 pagineElectrical Symbols Legend Abbreviations Legend: P U o R GjorgeNessuna valutazione finora

- Economic Considerations For Tall Multi-Use BuildingsDocumento5 pagineEconomic Considerations For Tall Multi-Use BuildingsNasim AhmadNessuna valutazione finora

- American Standard Unified Inch Screw Thread Form DataDocumento2 pagineAmerican Standard Unified Inch Screw Thread Form DataVaibhav ShuklaNessuna valutazione finora

- 18 GJ04D1 6Documento40 pagine18 GJ04D1 6sil_muahdibNessuna valutazione finora

- HLX 5T TabancaDocumento137 pagineHLX 5T TabancaOzan SahinNessuna valutazione finora

- Insulation PDS & MSDS PDFDocumento11 pagineInsulation PDS & MSDS PDFsmartayaz1987Nessuna valutazione finora

- Jandy Heaters LXI ManualDocumento56 pagineJandy Heaters LXI ManuallunicyNessuna valutazione finora

- Company Profile - UpdatedDocumento48 pagineCompany Profile - Updatedorlando fiel jrNessuna valutazione finora

- Benoit Datasheet BTS-6 2+7-8 8.70 L-80Documento1 paginaBenoit Datasheet BTS-6 2+7-8 8.70 L-80emadabdelsattarNessuna valutazione finora

- ScaffoldingDocumento24 pagineScaffoldingAzrulZamriNessuna valutazione finora

- A Systematic Review of Waste Materials in Cement Base - 2022 - Journal of BuildiDocumento29 pagineA Systematic Review of Waste Materials in Cement Base - 2022 - Journal of BuildiAliNessuna valutazione finora

- Upheaval Buckling PipelineDocumento11 pagineUpheaval Buckling PipelineRYZKI EFENDI SIMANULANGNessuna valutazione finora

- Midas Civil - Efficient Design Process As Per Eurocode 3Documento32 pagineMidas Civil - Efficient Design Process As Per Eurocode 3faumijkNessuna valutazione finora

- Facom Catalog PricelistDocumento8 pagineFacom Catalog PricelistFa'izan HidayatNessuna valutazione finora

- Reliable DDX Grooved End Fully Assembled Deluge Valve Stations PDFDocumento11 pagineReliable DDX Grooved End Fully Assembled Deluge Valve Stations PDFSavy PhanethNessuna valutazione finora

- Curing in ConstructionDocumento7 pagineCuring in ConstructionNgissah NketiahNessuna valutazione finora

- DPC Serie Brochure enDocumento2 pagineDPC Serie Brochure enabdu taliaNessuna valutazione finora

- Advances in ASME Section VIII Division 2 Pressure Vessel Design and Analysis PDFDocumento10 pagineAdvances in ASME Section VIII Division 2 Pressure Vessel Design and Analysis PDFVitor Rigueira de GodoyNessuna valutazione finora

- Eton West Wing Residences at North Belton Communities Quezon CityDocumento20 pagineEton West Wing Residences at North Belton Communities Quezon CityEvelyn L. AguinaldoNessuna valutazione finora

- Bxuv U917Documento3 pagineBxuv U917JULIO ALBANessuna valutazione finora

- TERRAM For Pipeline and UtilitiesDocumento20 pagineTERRAM For Pipeline and Utilitiessaneela bibiNessuna valutazione finora

- Goud-Umashankar2018 Article InterfaceShearStrengthPropertiDocumento14 pagineGoud-Umashankar2018 Article InterfaceShearStrengthPropertiJPDGLNessuna valutazione finora

- Forced Draft Cooling Tower: Bachelor of TechnologyDocumento9 pagineForced Draft Cooling Tower: Bachelor of TechnologySanjay NgarNessuna valutazione finora

- Manual Small Canal Structures PDFDocumento458 pagineManual Small Canal Structures PDFCristian MaximilianoNessuna valutazione finora

- CM 652 - Construction Contract AdministrationDocumento4 pagineCM 652 - Construction Contract AdministrationAlvin VillanuevaNessuna valutazione finora

- Satip A 004 02Documento10 pagineSatip A 004 02mohammadNessuna valutazione finora

- Mechanical Services Particular SpecificationDocumento12 pagineMechanical Services Particular SpecificationAhmed Mohamed AliNessuna valutazione finora

- PSC Question Paper Civil PDFDocumento162 paginePSC Question Paper Civil PDFprasanthNessuna valutazione finora