Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ansiflo Ans Ansz Ansg Series

Caricato da

arietilangDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ansiflo Ans Ansz Ansg Series

Caricato da

arietilangCopyright:

Formati disponibili

DEEP BLUE PUMP CO.

part of the Akay Industries group

Chemical process pump

ANS, ANSZ, ANSG Series

Chemical Process Pump

According to ANSI/ASME standard

Capacity: ANS: up to 2000 m3/h, ANSG/ANSZ: 2~250 m3/h (50HZ)

ANS: up to 2400 m3/h, ANSG/ANSZ: 2.4~300 m3/h (60HZ)

Head:

ANS: up to 250 m, ANSG/ANSZ: up to 150 m (50HZ) ANS: up to 360 m, ANSG/ANSZ: up to 250 m (60HZ)

Pressure: ANS: 2.5MPa, ANSG/ANSZ: 2.0 MPa Temperature: ANS/ANSZ-40~+260 oC, ANSG-40 ~150 oC Application:

General chemical service handling liquids of medium temperature, natural or corrosive, clean or containing solid particles.

DEEP BLUE PUMP COMPANY part of the Akay Industries groep.

Website: www.deepbluepumps.com

Brochure vers.2009-1

DEEP BLUE PUMP CO.

part of the Akay Industries group

Chemical process pump

1 General

ANSI standard chemical process pumps, including ANS, ANSZ and ANSG series of pumps, are of horizontal, single stage, single suction centrifugal pumps. They meet the standard of ASME/ANSI B73.1M/B73.2M.Because of their unique durability, reliability and economy, the ANS pumps have become the new substitutive products in the field of general chemical process.

2 Application

ANS series of ANSI standard horizontal chemical process pumps are mainly applied in chemical service, paper and pulp, pharmaceutical, food and sugar, etc. They are handling liquids of medium temperature, natural or corrosive, clean or containing solid particles. ANSZ series of ANSI standard horizontal self-priming chemical process pumps are mainly applied in the services of flumes drawing and draining, tank cars unload, oil wastes transfer and spent acid collection, etc. ANSG series of ANSI standard vertical standard chemical inline pumps are mainly applied in water supply and drainage, pipeline boosting, petroleum and chemical industry.

5 Designation

ANS 100X80X250

Impeller Nominal Diameter Discharge Nozzle Diameter Suction Nozzle Diameter Pump Series Code ANS (Basic design) ANSZ (self-priming design) ANSG (In-line design)

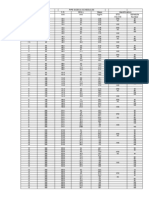

6 Performance Parameters

Nozzle size: 25~400 mm Capacity: ANS~2000 m3/h, ANSG/ANSZ2~250 m3/h (50HZ)

ANS:~2400 m3/h, ANSG/ANSZ2.4~300 m3/h (60HZ)

Head: Pressure:

ANS: ~250 m, ANSG/ANSZ: ~150 m (50HZ) ANS: ~360 m, ANSG/ANSZ: ~250 m (60HZ) ANS: ~2.5MPa, ANSG/ANSZ: ~2.0 MPa

Temperature: ANS/ANSZ-40~+260 oC, ANSG-40 ~150 oC

DEEP BLUE PUMP COMPANY part of the Akay Industries groep.

Website: www.deepbluepumps.com

Brochure vers.2009-1

DEEP BLUE PUMP CO.

7 ANS cross sectional drawing

1 2 3 4 5 6 7

part of the Akay Industries group

Chemical process pump

10

20

1 Casing 2 Impeller 3 Adaptor 4 Shaft

19

18

17

16

15

14

13

13 Bearing 14 Support 15 Water-cooled hose 16 Bearing cover

12

11

5 Bearing oil seal 6 Bearing 7 Slinger 8 Vent plug

9 Bearing retainer gland 10 Bearing housing 11 Bearing oil seal 12 Bearing box

17 Mechanical seal 18 Shaft sleeve 19 Casing cover 20 Casing wearing ring

8 ANSZ cross sectional drawing

1 2 3 4 5 6 7 8 9 10

20

1 Casing 2 Impeller 3 Shaft 4 Adaptor

19

18

17

16

15

.14

13

12

11

17 Shaft sleeve 18 Casing cover 19 Casing wearing ring 20 Cover

5 Bearing oil seal 6 Bearing 7 Slinger 8 Vent plug

9 Bearing retainer gland 10 Bearing housing 11 Bearing box 12 Bearing

13 Support 14 Draining plug 15 Bearing cover 16 Mechanical seal

DEEP BLUE PUMP COMPANY part of the Akay Industries groep.

Website: www.deepbluepumps.com

Brochure vers.2009-1

DEEP BLUE PUMP CO.

9 ANSG cross sectional drawing

10

part of the Akay Industries group

Chemical process pump

11 12

8 7

13

14 15

5 4

16

17

18

1 Casing 2 Casing cover 3 Adaptor 4 Bearing oil seal

5 Bearing housing 6 Grease retainer 7 Bearing 8 Oil refiller

9 Coupling 10 Motor pedestal 11 Bearing box 12 Lock nut

13 Shaft 14 Shaft sleeve 15 Lock bolt 16 Impeller

17 Casing wearing ring 18 Baseplate

10 Construction features

New hydraulic patterns

The efficiency and anti-cavitations ability are improved greatly.

Back Open Impeller

Axial thrusts are balanced as greatly as possible. The seal chamber pressure and thrust load can be predicted. As back open impeller, the casing cover is subject to wear. Seal chamber pressure and thrust load can be adjusted and set to original performance. The life of mechanical seal and bearing are extended. Because the critical tolerance locates between the impeller and casing cover, the mounting of impeller and seal can be conducted without casing mounted.

Casing cover

Available for various seal design of all the seal manufactory. Cooling/heating jackets are available as options for liquids under various operating conditions. They are recommended when the temperature is above 150 degree Celsius.

Impeller

Flange

Flanges can be fabricated according to the standard of ANSI, DIN, GB and so on.

DEEP BLUE PUMP COMPANY part of the Akay Industries groep.

Website: www.deepbluepumps.com

Brochure vers.2009-1

DEEP BLUE PUMP CO.

Construction features

Seal chamber and seal type

Available for soft packing, single mechanical seal, double mechanical seal and tandem mechanical seal. Also be configured as the type of balanced, unbalanced, cartridge and non-cartridge. Flow inducing bosses redirect flow from circumferential to axial, balanced flow with low-pressure drop in the chamber that helps keep solids in suspension, minimizing erosive characteristics of the process. They are helpful for purging of solids, vapor and heat from mechanical seals.

part of the Akay Industries group

Chemical process pump

Adaptor

With different material from bearing housing, the fractures of bearing housing can be avoid even when handling high corrosive liquids. Then stability and reliability of pump are improved.

Seal chamber

Bearing assembly

Being insulated from the exterior by bearing guard ring, bearings are prevented against being polluted and sprayed or spilled. The life of bearing assembly can be extended greatly. One inch diameter oil sight glass that is convenient to inspect is offered as well as constant level oiler that can add oil automatically. Applying the new type water-cooling hose, the cooling liquids are directly led through the lubricant oil to cool them. Not only the cooling effect is high, but also the lubricant oil space is saved. Optimized designs of rigid shaft have better deflection index, then the shaft vibration is reduced.

External axial adjustment

The clearance between impeller and casing cover can be adjusted exteriorly without External axial adjustment disassembling the pump. If bearing sand seals not requiring replacement, the maintenance process can be simplified. Casing Having two mounting types that are foot or centerline mounted, they can suit various liquids. When temperature is above 95 degree Celsiuscenterline mounted casing with supports being cooled is recommended. ANSZ pumps casings of self-priming type are integrated with priming chamber, gas-liquid separating chamber and suction channel. ANSG pumps suction and discharge nozzles are located in the same horizontal centerline. Pump and motor are connected by metallic flexible membrane coupling without spacer, the motor and bearing assembly can be removed without disturbing the casing and piping.

ANSZ Casing

ANSG Casing

DEEP BLUE PUMP COMPANY part of the Akay Industries groep.

Website: www.deepbluepumps.com

Brochure vers.2009-1

DEEP BLUE PUMP CO.

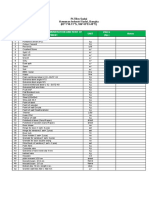

11 ANS performance range(50Hz)

part of the Akay Industries group

Chemical process pump

DEEP BLUE PUMP COMPANY part of the Akay Industries groep.

Website: www.deepbluepumps.com

Brochure vers.2009-1

DEEP BLUE PUMP CO.

part of the Akay Industries group

Chemical process pump

12 ANSZ, ANSG performance range (50 Hz) (the five biggest pump sizes not available for ANSZ)

DEEP BLUE PUMP COMPANY part of the Akay Industries groep.

Website: www.deepbluepumps.com

Brochure vers.2009-1

Potrebbero piacerti anche

- Handbook Flow Measurement PDFDocumento78 pagineHandbook Flow Measurement PDFarietilangNessuna valutazione finora

- AP-NozzleTutorial R01 PDFDocumento31 pagineAP-NozzleTutorial R01 PDFbalumagesh1979Nessuna valutazione finora

- Section C2: Outfall Construction and Design: Table of Attachments Item Title Map/Photo NoDocumento7 pagineSection C2: Outfall Construction and Design: Table of Attachments Item Title Map/Photo NoarietilangNessuna valutazione finora

- Mod1 PDFDocumento41 pagineMod1 PDFAhmad Budiman100% (2)

- Appendix T Route Selection Matrix PDFDocumento9 pagineAppendix T Route Selection Matrix PDFarietilangNessuna valutazione finora

- AGA Report 9 - USM, 2nd Edition, April 2007 PDFDocumento109 pagineAGA Report 9 - USM, 2nd Edition, April 2007 PDFAnderson Widmer Morales VillarrealNessuna valutazione finora

- Handbook Flow MeasurementDocumento78 pagineHandbook Flow MeasurementarietilangNessuna valutazione finora

- LINCOLN Kawat LasDocumento8 pagineLINCOLN Kawat LasarietilangNessuna valutazione finora

- Flow CalculatorDocumento45 pagineFlow CalculatorIndrajit BorikarNessuna valutazione finora

- HDPE InstallationDocumento12 pagineHDPE InstallationJohari A. KasimNessuna valutazione finora

- Plot Plan Flow Loop Test PDFDocumento1 paginaPlot Plan Flow Loop Test PDFarietilangNessuna valutazione finora

- Design of An Outfall Diffuser: Experiment 9Documento2 pagineDesign of An Outfall Diffuser: Experiment 9arietilangNessuna valutazione finora

- ArcelorMittal Offshore Structural Steel Stock ProgramDocumento12 pagineArcelorMittal Offshore Structural Steel Stock ProgramCemil GüneşNessuna valutazione finora

- WOM Subsea Brochure 8Documento40 pagineWOM Subsea Brochure 8arietilangNessuna valutazione finora

- 29-Horizontal Subsea Xmas Tree en PDFDocumento2 pagine29-Horizontal Subsea Xmas Tree en PDFarietilangNessuna valutazione finora

- ESDVDocumento48 pagineESDVPipitlyNessuna valutazione finora

- Appendix T Route Selection Matrix PDFDocumento9 pagineAppendix T Route Selection Matrix PDFarietilangNessuna valutazione finora

- MGP CPCN Vol3 Set 3 SDocumento44 pagineMGP CPCN Vol3 Set 3 SarietilangNessuna valutazione finora

- Ultrasonic Scanning Report: Client: Description: Location: Serial/Tag No: Date of TestDocumento3 pagineUltrasonic Scanning Report: Client: Description: Location: Serial/Tag No: Date of TestarietilangNessuna valutazione finora

- Instrument IndexDocumento4 pagineInstrument IndexarietilangNessuna valutazione finora

- Pressure Drop in Water PipesDocumento1 paginaPressure Drop in Water PipesarietilangNessuna valutazione finora

- Holding Time Pressure ChartDocumento3 pagineHolding Time Pressure ChartarietilangNessuna valutazione finora

- MTO Instrument CSRMDocumento14 pagineMTO Instrument CSRMarietilangNessuna valutazione finora

- Pipe Sizes and ScheduleDocumento2 paginePipe Sizes and Schedulechupacid0% (1)

- CL INS DTS 016 Cover Gas MeteringDocumento2 pagineCL INS DTS 016 Cover Gas MeteringarietilangNessuna valutazione finora

- Instrument Index and Io List Worksheet1Documento5 pagineInstrument Index and Io List Worksheet1arietilang100% (2)

- Geothermal Facility Reliability and Integrity Engineering Services Contract in Salak and Drajat Area Operation CONTRACT No: CW1005676Documento1 paginaGeothermal Facility Reliability and Integrity Engineering Services Contract in Salak and Drajat Area Operation CONTRACT No: CW1005676arietilangNessuna valutazione finora

- ABS Guide For Offshore InstallationsDocumento332 pagineABS Guide For Offshore InstallationsDang Dinh ChiNessuna valutazione finora

- 2007 Catalog WebDocumento5 pagine2007 Catalog WebarietilangNessuna valutazione finora

- Part A: Piping Fundamentals: Honors List Preface How To Use This HandbookDocumento5 paginePart A: Piping Fundamentals: Honors List Preface How To Use This HandbooknamasralNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Comparative Evaluation of The Mechanical Properties of Three Commercially Available Flexible Denture Base Materials - An in Vitro StudyDocumento132 pagineComparative Evaluation of The Mechanical Properties of Three Commercially Available Flexible Denture Base Materials - An in Vitro StudySkAliHassanNessuna valutazione finora

- Guidelines For Performance Based Seismic Design of Tall Building (PEER, 2017) )Documento148 pagineGuidelines For Performance Based Seismic Design of Tall Building (PEER, 2017) )Subash Bastola100% (1)

- DIY Solar Heater - Top 20 Tips How To Build and Use A Solar Air HeaterDocumento33 pagineDIY Solar Heater - Top 20 Tips How To Build and Use A Solar Air HeaterArsen Vidaković100% (1)

- 3 Flexure.6278.1598780738.8088 PDFDocumento79 pagine3 Flexure.6278.1598780738.8088 PDFpattrapong pongpattraNessuna valutazione finora

- Viscoplastic Model LS-DynaDocumento14 pagineViscoplastic Model LS-DynaJoe SatchNessuna valutazione finora

- Basic Price Inquiry-Kawasan Industri Sadai-BangkaDocumento4 pagineBasic Price Inquiry-Kawasan Industri Sadai-BangkaghmNessuna valutazione finora

- Australian Standard: Conveyor Belting-Textile ReinforcedDocumento7 pagineAustralian Standard: Conveyor Belting-Textile Reinforcedbashok20Nessuna valutazione finora

- Manual de InstalacionDocumento72 pagineManual de InstalacionRafael Centeno SantanaNessuna valutazione finora

- Socket Weld LateralDocumento1 paginaSocket Weld LateralEHT pipeNessuna valutazione finora

- Planning, Analysis and Designing of Residential Building (G+1)Documento8 paginePlanning, Analysis and Designing of Residential Building (G+1)Rob StenNessuna valutazione finora

- Structural Calculations and Analysis: Proposed 2-Storey Residential HouseDocumento39 pagineStructural Calculations and Analysis: Proposed 2-Storey Residential HouseGrace LagnayoNessuna valutazione finora

- Dhajji HouseDocumento5 pagineDhajji HouseTejesh NanawareNessuna valutazione finora

- Brush BondDocumento4 pagineBrush BondGibbs PerNessuna valutazione finora

- Tutorial 4: Transformation of Stresses (Use of Mohr's Circle)Documento3 pagineTutorial 4: Transformation of Stresses (Use of Mohr's Circle)Thilina RathnayakeNessuna valutazione finora

- Degradation of Insulating Materials of TransformerDocumento6 pagineDegradation of Insulating Materials of TransformerPaulomario RemuzgoNessuna valutazione finora

- PDF Din 976 - CompressDocumento7 paginePDF Din 976 - CompresskrisNessuna valutazione finora

- ASTM D 256-06ae1Documento20 pagineASTM D 256-06ae1Laboratório MateriaisNessuna valutazione finora

- Jmu 3001 - e 1Documento1 paginaJmu 3001 - e 1vrajakisoriDasiNessuna valutazione finora

- Tender No.: 21/Bvn/ Box Culvert/2018 (Re Invite)Documento77 pagineTender No.: 21/Bvn/ Box Culvert/2018 (Re Invite)raj kumarNessuna valutazione finora

- Outdoor Voltage Transformer: Type VOG-24Documento4 pagineOutdoor Voltage Transformer: Type VOG-24dfsgsdf df3tegdfgNessuna valutazione finora

- RCC Slab Design by ACI Coefficient Method DDocumento21 pagineRCC Slab Design by ACI Coefficient Method Dmohammed samiNessuna valutazione finora

- Design and Drawing of RC Structures: Dr. G.S.SureshDocumento40 pagineDesign and Drawing of RC Structures: Dr. G.S.SureshKanhaiya BhagatNessuna valutazione finora

- KA20903 - Lecture 1 Introduction To Mechanics of SolidsDocumento6 pagineKA20903 - Lecture 1 Introduction To Mechanics of SolidsKit Meng LimNessuna valutazione finora

- Akrylika PDFDocumento2 pagineAkrylika PDFDimos ApostolouNessuna valutazione finora

- Design Guidelines On Residential UnitsDocumento19 pagineDesign Guidelines On Residential Unitspriyasankar7Nessuna valutazione finora

- Industrial Training Project ProposalDocumento14 pagineIndustrial Training Project ProposalHafizWahidNessuna valutazione finora

- Fire Water Pumps Pre Commissioning Checklist.Documento4 pagineFire Water Pumps Pre Commissioning Checklist.Midha NeerNessuna valutazione finora

- Mos Cabin R1Documento13 pagineMos Cabin R1Mohd Farmi Izudin Che Ros100% (1)

- Broen Butterfly Valves v9Documento13 pagineBroen Butterfly Valves v9bojanmileticNessuna valutazione finora

- Curriculum Vitae Syed Sarmad Hussain Rizvi PDFDocumento2 pagineCurriculum Vitae Syed Sarmad Hussain Rizvi PDFSyed Muhammad Sarmad Husain RizviNessuna valutazione finora