Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mini Rice Mill

Caricato da

Shubham PandeyDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mini Rice Mill

Caricato da

Shubham PandeyCopyright:

Formati disponibili

MINI RICE MILL

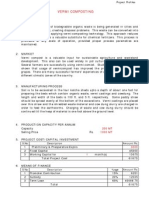

1. INTRODUCTION India is the second largest producer of rice in the world. The major portion of the paddy is being processed through hullers. The hullers are usually low capacity mills. In these hullers, both shelling and polishing operations are carried out simultaneously. Hence, there is no control on the polishing of rice, bran adn a higher breakage of rice occurs. To overcome all these a mini rice mill was designed to meet the needs of the villagers and a substitute for a huller mill, to get polished rice, rice bran and paddy husk. 2. MARKET Rice being the staple food of majority population, no problem is envisaged in arketing. Besides, the mill can be utilised as a service unit for custom milling. It also noticed the tribals are going for long distance to convert paddy to rice for domestic consumption. Thus, there exists demand for non-trading rice mill in some important centres. 3. MANUFACTURING PROCESS The mini rice mill consists of a paddy cleaner, sheller, separator and a polisher. The most important feature of the mill is that the shelling and polishing are kept separate. Because of the low capacity, a centrifugal sheller is most commonly employed. Different units could be used as polisher. For maximum advantage, it is necessary also to use a paddy separator, whereby need of a high polish can be avoided thus avoiding unnecessary loss of rice 4. PRODUCTION CAPACITY PER ANNUM Sale of rice, husk, bran 5. PROJECT COST/CAPITAL INVESTMENT S.No. 1) 2) 3)

Description Amount Rs.

Rs. 1600000 per annum

Fixed Capital Working Capital for 1 month(s) Preliminary & Preoperative Expanse Total Project Cost

450000 109700 5000 564700

6. MEANS OF FINANCE S.No 1 2 3

Description %age Amount Rs.

Promoter Contribution Subsidy/Soft Loan Term Loan Total

15% 20% 65%

84705 112940 367055 564700

7. FINANCIAL ASPECTS A. FIXED CAPITAL i. Land and Buildings Land Buildings ii. Machinery and Equipment S.No Description 1 Total plant and machinery Total B. WORKING CAPITAL i. Salaries & Wages (per month) S.No 1 2 3

Description Nos Sal/mon. Amount Rs.

Rs.50000 Rs. 200000

Qty. LS

Rate

Amount Rs.

200000 200000

Supervisor/Entrepreneur Skilled worker Unskilled worker Total

1 1 1

2500 2000 1500

2500 2000 1500 6000

ii.

Raw Material (per month) S.No Description 1 Paddy tons Total

Unit Qty. Rate Amount Rs.

LS

100000 100000

iii.

Utilities (per month) S.No Description 1 Power 2 Water Total

Unit Amount Rs.

LS LS

1000 200 1200

iv. S.No. 1) 2) 3) 4) 5)

Other Expenses (per month)

Description Amount Rs.

Postage, Telephones & Stationery Expenses Transportation & Conveyance Expenses Consumeble Stores Reparis and Maintenance Expenses Miscellaneous Expenses Total Total Working Capital (per month)

Description

200 1000 300 500 500 2500

V. S.No. 1) 2) 3) 4)

Amount Rs.

Salaries and Wages Raw Material Utilities Other Expenses Total

6000 100000 1200 2500 109700

8. COST OF PRODUCTION (PER ANNUM) S.No. Description 1) Total Working Capital 2) Depreciation - Buildings 5% - Plant and machinery 15% 3) Interest on term loan @ 12% Total 9. TURNOVER (PER YEAR) S.No Description 1 Sale of rice, husk, bran Total

Qty. Rate Amount Rs. Amount Rs.

1316400 10000 30000 44047 1400447

LS

1600000

1600000 1600000

10.FIXED COST (PER YEAR) S.No. Description 1) Depreciation 2) Interest

Amount Rs.

40000 44047

3) 4)

Salaries & Wages @ 40% Other Expenses incl. Utilities @ 40% Total

28800 17760 130607

11.PROFIT ANALYSIS & RATIOS 1 2 3 4 Net Profit Percentage of Profit on Sales Percentage of Return on Investment Break Even Point Rs. 199553 12% 35% 40%

Potrebbero piacerti anche

- Flour Mill UnitDocumento4 pagineFlour Mill UnitKrishnamoorthy SureshNessuna valutazione finora

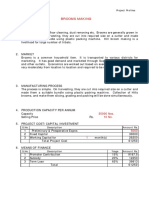

- Vermi Composting: Nsic Project ProfilesDocumento4 pagineVermi Composting: Nsic Project Profilesdrumil_kananiNessuna valutazione finora

- 16 Jaggery From SugarcaneDocumento8 pagine16 Jaggery From Sugarcanekiran_wakchaureNessuna valutazione finora

- Tamarind Paste MakingDocumento3 pagineTamarind Paste MakingRakesh KondaveetiNessuna valutazione finora

- 10 Pigeon Pea ProcessingDocumento8 pagine10 Pigeon Pea ProcessingPaneendra KumarNessuna valutazione finora

- Hawai ChappalsDocumento3 pagineHawai ChappalsvambuNessuna valutazione finora

- Potato Banana Wafers: Nsic Project ProfilesDocumento4 paginePotato Banana Wafers: Nsic Project ProfilesRaju SarellaNessuna valutazione finora

- Mini Dal MillDocumento4 pagineMini Dal MillLitesh MahakalkarNessuna valutazione finora

- Business Model For Tasty ChikkiesDocumento9 pagineBusiness Model For Tasty Chikkiesvenurao dindi100% (1)

- Adda Leaf PlatesDocumento5 pagineAdda Leaf PlatesSenkatuuka LukeNessuna valutazione finora

- Papad MFGDocumento8 paginePapad MFGFarhat DurraniNessuna valutazione finora

- 09 Peanut Processing PDFDocumento8 pagine09 Peanut Processing PDFkalaamolNessuna valutazione finora

- Mini Flour Mill KarnalDocumento9 pagineMini Flour Mill KarnalAnand Kishore100% (2)

- Cattle Feed PDFDocumento6 pagineCattle Feed PDFRangasamyNessuna valutazione finora

- Fruit SquashDocumento9 pagineFruit SquashGanesh DarsipudiNessuna valutazione finora

- Coir Pith Block Making UnitDocumento3 pagineCoir Pith Block Making UnitMohan RajNessuna valutazione finora

- Maize PpopcornDocumento7 pagineMaize PpopcornFarhat DurraniNessuna valutazione finora

- Milled Maize ProductDocumento7 pagineMilled Maize ProductFarhat DurraniNessuna valutazione finora

- Cold Storage Project ProfileDocumento19 pagineCold Storage Project ProfileSachin BandariNessuna valutazione finora

- Papad NamkeenDocumento9 paginePapad NamkeenSneha Dudhe YadavNessuna valutazione finora

- Desiccated CoconutDocumento8 pagineDesiccated CoconutYohanes Slamet WidodoNessuna valutazione finora

- Project Report of Soya FlourDocumento8 pagineProject Report of Soya FlourAkhilesh KumarNessuna valutazione finora

- Soya Flour Mill ProjectDocumento8 pagineSoya Flour Mill ProjectAkhilesh Kumar100% (2)

- Mini Wheat Flour MillDocumento5 pagineMini Wheat Flour Millstalinkbc2847Nessuna valutazione finora

- PMEGPDocumento260 paginePMEGPsuryanathNessuna valutazione finora

- Rice FlakesDocumento9 pagineRice FlakesAkhil PittyNessuna valutazione finora

- Clay Bricks ManufacturingDocumento3 pagineClay Bricks Manufacturingdownload0178Nessuna valutazione finora

- Extruded Puffed SnacksDocumento8 pagineExtruded Puffed SnacksAjay ChaudharyNessuna valutazione finora

- 18 Icecream Cones MFGDocumento12 pagine18 Icecream Cones MFGSunil ShawNessuna valutazione finora

- Agricultural Implements: Nsic Project ProfilesDocumento3 pagineAgricultural Implements: Nsic Project ProfilesJames WoodNessuna valutazione finora

- Brooms MakingDocumento3 pagineBrooms MakingGohilaRajNessuna valutazione finora

- Oil MillDocumento8 pagineOil Millmanish.eer2394Nessuna valutazione finora

- Soya SauceDocumento8 pagineSoya Sauceizaru24Nessuna valutazione finora

- Project Profile On Mini Flour Mill: Prod U CTDocumento11 pagineProject Profile On Mini Flour Mill: Prod U CTSunil ShawNessuna valutazione finora

- Shamp PapadDocumento5 pagineShamp PapadRaj GiriNessuna valutazione finora

- Oil Mill: Nsic Project ProfilesDocumento3 pagineOil Mill: Nsic Project ProfilesSachin KharechaNessuna valutazione finora

- 11 PohaDocumento8 pagine11 PohapritamrbhadadeNessuna valutazione finora

- Jute and Mestha ProductsDocumento4 pagineJute and Mestha ProductsJahangir Hossain ChowdhuryNessuna valutazione finora

- Project of Rexin BagDocumento11 pagineProject of Rexin BagShayan Pitruja100% (1)

- Card Board Boxes: Apitco Project ProfilesDocumento3 pagineCard Board Boxes: Apitco Project ProfilesDurga PrasadNessuna valutazione finora

- Mango Jelly NSIC ProjectDocumento3 pagineMango Jelly NSIC ProjectAnonymous EAineTizNessuna valutazione finora

- Rice Mill ProjectDocumento24 pagineRice Mill Projectbull88% (8)

- Garlic & Ginger Paste Project ProfilesDocumento7 pagineGarlic & Ginger Paste Project ProfilesArshad SheikNessuna valutazione finora

- Ground and Processed Spices and Cereals Project ReportDocumento5 pagineGround and Processed Spices and Cereals Project ReportGirish DaryananiNessuna valutazione finora

- Improving Rice Production and Commercialization in Cambodia: Findings from a Farm Investment Climate AssessmentDa EverandImproving Rice Production and Commercialization in Cambodia: Findings from a Farm Investment Climate AssessmentValutazione: 5 su 5 stelle5/5 (1)

- Farm Machinery and Equipment : Improving Productivity in the FieldDa EverandFarm Machinery and Equipment : Improving Productivity in the FieldNessuna valutazione finora

- Cambodia Agriculture, Natural Resources, and Rural Development Sector Assessment, Strategy, and Road MapDa EverandCambodia Agriculture, Natural Resources, and Rural Development Sector Assessment, Strategy, and Road MapNessuna valutazione finora

- Industrial Water Resource Management: Challenges and Opportunities for Corporate Water StewardshipDa EverandIndustrial Water Resource Management: Challenges and Opportunities for Corporate Water StewardshipNessuna valutazione finora

- Lao People’s Democratic Republic: Agriculture, Natural Resources, and Rural Development Sector Assessment, Strategy, and Road MapDa EverandLao People’s Democratic Republic: Agriculture, Natural Resources, and Rural Development Sector Assessment, Strategy, and Road MapNessuna valutazione finora

- New Theory and Practice of Capitalism: New Market Theory, Investment, and the Path to End the Global Economic CrisisDa EverandNew Theory and Practice of Capitalism: New Market Theory, Investment, and the Path to End the Global Economic CrisisNessuna valutazione finora

- Azerbaijan: Moving Toward More Diversified, Resilient, and Inclusive DevelopmentDa EverandAzerbaijan: Moving Toward More Diversified, Resilient, and Inclusive DevelopmentNessuna valutazione finora

- Promoting Investment in Agriculture for Increased Production and ProductivityDa EverandPromoting Investment in Agriculture for Increased Production and ProductivityNessuna valutazione finora

- Informal Services in Asian Cities: Lessons for Urban Planning and Management from the Covid-19 PandemicDa EverandInformal Services in Asian Cities: Lessons for Urban Planning and Management from the Covid-19 PandemicNessuna valutazione finora

- Technological Trends in Water Sector for a Sustainable SolutionDa EverandTechnological Trends in Water Sector for a Sustainable SolutionNessuna valutazione finora

- The State of Food and Agriculture 2017. Leveraging Food Systems for Inclusive Rural TransformationDa EverandThe State of Food and Agriculture 2017. Leveraging Food Systems for Inclusive Rural TransformationNessuna valutazione finora

- Remote Farming : Harnessing Automation and Robotics in AgricultureDa EverandRemote Farming : Harnessing Automation and Robotics in AgricultureNessuna valutazione finora

- VanGalder RouteFlyerDocumento2 pagineVanGalder RouteFlyerblazeNessuna valutazione finora

- Purchase Order PDFDocumento1 paginaPurchase Order PDFAli RazaNessuna valutazione finora

- Banking Law Syllabus Atty VeraDocumento2 pagineBanking Law Syllabus Atty VeraLawrence Villamar100% (1)

- Open Electricity Economics - 3. The Cost of Electricity PDFDocumento13 pagineOpen Electricity Economics - 3. The Cost of Electricity PDFfaheemshelotNessuna valutazione finora

- United Way Michigan ALICE ReportDocumento250 pagineUnited Way Michigan ALICE ReportWDET 101.9 FMNessuna valutazione finora

- Marketing Assignment On MarutiDocumento7 pagineMarketing Assignment On MarutiSumit SinhaNessuna valutazione finora

- SCP APPLIED ECONOMICS LessonDocumento6 pagineSCP APPLIED ECONOMICS LessonCamille Flor MagdasalNessuna valutazione finora

- 1923 Baragwanath The Ballarat Goldfield, Memoir 14 - pt-2Documento143 pagine1923 Baragwanath The Ballarat Goldfield, Memoir 14 - pt-2Yuri Vladimir Ordonez LamaNessuna valutazione finora

- Chapter 1 Microeconomics For Managers Winter 2013Documento34 pagineChapter 1 Microeconomics For Managers Winter 2013Jessica Danforth GalvezNessuna valutazione finora

- Air India Analyst ReportDocumento14 pagineAir India Analyst ReportRicha100% (1)

- Microfinance & Rural Banking Conventional and IslamicDocumento20 pagineMicrofinance & Rural Banking Conventional and IslamicIstiaqueNessuna valutazione finora

- Environmental Management Systems (EMS) : Components of An EMSDocumento7 pagineEnvironmental Management Systems (EMS) : Components of An EMSBhaskar RoychoudhuriNessuna valutazione finora

- Inside Job TermsDocumento8 pagineInside Job TermsKavita SinghNessuna valutazione finora

- MCQ Dcs 3Documento7 pagineMCQ Dcs 3Christopher JakeNessuna valutazione finora

- ReportDocumento10 pagineReportNeeraj KishoreNessuna valutazione finora

- CPP Form (New License)Documento4 pagineCPP Form (New License)Kopil uddin NishanNessuna valutazione finora

- Tahsildar Income CertificateDocumento1 paginaTahsildar Income CertificateSandeep Kumar100% (1)

- 17 CIR v. Tours SpecialistsDocumento3 pagine17 CIR v. Tours SpecialistsChedeng KumaNessuna valutazione finora

- Bing SummaryDocumento3 pagineBing SummarySanta PermatasariNessuna valutazione finora

- IssuesDocumento30 pagineIssuesJessy BascoNessuna valutazione finora

- Entrepreneurship and The EconomyDocumento15 pagineEntrepreneurship and The EconomyDennis ValdezNessuna valutazione finora

- Indian Stock MarketDocumento60 pagineIndian Stock Marketmokshasinchana100% (1)

- Kay Venteicher-Shulman Commented 2Documento11 pagineKay Venteicher-Shulman Commented 2api-238107999Nessuna valutazione finora

- 2019 - ACA Exam Dates and Deadlines - WebDocumento2 pagine2019 - ACA Exam Dates and Deadlines - WebSree Mathi SuntheriNessuna valutazione finora

- Arrow and The Apparel IndustryDocumento6 pagineArrow and The Apparel IndustryShikha Prakash0% (1)

- Pablo Design Link Lamp Press ReleaseDocumento2 paginePablo Design Link Lamp Press Releasewww.everything4less.comNessuna valutazione finora

- Farewell Address WorksheetDocumento3 pagineFarewell Address Worksheetapi-261464658Nessuna valutazione finora

- Digested CasesDocumento36 pagineDigested CasesJepoy Nisperos ReyesNessuna valutazione finora

- Ecl Annual Report 2018-19Documento208 pagineEcl Annual Report 2018-19Rohit VishwasNessuna valutazione finora