Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Vibrofloatation

Caricato da

SelvemCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Vibrofloatation

Caricato da

SelvemCopyright:

Formati disponibili

Vibratory deep compaction of hydraulic fills

Le compactage vibratorie des remblais hydrauliques

A. Gkalp, R.Dzceer

Kasktas A.S., Istanbul, Turkev, alpgokalpsuperonline.com

KEYWORDS: Hydraulic fill, vibro compaction, vibroflotation, CPT, compaction energy

ABSTRACT: This case history describes the compaction of loose hydraulic sand fills by

vibroflotation method. A total of 1,034,000 m

3

of hydraulic fills covering an area of 181,000 m

2

were

vibro compacted to a minimum relative density of 70 as of February 2003. The physical properties

of the hydraulic fills and the details of the vibro compaction works are presented and the results of the

quality control tests are discussed.

RESUME: Le compactage par la methode de vibroflottation des remblais hydrauliques en sable lches

est decrit dans cet article. Jusqu` a Fevrier 2003, un volume total de 1,034,000 m

3

de remlai couvrant

une superficie de 181,000 m

2

a ete compacte par cette methode, a une densite relative minimale

prescrite de 70. Les proprietes physiques des materiaux de remblai et les details des travaux de

compactage ainsi que les resultats des essais de contrle de la qualite du compactage sont discutes.

1 INTRODUCTION

The proposed port, which is situated on the east cost of the Mediterranea n Sea has been under

operation since 1965. Due to the development of the maritime transport methods and port facilities in

the recent years, a development plan was required to meet future traffic demands.

The development works consist of the extension of the main breakwater by 1,150 m, 1,700 m long

new general cargo and container quays for the handling of containers, a development of the port`s

hinderland, 2,600,000 m

3

of dredging works and 1,300,000 m

3

of vibro compaction works.

Only the general information of the dredging works, the characteristics of the hydraulic fill and the

operational details of the vibro compaction works including the quality control program pursued in the

project are discussed in this paper because of the length restriction.

2 SOIL INVESTIGATIONS & SUBSOIL CONDITIONS

A comprehensive soil investigation programme was implemented at the proposed site. A total of 13

cone penetration tests (CPT) and a total of 65 borings, with standard penetration tests (SPT), in the

range of 28 m to 100 m, sampling of disturbed and undisturbed samples and laboratory tests (grain

size and hydrometer analyses, atterberg limits, consolidation tests, CU triaxial tests) were carried out.

In 1998 an additional soil investigation including a series of 20 vibrocore tests with sampling of

Proc. XIII ECSMGE, Vanek et al. (eds). GtS, Prague, ISBN 80-86769-00-3, (Vol. 1)

Main Session 1 "Man-made deposits - recent and ancient" 107

underwater soil and 10 electric cone penetration tests were also conducted in order to obtain

additional information on the pyhsical properties of material to be dredged and the upper soil layers.

On the basis of the soil investigations, sandy layers have been encountered within the quays area.

These sandy layers contain fines content between 2 to 10 percent, classified as poorly graded sand

(SP) and poorly graded sand with silt (SP-SM). The sandy material consist of 0.4 to 5.6 of gravel,

92.2 to 95.1 of sand and 1.9 to 7.5 of silty and clayey materials. The minimum and maximum

dry densities of the sand fill vary between 12.40 to 14.30 kN/m

3

and 16.20 to 17.73 kN/m

3

respectively. The coefficient of uniformity, C

u

is between 1.5 and 25 and the mean grain size D

50

ranges from 0.13 mm to 0.38 mm.

Figure 1. Site Plan

3 DREDGING WORKS & THE CHARACTERISTICS OF THE HYDRAULIC FILL

Based on the results of the vibrocore and electric cone penetration t ests carried out in 1998-99, the

dredged sandy material was approved to be used as hydraulic fill material. The dredging works were

mainly performed in the area defined by the Existing Quay 22 and 23, the future Quays 21, 22, 23 and

the turning circle to a level of -14.0 m; in the manoeuvring area limited by the Main Breakwater

extension, Quay 24 and the basin to a level of -15.0 m; and the new entrance channel of the port to a

level of -16.0 m.

A Cutter Suction Dredger was selected as the most suitable equi pment for execution of the

dredging works since the dredged material was dumped into the quay reclamation areas. The dredged

materials were pumped throughout floating and land based pipelines to the reclamation areas.

Pipelines and water outlets were insta lled in several points of the fill areas to provide the adequate

settlement of sand and permit silty and clayey material to run off the reclamation areas. A Trailing

N

SCALE

200m 100 0

LEE BREAKW

ATER

1B

1A

1

2 3

4

5

Q

U

A

Y

2

2

QUAY 21

QUAY 23

Q

U

A

Y

2

4

7 7A

6

8A

8

M

A

I

N

B

R

E

A

K

W

A

T

E

R

M

A

I

N

B

R

E

A

K

W

A

T

E

R

E

X

T

E

N

S

I

O

N

Proc. XIII ECSMGE, Vanek et al. (eds). GtS, Prague, ISBN 80-86769-00-3, (Vol. 1)

Main Session 1 "Man-made deposits - recent and ancient" 108

Suction Hopper Dredger was used for dredging unsuitable and surplus material and disposal into the

open sea.

Sand for hydraulic fill was controlled by obtaining five samples of the dredged material for each

20,000 m

3

of fill material. Sieve analysis tests according to the ASTM E -11 were performed on those

selected samples and the dredged fill materials complying with the following criteria were defined as

suitable for hydraulic fill.

S Percent by weight passing ASTM sieve no.200 : maximum 10

S D

50

: 0.13 0.50 mm

S Percent by weight passing the 5 opening ASTM sieve : 100

The results of sieve analysis are shown in Figure 2., where each line corresponds to the average of

the five sieve tests performed on samples taken from the fill. The average of the coefficient of

uniformity, C

u

and the coefficient of curvature, C

z

of the fill material vary from 2.70 to 4.30 and 0.52

to 1.20 respectively. The suitability number (S

N

) was calculated using the formula suggested by

Brown (1977). The suitability number (S

N

) calculated ranges from 11.7 to 23.8, with an average of

19.5 which means that the hydraulic fil l material is Good to Fair as a hydraulic fill material.

0

10

20

30

40

50

60

70

80

90

100

0,001 0,01 0,1 1 10

Particle Size (mm)

C

u

m

u

l

a

t

i

v

e

p

e

r

c

e

n

t

a

g

e

p

a

s

s

i

n

g

(

)

Figure 2. The results of sieve analysis tests performed on samples taken from the hydraulic fill

4 VIBRO COMPACTION WORKS

Since the predicted settlements for the fou ndations of the various structures and container storage

areas are not tolerable and the risk of liquefaction is high, the loose hydraulic sand fills whose

thickness varies from 3.0 m to 12.0 m are implemented to be vibro compacted by vibrofloatation

method to a minimum relative density of 70 down to a depth of 1 m below the existing seabed

level.

A 100 kW vibratory probe, having a maximum operating speed of 3000 rpm (50Hz) with a

corresponding maximum centrifugal force of 400 kN was selected for the vib ro compaction works. In

October 2001, a test area of 1,000 m

2

prepared at Zone 8 was vibro compacted. Installations were

carried out with an equilateral triangular grid having a triangular side of 2.5 m and a compaction

energy of min. 750 KJoule per meter was applied to the hydraulic fill.

Proc. XIII ECSMGE, Vanek et al. (eds). GtS, Prague, ISBN 80-86769-00-3, (Vol. 1)

Main Session 1 "Man-made deposits - recent and ancient" 109

After the treatment two sets of three CPT tests each, located at the mid (C -8 & C-12) and quarter

(C-9 & C-11) of one of the triangular grid sides and at its centroid (C -6 & C-10) were carried out four

days upon compl etion. The construction specification required that after compaction minimum D

R

of

70, 75 and 85 of the hydraulic fill are to be achieved at the centroid of the triangular grid, the

mid and quarter of one of the triangular grid sides respectively. The c orresponding curves of q

c

along

the vertical beneath a certain point for the required value of D

R

were calculated, based on the

following relationship (Jamiolkowski, 1985). See equation (1). The average and standard deviation of

the q

c

values along the depth of a certain point obtained from CPT tests were calculated and compared

with the minimum required D

R

Criteria after q

c

values were normalized by the in situ state of stress.

Since the results of the CPTs performed after the treatment were in good confor mity with the

compaction criteria, the method of statement used in the installations of the preliminary test was

approved as the operational parameters.

( 1 )

5 QUALITY CONTROL TESTS

A strict quality control and quality assurance program pursued in the project, implemented the static

cone penetration test with pore pressure measurement (CPTU) as a primary quality control. Each

CPTU is carried out for every 1,600 m

2

of vibro-compacted area in order to verify compliance with

the specified compaction criteria. Thus as of February, 2003 a total of one hundred fourteen CPTU

tests were performed by an independent laboratory. (Table 1) Based on the test results it was not only

concluded that the average relative density of the compacted h ydraulic fill successfully exceeded the

specified minimum relative density of 70 , but also revealed that the measured density values are in

conformity with the values obtained for similar soil conditions.

Table 1. Results of quality control tests as of February 2003

Quay No Zone No Completed Area Completed Volume CPTs Performed

Zone-8 63,000 m

2

268,640 m

3

37 no.

Zone-8A 58,400 m

2

394,560 m

3

30 no.

Zone-6 14,600 m

2

112,550 m

3

7 no.

Zone-7 3,500 m

2

37,050 m

3

6 no.

23

Zone-7A 10,000 m

2

91,205 m

3

16 no.

Zone-3 3,300 m

2

15,250 m

3

1 no.

Zone-2 14,500 m

2

64,200 m

3

9 no.

21

Zone-1 13,700 m

2

50,800 m

3

8 no.

Total : 181,000 m

2

1,034,255 m

3

114 no.

The compaction process is monitored using an electronic process control system capable of

recording actual compaction data in real time; compaction energy, amount of water and depth of the

vibratory probe versus time in order to assist the operator and to control and collect the actual vibro

compaction data.

Two sets of CPTs performed before and after the vibro compaction installations at two different

areas in Zone 8A and the compaction energy applied to the soil by the vibratory probe in the vicinity

of CPT test locations were shown in Figure 3 and tabulated in Table 2. It was observed that the

log 66 98

5 . 0

(

(

'

+ =

vo

c

R

q

D

8

Proc. XIII ECSMGE, Vanek et al. (eds). GtS, Prague, ISBN 80-86769-00-3, (Vol. 1)

Main Session 1 "Man-made deposits - recent and ancient" 110

increase in q

c

decreases as the fines content in the hydraulic fill increases although the compaction

energy applied to the fill is the same.

Figure 3.CPTs performed before and after vibro compaction & compaction energy applied to the fill (At two

different areas in Zone 8A)

Table 2. Increase in q

c

obtained from CPTs and the corresponding compaction energy applied to the fill

Zone

No.

Area No.

Average qc

(Before Compaction)

Average qc

(After Compaction)

Ave. Compaction Power

(kW / m)

Increase in qc ()

(qc

aftter

- qc

before

) / qc

before

8A M05 - N06 12.10 MPa 23.70 MPa 30.9 kW 75 to 375

8A M08 - N09 17.50 MPa 26.10 MPa 32.7 kW 50 to 390

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

0 10 20 30 40 50

Zone: 8A - Area: M08-N09

qc ( MPa )

E

I

e

v

a

t

i

o

n

(

m

)

Bef ore Compaction

Af ter Compaction

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

20,0 25,0 30,0 35,0 40,0 45,0 50,0

Zone: 8A - Area: M08-N09

Compaction Power ( kW / m )

E

I

e

v

a

t

i

o

n

(

m

)

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

0 10 20 30 40 50

Zone:8A - Area:M05-N06

qc ( MPa )

E

I

e

v

a

t

i

o

n

(

m

)

Bef ore Compaction

Af ter Compaction

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

20,0 25,0 30,0 35,0 40,0 45,0 50,0

Zone:8A - Area:M05-N06

Compaction Power ( kW / m )

E

I

e

v

a

t

i

o

n

(

m

)

Proc. XIII ECSMGE, Vanek et al. (eds). GtS, Prague, ISBN 80-86769-00-3, (Vol. 1)

Main Session 1 "Man-made deposits - recent and ancient" 111

6 CONCLUSION

As a result, the successful execution of vibro -compaction in this project illustrates the effectiveness of

the selected method for densification of loose hydraulic fill. The specific findings of the project are:

1. Installations were successfully carried out with an equilateral triangular grid having a triangular

side of 2.5 m and a compaction energy of min. 750 KJoule per meter was applied by a 100 kW

vibratory probe, having a maximum operating speed of 3000 rpm (50Hz) with a corresponding

maximum centrifugal force of 400 kN to the hydraulic fill during installati ons.

2. The compaction process is successfully monitored by an electronic process control system

capable of recording the actual compaction data in real time in order to assist the operator and to

control and collect the actual vibro compaction data.

3. Based on the quality control test results it was not only concluded that the average relative

density of the compacted hydraulic fill successfully exceeded the specified minimum relative

density of 70 , but also revealed that the measured density values are in co nformity with the

values obtained for similar soil conditions. It is also observed that the cone resistance (q

c

) could

be increased by a factor of 1 to 4.

4. It is observed that even thin layers of sil t and clay in hydraulic fill can negatively affect the

densification process. Thus a detailed soil investigation including CPTU is recommended in

order to detect soil strafication exactly.

5. Since the dredging works were carried out by different types of dredgers (cutter suction dredger

and trailing suction hopper dredger) and the methods used for placement of the dredged material

were also different, the hydraulic fill was encountered as non -homogeneous.

6. The suitability number (S

N

) was calculated using t he formula suggested by Brown (1977) and it

is observed that the hydraulic fill material is Good to Fair.

REFERENCES

Brown R.E. (1977) 'Vibroflotation compaction of cohesionless soils, Journal of the Geotechnical Engineering

Division, pp.1437-1451.

Dzceer R., Gkalp A. (2001) 'Technical Report on densification of hydraulic fills by vibro compaction method

at Extension of Ashdod Port, Internal Technical Report, Istanbul, Turkey.

Lee, K.M., (1999), 'Effects of placement method on geotechnical behavior of hydraulic fill sands, Journal of

Geotechnical and Geoenvironmental Eng., No. : October, pp.832- 846.

Sladen J.A., Hewitt K.J., (1989) 'Influence of placement method on the in situ density of hydraulic sand fills,

Can. Geotech. Journal, Vol. 26, pp.453 466.

Slocombe B.C., et.al. (2000) 'The densification of granular soils using vibro methods, Getechnique 50, No.6,

pp. 715-725.

Proc. XIII ECSMGE, Vanek et al. (eds). GtS, Prague, ISBN 80-86769-00-3, (Vol. 1)

Main Session 1 "Man-made deposits - recent and ancient" 112

Potrebbero piacerti anche

- Ground Settlement Considerations For The Design of Long Culverts Beneath High Embankments On ClayDocumento12 pagineGround Settlement Considerations For The Design of Long Culverts Beneath High Embankments On ClayLuca BrandiNessuna valutazione finora

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsDa EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNessuna valutazione finora

- Micro Pile Liquefaction MitigationDocumento6 pagineMicro Pile Liquefaction MitigationViswanathan NaraNessuna valutazione finora

- Estabilidad de Tuneles CPT AplicacionesDocumento208 pagineEstabilidad de Tuneles CPT AplicacionesAnto VerduNessuna valutazione finora

- Case Study Delayed Failure of A Deep Cutting in Lodgement TillDocumento10 pagineCase Study Delayed Failure of A Deep Cutting in Lodgement TillthadikkaranNessuna valutazione finora

- (PDF) Rockfall Characterisation and Structural Protection - A Review PDFDocumento49 pagine(PDF) Rockfall Characterisation and Structural Protection - A Review PDFMuhammad Imran ZafarNessuna valutazione finora

- Equivalence DPSH (B) and SPT - 2007Documento4 pagineEquivalence DPSH (B) and SPT - 2007eduardomanar1224100% (1)

- Effects of Slaking On The Strength of Clay Shales: A Critical State ApproachDocumento13 pagineEffects of Slaking On The Strength of Clay Shales: A Critical State Approachmbotts100% (1)

- Proceedings Rockfall PDFDocumento131 pagineProceedings Rockfall PDFChin Thau WuiNessuna valutazione finora

- DCP Soil Strength EvaluationDocumento52 pagineDCP Soil Strength EvaluationIvan MasubaNessuna valutazione finora

- 11analysis of Shield TunnelDocumento35 pagine11analysis of Shield Tunnelnguyen tuanNessuna valutazione finora

- GeoMos 2010 SchweigerDocumento13 pagineGeoMos 2010 SchweigerIancu-Bogdan TeodoruNessuna valutazione finora

- Soil Mechanics in Pavement EngineeringDocumento44 pagineSoil Mechanics in Pavement EngineeringalexgomezsNessuna valutazione finora

- Shrinkage and Atterberg Limits in Relation To Other Properties of Principal Soil Types in IsraelDocumento19 pagineShrinkage and Atterberg Limits in Relation To Other Properties of Principal Soil Types in Israelbkollarou9632Nessuna valutazione finora

- Zhang2014.Numerical Investigation On Factors For Deep-Seated Slope Stability of StoneDocumento10 pagineZhang2014.Numerical Investigation On Factors For Deep-Seated Slope Stability of Stonejose monteNessuna valutazione finora

- Analysis of Dynamic Loading Behaviour For Pavement On Soft Soil Thesis PlaxisDocumento200 pagineAnalysis of Dynamic Loading Behaviour For Pavement On Soft Soil Thesis PlaxisAnonymous 5exSerNessuna valutazione finora

- Numerical Analysis of Performance of Soil Nail Walls in Seismic ConditionsDocumento10 pagineNumerical Analysis of Performance of Soil Nail Walls in Seismic ConditionsDeepthiNessuna valutazione finora

- Uplift Pressure Removal by GeocompositeDocumento8 pagineUplift Pressure Removal by GeocompositethadikkaranNessuna valutazione finora

- Burland - Rankine LectureDocumento51 pagineBurland - Rankine LectureanarNessuna valutazione finora

- Boulanger & Idriss - 2003Documento21 pagineBoulanger & Idriss - 2003suazologNessuna valutazione finora

- UGS2011 Application of The Hardening Soil Model in Deep Excavation AnalysisDocumento14 pagineUGS2011 Application of The Hardening Soil Model in Deep Excavation AnalysisfreezefreezeNessuna valutazione finora

- Assessment of Rockfall Hazard MahabaleshwarDocumento9 pagineAssessment of Rockfall Hazard MahabaleshwarMahesh HanmawaleNessuna valutazione finora

- Foundations On Soft Soils For Khulna MedicalDocumento6 pagineFoundations On Soft Soils For Khulna MedicalJahid Jahidul Islam KhanNessuna valutazione finora

- RMRb and GSI relationship based on field dataDocumento7 pagineRMRb and GSI relationship based on field dataJuan Pablo Alvarado RiquelmeNessuna valutazione finora

- Effectiveness of Using Geotextiles in Flexible PavementDocumento108 pagineEffectiveness of Using Geotextiles in Flexible PavementMaynard BaricaNessuna valutazione finora

- 16907Documento5 pagine16907kiriNessuna valutazione finora

- Dot 42462 DS1 PDFDocumento392 pagineDot 42462 DS1 PDFClaudia Victoria Vallejos CatalanNessuna valutazione finora

- Recommendations For SC PDFDocumento15 pagineRecommendations For SC PDFPau VallsNessuna valutazione finora

- Case Study of The Changi East Land Reclamation Project SingaporeDocumento13 pagineCase Study of The Changi East Land Reclamation Project SingaporeVictoria JungNessuna valutazione finora

- Mechanical Behavior of Non-Textbook SoilsDocumento69 pagineMechanical Behavior of Non-Textbook SoilsRodolfo Rojas MontenegroNessuna valutazione finora

- Triaxial Testing of Granular Soil (Colliat-Dangus, 1988)Documento21 pagineTriaxial Testing of Granular Soil (Colliat-Dangus, 1988)Abraham FIgueroa ARevaloNessuna valutazione finora

- The New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsDocumento10 pagineThe New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsabualamalNessuna valutazione finora

- Compendium of Ground Modification FDOT - BC354 - 64 - RPTDocumento371 pagineCompendium of Ground Modification FDOT - BC354 - 64 - RPTBluebelgianNessuna valutazione finora

- Powrie - Solutions Chs 6-11Documento59 paginePowrie - Solutions Chs 6-11Nestor Bendezu UrbayNessuna valutazione finora

- Ground Improvement Oct2014 PDFDocumento24 pagineGround Improvement Oct2014 PDFPatrick AscañoNessuna valutazione finora

- Faroukhi - Monogram On Thermal CoductivityDocumento151 pagineFaroukhi - Monogram On Thermal CoductivitynitingkulkarniNessuna valutazione finora

- Using Pindan Sand-Clay in Pavement Structural LayersDocumento15 pagineUsing Pindan Sand-Clay in Pavement Structural Layersganguly147147Nessuna valutazione finora

- A Correlation For Permanent Earthquake-Induced DeformationDocumento12 pagineA Correlation For Permanent Earthquake-Induced DeformationhnavastNessuna valutazione finora

- A Simple Review of Soil Reinforcement Using Natural and Synthetic FibersDocumento17 pagineA Simple Review of Soil Reinforcement Using Natural and Synthetic Fibersgabriel oliveira100% (1)

- Secondary Creek in Soft SoilsDocumento9 pagineSecondary Creek in Soft Soilsgeo_unoNessuna valutazione finora

- Ha 6894Documento108 pagineHa 6894Daniel GaonaNessuna valutazione finora

- Landslide Case StudyDocumento13 pagineLandslide Case StudyangemonaxNessuna valutazione finora

- International Society for Rock Mechanics: List of Members 1980Da EverandInternational Society for Rock Mechanics: List of Members 1980Valutazione: 3.5 su 5 stelle3.5/5 (2)

- Engineering Geology Field Manual Volume I ContDocumento11 pagineEngineering Geology Field Manual Volume I ContLibAmauNessuna valutazione finora

- 2-02 On The InterpretationDocumento8 pagine2-02 On The InterpretationPablo Cesar TrejoNessuna valutazione finora

- AAPA IG6 Selection and Design of Flexible Pavements ReducedDocumento68 pagineAAPA IG6 Selection and Design of Flexible Pavements Reducedrefika ivan0% (1)

- 2014 - Ground Improvement by Vacuum Consolidation - A Review - ICE Ground ImprovementDocumento17 pagine2014 - Ground Improvement by Vacuum Consolidation - A Review - ICE Ground ImprovementG-SamNessuna valutazione finora

- Designing Singular Jet Grouting Column For Sandy Soils: Gulsah Nur Karahan Osman SivrikayaDocumento11 pagineDesigning Singular Jet Grouting Column For Sandy Soils: Gulsah Nur Karahan Osman SivrikayaJose Alberto Duran BaqueroNessuna valutazione finora

- George Massey Crossing Independent Technical Review FINALDocumento302 pagineGeorge Massey Crossing Independent Technical Review FINALThe Vancouver SunNessuna valutazione finora

- MDT Geotech Manual Covers Roadway Slope and Embankment DesignDocumento40 pagineMDT Geotech Manual Covers Roadway Slope and Embankment DesignAlhaz UddinNessuna valutazione finora

- Geomaterial Behavior and Testing (SOAPresentation) - Mayne Et Al 2009Documento43 pagineGeomaterial Behavior and Testing (SOAPresentation) - Mayne Et Al 2009Rosnei StefaniNessuna valutazione finora

- Correlations of SPT, CPT and DPL Data For Sandy Soil in TanzaniaDocumento13 pagineCorrelations of SPT, CPT and DPL Data For Sandy Soil in TanzaniaDavid GurionNessuna valutazione finora

- Ghamgosar 2010 Rock Mass Deformation ModulusDocumento4 pagineGhamgosar 2010 Rock Mass Deformation ModulusahmadNessuna valutazione finora

- Swelling MechanismDocumento5 pagineSwelling MechanismS PandaNessuna valutazione finora

- Ap T240 13Documento92 pagineAp T240 13mehdiNessuna valutazione finora

- 6th Grade ModifiedDocumento83 pagine6th Grade ModifiedsravanthiNessuna valutazione finora

- Cambridge MatchGrid - IGCSE - CompleteChemDocumento3 pagineCambridge MatchGrid - IGCSE - CompleteChemHakan OlgunNessuna valutazione finora

- Dual-Band A-Panel Dual Polarization Half-Power Beam Width Fixed Electrical Downtilt Integrated CombinerDocumento1 paginaDual-Band A-Panel Dual Polarization Half-Power Beam Width Fixed Electrical Downtilt Integrated CombinerПётр НовиковNessuna valutazione finora

- Postlude To The Adam and Eve StoryDocumento28 paginePostlude To The Adam and Eve StoryGlauci GrohsNessuna valutazione finora

- Problemario Prácticas TermoDocumento35 pagineProblemario Prácticas TermoEsaú RSNessuna valutazione finora

- Basic Microscopy Concepts: Resolution & MagnificationDocumento4 pagineBasic Microscopy Concepts: Resolution & MagnificationAlejandro Palomino AmaroNessuna valutazione finora

- Section DataDocumento5 pagineSection Datamiteshpatel191Nessuna valutazione finora

- Rigging of Transmission TowerDocumento31 pagineRigging of Transmission TowerSagar BhardwajNessuna valutazione finora

- Instructions manual for JBC soldering station consoleDocumento23 pagineInstructions manual for JBC soldering station consoleGabriel TaberneroNessuna valutazione finora

- Circuit Analysis MethodsDocumento176 pagineCircuit Analysis MethodsVeryyoga SihombingNessuna valutazione finora

- SEd Sci 221 0rgenic Chemistry Module 5 Constitutional IsomersDocumento38 pagineSEd Sci 221 0rgenic Chemistry Module 5 Constitutional IsomersJelaica EspinuevaNessuna valutazione finora

- BS en 88-1-2007-11Documento29 pagineBS en 88-1-2007-11Abey Vettoor100% (1)

- Floating Hoses and EquipmentDocumento3 pagineFloating Hoses and EquipmentAyman64Nessuna valutazione finora

- SET Motion in A: CircleDocumento11 pagineSET Motion in A: Circle臧华运Nessuna valutazione finora

- Composites: Part B: James Leblanc, Nate Gardner, Arun ShuklaDocumento10 pagineComposites: Part B: James Leblanc, Nate Gardner, Arun ShuklaDiego Andres Rubio ContrerasNessuna valutazione finora

- Flumes: Theory & Application: PDFDocumento36 pagineFlumes: Theory & Application: PDFETNessuna valutazione finora

- Horizontal and Vertical Wind TurbineDocumento10 pagineHorizontal and Vertical Wind TurbinejhonNessuna valutazione finora

- Method Statement For Pile Chipping and Capping Beam: Vascon Engineers LTDDocumento12 pagineMethod Statement For Pile Chipping and Capping Beam: Vascon Engineers LTDshahaji0% (1)

- Lab Assignment 1 EEE-466, Power Electronics Lab: Design and Simulation of Bridge RectifiersDocumento9 pagineLab Assignment 1 EEE-466, Power Electronics Lab: Design and Simulation of Bridge RectifiersKhairulNessuna valutazione finora

- Semiconductor Protection Fuses: Amp-Trap - Form 101Documento2 pagineSemiconductor Protection Fuses: Amp-Trap - Form 101M. Taufik HidayatNessuna valutazione finora

- Latex 3000Documento8 pagineLatex 3000cabruceNessuna valutazione finora

- Ansys Fluent Fluid Simulation SoftwareDocumento1 paginaAnsys Fluent Fluid Simulation SoftwareLuausNessuna valutazione finora

- Physical Geology 15th Edition Plummer Test Bank PDFDocumento35 paginePhysical Geology 15th Edition Plummer Test Bank PDFtenuous.butyrin.nfrm100% (19)

- Easy 3-Step Meringues RecipeDocumento8 pagineEasy 3-Step Meringues RecipePrashant Bhawnani0% (1)

- Steel Column DesignDocumento3 pagineSteel Column DesignGlenn TeNessuna valutazione finora

- Eddy Current Testing HolesDocumento12 pagineEddy Current Testing HolesAndres GonzalezNessuna valutazione finora

- A Student Must Use 225 ML of Hot Water in A Lab ProcedureDocumento2 pagineA Student Must Use 225 ML of Hot Water in A Lab ProcedureAmelia yuni saputriNessuna valutazione finora

- Handbook of Port and Harbor Engineering Geotechnical and Structural Aspects-276-363Documento88 pagineHandbook of Port and Harbor Engineering Geotechnical and Structural Aspects-276-363ÄphinNessuna valutazione finora

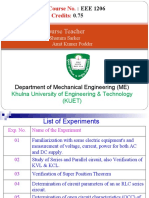

- 1503567144me 1206 1ST LabDocumento34 pagine1503567144me 1206 1ST Labcportrait artNessuna valutazione finora

- Kvpy Sa - 6 Model Test PapersDocumento62 pagineKvpy Sa - 6 Model Test PapersHarvey SpectreNessuna valutazione finora