Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Weider System 3 15922 Manual

Caricato da

oopsilonCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Weider System 3 15922 Manual

Caricato da

oopsilonCopyright:

Formati disponibili

r

~ - - - -

MODEl. NO. 15922

MODEL N0.15922

SKU NO. 354.15922

SERIAL NO.

Write the serial number in the space

above for reference.

SERIAL NUMBER DECAL

WAIT, READ THIS FIRSTI

ff you find this unit to hal/8 missing or defectlve parts

please have reedy the following information listed

below before calling the BOO NUMBER.

The ASSEMBLY MANUAL

MODEL NUMBER of this UN"

PART NAME or DESCRIPTION

ORDERING NUMBER

THE QUANTITY of each part that you nflfld.

THE MODEL NUMBER of this unit Is found In the

UPPER LEFT-HAND or RIGHT-HAND CORNER of this

page. The MODEL NUMBER Is B sflriBS of LETTERS

followed by s NUMBER.

THE PART NAME or DESCRIPTION and the

ORDERING NUMBER can be found on the PARTS

=icdJcw.

OWNER'S MANUAL

++ ..

MADE IN CANADA

WEIDER is committed to providing you complete customer satisfaction. If you have any questions concerning the assembly of

this product or find damaged or missing parts, we guarantee you direct assistance. AVOID THE HASSLE OF CONTACTING

THE STORE FOR PARTS OR RETURNING THE PRODUCT. Call our "CUSTOMER ASSISTANCE UNE" for assistance

with parts and information by calling our toll free number 1-800-225-0653, Mon. - Fri., 8 am - 5 pm CST.

"' . - ~ ~ _ . , _ ...

IMPORTANT: Read all safety precautions and instructions in this manual carefully before using this equipment. Save this

manual for Mure reference.

WEIDER HEALTH AND FITNESS

21100 Erwin Street, Woodland Hills, Ca. 91367 USA

BEFORE BEGINNING ASSEMBLY READ THE FOLLOWING

THIS PRODUCT REPRESENTS THE STATE OF THE ART IN TECHNOLOGY IN HOME

FITNESS EQUIPMENT. EVERY EFFORT HAS BEEN MADE TO BRING TO YOU A PRODUCT

OF THE HIGHEST QUALITY AND WORKMANSHIP. WE HOPE YOU WILL FIND THIS

PRODUCT BENEFICIAL TO YOUR PHYSICAL CONDITIONING AND

..

HELPI=UL HINTS I=OR ASSEMBLY

1. TOOLS REQUIRED FOR ASSEMBLY INCLUDE: A HAMMER, PLIERS, MEDIUM SIZE FLAT HEAD

SCREWDRIVER, AND TWO 6" ADJUSTABLE WRENCHES.

2. PRIOR TO BEGINNING THE ASSEMBLY OF THIS PRODUCT WE RECOMMEND THAT YOU TAKE A FEW

MINUTES TO UNPACK AND LAY OUT ALL THE PARTS SO THEY CAN BE EASILY IDENTIFIED. IT IS

EXTREMELY HELPFUL IF THE CONTENTS OF THE HARDWARE BAG ARE EMPTIED OUT AND LIKE PARTS

GROUPED TOGETHER; I.E. 5116" X 3" HEX HEAD BOLTS TOGETHER, ETC. A HANDY PLACE TO HOLD THE

HARDWARE MIGHT BE TO USE THE INSIDE OF THE CARTON TOP. AFTER GROUPING PARTS AGAINST

THE PARTS LIST TO IDENTIFY PARTS AND SIZES, WRITE THE SIZE AND PART NAME BESIDE EACH PART

SO YOU KNOW EXACTLY WHICH PART TO GO TO FOR A PARTICULAR ITEM.

3. THE ASSEMBLY INSTRUCTIONS HAVE BEEN WRmEN USING CHECK-v'AS YOU GO ASSEMBLY METHOD.

BY CHECKING THE BOXES AS YOU GO IT IS VERY EASY TO FOLLOW ALONG THE ASSEMBLY WITHOUT

REREADING TO FIND YOUR PLACE IN THE ASSEMBLY.

4. YOU WILL ALSO NOTICE THAT AT THE BEGINNING OF EACH ASSEMBLY STEP THERE IS A HARDWARE

LIST SHOWING THE QUANTITY AND DESCRIPTION OF THE HARDWARE REQUIRED TO DO ALL

ASSEMBLIES IN THAT STEP. BY PRE-SELECTING THE HARDWARE FOR EACH STEP YOU WILL SAVE

TIME AND CONFUSION.

5. TAKE NOTE OF ANY SPECIAL WARNINGS, CAUTIONS, NOTES, OR NOTICES. LAY OUT UNASSEMBLED

PARTS: FAMILIARIZE YOURSELF WITH THE DRAWINGS THEN READ AND UNDERSTAND THE

INSTRUCTIONS THOROUGHLY. .

6. THIS PRODUCT MUST BE ASSEMBLED BY AN ADULT PRIOR TO USE;

7. DO NOT DESTROY THE PACKING AND CARTON UNTIL THE UNIT I_S COMPLETELY ASSEMBLED.

.

8. DO NOT DESTROY THE INSTRUCTION MANUAL, USE IT FOR ORDERING REPLACEMENT PARTS.

9. IN ASSEMBI.. Y, WHEN THERE ARE INSTRUCTIONS_ THAT INDICATE THE USE OF A WASHER WHEN

BOLTING, IT IS VERY IMPORTANT TO USE THE WASHER IN EACH PLACE SHOWN. THE WASHERS ARE

USED TO DISTRIBUTE THE LOAD ON THE BOLT AND ARE VERY IMPORTANT.

10. TO HELP SECURE PLASTIC CAPS IN TUBING IT IS ADVISABLE TO GLUE ON ALL PLASTIC CAPS DURING

ASSEMBLY USING ANY HOUSEHOLD TYPE GLUE.

11. PERIODICALLY CHECK THE UNIT FOR BOLT TIGHTNESS AND PARTS WEAR TO INSUR.E THAT YOUR

EQUIPMENT IS KEPT IN TOP CONDITION.

12. WITH CON11NUEO USE THE MOVING PARTS OF THIS UNIT WILL BECOME _STIFF AND PoSSIBLY B_EGIN

SQUEAKING. LUBRICATE THE MOVING PARTS WITH ANY HOUSEHOLD LUBRICATING OIL NOTE: IT MAY

BE NECESSARY TO PARTIALLY DIS-ASSEMBLE THE PARTS TO LUBRICATE THE PARTS PROPERLY.

-:-- .. ____ :_-

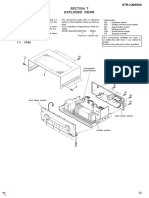

PART LIST 15922

DIAGRAM NO. PART NAME

1 BASE

2 SIDE BASE

3 BASE PLATE

4 REAR BRACE

5 ARM PRESS FRAME UPRIGHT

6 SQUAT STATION UPRIGHT

7 SIDE BRACE

9 TOP FRAME

10 BACK SUPPORT BRACKET

---

11 AB FLEX ARM

12 AB FLEX ARM HANDLE

13 AB FLEX ARM CONNECTOR TUBE

14 SEAT FRAME

15 SEAT BRACE

16 MOUNTING PLATE

17 WEIGHT SELECTOR TUBE

18 WEIGHT PLATE

19 GUIDEROD .

20 SEAT

21 BACKREST

22 ARM PRESS ASSEMBLY

23 1' X 13' PIVOT TUBE

24 PEC-OECK ARM -RIGHT

25 PEC-DECK ARM LEFT

26 FOAM ROLLER 4" X 7 1/2'

27 ARM PRESS HANDLE

28 FOAM GRIP 1' X 5'

29 LEG EXTENSION TUBE

30 PAD BAR 314" X 13 314"

31 FOAM PAD - 3" X 5 314"

32 PEC.DECK CABLE - 267 112'

33 PULLEY 3 112"

34 PEC-DECK PULLEY BRACKET (RIGHT HOLE)

35 PEC-DECK PULLEY BRACKET (LEFT- HOLE)

,_

36 WEIGHT STACK CABLE 67"

37 PULLEY CONNECTOR PLATE

38 BENT PULLEY TRAP BRACKET

39 LEG EXTENSION CABLE 55 1/4"

-- ----- ------ -- -

___ : __ ---

...------ "- ---,....- ,

QTY ORDERING NO

t

1 C3193-F21 *F21

1 C3194-F21 *F21

1 C3195-F21 *F21

1 C319&-F21*F21

1 C3197-F21*F21

1 C3198-F21*F21

1 C3198-F21 *F21

1 C3200.F21 *F21

1 C6763-F21 *F21

1 C6376-F21 *F21

2 C6377F21 *F21

1 C6954-F21 *F21

1 C3201-F21 *F21

1 C6764-F21 *F21

1 C6765-F21 *F21

'

1 C6374-F21*F21

10

2 C6826-F21 *F21

1 C1372-F21 *F21

1 C1373-F21 *F21

1 C3202-F21 *F21

1 C6375-F21 *F21

1 C3203-F21 *F21

1 C3204-F21 *F21

2 C0450-E08*F21

2 C6378-F21 *F21

4 C0417B05*F21

1 C2212-E28*F21

2 C6331-E28*F21

4 C0454-E04*F21

1 C6634-F21 *F21

11 AA-8133*F21

1 C5955-F21*F21

1 C5956-F21 *F21

1 C6635-F21 *F21

2 C6767-F21*F21

2 C6768-F21 *F21

1 C6636-F21 *F21 1

---

r- -

PART LIST 15922

DIAGRAM PARTNAI\IIi:

QTY ORDERING NO

40 CABLE TRAP BRACKET

.4 C6766-F21*F21

41 PEC-DECK PULLEY BRACKET (CENTER- HOLE) 2 C6957-F21*F21

42 PULLEY - 4 112"

3 AA-8122*F21

43 AB BACKREST

1 C1374-F21

44 ARM PADS

2 C1375-F21*F21

45 SQUAT STATION BAR

1 C6958-F21*F21

46 FOAM ROLLER 3 114' X 7' 2 C0443-E02*F21

47 LATBAR 1 C6803-D35*F21

48 5-HOOK 1 WW-7030*F21

49 LEG STRAP W/DUMBBELL HANDLE 1 EE-0075*F21

50 ACCESSORY ROPE 1 C6602-D23*F21

58 318" X 3" HEX HEAD BOLT 1 HH-5059*F21

5/16" X3" HEX HEAD BOLT 5 HH-5167*F21

5/16' X21/4" HEX HEAD BOLT 7 HH-5199*F21

61 5/16" X2 314" HEX HEAD BOLT 16 HH-5058*F21

62 5/16" X31/4" HEX HEAD BOLT 2 HH-5297*F21

5/16" X 2' HEX HEAD BOLT 5 HH-5054*F21

,'64

5/16" X 2112" HEX HEAD BOLT 4 HH-5053*F21

65 5/16" X 1112" HEX HEAD BOLT 5 HH-5312*F21

66 5/16" X 314" HEX HEAD BOLT 2 HH-5245*F21

67 5/16" NYLON LOCK NUT 46 HH-5012*F21

468-/.- 5/16" FLAT WASHER 33 HH-5127*F21 v

69 1/4" X 314" MACHINE SCREW 4 HH-5022*F21

70 1/4" X 2" MACHINE SCREW 4 HH-5256*F21

72 1/4" X 2 112" CARRIAGE BOLT 1 HH-5333*F21

73 1/4" FLAT WASHER 4 H H-5048*F21

74 1/4" NXLON LOCK NUT 2 HH-5011*F21

75 318" X 1 314" HEX HEAD BOLT 9 HH-5308*F21

76 318" NYLON LOCK NUT 14 HH-5088*F21

77 1/4" X 2 314" MACHINE SCREW 3 HH-5326'F21

78 318" FLAT WASHER 6 HH-5265*F21

79 318" X 2 314" HEX HEAD BOLT 1 HH-5238*F21

80 2" X 1 3116" FLAT WASHER 2 HH-5454*F21

81 318" X 2 1/4" HEX HEAD BOLT 1 HH-5061*F21

82 318" X 31/4" HEX HEAD BOLT 1 HH-5063*F21

83 1/4" X 1 314" HEX HEAD BOLT 1 HH-5024*F21

f--- 64 318" X 3 112" HEX HEAD BOLT 1 HH-5062*F21

85 PEC-DECK LOCK PIN 5/16" X 2 112" 2 WW-7053*F21

86 112' LONG METAL SPACER 1 HH-5317*F21

....

a

/

0

)V'<

'-'

v )' l

'

,-.......... -=.,__

PART LIST 15922

DIAGRAM NO. PART NAME QTY ORDERING NO

87 17132" LONG METAL SPACER 2 HH-5317*F21

88 9/32" LONG METAL SPACER 2 HH-5413*F21

89 314" LONG METAL SPACER 1 HH-5335*F21

90 2" SQUARE PLASTIC INSERT CAP 4 AA-8002*F21

91 1 112" SQUARE PLASTIC INSERT CAP 9 AA-8001*F21

92 1" ROUND PLASTIC INSERT CAP 12 AA-8005*F21

93 2" SQUARE PLASTIC COVER CAP 4 AA-8015*F21

94 1 1/4" SQUARE PLASTIC INSERT CAP 2 AA-8069*F21

95 WEIGHT SELECTOR TUBE END CAP 1 AA-8123*F21

96 RUBBER BUMPER WASHER 2 AA-8124*F21

97 WEIGHT SELECTOR PIN 1 WW-7013*F21

98 1 1/4" SQUARE END BUSHING 8 AA-8203*F21

99 1 314" SQUARE PLASTIC INSERT CAP 1 AA-8006*F21

100 314" ROUND PLASTIC INSERT CAP 4 AA-80.12*F21

105 WEIGHT PLATE DECAL 1 SET DE-4232*F21

l 106 STATION 1 DECAL 1 SET DE-4232*F21

107 POWER STACK DECAL 1 SET DE-4232*F21

108 STATION 2 DECAL 1 SET DE-4232*F21

109 STATION 3 DECAL 1 SET DE-4232*F21

110 WEIDER SYSTEM 3 DECAL 1 SET DE-4232*F21

ASSEMBLY MANUAL 1 NN-1177*F21

TRAINING MANUAL 1 NN-1178*F21

HARDWARE BAG (STEP 1-4) 1 C5957-F21*F21

HARDWARE BAG (STEP 5-8) 1 C5958-F21*F21

HARDWARE BAG (STEP 9-13) 1 C5958-F21*F21

HARDWARE BAG (STEP 14-18) 1 C5960-F21*F21

HARDWARE BAG (3 112" PULLEYS) 1 C5961-F21*F21

HARDWARE BAG (4 112" PULLEYS, LEG STP, ROPE) 1 C6962-F21*F21

THERE ARE SEVERAL ACCESSORY ITEMS INCLUDED WITH THE HOME GYM

LATBAR:

0 To LONG LA T BAR (47) press 1" ROUND PLASTIC INSERT CAPS (92) into each end of Bar and assemble 1' X 5" FOAM

GRIPS (28) to Bar with the aid of a small amount of liquid dish detergent.

0 To use Lat Bar, connect to Cable at Top Mast Tube with s HOOK (48). This Bar is used to do all Lat Pull-Down Exercises.

LEGSTRAP:

D Slide anached Dumbbell Handle to one end of strap .--0 &1\

o Usmg "S" HOOK (48) LEG STRAP (49) IS connected Pulley at front of the umt 47

D ThiS accessol}' IS used !oral/Leg Exerc1ses. 28

DUMBBELL HANDLE: 9.2

D Slide anached Dumbbell Handle to center of LEG STRAP (49) and connect dumbell handle to Base Pulley to perform single

Arm Curls, and Side Lateral Raises.

D Note: Many of the exercises performed with these accessories may need to be connected with the use of the 34

ACCESSORY ROPE (50) as desired to give proper distancing from unit.

WBDER HEALTH and RTNESS PAGES

STEP 'f BASE I=RAME ASSEMBLY

' 0 Begin by capping each tubing end of the BASE (1) with 2" SQUARE

~ COVER CAPS (93).

PART NAME

" '.

QTY

60 5116" X 2 1/4" HEX HEAD BOLT 1

61 5116" X 2 314" HEX HEAD BOLT

64 5116" X 2 112" HEX HEAD BOLT

67 5116" NYLON LOCK NUT

68 5116" FLAT WASHER

90 2" SQUARE PLASTIC INSERT CAP

92 1" ROUND PLASTIC INSERT CAP

93 2" SQUARE PLASTIC COVER CAP

67..--8

60

2

2

5

4

1

2

4

0 Cap one end of the SIDE BASE (2) with a 2" SQUARE COVER CAP

(93) and the other end with a 2" SQUARE INSERT CAP (90).

0 Orient the SIDE BASE (2) so that the dimpled-in holes are faced to

the floor.

0 Assemble the BASE (1) to the SIDE BASE (2) by bolting with 5116" X 2 3/4" HEX HEAD BOLTS (61) through the bracket

of the Base and then through the Side Base. Assemble 5/16" FLAT WASHERS (68) onto the end of the bolt and secure

with 5/16" NYLON LOCK NUTS (67).

0 Assemble the BASE PLATE (3) to the SIDE BASE (2) by bolting with 5/16" X 2 1/2" HEX HEAD BOLTS (64) through the

BASE PLATE (3) and the SIDE BASE (2). Assemble 5/16" FLAT WASHERS (68) on the bolt and fasten assembly with

5/16" NYLON LOCK NUTS (67).

0 Attach the REAR BRACE (4) to the Base Frame Assembly by bolting with a 5/16" X 2 1/4" HEX HEAD BOLT (60) up

through the bottom of the Base Assembly and then through the bracket of the REAR BRACE (4). Fasten with 5116"

NYLON LOCK NUT (67).

0 Cap each end of the tubing on the REAR BRACE (4) with 1" ROUND PLASTIC INSERT CAPS (92).

1.

WEIDER HEALTH and RTNESS

STEP 2 I=RAME UPRIGHT ASSEMBLY

PART NAME.

.. 60 5116" X 21/4" HEX HEAD BOLT

61 5116" X 2 314" HEX HEAD BOLT

67 5116" NYLON LOCK NUT

68 5116" FLAT WASHER

91 1 1/2" SQUARE PLASTIC INSERT CAP

D To the SIDE BASE (2), attach the

SIDE BRACE (7) by bolting with

5/16" X 2 1/4" HEX HEAD BOLTS

(60) up through the Base Plate

Assembly and then through the

bracket of the SIDE BRACE (7).

Fasten with 5/16" NYLON LOCK

NUTS (67).

D Assemble the SQUAT STATION

UPRIGHT (6) to the BASE (1) using

5/16" X 2 1/4" HEX HEAD BOLTS

(60) and bolting up through the Base

and then through the bracket of the

SQUAT STATION UPRIGHT (6).

Secure with 5/16" NYLON LOCK

NUTS (67).

D Attach the SIDE BRACE (7) to the

SQUAT STATION UPRIGHT (6) by

assembling 5/16" FLAT WASHERS

(68) onto two 5/16" X 2 314" HEX

HEAD BOLTS (61) and bolting

through the Upright and the bracket

of the SIDE BRACE (7). Fasten

with 5/16" NYLON LOCK NUTS

(67).

D Assemble the ARM PRESS FRAME

UPRIGHT (5) to the BASE (1) by

bolting up through the bottom of the

Base and then through the bracket

of the ARM PRESS FRAME

UPRIGHT (5) with 5/16" X 2 1/4"

HEX HEAD BOLTS (60). Secure

with 5/16" NYLON LOCK NUTS

(67).

D Cap the Welded Stop Tube at the

top of the Squat Station Upright with

a 1 112" SQUARE PLASTIC

INSERT CAP (91 ).

D The REAR BRACE (4) wm be bolted

to the Upright at the end of the

assembly when the Pulley is

attached.

QTY

6

2

8

2

1

PAGE 6

5

61 68

t)

l

W8DER HEALTH and RlNESS PAGE7

S T E P ~ TOP FRAME ASSEMBLY

PART NAME

...

61 5116" X 2 314" HEX HEAD BOLT

66 5116" X 314" HEX HEAD BOLT

67 5116" NYLON LOCK NUT

68 5116" FLAT WASHER

90 2" SQUARE PLASTIC INSERT CAP

~

90

..

QTY

4

1

5

2

2

0 Attach TOP FRAME (9) to the ARM PRESS FRAME UPRIGHT (5) by

bolting with a 5/16" X 2 3/4" HEX HEAD BOLT (61) and 5/16" FLAT

WASHER (68) down through the hole in front of the welded bracket at

the top of the Frame and then through the bracket of the ARM PRESS

FRAME UPRIGHT (5). Fasten with a 5/16" NYLON LOCK NUT (67).

Behind the welded bracket, bolt with a 5/16" X 314" HEX HEAD BOLT

(66) down through the top of the Frame and then through the bracket of

the Upright. Fasten with a 5116" NYLON LOCK NUT (67).

0 Assemble the TOP FRAME (9) to the Brace Extension on the front of the ARM PRESS FRAME UPRIGHT (5) using a 5/16"

X 2 314" HEX HEAD BOLT (61), 5116" FLAT WASHER (68) and a 5/16" NYLON LOCK NUT (67).

0 Cap each end of the TOP FRAME (9) with 2" SQUARE PLASTIC INSERT CAPS (90).

0 Assemble the SQUAT STATION UPRIGHT (6) to the Top Frame first bolting with 5/16" X 2 3/4" HEX HEAD BOLTS (61)

down through the BACK SUPPORT BRACKET (10), the TOP FRAME (9), and then through the Bracket of the SQUAT

STATION UPRIGHT (6). Secure with 5/16" NYLON LOCK NUTS (67).

0 Remove WEIDER SYTEM 3 DECALS (11 0) from backing sheet and affix to both sides of the TOP FRAME (9).

WEIDER HEALTH and RTNESS

STEP 4 SEAT BRACKET ASSEMBLY

PART NAME QTY

61 5116" X 2 314" HEX HEAD BOLT

64 5116" X 21/2" HEX HEAD BOLT

67 5116" NYLON LOCK NUT

68 5116" FLAT WASHER

72 1/4" X 21/2" CARRIAGE BOLT

73 1/4" FLAT WASHER

74 1/4" NYLON LOCK NUT

90 2" SQUARE PLASTIC INSERT CAP

0 Attach SEAT BRACE (15)

to the rear hole in the SEAT

FRAME (14) by bolting with

a 5/16" X 2 112" HEX

HEAD BOLT (64) down

through the top of the Seat

Frame and then through the

SEAT BRACE (15).

Secure with 5/16" NYLON

LOCK NUT (67).

0 Attach the SEAT FRAME

(14) to the ARM PRESS

UPRIGHT (5) using 5/16" X

2 3/4" HEX HEAD BOLTS

(61), 5116" FLAT

WASHERS (68), and 5/16"

NYLON LOCK NUTS (67).

0 Cap the end of the SEAT

FRAME (14) with a 2"

SQUARE PLASTIC

INSERT CAP (90).

0 Attach the SEAT BRACE

(15) to the ARM PRESS

UPRIGHT (5) by

assembling a 5/16" X 2

3/4 HEX HEAD BOLT (61)

and a 5/16" FLAT

WASHER (68) and bolting

through the back of the

Upright Frame and then

through the SEAT

BRACKET. Fasten with

5/16" NYLON LOCK NUT

(67).

3

4

3

72,Jl

11 67 ft-64 D

1 6 ~ ~ ' 1 f

14

PAGES

0 To the front hole of the SEAT FRAME (14) attach a MOUNTING PLATE (16) by bolting with a 1/4" X 2 112" CARRIAGE

BOLT (72) through the Plate, then down through the Seat Frame. Place a 1/4" FLAT WASHER (73) onto the bolt and

secure with a 1/4" NYLON LOCK NUT (74).

WBDEA HEALTH and RTNESS

STEP 5 WEICHT STACK ASSEMBLY

PARTNAME QTY

95 WEIGHT SELECTOR TUBE END CAP

96 RUBBER BUMPER WASHER 2

CAUTION: To aid in this step it is advised

that you secure the assistance of a helper to

assist in steadying of the Weight Plates as

they are stacked

0 Locate the RUBBER BUMPER WASHERS

(96) atop the welded Guide Rod Locating

Bracket on the BASE FRAME (1}.

0 With the aid of your helper, begin stacking

the WEIGHT PLATES (18} atop the Rubber

Washers on the Guide Rod Bracket on the

BASE (1).

0 Stack Weights one at a time until all but one

are stacked on the Base.

0 Insert the WEIGHT

SELECTOR TUBE END

CAP (95} into bottom end

of the WEIGHT

SELECTOR TUBE (17).

Insert the Selector Tube

into the center hole

through the stack of

Weight Plates and align

the pre-assembled roll pin

of the Selector Tube with

the groove in the top of

the Weight Plate.

" NOTE: Weight Selector

Tube should insert

completely through the

stack of Weight Plates if

they are in proper

alignment with the welded

Guide Rod Bracket on the

Base Frame. If it does

not insert completely,

adjust the Weight Stack

positioning until it does.

0 When the WEIGHT

SELECTOR TUBE (17}

has been inserted fully

into the Weight Stack,

position the final WEIGHT

PLATE (18) over the

Selector Tube atop the

Weight Stack.

PAGE9

PRE-ASSEMBLED ROLL PIN

17

r

WBDER HEALTH Mel RTNESS

STEP & C:UIDE ROD ASSEMBLY

PART NAME ...........

QTY

65 5116" X 1112" HEX HEAD BOLT 2

67 5116" NYLON LOCK NUT 2

97 WEIGHT SELECTOR PIN 1

0 With the bolt holes of the GUIDE RODS

(19) to the top, insert the Rods into the

two remaining holes in the top of the

Weight Stack. (SEE DETAIL A.)

0 Bolt the GUIDE RODS (19) to the front

side of the welded brackets on the TOP

FRAME (9) using 5116" X 1 112" HEX

HEAD BOLTS (65) through the Rod,

then the Bracket and fasten with 5/16"

NYLON LOCK NUTS (67). (SEE

DETAIL B.)

0 Remove WEIGHT PLATE DECALS

(1 05) from backing sheet and apply to

the Weight Plates starting with 12.5 lbs

on the top plate and increasing to 125

lbs. on the bottom plate.

0 Insert WEIGHT

SELECTOR PIN (97)

into the Weight Stack

at a low setting to aid

in future cable

assembly.

D Remove STATION

ONE DECAL (106)

from backing sheet

and affix it to the

front side of the ARM

PRESS FRAME

UPRIGHT (5) about

4 inches below

welded brackets.

PAGE10

DETAIL B

5

WBDEA HEALTH and RTNESS PAGE11

STEP 7 SEAT & BACKREST ASSEMBLY

................

PAATNAME ... .......

.....

69 1/4" X 314" MACHINE SCREW

73 1/4" FLAT WASHER

77 1/4" X 2 314" MACHINE SCREW

D Attach the SEAT (20} to the

MOUNTING PLATE (16} on the

SEAT FRAME (14} using 114 X

314 MACHINE SCREWS (69} and

bolting up through the Mounting

Plate and into the Seat.

D Fasten the back portion of the SEAT

(20} to the SEAT FRAME (14} by

bolting up through the Seat Brace

and the Seat Frame with a 114 X 2

314 MACHINE SCREW (77} and a

114 FLAT WASHER (73} and into

the Seat.

D Attach the BACKREST (21} to the

ARM PRESS FRAME UPRIGHT (5}

by assembling 114 FLAT

WASHERS (73} on two 114 X 2

314 MACHINE SCREWS (77} and

bolting through the back of the

Upright Frame and into the Seat.

QTY

2

3

3

21

T7

STEP 8 LEG EXTENSION ASSEMBLY

..........

PART NAME ... orv

61 5116" X 2 314" HEX HEAD BOLT

;7 5116" NYLON LOCK NUT 1

99 1 314" SQUARE PLASTIC INSERT CAP 1

100 314" ROUND PLASTIC INSERT CAP 4

NOTE: To each Pad Bar wipe a small amount

of liquid dish detergent along the length of the

Bar. This helps in the assembly of the Foam

Pads. When the detergent dries, it acts as an

adhesive.

D To one end of each PAD BAR (30} press on

one3 X5 314 FOAM PAD (31}.

D Insert one PAD BAR (30} into the brackets of

the SEAT FRAME (14} and assemble another

3 X5 3/4 FOAM PAD (31).

D Assemble the other PAD BAR (30} into a hole

on the lower section of the LEG EXTENSION

TUBE (29).

D Press another 3 X 5 3/4 FOAM PAD (31)

onto the inserted tube end.

0 Assemble LEG EXTENSION TUBE (29} into the brackets of the SEAT

FRAME (14} with a 5/16 X 2 3/4 HEX HEAD BOLT (61} and a 5116

NYLON LOCK NUT (67). Cap top of Leg Extension tube with a 1 3/4

SQUARE PLASTIC INSERT CAP (99).

0 Press 3/4 ROUND PLASTIC INSERT CAPS (100} into ends of3J4

X 13 3/4 PAD BARS (30).

--

WBDER HEALTH and RlNESS

STEP 8 ARM PRESS ASSEMBLY

PART NAME . . QTY

61 5116" X 2 314" HEX HEAD BOLT

67 5116" NYLON LOCK NUT

68 5116" FLAT WASHER 2

89 314" LONG ME.TAL SPACER

92 1" ROUND PLASTIC INSERT CAP 2

98 1 1/4" SQUARE END BUSHINGS 8

0 Assemble 1114 SQUARE END BUSHINGS (98)

into each end of the tubes of the ARM PRESS

ASSEMBLY (22).

0 Align the ARM PRESS ASSEMBLY (22) with the

welded cross tubing toward the front of the unit.

Then align the Assembly with the larger second

hole from the front of the TOP FRAME (9) and

insert 1 X 13 PIVOT TUBE (23) through the

ARM PRESS ASSEMBLY (22) and the TOP

FRAME (9). The Pivot Tube may require the use

of a hammer to tap it through since this is a tight

fit. The use of a buffer such as a small thin board

is suggested to keep from damaging the Tube.

107

I 98

@t

PAGE12

0 Rotate the PIVOT TUBE (23) until the bolt holes align. Assemble a 5116" FLAT WASHER (68) and a 3/4 LONG METAL

SPACER (89) onto a 5/16 X 2 3/4 HEX HEAD BOLT (61) and insert the bolt from the bottom up through the TOP

FRAME (9) and Pivot Tube. Assemble another 5/16 FLAT WASHER (68) on to the bolt and fasten with a 5/16 NYLON

LOCK NUT (67). (SEE DETAIL A.)

0 Press a 1 ROUND PLASTIC INSERT CAP (92) into each end of PIVOT TUBE (23).

,

0 Remove POWER STACK DECAL (1 07) from the backing and adhere it onto the ARM PRESS ASSEMBLY (22) in position

shown.

L

WBDER HEALTH and RTNESS PAGE 13

STEP '10 PECDECK ARM ASSEMBLY

PART NAME

..

I crr'l

65 5116" X 1 112" HEX HEAD BOLT 2

67 5116" NYLON LOCK NUT 2

80 2" X 1 3116" FLAT WASHER 2

85 5116" X 2112" PEC-DECK LOCK PIN 2

91 1 112" SQUARE PLASTIC INSERT CAP 4

92 1" ROUND PLASTIC INSERT CAP 4

" There are two Pee-Deck Arms with this unit:

a RIGHT PEC-DECK ARM (24) and a LEFT

PEC-DECK ARM {25). Instructions are

given for one and. are repeated to assemble

the other.

0 Insert the Pee-Deck Arm Pivot Tube into the

ARM PRESS ASSEMBLY (22) and place a

large 2 X 1 3/16 FLAT WASHER (80)

over the Pivot Tube. (SEE DETAIL A.)

0 Secure each Pee-Deck Arm in place by

bolting through the top of the Pivot Tube

with a 5/16 X 1 112 HEX HEAD BOLT

{65} and a 5116 NYLON LOCK NUT (67).

0 Cap the top and bottom of the Pivot Tube

with a 1 ROUND PLASTIC INSERT CAP

(92).

I W ~

Ll ':.\ Pee-Deck Arms from pivoting by

inserting 5116 X 2 112 PEC-DECK LOCK

PINS (85) down through the brackets on the

sides of the ARM PRESS ASSEMBLY (22)

and through the pin holes in the Pee-Deck

Arms.

0 When doing Butterfly Exercises, a

PEC-DECK LOCK PIN (85) . should be

inserted down through the center tube

section of the ARM PRESS ASSEMBLY

(22). (SEE DETAIL B.)

0 Press 1 112 SQUARE PLASTIC INSERT

CAPS (91) into ends of the Pee-Deck Arms.

" NOTE: WHEN DOING ARM PRESS

EXERCISES CHECK TO MAKE SURE

THAT EACH OF THE PEC-DECK ARMS

IS LOCKED INTO PLACE WITH THE

PEC-DECK LOCK PINS.

91

~

25

" NOTE: WHEN DOING PEC-DECK EXERCISES CHECK TO MAKE SURE THAT THE CENTER PIN ONLY IS LOCKING

THE ARM PRESS ASSEMBLY TO THE L-BRACKET.

WBDER HEALTH and RTNESS

STEP II ARM PRESS HANDLE ASSEMBLY

PARTN.AME QTY

63 5116" X 2" HEX HEAD BOLT 2

67 5116" NYLON LOCK NUT 2

68 5116" FLAT WASHER 4

88 9132" LONG METAL SPACER 2

92 1" ROUND PLASTIC INSERT CAP 4

D Wipe a small amount of liquid dish

detergent onto lower section of

PEC-DECK ARMS (24) and (25) and

slide on a 4" X 7 1/2" FOAM ROLLER

(26). Position Rollers up about 8 inches

from the tube end.

D Cap the ends of the ARM PRESS

HANDLES (27) with 1" ROUND

PLASTIC INSERT CAPS (92).

D Insert the end of the ARM PRESS

HANDLE (27) with the holes into the

PEC-DECK ARM (24) and (25).

D Rotate the Handle until the bolt holes

align.

D Assemble a 5/16" FLAT 24

WASHER (68) and a 9132"

LONG METAL SPACER (88)

onto a 5/16" X 2" HEX HEAD

BOLT (63) and insert through

the front of the Pee-Deck Arm

and then through the hole in

the Arm Press Handle.

Attach another 5/16" FLAT 28 27

WASHER (68) and Bsecure

with 5/16" NYLON LOCK t!t

NUT (67). ()

0 Wipe a small amount of liquid 92

dish detergent onto outer

section of ARM PRESS

HANDLE (27) and slide on

1" X 5" FOAM GRIP (28).

6768

Of

92

26

PAGE14

88

68 63

WBDER HEALTH .nd R1NESS

STEP '12 AB I=LEX ARM ASSEMBLY

PAi:ttNAME . QTY .

62 5116" X 31/4" HEX HEAD BOLT 2

63 5116" X 2" HEX HEAD BOLT 2

67 5116" NYLON LOCK NUT 4

68 5116" FLAT WASHER 8

91 1 112" SQUARE PLASTIC INSERT CAP 2

92 1" ROUND PLASTIC INSERT CAP 2

94 11/4" SQUARE PLASTIC INSERT CAP 2

0 Position AB FLEX ARM HANDLES (12)

down into tubing of the AB FLEX ARMS

(1.1 ).

D Align hole in handle with the hole in the

tubing and bolt through the inside hole at

the tubing end with a 5116 X 2 HEX HEAD

BOLT (63) and 5116 FLAT WASHER (68)

and then through the Ab Flex Arm Handle.

Attach another 5/16 FLAT .WASHER (68)

to the bolt and secure with a 5/16 NYLON

LOCK NUT (67).

94 13

~

PAGE15

0 Assemble 5/16 FLAT WASHERS (68) on two 5/16 X 3 114 HEX HEAD BOLTS (62) and bolt up through the bottom of

the AB FLEX ARM CONNECTOR TUBE {13) and then through the AB FLEX ARM (11). Assemble another5116 FLAT

WASHER onto each bolt and secure with 5116 NYLON LOCK NUTS (67).

0 Cap the ends of the AB FLEX ARM CONNECTOR TUBE (13) with 1 1/4 SQUARE PLASTIC INSERT CAPS (94).

0 Cap the ends of the AB FLEX ARM (11} with 1 112 SQUARE PLASTIC INSERT CAP {91).

0 Cap the ends of the AB FLEX ARM HANDLES (12) with 1 ROUND PLASTIC INSERT CAPS {92).

STEP '15 ATTACHING AB I=LEX ARM ASSEMBLY

PART NAME .. . . . . . . . .. arv

61 5116" X 2 314" HEX HEAD BOLT

67 5116" NYLON LOCK NUT

68 5116" FLAT WASHER

D Attach the Ab Flex Arm

Assembly to the upper two holes

in the SQUAT STATION

UPRIGHT (6) by assembling

5116 FLAT WASHERS {68) on

two 5116 X 2 314 HEX HEAD

BOLTS (61) and bolting through

the Upright and welded bracket

on the Ab Flex Arm Assembly.

Secure with 5/16 NYLON

LOCK NUTS (67).

2

2

2

5

12

I

WBDER HEALTH and RTNESS PAGE 16

STEP '14 BACKREST & ARM PAD ASSEMBLY

.....................

... .....

63 5116" X 2" HEX HEAD BOLT

67 5116" NYLON LOCK NUT

68 5116" FLAT WASHER

69 1/4" X 314" MACHINE SCREW

70 1/4" X 2" MACHINE SCREW

0 Attach the BACKREST (43) to

BACK SUPPORT

BRACKET (10) using 114 X

314 MACHINE SCREWS (69)

and bolting through the back of

the Bracket and into the

Backrest.

D Attach the ARM PADS (44) to

the AB FLEX ARM (11) by

assembling 5/16 FLAT

WASHERS (68) on two 114 X

2 MACHINE SCREWS (70)

and bolting up through the Ab

Flex Arm and into the Arms

Pads.

0 Remove the STATION 3

DECAL (1 09) from the backing

sheet and affix to the SQUAT

STATION UPRIGHT (6) just

below the Ab Flex Arm

Assembly.

2

4

0 Fasten the BACK SUPPORT BRACKET (10) to the Ab Flex Arm

Assembly using a 5/16 X 2 HEX HEAD BOLT (63) and bolting

through the Bracket and then the center hole in the AB FLEX ARM

CONNECTOR TUBE (13). Place a 5/16 FLAT WASHER (68)

the bolt and secure with a 5/16 NYLON LOCK NUT (67).

STEP t5 SOUAT STATION BAR ASSEMBLY

PART NAME

. QTY

59 5116" X 3" HEX HEAD BOLT 1

67 5116" NYLON LOCK NUT 1

91 1 112" SQUARE PLASTIC INSERT CAP 2

D Assemble the SQUAT STATION BAR (45) to the

SQUAT STATION UPRIGHT (6) by bolting with

5116 X a HEX HEAD BOLT (59) through the

U-Bracket of the Bar and then through the

Upright. Fasten with 5/16 NYLON LOCK NUT

(67).

0 Cap the ends of the SQUAT STATION BAR (45)

with 1 112 SQUARE PLASTIC INSERT CAP

(91).

D Wipe a small amount of liquid detergent onto the

lower section of the SQUAT STATION BAR (45)

and press on 3 114 X 7 FOAM ROLLER (46).

0 Remove the STATION 2 DECAL (108) from the

backing sheet and affix to top of the SQUAT

STATION UPRIGHT (6) above the SQUAT

STATION BAR (45).

WBDER HEALTH and RTNESS

STEP I& TOP CABLE ASSEMBLY

PART NAME

33 3 112" PULLEY

42 4 112" PULLEY

75 318" X 1 314" HEX HEAD BOLT

76 318" NYLON LOCK NUT

78 318" FLAT WASHER

79 318" X 2 314" HEX HEAD BOLT

87 17/32" LONG METAL SPACER

D

D Assemble a 3/8" FLAT WASHER

(78) and a 17/32" LONG METAL

SPACER (87) onto a 3/8" X 2

314" HEX HEAD BOLT (79).

0 Fit a 4 1/2" PULLEY (42) down

into the slot on the TOP FRAME

(9) and using the previous

assembled 3/8" X 2 3/4" HEX

HEAD BOLT (79), insert it

through the hole at the front of the

Top Frame and through the 3 1/2"

PULLEY (33).

D Assemble another 17/32" LONG

METAL SPACER (87) and 318"

FLAT WASHER (78) onto the bolt

and fasten with 318" NYLON

LOCK NUT (76).

D NOTE: Tighten 318" X 2 3/4"

HEX HEAD BOLT (79) only

enough to secure 4 1/2"

PULLEY (42). Pull slightly on the

Cable to check Pulley. If the bolt

is too tight it will turn with the

Pulley. If it is too tight, loosen the

Lock Nut slightly until the bolt

does not turn.

QTY

2

1

1

2

2

1

2

PAGE17

II

D Insert the cable through the welded bracket on top of the TOP FRAME (9) and down through the Cable access hole in the

Frame tube behind the bracket.

D Assemble another 3 1/2" PULLEY (33) by fitting it beneath the Cable and in the welded bracket atop the Frame. Bolt

through the bracket and the Pulley with a 3/8" X 1 314" HEX HEAD BOLT (75) and fasten with 3/8" NYLON LOCK NUT

(76).

0 Bring the Cable approximately half way down from the top of the unit leaving a large loop.

WEIDER HEALTH and RlNESS PAGE 18

STEP '17 PULLEY BRACKETS

PART.NAME ......

59 5116" X 3" HEX HEAD BOLT

67 5116" NYLON LOCK NUT

QTY

4

4

0 Attach the PEC-DECK PULLEY BRACKETS (RIGHT & LEFT- HOLE)

(34) and (a5) to the welded U-Brackets on the back of the PEC-DECK

ARM (24) and (25) by bolting with 5/16 X a HEX HEAD BOLTS (59)

through the welded bracket and then the Pee-Deck Pulley Bracket.

Fasten with 5/16 NYLON LOCK NUTS {67).

D Attach the PEC-DECK PULLEY BRACKET

(CENTER- HOLE) (41) to the welded U-Bracket at

the top and on the side of the ARM PRESS FRAME

UPRIGHT (5) by bolting with a 5116 X a HEX

HEAD BOLT {59) down through the welded

U-bracket and then through the Pulley Bracket.

Fasten with a 5/16 NYLON LOCK NUT (67).

0 To the welded U-Bracket at the top and side of the

SQUAT STATION UPRIGHT (6), attach a

PEC-DECK PULLEY BRACKET (CENTER - HOLE)

(41) by bolting with a 5/16 X a HEX HEAD BOLT

(59) down through the top of the welded U-Bracket

and then through the Pulley Bracket. Fasten with a

5/16 NYLON LOCK NUT (67). 67

'9

WBDER HEALTH and RTNESS PAGE 19

STEP '18 PULLEYS

PART NAME

'><

...

QTY

58 318" X 3" HEX HEAD BOLT 1

61 5116" X 2 314" HEX HEAD BOLT 1

67 5116" NYLON LOCK NUT 1

68 5116" FLAT WASHER 1

75 318" X 1 314" HEX HEAD BOLT 5

76 318" NYLON LOCK NUT 7

78 318" FLAT WASHER 2

84 318" X 3 112" HEX HEAD BOLT 1

0 Bring the PEC-DECK CABLE (32) up and set into a

3 112 PULLEY (33) and bolt the Pulley onto the

PEC-DECK PULLEY BRACKET (41) on the ARM

PRESS UPRIGHT (5).

0 Trap the Cable into the Pulley with a CABLE TRAP

BRACKET (40) and fasten_with a 3/8 X 1 314 HEX

HEAD BOLT (75) by bolting through the Pulley

Bracket, the Pulley, and then the Cable Trap

Bracket. Fasten with a 3ta NYLON LOCK NUT

(76).

0 Next bring the Cable forward and set into 3 112

PULLEYS (33) and bolt the Pulleys onto the

PEC-DECK PULLEY BRACKETS (34) and (35) on

the back of the PEC-DECK ARMS (24) and (25).

0 Trap the Cable into the Pulleys with CABLE TRAP

BRACKETS (40) and fasten with 318 X 1 3/4 HEX

HEAD BOLTS (75) by bolting down through the

CABLE TRAP BRACKETS (40), the PULLEYS (33),

and then the PEC-DECK PULLEY BRACKETS (34).

Secure with 318 NYLON LOCK NUTS (76).

0 Bring the Cable next to the welded brackets on the

front of the ARM PRESS FRAME (5) and assemble

another 3 112 PULLEY (33), trapping the cable

between the Pulley and the Frame Brackets. Bolt

with a 3J8 X 1 3/4 HEX HEAD BOLT (75) up

through the bottom of the welded bracket and then

through the Pulley. Fasten with a 3ta NYLON

LOCK NUT (76).

0 Bring the Cable around to the welded U-Bracket on

the top and at the side of the SQUAT STATION

UPRIGHT (6).

0 Next fasten a 3 112 PULLEY (33) to the PULLEY

BRACKET (41) while trapping the Cable in the

Pulley with a CABLE TRAP BRACKET (40).

0 Bolt together with a 319 X 1 314 HEX HEAD BOLT

(75) and by bolting through the Cable Trap Bracket,

the Pulley, and then the Pulley Bracket. Secure with

3/8 NYLON LOCK NUT (76).

-

WBDER HEALTH and RTNESS

D Continue bringing the Cable

down behind the SQUAT

STATION UPRIGHT (6) and

under the Upright Brace.

Just below the Brace is a

Hole position to mount

another Pulley. To this

location fit the Cable into a 3

112 PULLEY (33) then

position a CABLE TRAP

BRACKET (40) to the bottom

of the Pulley and bolt in place

with a 318 X 3 112 HEX

HEAD BOLT (84) through

the Cable Trap and Pulley,

and secure with another

3/a FLAT WASHER (78)

and318 NYLON LOCK NUT

(76).

D Now bring the Cable back up

to the right side of the

SQUAT STATION BAR (45)

and loop around another 3

112 PULLEY (33) so the

Cable runs over the Pulley

from front to back. Fasten to

Bar with a 3/a X 3 HEX

HEAD BOLT (58) through

the Pulley, then through

the Bar and secure with

3/a FLAT WASHER

(78) and a 3/8 NYLON

LOCK NUT (76).

D Bring the Cable back down to

where the Upright support is

attached to the SQUAT

STATION UPRIGHT (6) and

boft through the loop of the

Cable and the Support Arm

and Upright using a 5/16 X

2 3 ~ HEX HEAD BOLT

(61), a 5/16 FLAT

WASHER (68) on the front

side and another 5/16 FLAT

WASHER (68) and 5/16

NYLON LOCK NUT (67) on

the back.

PAGE20

32

DRAWING OF ENTIRE CABLE ROUTING

WBDER HEALTH and RTNESS PAGE21

STEP '18 LOWER PULLEYS & CABLES

PART NAME ...

64 5116" X 2 112" HEX HEAD BOLT

65 5116" X 1 112" HEX HEAD BOLT

66 5116" X 314" HEX HEAD BOLT

67 5116" NYLON LOCK NUT

68 5116" FLAT WASHER

74 1/4" NYLON LOCK NUT

75 318" X 1 314" HEX HEAD BOLT

76 318" NYLON LOCK NUT

78 318" FLAT WASHER

81 318" X 2 1/4" HEX HEAD BOLT

82 318" X 3 1/4" HEX HEAD BOLT

83 1/4" X 1 314" HEX HEAD BOLT

86 112" LONG METAL SPACER

QTY

1

1

1

3

3

1

3

5

2

1

1

1

1

0 Attach the WEIGHT STACK CABLE (36) to the WEIGHT SELECTOR

TUBE (17) by inserting the loop end of the Cable into the top of the

Tube and bolting through the side of the tube and through the Cable

loop with a 5116" X 1 1/2" HEX HEAD BOLT (65). Fasten with 5/16"

NYLON LOCK NUT (67).

D Bring the Cable up and make a dual Pulley Assembly (SEE DETAIL

A.). Assemble two 318" X 1 3/4" HEX HEAD BOLTS (75) into a

PULLEY CONNECTOR PLATE (37). Then assemble a 4 1/2"

PULLEY (42) onto each bolt. Bring the WEIGHT STACK CABLE

(36) over the top of the lower Pulley. Bring the upper PEC-DECK

CABLE (32) down and around the upper Pulley. Fasten another

PULLEY CONNECTOR PLATE (37) onto the ends of the two bolts

and secure with two 3/8" NYLON LOCK NUTS (76).

0 Bring the WEIGHT STACK CABLE (36) down to the welded base bracket on the ARM PRESS FRAME UPRIGHT (5) and fit

into a 3 1!1" PULLEY (33). Using a 3/8" X 2 1/4" HEX HEAD BOLT (81), bolt a CABLE TRAP BRACKET (40) the Pulley,

and a 112" LONG METAL SPACER to the base bracket on the side of the Upright. Secure with a 3/8" NYLON LOCK NUT

(76).

0 Bolt the BENT PULLEY TRAP BRACKET (38) together through the center hole with a 1/4" X 1 3/4" HEX HEAD BOLT (83)

and a 1/4" NYLON LOCK NUT (74).

0 Bolt the Cable end to the BENT PULLEY TRAP BRACKETS (38) by bolting with a 5/16" X 314" HEX HEAD BOLT (66)

through one Bent Pulley Trap Bracket, then through the Cable loop, and then another Bent Pulley Trap Bracket. Fasten with

5/16" NYLON LOCK NUT (67).

0 Connect the LEG EXTENSION CABLE (39) to the upper section of the LEG EXTENSION TUBE (29) using a 5/16" X 2 112"

HEX HEAD BOLT (64) and bolting through a 5/16" FLAT WASHER (68), through the loop end of the Cable, and then

through the Leg Extension Tube. Add another 5116" FLAT WASHER (68) to the bolt end and fasten with 5/16" NYLON

LOCK NUT (67).

D Take the LEG EXTENSION CABLE (39) rearward and around a 3 112" PULLEY (33). Bolt the Pulley to the other end of the

BENT PULLEY TRAP BRACKETS (38) using a 318" X 1 314" HEX HEAD BOLT (75) to bolt through the Bracket, the Pulley,

and the other Bracket. Fasten with a 3/8" NYLON LOCK NUT (76). (SEE DETAIL B.)

0 Pull the Cable forward to the bottom of the LEG EXTENSION TUBE (29).

D Fit a 3 1/2" PULLEY (33) atop the Cable and fasten the Pulley to the Leg Extension Tube by bolting with a 3/8" X 3 1/4" HEX

HEAD BOLT (82) through the Pulley, a 3/8" FLAT WASHER (78), and then the Tube. Add a 318" FLAT WASHER (78) to

the bolt and fasten with a 3/8" NYLON LOCK NUT (76).

NOTE: CHECKING TO SEE THAT ALL CABLES ARE SEATED IN PULLEY GROOVES, PULL LEG EXTENSION CABLE

(39) FORWARD SO ALL SLACK IS TAKEN OUT OF THE CABLE SYSTEM. SLIDE RUBBER BALL STOPPER BACK

AGAINST LEG EXTENSION AND SNUG CABLE CLAMP FIRMLY AGAINST STOPPER AND TIGHTEN HEX BOLT TO

SECURE. (SEE DETAIL C.) WITH USE, CABLE WILL STRETCH AND YOU MAY HAVE TO RE-SET CABLE STOP TO

TAKE OUT ANY SLACK THAT DEVELOPS.

WBDER HEALTH and RTNESS

DETAILC

-

PAGE22

65

LEG EXTENSION CABLE

When assembling the LEG EXTENSION CABLE (39) make

sure the end of the cable that is bolted to the Purley at the

base of the Leg Extension has the crimped ferrule at the

very end, then the sliding ad,ustment ferrule with the hex

bolt, and then the rubber ba I stop, in that order. If this

order" is not correct, then you must slide the sliding

adjustment ferrule and rubber stop to the opposite end.

SEE ILLUSTRATION!

!

....

CONDITIONING GUIDELINES

The following guidelines will help you to plan and regulate your personal fitness program. Remember that

adequate rest and good nutrition are also essential to the success of any fitness program. BEFORE

BEGINNING THIS OR ANY EXERCISE PROGRAM, CONSULT YOUR PHYSICIAN!

EXERCISE INTENSITY

To maximize the benefits from exercising, your level of exertion must exceed mild demands while falling

short of causing breathlessness and fatigue. The proper level of exertion can be determined using the

heart rate as a guide. For effective aerobic exercise, the heart rate must be maintained at a level between

70% and 85% of your maximum heart rate. This is your "Training Zone". You can determine your Training

Zone by consulting the table below. Training Zones are listed for both conditioned and unconditioned

persons according to age. Use the column that is appropriate for you.

UNCONDITIONED CONDITIONED UNCONDITIONED CONDITIONED

AGE TRAINING ZONE TRAINING ZONE AGE TRAINING ZONE TRAINING ZONE

(BEATS/MIN) (BEATS/MIN) (BEATS/MIN) (BEATS/MIN)

20 138-167 133-162 55 127-155 122-149

25 136-166 132-160 60 126-153 121-147

30 135-164 130-158 65 125-151 119-145

35 134-162 129-156 70 123-150 118-144

40 132-161 127-155 75 122-147 117-142

45 131-159 125-153 80 12Q-146 115-140

50 129-156 124-150 85 118-144 114-139

During the first few weeks of your exercise program, you should keep your heart rate near the low end of

your Training Zone. Over the course of a few months, gradually increase your heart rate until it reaches the

hi9h end of your Training Zone. As your condition improves, a greater workload will be required in order to

ra1se your heart rate to your Training Zone.

The easiest way to measure your heart rate is to stop

exercising and place two fingers on your wrist where you feel a

pulse. Carefully take a six-second heart beat count. (A

six-second count is used because your heart rate will drop

rapidly after you stop exercising.) Add a 0 to the result to find

your heart rate. Compare your heart rate to your Training

Zone. If your heart rate is too low, increase your level of

exertion. If your heart rate is too high, decrease your level of

exertion.

WORKOUT PATTERN

Each workout should consist of 5 basic parts: 1. AT REST, 2.

WARMING-UP, 3. TRAINING ZONE EXERCISE,

4.COOLING-DOWN, 5. AT REST.

Warming up is an important part of every workout. Warming up prepares the body for more strenuous

exercise by increasing circulation, delivering more oxygen to the muscles, and raising the body

temperature. This can be done by stretching for 5-10 minutes prior to exercising.

After warming up, begin exercising at a low intensity level for a few minutes. Then increase the intensity to

raise your heart rate to your Traimng Zone for a period of 20-30 minutes.

Cooling down after vigorous exercise is important in aiding circulation and preventing soreness. 5-10

minutes of stretching or light exercise will allow the body to cool down .

~

r

I

EXERCISE FREQUENCY

To maintain or improve your condition, you must workout 2-3 times per week following the pattern described above. A

day of rest between workouts is recommended. After several months of exercise, the number of workouts can be

increased to 4-5 times per week. The key to a successful program is REGULAR exercise.

SUGGESTED STRETCHES

The following stretches provide a good warm-up, or

cool-down. Move slowly as you stretch - never bounce.

HAM STRING STRETCH

Sit with one leg extended. Bring the sole of the opposite

foot toward you, resting it against the extended leg's inner

thigh. Stretch toward your toe as far as possible, hold for

15 counts, then relax. Repeat three times for both legs.

Stretches: Hamstrings. Lower Back and Groin

INNER THIGH STRETCH

Sit with the soles of your feet together and knees pointing

outward. Pull your feet as close into the groin area as

possible. Hold for 15 counts, then relax. Repeat three

times.

Stretches: Quadriceps. Hip Muscles

TOE TOUCHES

Standing with your knees bent slightly, slowly bend

forward from the hips. Allow your back and shoulders to

relax as you stretch down toward your toes. Go as far as

you can and hold for 15 counts, then relax. Repeat three

times.

Stretches: Hamstrings. Back of Knees. Back

QUADRICEPS STRETCH

With one hand against a wall for balance, reach behind

you and pull up your foot. Bring you heel as close to your

buttocks as possible. Hold for 15 counts. Repeat.

Stretches: Quadriceps. Hip Muscles

CALF/ACHILLES STRETCH

W ~ h one leg in front of the other and arms out, lean

against the wall. Keep your back leg straight and back

foot flat on the ground; then bend the front leg and lean

forward by moving your hips toward the wall. Hold, then

repeat on the other side. To cause even further

stretching of the Achilles tendons, slightly bend back leg

as well.

Stretches: Calves. Achilles Tendons. and Ankles

[\

( m l

IMPORTANT

BEPORE CALLING THE BOO NUMBER

IN ORDER TO RECEIVE SERVICE ON THIS PRODUCT YOU WILL HAVE TO FIRST SEND IN

YOUR WARRANTY CARD

ALL OF THE PARTS FOR THE WEIGHT BENCH CAN BE ORDERED FROM WEIDER HEALTH AND

FITNESS, PARTS SERVICE DEPT., 900 WEST ST. JOHN ST., OLNEY, IL. 62450. WHEN

ORDERING, PARTS WILL BE SENT AND BILLED AT THE CURRENT PRICES. PRICES MAY BE

SUBJECT TO CHANGE WITHOUT NOTICE. STANDARD HARDWARE ITEMS ARE AVAILABLE AT

LOCAL HARDWARE STORES.

TO OBTAIN PARTS DO NOT GO BACK TO THE STORE WHERE YOU

PURCHASED THIS UNIT

ALWAYS INCLUDE THE FOLLOWING INFORMATION WHEN ORDERING PARTS:

MODEL NO. NAMEOPPART ORDERING NO.

... ::::::::::::::::.:: ::::::.::: .:.:::: :::::::::: =..: ::.:.:::::::::::.. . . ..

. :::::::::::=:::::::::::: .. :: ::::::::- .. ::.::.::.::- :.: .. ::: .:.::::::.:: : :::::::.

......... . . . ........ . . ... .

, " . , ...... ,.................... ..':WARNING .

H ., ........ , .... , ............... ,. ' .. ,,, ... ,, ... <<

. coNsOI..fvoUFfPHvslciAN

: jj :; ; ;; li .; ; ::. ::::: ::::::: :] :: .... :;::.:::::: ::::.:.:::: .. :::::::::;;.: : :: .. :]::. :=::::.::: .. ::.: ..... ; .. : l::: \:\:\:::;::: :

CONSULT YOUR PHYSICIAN.BEFORE STARTING voORExERCISE PROGRAM.rras

/ ADVISABLE roHAVE A PHYSICAL EXAMINATioN Bvvol.JR PHYSICIAN BEFORE

You ENTER ANY EXERCISE PROGRAM. . . ...... . .. .. . ....... . ........... ........ .

:::::::::::: :::::::::::::::: :::::::::::::::-::::::::::::::::::::::::: :::;-:::::::=::::=: =.=:::: .. : . =. : :::::::: :::::::= :::.:=.:::::=.::::.: =::.::::::::::::::::::::

... ........... ........... ............ .... .. . .... . ........... ... . ... . . ... . . . . . ...... .... .......... ..... . ........... .

.. ............. ..... .. ............ ..... .... . ... . ....... ... ....... .. .. .. . . . . .. ... .. . ... . . . . ... . ................ ..

. ::: ::::::::::::::":::::.:::::::::::::::::::::::: .. . :: :::::::.:::::::::::.::. :: :. .. .. : : .... :: .. ::::::::::: .: ."::: .... : . .. ":: .::: :::: ... .

. ::::::.:::::::: .. : .. :.::::::::::.: ;:::::: .. :::::: ::::::::::: ::::::.::: .... :::::::: .. :.:::.: ::.:::::::::: ... :: :: :: .. : :. .. ::: .: . . .. : :: .. .: :::

f:PRvR t>WN sAf=EiY. o6 N()T BEGIN ANYeXI:Rcr$E\VIl"HC>ut PRC)PeR.

. INSTRUCTION; ..

.. =.:::=:.- :>><::.... . .: ::= .: ...... .

.. .. . ............ .

.. . . .. ........... ..

. . . . ........... ..

. ...... . .. . .. . . . . . .. .

TRAIN WITH A PARTNER

.

. TRAINING p/JrrNER IN SET OP '\'OUR PROGRAM to

ACC::QI\IIMoDA"TI: TWo PJ:OPLE AND VOOWILL BE HIGHLY I\II()TlVATED.

I

I

.

t

!

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Manual MutekyDocumento4 pagineManual MutekyDamian CampilloNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- User Manual For Wireless Controller HAMA SCORPAD 00051838 PS3Documento3 pagineUser Manual For Wireless Controller HAMA SCORPAD 00051838 PS3Victor GheorgheNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Deepak Sharma 1211Documento3 pagineDeepak Sharma 1211peter samuelNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- LogDocumento46 pagineLogJuan Pablo Reina MontañezNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- On A/C All: Wiring Diagram ManualDocumento4 pagineOn A/C All: Wiring Diagram ManualatrflyerNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Performance PDFDocumento458 paginePerformance PDFmsmamoyaNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- D204-06-001 - Issue - 3 - STExCP8 - CONEXAO ELETRICADocumento4 pagineD204-06-001 - Issue - 3 - STExCP8 - CONEXAO ELETRICARoberto Martin NavarroNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Arid Agriculture University, RawalpindiDocumento7 pagineArid Agriculture University, RawalpindiRao HarisNessuna valutazione finora

- 10.boot Process For RHEL7Documento7 pagine10.boot Process For RHEL7Chennamadhavuni SahithiNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Various Addressing Modes of 8086 - 8088Documento3 pagineVarious Addressing Modes of 8086 - 8088NeelmaniNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Modul IotDocumento9 pagineModul IotArman MaulanaNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Growing A Local Datastore From The Command Line in Vsphere ESXi (2002461)Documento5 pagineGrowing A Local Datastore From The Command Line in Vsphere ESXi (2002461)MM CvNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- A36 Annunciator Light DiagramDocumento3 pagineA36 Annunciator Light Diagramh26mmhng7qNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- MST Instructions 2020Documento10 pagineMST Instructions 2020Jon RupiahNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Sir Kyle Perez 2Documento11 pagineSir Kyle Perez 2Paulo Celis100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Rev0 (Technical and User's Manual)Documento72 pagineRev0 (Technical and User's Manual)mohamedNessuna valutazione finora

- MPMC - LAB - W6.E6 8051 Keil-HW LCDDocumento38 pagineMPMC - LAB - W6.E6 8051 Keil-HW LCDDhanashree PanchawatkarNessuna valutazione finora

- Avnet Ultrazed Board Definition File Installation and Tutorial (Vivado 2016.2)Documento19 pagineAvnet Ultrazed Board Definition File Installation and Tutorial (Vivado 2016.2)venugopal mNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Cs8493 Operating Systems Important QuestionsDocumento29 pagineCs8493 Operating Systems Important Questions5016 V.GayathriNessuna valutazione finora

- Configuring Xenserver 7.0 For Graphics May 2016Documento21 pagineConfiguring Xenserver 7.0 For Graphics May 2016dealahzNessuna valutazione finora

- Ammonium Amtax ManualDocumento118 pagineAmmonium Amtax ManualLaura DelfaNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Contoh Preventive MaintenanceDocumento35 pagineContoh Preventive MaintenanceAimanullahNessuna valutazione finora

- Asus 1201ha (Diagramas - Com.br)Documento51 pagineAsus 1201ha (Diagramas - Com.br)Ruan RomãoNessuna valutazione finora

- TLE-CSS10 - 11 - q2 - wk3 - Install Operating System and Drivers For Peripherals Devices - v3Documento24 pagineTLE-CSS10 - 11 - q2 - wk3 - Install Operating System and Drivers For Peripherals Devices - v3EVELYN GRACE TADEONessuna valutazione finora

- Ipc Yaw Wiring 23cdaDocumento3 pagineIpc Yaw Wiring 23cdaPee TockNessuna valutazione finora

- Logical Address To Physical Address ConversionDocumento7 pagineLogical Address To Physical Address Conversionlexter Marcia2ndNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Gigabyte GA-H110M-S2 DDR3 Rev1.0Documento45 pagineGigabyte GA-H110M-S2 DDR3 Rev1.0TimurNessuna valutazione finora

- Assembly Language ProgramsDocumento33 pagineAssembly Language ProgramsPiyush chaudhariNessuna valutazione finora

- 04 Brosur Paket Hikvision Audio Dan ColorVuDocumento2 pagine04 Brosur Paket Hikvision Audio Dan ColorVuAgung PNessuna valutazione finora

- Asus Vivobook Gaming 15 (F571GT-AL369T) 15.6 - I7 16GB RAM Laptop - Harvey Norman SingaporeDocumento3 pagineAsus Vivobook Gaming 15 (F571GT-AL369T) 15.6 - I7 16GB RAM Laptop - Harvey Norman SingaporePeter NgNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)