Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Design Calculation and Performance Testing of Heating Coil in Induction Surface Hardening Machine

Caricato da

IjabiDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Design Calculation and Performance Testing of Heating Coil in Induction Surface Hardening Machine

Caricato da

IjabiCopyright:

Formati disponibili

World Academy of Science, Engineering and Technology 18 2008

Design Calculation and Performance Testing of Heating Coil in Induction Surface Hardening Machine

Soe Sandar Aung, Han Phyo Wai, and Nyein Nyein Soe

= specific permeability f = frequency, Hz This formula shows that as the frequency is higher, will be smaller and the heating will be concentrated as the surface in case the materials are same. However in actual heating, the heated tends to become bigger because of heat conduction in the heated material.

Alternating current Induced current

AbstractThe induction hardening machines are utilized in

the industries which modify machine parts and tools needed to achieve high ware resistance. This paper describes the model of induction heating process design of inverter circuit and the results of induction surface hardening of heating coil. In the design of heating coil, the shape and the turn numbers of the coil are very important design factors because they decide the overall operating performance of induction heater including resonant frequency, Q factor, efficiency and power factor. The performance will be tested by experiments in some cases high frequency induction hardening machine.

KeywordsInduction Heating, Resonant Circuit, Inverter Circuit, Coil Design, Induction Hardening Machine. I. INTRODUCTION HE principle of induction heating is shown in Fig. 1, there an electric conductor such as iron or steel placed in the inductor is heated rapidly by induced eddy current caused by electromagnetic induction, and hysteretic heat loss, which is generated by vibration and friction of each molecule in magnetic material under AC magnetic flux. In induction heating, as the frequency of the heating current tends to concentrate close to the metal surface (work piece).This is referred to as the skin effect. The skin effect is the phenomenon, which electric current flows only in the limited area near surface of conductive material, and proximity effect is the phenomenon, which the primary current in the inductor and the secondary current in the conductive material pull each other because the direction of current is opposite each other, and flows in the limited area near surface where distance is nearest each other. The depth depends upon the frequency and as the frequency is higher, the depth becomes smaller. [1] The penetration depth is calculated as follows;

Work coil

Alternating magnetic field

Work piece

Fig. 1 Basic Induction Type Heating System

II. SYSTEM CONFIGURATION Fig. 2 shows the general block diagram of the induction heating system. The AC power source is single phase and it applies line frequency and line voltage. The non controlled rectifier converts the AC voltage to the DC values and applies the desired DC current to the inerter circuit. The inverter changes the DC signals to the AC signals with desired frequency to apply the work coil. When the work piece has been heated for a time, the quenching system is applied to the work piece.[2]

Single phase power supply Non controlled rectifier circuit Inverter circuit Work coil

1 f

(m)

(1)

Triggering cirrcuit

Where, = penetration depth, m

Soe Sandar Aung is with the Electrical Power Engineering Department, Mandalay Technological University, Mandalay, Myanmar (corresponding author to provide phone: 095-067-22123; e-mail: soesandarag@gmail.com). Han Phyo Wai is with the electrical Power Engineering Department, Mandalay Technological University, Mandalay, Myanmar (e-mail: hanphyowai@2007.com). Nyein Nyein Soe is with the Electrical Power Engineering Department, Mandalay Technological University, Mandalay, Myanmar (e-mail: nyeinnsoe@gmail.com).

416

Fig. 2 General Block Diagram

III. SYSTEM ANALYSIS A. Equivalent Circuit The work coil and work piece have the special property of resistance and reactance values due to their resistivity and inserted flux. Using Wheelers formula, the inductance of the work coil can be calculated as follows.

World Academy of Science, Engineering and Technology 18 2008

2 rout N Lc = 0.0254 9rout + 10l wc

(2)

Where Lc = inductance of work coil, H rout = outer radius of work coil, m lwc = length of work coil, m

Fig. 3 Impedance Circuit of Work Coil and Work Piece

The work coil and work piece can be represented by an equipment series inductance and resistance model as shown in Fig. 4.

L eq = L c + M

(3) (4)

R eq = R c + R w

Where M = magnetizing inductance, H Leq =equivalent inductance of work coil and work piece Req= equivalent resistance of work coil and work piece

C. Series Parallel Resonant Inverter This configuration has the desirable characteristics of series and parallel resonant inverters. The load short circuit and the no load regulation are possible. High part-load efficiency is possible with the proper choice of resonating components. A resonant inverter can be operated either below or above resonance frequency. This inverter contains impedance matching system. The tank circuit incorporating the work coil (Lw) and its capacitor (Cw) can be though of as a parallel resonant circuit This has a resistance (R) due to the loss work piece coupled into the work coil due to the magnetic coupling between the two conductors. In practice, the resistance of the work coil, the resistance of the tank capacitor and the resistance of the work piece all introduce a loss into the tank circuit and damp resonance. Therefore, it is useful to combine all of these cases into a single loss resistance. In the case of parallel resonant circuit this loss resistance appears directly across the tank circuit. This resistance represents the only component that can consume power and therefore it can be though of resistance as the load that it is being tried to drive power into as efficiently as possible.

CW

LW

Fig. 6 Circuit Diagram of Tank Circuit

CS A Rw Cp Cw RL B LS Lw

Fig. 4 Equivalent Circuit of Work Coil and Work Piece

B. Resonant Circuit As shown in Fig. 4, the equipment inductance and resistance of work coil and work piece are in series connection. To resonate the circuit a capacitor is connected in parallel resonant circuit and it is shown in Fig. 5.

Fig. 7 Diagram of Matching Network

Ic IT C

Leq

IV. REQUIRED SPECIFICATIONS FOR INDUCTION SURFACE HARDENING MACHINE The specifications for operating are the ambient temperature is assumed 300.15 K, the desired hardened temperature is 1116.48 K, the duration of hardened time is 10 sec, the output power is 5 kW and the use of apply frequency is 35 kHz. Table I is for the specifications of conductor used as work coil.

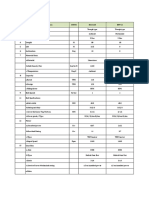

TABLE I SPECIFICATIONS OF CONDUCTOR Unit m Hm kg/m2 Specification material resistivity permeability density value copper 1.710-8(at 293.15 K) 1 7861.13

Req

Fig. 5 Resonant Circuit for the Load

If the capacitor is charged to a supply voltage, the energy stored in CVT2 2 . And this energy transfer to the inductance Leq and returns again to the capacitor so the frequency of the oscillation depends on the values of inductance and capacitance. In the circuit, the dissipated energy in resistance Req, and after each cycle of oscillation the store of energy in the capacitor is reduced.

417

World Academy of Science, Engineering and Technology 18 2008

TABLE II SPECIFICATIONS OF WORK PIECE Unit m Hm J/kg.K K K kg/m2 Specification Material Resistivity Permeability Specific heat Melting temperature Hardened temperature Density value 1040 carbon steel 1.710-8(at 293.15 K) 115.610-8(at 1253.15 K) 1 434 (at 300 K ) 1169 (at 1000 K ) 1794.26 1116.48 _ 1172.03 7861.13

B. Calculation of Impedance Matching System

L Q =

s C s

(10)

F=

(11)

V. CALCULATIONS OF INDUCTION SURFACE HARDENING MACHINE A. Calculation of Work Coil The number of turns of work coil is mainly based on the length of work piece and the pitch of coil windings. Thus, lw (5) N= d c +C p Where, N = number of turns of work coil Lw = length of work piece to be hardened, m And the inner diameter of work coil is

o From Equation (10) and (11), LS = 0.033185 mH CS = 0.753953 F CP = 0.753953 F The capacitor in the matching net work (CP) and tank capacitor (Cw) are both in parallel. In practice, both of these functions are usually accomplished by a single capacitor. Cpw = Cp + Cw = 1.796509 F

Cs

LS A

Is

Lw

Rw

+ VAB _

B

Ic

It

Cpw

VC

RL

D in =d w + 2C p

The outer diameter of work coil is

(6)

Fig. 8 Circuit Diagram of Matching System

D out =D in + 2d c

(7)

Z cpw =R - jX cpw = - j Vc Z cpw

119

1 C pw

= - j2.531178

Where, dw = diameter of work coil, m dc = diameter of conductor, m The total length of conductor for work coil is 2 2 l c = 2l lead +N ( 2 ) +(1.5d c ) (8) m Where, lc = length of conductor, m llead = length of work coil lead, m rm = inner radius of work coil, m The minimum thickness of conductor must be at least two times of depth of current penetration in conductor itself. Therefore, the minimum thickness of conductor is

Ic=

=

-j2.531178

= j47Amp It - Is = Ic = 16.042916 + j22.655880 = 27.760837( =54.70)

t c = 2 c

Where, tc = minimum thickness of conductor, m c = depth of current penetration in conductor, m The depth of current penetration in conductor is 1 c = f c o c Where, c = permeability of conductor, H/m o = permeability of free space, H/m c = electric conductivity of conductor, mho/m f = applied frequency, Hz

VAB =I s Z s - Vc Z s =jX ls - jX cs

= j s L s -

1 js Cs

(9)

= j7.297822 j6.0312583 = j1.266564 VAB = -147.696106 +j20.317976 =149.087088( =172.17) Required voltage for matching system is VAB = 149.087088Volt Required current for matching system is Is = 27.760837Amp ( =54.70) The selected series capacitor CS is 0.8 F, 600 Volt. The selected series inductor LS is 0.03 mH, 600 Volt, 2 Amp.

418

World Academy of Science, Engineering and Technology 18 2008

The selected parallel capacitor Cpw is 1.796507 F, 600 Volt. C. Calculation of Voltage and Current Ratings for Inverter Device voltage and current rating must to be satisfied supply bus voltage and the load impedance so that power can be delivered to the load. The required voltage for the load is VAB =149.087088 Volt. The supply dc voltage is 149.087088 volt. Peak of supply voltage = 2 149.087088 = 210.840982 Volt The inverter is driven high frequency switching. This is supplied by inductance load. D. Calculation of Single Phase Rectifier Circuit Inverter input voltage Ed = 149.087088 Volt Inverter input current Id = 27.760837 Amp So, required dc voltage Ed = 149.087088 149 Volt Required dc current Id = 27.760837 28 Amp Average load voltage V0(avg) = 0.636 Vm Vm is peak load voltage.

Unit m m m m2 m2 m3

TABLE III

RESULT FOR WORK PIECE

Specification Material shape Nature of surface Depth of hardness Diameter Length Cross sectional area Surface area Volume

Design Value 1040 carbon steel cylindrical uniform 0.0009587 0.067008 0.033504 0.000199 0.007053 6.665071

TABLE IV

RESULTS FOR WORK COIL

Unit m m m m m

Specification shape number of turns inner diameter outer diameter Length coil pitch coupling distance

Design Value round 4 0.070184 0.082884 0.0381 0.003175 0.001588

V= 2VRMS VRMS is supplied voltage RMS value. Ed = V0 (avg) Vm = V0(avg)/ 0.636 = 149.087088 / 0.636 = 234.276730 Volt

Supply voltage for system = 234.276730 / 2 = 165.658664 166 Volt Required supply voltage is 166 Volt to 220 Volt RMS value of load current = average load current = 27.760837 Amp Average current in each diode ID(avg) = I0(avg) / 2 = 13.880419 14 Amp Peak load current, I m =

TABLE V

RESULTS FOR CONDUCTOR

Unit m m m

Specification material shape thickness diameter length

Design Value copper round 0.000702 0.00635 1.282781

TABLE VI RESULT FOR ELECTRICAL PROPERTIES OF THE SYSTEM Unit Specification Resistance of work coil Resistance of work piece Inductance of work coil Magnetizing inductance Resonated capacitance Power factor Quality factor Total impedance Supply current Supply voltage Design Value 0.003114 0.121220 1.434858 0.551223 1.0411355 0.273791 3.512809 1.658596 71 119

I o(avg) 0.636

= 43.649115Amp

H H F

A V

Supply current for system, 43.649115 I rms = = 30.864585 31Amp 2 Required power =VI =5.11597 kW

A.C 220V,

+ D.C VII. PERFORMANCE TESTING A. Testing of Control Circuit Wave shape, frequency and voltage values at the input and output of control circuit are measured with oscilloscope. Resulting waves are square wave and the wave shapes are shown in Fig. 10.

Fig. 9 Circuit Diagram of Rectifier Circuit

VI. DESIGN RESULTS The results for work piece, conductor, work coil and electrical properties of the system are calculated. The results are shown in table respectively.

419

World Academy of Science, Engineering and Technology 18 2008

Fig. 13 Wave Shape of Inverter Output with Tank Circuit Fig. 10 IGBT gate driver circuit (for start heating)

ACKNOWLEDGMENT Firstly, the author would like to express her deepest great thank to her parents. The author deeply wants to express her special appreciation to Dr. Ni Ni Win, Department of Electrical Power Engineering Department, Mandalay Technological University, for her invaluable support and advice. REFERENCES

[1] [2] Curits,F.W.1944. High Frequency Induction Heating. 1sted. New York: McGraw-Hill Book Company, Inc. Zinn S., and Semiatin, S.L. 1988. Coil Design and Fabrication: Basic Design and Modifications. July 2005. Available: http://www.ameritherm.com Bhattachrya, S.K and Chute, R.D. 1971. Industrial Electronic and Control. New Delihi; Tata MC Graw-Hill Publishing Company Ltd.

[3]

Fig. 11 IGBT gate driver circuit (after heating)

B. Performance Testing of Inverter First, the inverter output is measured without tank circuit as shown in Fig. 12 and resulting wave shape is square wave with spite. Then, the inverter is concerned with tank capacitor and measured. The resulting wave shape is pure sine wave. The wave shapes are shown in Fig. 13.

Soe Sandar Aung studied in Electrical Power Engineering Major and held B.E degree in 2004 from Mandalay Technological University, Mandalay, Myanmar. Then I was awarded M.E degree of Electrical Power Engineering in 2006 from Yangon Technological University, Yangon, Myanmar. I am now studying and making induction heating research in my University..

Fig. 12 Wave Shape of Inverter Output without Tank Circuit

420

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Certified Six Sigma: Govind RamuDocumento4 pagineThe Certified Six Sigma: Govind Ramuoxovxkuptrxdomumsy33% (6)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Thesis On Cavitation in Centrifugal Pumps PDFDocumento238 pagineThesis On Cavitation in Centrifugal Pumps PDFIjabi100% (2)

- Engineering Standard Specification For Steam TracingDocumento53 pagineEngineering Standard Specification For Steam Tracingkaruna346100% (1)

- FEA TheoryDocumento49 pagineFEA Theoryof_switzerlandNessuna valutazione finora

- WB-Mech 120 Ch05 Modal PDFDocumento16 pagineWB-Mech 120 Ch05 Modal PDFchiragNessuna valutazione finora

- Stone Blower 1Documento22 pagineStone Blower 1kbaker001Nessuna valutazione finora

- E155-00 Aluminum & Magnesium CastingsDocumento4 pagineE155-00 Aluminum & Magnesium Castingschitti409Nessuna valutazione finora

- FEM Chapter 10Documento62 pagineFEM Chapter 10Nävèéñ TëjâNessuna valutazione finora

- m5l24 PDFDocumento6 paginem5l24 PDFsrinadh1602Nessuna valutazione finora

- 2 D ElementsDocumento18 pagine2 D ElementsBennet KuriakoseNessuna valutazione finora

- Datasheet-Creo Piping and Cabling Extension-EnDocumento5 pagineDatasheet-Creo Piping and Cabling Extension-EnGovind RajNessuna valutazione finora

- Four Node Iso-Parametric Quadrilateral ElementDocumento15 pagineFour Node Iso-Parametric Quadrilateral ElementBiao LiNessuna valutazione finora

- HourglassDocumento7 pagineHourglassSurya KiranNessuna valutazione finora

- Materials Selection For Seawater PumpsDocumento8 pagineMaterials Selection For Seawater PumpsIjabiNessuna valutazione finora

- GDand TDocumento0 pagineGDand TKaliya PerumalNessuna valutazione finora

- Machine Tool Spindle Bearing Selection Mounting GuideDocumento90 pagineMachine Tool Spindle Bearing Selection Mounting GuideIjabiNessuna valutazione finora

- Asssement of Wear Erosion in Pumps PDFDocumento6 pagineAsssement of Wear Erosion in Pumps PDFIjabiNessuna valutazione finora

- An Investigation On Texture-Property PDFDocumento54 pagineAn Investigation On Texture-Property PDFIjabiNessuna valutazione finora

- مضخة الطرد المركزى- كتيب للتحميلDocumento128 pagineمضخة الطرد المركزى- كتيب للتحميلGrundfosEgypt100% (4)

- Engineering Drawings Lecture Linear Geometric Tolerancing PDFDocumento22 pagineEngineering Drawings Lecture Linear Geometric Tolerancing PDFIjabiNessuna valutazione finora

- Improving Performance of An Energy Efficient Hydraulic Circuit PDFDocumento175 pagineImproving Performance of An Energy Efficient Hydraulic Circuit PDFIjabiNessuna valutazione finora

- Surface Texture & Machining SymbolsDocumento17 pagineSurface Texture & Machining SymbolsIjabiNessuna valutazione finora

- Troubleshooting GuideDocumento25 pagineTroubleshooting GuideIjabiNessuna valutazione finora

- BACHELOR THESIS - Centrifugal Pumps - Christian Allerstorfer (m0535041) v1.3 PDFDocumento40 pagineBACHELOR THESIS - Centrifugal Pumps - Christian Allerstorfer (m0535041) v1.3 PDFIjabiNessuna valutazione finora

- Centrifugal PumpDocumento42 pagineCentrifugal Pumprumabiswas853100% (2)

- Solution of Viscous Flow in Radial Flow PumpsDocumento9 pagineSolution of Viscous Flow in Radial Flow PumpsIjabiNessuna valutazione finora

- Hardness Conversion ChartDocumento6 pagineHardness Conversion ChartIjabiNessuna valutazione finora

- Guideline - Pump - System - Designers (Pump Fundamentals) PDFDocumento16 pagineGuideline - Pump - System - Designers (Pump Fundamentals) PDFyyukin1100% (1)

- Part Winding Startting The Three-Phase Squirrel Cage Induction Motor Air Gap Magnetic Field AnalysisDocumento6 paginePart Winding Startting The Three-Phase Squirrel Cage Induction Motor Air Gap Magnetic Field AnalysisIjabiNessuna valutazione finora

- مضخة الطرد المركزى- كتيب للتحميلDocumento128 pagineمضخة الطرد المركزى- كتيب للتحميلGrundfosEgypt100% (4)

- Design Improvement of Mixed Flow Pump Through CFD PDFDocumento123 pagineDesign Improvement of Mixed Flow Pump Through CFD PDFIjabiNessuna valutazione finora

- Blocked Rotor TestDocumento11 pagineBlocked Rotor TestIjabi100% (1)

- Corrioson TestDocumento14 pagineCorrioson Testcombahee100% (1)

- Parker FittingsDocumento62 pagineParker FittingsIacob Cozonac100% (1)

- Composites Knowledge Competition AnswersDocumento13 pagineComposites Knowledge Competition AnswersAhmed Akram AlkhashabNessuna valutazione finora

- SP 90 00Documento78 pagineSP 90 00aminNessuna valutazione finora

- C10129004 PDFDocumento20 pagineC10129004 PDFChristopherNessuna valutazione finora

- Biodegradable and Non Bio-Degradable SubstancesDocumento12 pagineBiodegradable and Non Bio-Degradable SubstancessdfkjklsdfNessuna valutazione finora

- D2784Documento7 pagineD2784rimi7alNessuna valutazione finora

- Lava Heat Italia - Lava Lite KD Patio Heater - Owners ManualDocumento23 pagineLava Heat Italia - Lava Lite KD Patio Heater - Owners ManuallavaheatitaliaNessuna valutazione finora

- Engineering Services Related To Process Study: SRU RevampDocumento16 pagineEngineering Services Related To Process Study: SRU RevampSiddiqui Muhammad AshfaqueNessuna valutazione finora

- W7 Smith CapacitorsDocumento31 pagineW7 Smith CapacitorsyjandeNessuna valutazione finora

- Aplikasi Teknologi Pengolahan Air Asin Desa Tarupa Kecamatan Taka Bonerate Kabupaten SelayarDocumento15 pagineAplikasi Teknologi Pengolahan Air Asin Desa Tarupa Kecamatan Taka Bonerate Kabupaten SelayarChrist ManapaNessuna valutazione finora

- Data SheetDocumento24 pagineData Sheetbashok20Nessuna valutazione finora

- Aspen Exchanger Design and Rating Shell & Tube V10Documento1 paginaAspen Exchanger Design and Rating Shell & Tube V10MAYANK AGRAWALNessuna valutazione finora

- Section 05505 METAL FABRICATIONS PDFDocumento13 pagineSection 05505 METAL FABRICATIONS PDFIm ChinithNessuna valutazione finora

- Ra12 100Documento2 pagineRa12 100M Irfan MaulanaNessuna valutazione finora

- Potential Measurement To Determine The Chloride Threshold Concentration That Initiates Corrosion of Reinforcing Steel Bar in Slag ConcretesDocumento17 paginePotential Measurement To Determine The Chloride Threshold Concentration That Initiates Corrosion of Reinforcing Steel Bar in Slag ConcretesTarek ChikerNessuna valutazione finora

- M606 CAD Module 3Documento6 pagineM606 CAD Module 3jobingpNessuna valutazione finora

- 080 Chlorine AlkalineDocumento6 pagine080 Chlorine AlkalineChristian CoboNessuna valutazione finora

- Batch-7 Phase - LI FinalDocumento45 pagineBatch-7 Phase - LI Final19TUCV038 SHUHAIL AKTHAR.ANessuna valutazione finora

- Astm D323 - 1999Documento10 pagineAstm D323 - 1999Teymur RegenmaisterNessuna valutazione finora

- 07a3ec02 Fluid Mechanics and Hydraulic Machinery PDFDocumento8 pagine07a3ec02 Fluid Mechanics and Hydraulic Machinery PDFfotickNessuna valutazione finora

- MagnaflocDocumento3 pagineMagnaflocfrancsanchezNessuna valutazione finora

- Installation Instructions: Fireplace InsertsDocumento28 pagineInstallation Instructions: Fireplace InsertssebkahnNessuna valutazione finora

- Lec No.5 Screening RevDocumento11 pagineLec No.5 Screening Revnoel50% (2)

- Polypropylene: Product Data SheetDocumento2 paginePolypropylene: Product Data Sheet李万福Nessuna valutazione finora

- VCMStudy UOP Advanced MTO Tehran ConferenceDocumento21 pagineVCMStudy UOP Advanced MTO Tehran ConferenceUsamah ZakiNessuna valutazione finora

- MGPS and Ferrous Ion GeneratorDocumento31 pagineMGPS and Ferrous Ion GeneratorRodolfo L Suarez100% (1)