Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Quotation Cold Room An NAM Group - 17 Aug 2010

Caricato da

huyly34Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Quotation Cold Room An NAM Group - 17 Aug 2010

Caricato da

huyly34Copyright:

Formati disponibili

PROPOSAL

TURN-KEY REFRIGERATION PLANT SOLUTION AND PANELS FOR AN NAM GROUP COLD ROOM PROJECT CAT LAI PORT, HCMC, VIETNAM

_____________________________________________________________________________________________________________

QUOTATION SGN 1008 092 R134a REFRIGERATION SYSTEM AND PANELS

____________________________________________________________________________________________________________

VEE VIET Engineering Date of submission

Mr. Truong Ngoc Tinh 17th August, 2010

282 BA THANG HAI AVENUE, DISTIRCT 10 HOCHIMINH CITY VIETNAM 70000 TEL (848) 3862 6600 FAX (848) 3862 6644 E MAIL: info@veevn.com

CODES AND STANDARDS (general guidelines) Design and installation: Leakage and pressure testing: Electrical: Panel and installation: ASHRAE / TCVN by nitrogen Included 3 x 380V / 220V / AC / 50Hz IEC 60 439-1, IEC 60 204-1 Short circuit current: Degree of protection: Color, Outside/ Inside: Color coding for wiring: Internal wire marking:

63 Ka IP 54 white IEC 204-1 Legrand or equiv. marking system Control wires: minimum 0.5 mm2 Panel and installation: IEC60 439-1, IEC 60 204-1 Motor starters and supplies: DOL for 15 kW, below Star/delta above 15 kW

282 BA THANG HAI AVENUE, DISTIRCT 10 HOCHIMINH CITY VIETNAM 70000 TEL (848) 3862 6600 FAX (848) 3862 6644 E MAIL: info@veevn.com

BASIS OF PROPOSAL: Based on meeting at your office on 10 th August 2010 Participants: ANNAM Group: Mr. Hubert Mouret, Mrs. Regina Malgouyres, Ms. Hieu VEE Co.: Mr. Truong Ngoc Tinh, Mrs. Vo Phuong Hoa, Ms. Nguyen Thi Xanh REFRIGRATION PLANT SOLUTION AND DESIGN CONSIDERATIONS The system is designed to meet the abnormal operating conditions and electricity cost tariffs in Vietnam. The system cooling demand is based on 16 hours operating per day of all cold rooms (CR1 and CR2). The cost of electricity between low peak hours and high peak hours is tremendous, and from experience we know that the end-user can save as much 30% on the electricity bill associated with cold room operation if the cold rooms are off during high peak hours and run full blast during night time (low peak hours). The latter will lead to delayed cooling call from cold rooms due to the excessive cooling capacity available and air cooler sizing, hence additional savings. Electricity cost for Industrial Zones as of March 2009: 10am 12pm: 12pm 5.30pm: 5.30pm 8.30pm: 8.30pm 10.30pm: 10.30pm 4.30am: 4.30am 10am: 2,830 VND /kWh 1,540 VND /kWh 2,830 VND /kWh 1,540 VND /kWh 835 VND /kWh 1,540 VND /kWh

SUMMARY OF HEAT LOADS Cold rooms: CR1 (+6C / +8C) CR2 (+2C/+4C) Total

4.8 kW (1 unit Cubic evaporator, electrical defrost) 2.7 kW (1 unit Cubic evaporator, electrical defrost) 7.5 kW

PROVISION FOR SUCTION LINE LOSES Medium temperature circuit (-13oC) 2K (air cooler evaporating temperature -13oC)

Condensing capacity available: CT/WB = +37oC/+28oC (15% excess capacity)

282 BA THANG HAI AVENUE, DISTIRCT 10 HOCHIMINH CITY VIETNAM 70000 TEL (848) 3862 6600 FAX (848) 3862 6644 E MAIL: info@veevn.com

100 101

CONDENSING UNIT I PROJECT: USE LHV Condensing Unit (Ecostar) (GERMANY) 01- LHV Condensing Unit (Ecostar) Semi-Hermetic Reciprocation compressor built-in motor, - Oil charge, protective charge, - Suction and discharge shut-off valve, - Motor PTC sensors with electronic control unit SE-B1, terminal box enclosure class IP 65 ECOSTAR With integral frequency inverter for stepless capacity control, base plate, - Air cooled condenser with 2 fans enclosure class IP 54, complete with guard, - Receiver with rotalock shut-off valve for liquid & pressure gauge connection, - 02 sight glasses, connection for pressure relief valve, - Approval according to EC pressure Equipment Directive (PED) 97/23/EC - Discharge line, suction line and liquid line (incl. sight glasses and filter drier) - Mounted to the outer contour of the unit, - Weather protective housing, protective charge. - Electrical switchboard incl. main switch, contactors, - Programmable controller for compressor speed and unit control, with connections; - All electrical and electronic components prewired to terminal strips in switchboard Technical Data: Type: LHV6/4EC-6.F1Y-40S Refrigerant: R-134a, Suction/condensing temperature: -13C/+45C @ Frequency: Cooling Capacity: COP: 30 Hz 3.25 kW 1.94 50 Hz 5.52 kW 2.86 kW 1.93 70 Hz 7.55 kW 4.05 kW 1.84

Power consumption: 1.68 kW

282 BA THANG HAI AVENUE, DISTIRCT 10 HOCHIMINH CITY VIETNAM 70000 TEL (848) 3862 6600 FAX (848) 3862 6644 E MAIL: info@veevn.com

102

II PROJECT: USE AIR-COOLED Condensing Unit (GERMANY) 01 Air- Cooled Condensing Unit (A-CDU) Semi-Hermetic Reciprocation compressor built-in motor, - Oil charge, protective charge, - Suction and discharge shut-off valve, - Motor PTC sensors with electronic control unit SE-B1, terminal box enclosure class IP 65 Condensing Unit with base plate, - Air-cooled condenser with 1 fan enclosure class IP 54 - Complete with blade and guard, - Receiver with rotalock shut-off valve for liquid & pressure gauge connection, - Approval according to EC pressure Equipment Directive (PED) 97/23/EC - Other approvals on request; discharge line and protective charge Technical Data: Type : LH84/4CC-6.2Y-40S Refrigerant : R-134a, Suction/condensing temperature: -13C/+45C Cooling Capacity at : 7.73kW Power consumption : 3.79 kW COP : 2.0

200

R134a EVAPORATORS All air coolers for cold rooms are cubic, ceiling hung type. Please refer to enclosed layout sketches, technical specifications and catalogues for further information on the advantages of cubic air cooler arrangement

201 .

01 GUNTNER FINNED EVAPORATOR FOR COLD ROOM 1 (CR1) Manufactured with copper tubes and aluminium steel fins. Technical Data (each): Model Refrigerant Design Capacity Room temperature Evaporating temperature Tube volume Surface : : : : : : : : S-GSF 020.2D/27-ENW50.E R-134a Single-Air-Discharge (Draw through) 3.0 kW +2 C -13 C 2.5 L 6.1 m2

282 BA THANG HAI AVENUE, DISTIRCT 10 HOCHIMINH CITY VIETNAM 70000 TEL (848) 3862 6600 FAX (848) 3862 6644 E MAIL: info@veevn.com

Defrosting Dry weight Fan motor Fan motor speed Air flow outlet

D F A C E E

: : : : :

electric Approx. 21 kg 2 x 0.04 kW 2400 rpm 1.490 m/hr

Dimensions : L = 963 mm B = 362 mm H = 326mm

E = 700 mm F = 345 mm C = 147 mm

A = 300 mm D = 11 mm K = G3/4

K B 45 L

202 .

01 -GUNTNER FINNED EVAPORATOR FOR COLD ROOM 2 (CR2) Manufactured with copper tubes and aluminium steel fins. Technical Data (each): Model Refrigerant Design Capacity Room temperature Evaporating temperature Tube volume Surface Defrosting Dry weight Fan motor Fan motor speed Air flow outlet : : : : : : : : : : : : :

E

S-GSF 020.2C/34-ENW50.E R-134a Single-Air-Discharge (Draw through) 5.5 kW +6 C -10 C 2.6 L 11.4 m2 electric Approx. 27 kg 3 x 0.04 kW 2400 rpm 2.175 m/hr

Dimensions : L = 1313 mm B = 362 mm H = 326mm

K B 45 L

E = 1050 mm F = 345 mm C = 147 mm

A = 300 mm D = 11 mm K = G3/4

300

R134a VALVES AND CONTROLS FOR REFRIGERATION PLANT Include complete lot of Emerson / Danfoss valves and controls for the proposed refrigeration plant. We wish to emphasize here that the entire supply of valves and controls is designed and sized to minimize pressure losses and to optimize serviceability and durability of the plant. All air coolers are equipped with individual valves stations. Defrosting is fully automatic (auto / manual)

282 BA THANG HAI AVENUE, DISTIRCT 10 HOCHIMINH CITY VIETNAM 70000 TEL (848) 3862 6600 FAX (848) 3862 6644 E MAIL: info@veevn.com

One special valve for each suction header of cold room air coolers have been chosen to avoid any risk for pressure shock when the defrosting is over. All solenoid valves are installed with manual shut-off valves (stop valve) for increased serviceability. REG valves shall not be used as stop valves due to risk of improper adjustment by operators after servicing.

400 INSTALLATION MATERIALS AND INSTALLATION 401 INSTALLATION MATERIALS Comprising of: 11111Lot of copper pipes and fittings Lot of water drain piping for air coolers including insulation materials Lot pipe supports with brackets, hangers and saddles (hot dip galvanized) Lot of primer and paint for R134a piping and valve stations Lot of labeling and tagging materials First charge of R134a refrigerant for compressor lubrication oil 1- Lot of power cables and control wires for field installation 1- Lot of conduits, glands and local switches 402 INSTALLATION Mechanical, electrical and insulation works include: Mechanical installation of all equipment and piping in engine room including piping for oil cooling and vent piping - Mechanical installation of Condensing unit - Installation of drain piping with insulation and supports - Mechanical installation of all distribution piping with valve stations including supports and drip trays - Painting and surface treatment of piping and valve stations - Labeling and tagging - Electrical installation including supports, trays, conduits, cabling, wiring, temperature sensors. - Leakage and pressure testing with nitrogen Installation time is 2 weeks from site mobilization until plant is reported ready for start-up 500 CONCEPTION, DESIGN, MANUFACTURE, TRANSPORTATION OF COLDSTORE'S WALLS, CEILINGS, DOORS & PARTS, CONCERNING THE THERMAL INSULATION OF REFRIGERATED ENCLOSURES/ BUILDINGS Construction: -

282 BA THANG HAI AVENUE, DISTIRCT 10 HOCHIMINH CITY VIETNAM 70000 TEL (848) 3862 6600 FAX (848) 3862 6644 E MAIL: info@veevn.com

Polyurethane Panel : (Wall & ceiling)

Laminated with both sides 0.5mm (thick) hot dipped pre-painted galvanized (white) colour bond sheet for external & internal finishing and surface with (blue) plastic protective film for both sides finishing. 44 2 kg/m3 Semi camlock system.

Density of polyurethane: Type of panel :

Finish: walls and ceilings: Positive enclosure: PVC clipped & silicone - sealed coving sections in the vertical & horizontal internal corners or Lacq. flashings for the vertical + horizontal salient corners. Walls e = 100mm height under ceiling 3.00 m 86 m2 of 100mm panels, injected poly urethane foam insulation, 442 Kg/m density, - Both sides in 25 lacquered steel white colour

Ceilings e = 100 height under ceiling 3.00 m 28m2 of 100mm panels, injected poly urethane foam insulation, 442 Kg/m density, - Both sides in 25 lacquered steel white colour Accessories: 01 lot PU panel (Wall, ceiling) installation accessories 02 units Relief Pressure valves 04 sets of lamps for CR1, CR2 DOORS 2 x Positive manual right/ left hinged door (100 mm thick) with polyamide hinges, - clear opening H.2000 x 915 mm with , injected poly urethane foam insulation, 442 Kg/m density, Both sides in 25 lacquered steel white colour PACKAGING and transport: Estimation 1 x TC 20 H.C + 1 x TC 20 We are in charge of packaging and transport DDP HO CHI MINH STORAGE Conditions: If the panels can't be installed just after their delivery on site, please comply with the following instructions: store the panels flat down and don't remove the pallets. If it isn't possible to keep in-factory packing, place intermediate ventilation-rafters between the ground floor and the bottom panel. Never store these panels on soft floor or subject to flooding Store preferably the panels in a warehouse sheltered from heat & humidity : if the storing can only be outside, protect the panels with opaque & white canvass-sheets (cloth or plastic) : never use transparent (or dark colour) plastic film

282 BA THANG HAI AVENUE, DISTIRCT 10 HOCHIMINH CITY VIETNAM 70000 TEL (848) 3862 6600 FAX (848) 3862 6644 E MAIL: info@veevn.com

Removing of the protection PE film : this adhesive film is sensitive to the ultraviolet-rays & to the heat : for that reason, the above conditions of storage have a very large effect on the life-time the un sticking of the film which has to be removed : o 15 days latest after delivery if stocking without any protection, o 2 months if stored outside under opaque canvass, o 6 months if stored inside and sheltered from heat & humidity, o If longer storing, we recommend to remove the PE film before stocking. ENGINEERING & DESIGN PROJECT MANAGEMENT, SUPERVISION AND START-UP VIET Engineering will provide all engineering & design for refrigeration plant in connection to the scope of supply for optimal plant efficiency, reliability and safety. VIET Engineering will undertake the following obligations and requirements. 1. 2. 3. 4. 5. 6. 7. Preparation of proposals for work flows and flow sheets in general. Preparation of proposals for machinery layout. After final approval by the client, VIET Engineering will make the final design of machinery arrangement and flow sheets (P&ID). Original copies of all certified test records and approvals will be compiled and sent as soon as they are available from the factory. Delivery of 3 sets of instruction manuals in English. As-built drawings including testing and commission reports Scheduled training of ANNAMs operators and maintenance personnel in the correct and safe operation and maintenance of the refrigeration plant.

600

The anticipated installation time is 2 weeks followed by 2 weeks of start-up, testing and commission and temperature pull-down. During the entire engagement VIET Engineering will have full-time personnel on site to supervise the mechanical and electrical installation and insulation works, and non-destructive testing. A specialist engineer will be on site during start-up, testing and commissioning of the plant. The supervising site personnel will be supported by experienced Project Manager who resides in HCMC and shall attend weekly site-meetings and ensure that the project is progressing to agreed quality and program. All cost associated with remuneration, inland transportation, air fares, and accommodation is included in this offer. I case the project is prolonged for reasons beyond VIET Engineerings control, VIET Engineering shall be entitled to receive compensation on pro-rate basis.

282 BA THANG HAI AVENUE, DISTIRCT 10 HOCHIMINH CITY VIETNAM 70000 TEL (848) 3862 6600 FAX (848) 3862 6644 E MAIL: info@veevn.com

PRICE SPECIFICATION

A. Item 100(101) 200 300 REFRIGERATION EQUIPMENT Description 01 LHV Condensing Unit (Ecostar) 02 units of ceiling hung air coolers Valves and controls Price in USD Included Included Included

Sub-total, item 100(101), 200 & 300, DDP HCMC 400 600 Installation materials and installation Engineering & Design Project Management, Supervision and Start-u Sub-total, item 400 to 600, before VAT 10% Total, item 100 (101) to 400, and 600

11,897 Included Included 2,950 14,847 USD

B. 500

COLD ROOMS PANELS Lot of panels and accessories, installation and commissioning Sub-total, item 500, before VAT 10% Total, item 100 to 600 8,487 USD 8,487 USD 23,334 USD

If you choose the II project for 100(102) item (use Air-cooled Condensing Unit) then we will diminish 2,700 USD. That is total from 100(102) to 600 to be 20,634 USD, before VAT 10%

Note : Port clearance, handling and associated charges, pre-shipment inspection, and inland freight in country of destination are included. Also excluded are: VAT

282 BA THANG HAI AVENUE, DISTIRCT 10 HOCHIMINH CITY VIETNAM 70000 TEL (848) 3862 6600 FAX (848) 3862 6644 E MAIL: info@veevn.com

10

GENERAL CONDITIONS Delivery : It is to be understood DDP Ho Chi Minh City, Vietnam and packed for container transport unless otherwise agreed in writing. : With reservation for intermediate sales, delivery can take place approx. 4 to 5 working weeks (Ex. Works) from date of receipt of confirmed order and confirmation of the receiving of the first installment. Kindly allow approx. 1 week for Pre-shipment Inspection (if required) and approx. 4 to 5 working weeks for preparation of equipment shipment and by sea freight. : 100% by Swift as follows: 1st installment: 20% down payment upon order nd 2 installment: 65% against of presentation of Bill of Lading 3rd installment: 15% against of reception document In favor of:

Delivery time

Payment

VIET ENGINEERING CO LTD

282 BA THANG HAI Avenue, DISTRICT 10 HO CHI MINH CITY, 70000 VIETNAM Issued by an internationally well know bank and advised through: MILITARY JOINT STOCK BANK HO CHI MINH BRANCH TAN SON NHUT TRANSACTION OFFICE HO CHI MINH CITY, VIETNAM VIET ENGINEERING CO LTD VND Account: 109 11000 26006 Validity Guarantee : Prices are valid for 30 days from the date of this quotation. : The guarantee period for compressor units is 12 months from start-up of the plant, but not more than 18 months from the date when we have reported the equipment ready for delivery ex. works. For all other items, guarantee period is 12 months from start-up of the plant, but not more than 18 months from the date when we have reported the equipment ready for delivery ex. Works. The guarantee covers replacement free of charge (excluding carriage and installation) of any parts found to contain any defects in workmanship material. Handling and local duty costs are borne by the client. The guarantee does not cover consequential damage or loss. The refrigeration plant is considered to have taken over by client if it began production operation without approval from VIET ENGINEERING Co.

EXCLUSIONS

282 BA THANG HAI AVENUE, DISTIRCT 10 HOCHIMINH CITY VIETNAM 70000 TEL (848) 3862 6600 FAX (848) 3862 6644 E MAIL: info@veevn.com

11

Our quotation contains the items according to specifications and the following is for instance not included: - Foundation, civil construction, and structural works in general, - Making and mending of holes for pipes, cables, etc. - Main structural supports of any kind for the equipment items and piping proposed, - Access provisions and service platforms, - Any other kind of service lights, - Power and water supply during installation, - Telephone line and internet connection for on-site office container (shall be provided by client), - Plant room ventilation system and louvers, - Installation and water piping for shower station, - Water/glycol piping work with materials, - Necessary assistance for machine inspection, including scaffolding, forklifts and cranes, etc. - All other parts not mentioned in our quotation. We thank you for your attention and continued interest in our company, services and products, and shall look forward to discuss our proposal with you at your convenience. Thank you. Yours faithfully, VIET Engineering Co. Ltd Truong Ngoc Tinh, CEO

282 BA THANG HAI AVENUE, DISTIRCT 10 HOCHIMINH CITY VIETNAM 70000 TEL (848) 3862 6600 FAX (848) 3862 6644 E MAIL: info@veevn.com

12

Potrebbero piacerti anche

- ValvesDocumento194 pagineValvesvikrantsingh2908100% (2)

- Advanced GRE Math QuestionsDocumento22 pagineAdvanced GRE Math Questionsmulasravanialekhya84% (19)

- Dasco 19-26Documento8 pagineDasco 19-26Ahmed AzadNessuna valutazione finora

- 2015 - Mcat PDFDocumento158 pagine2015 - Mcat PDFhuyly34Nessuna valutazione finora

- 2015 - Mcat PDFDocumento158 pagine2015 - Mcat PDFhuyly34Nessuna valutazione finora

- Pipe and Tube Thickness Chart - Is 1239 and Is 3589Documento3 paginePipe and Tube Thickness Chart - Is 1239 and Is 3589tvsshinde100% (2)

- Project Location Client Consultant DateDocumento4 pagineProject Location Client Consultant DategurramviswaNessuna valutazione finora

- Ariston Electric Water HeatersDocumento2 pagineAriston Electric Water HeatersSuresh SubbarayanNessuna valutazione finora

- Competency ListDocumento2 pagineCompetency Listhuyly34Nessuna valutazione finora

- BTU MeterDocumento13 pagineBTU MeterMahesh Sadasivan NairNessuna valutazione finora

- SAES-J-605 - Surge Relief Protection SystemsDocumento16 pagineSAES-J-605 - Surge Relief Protection SystemsyouaresweetNessuna valutazione finora

- Selection Sheet - 30XA452 Screw ChillerDocumento1 paginaSelection Sheet - 30XA452 Screw Chillercalvin.bloodaxe4478Nessuna valutazione finora

- Duct CalculationsDocumento38 pagineDuct CalculationsDilnesa EjiguNessuna valutazione finora

- Thermal Fatigue Monitoring GuidelinesDocumento104 pagineThermal Fatigue Monitoring Guidelinesvarunsuri8100% (2)

- DampersDocumento25 pagineDampersmpwasaNessuna valutazione finora

- Engine Room Ventilation - Necesar AerDocumento1 paginaEngine Room Ventilation - Necesar AerBirshopulosNessuna valutazione finora

- Astm - A761 A761m 04 (2009)Documento8 pagineAstm - A761 A761m 04 (2009)nugroho teguhNessuna valutazione finora

- Hvac For AuditoriumDocumento15 pagineHvac For AuditoriumkomalNessuna valutazione finora

- Ahu & Chiller OkDocumento40 pagineAhu & Chiller OkAndy DwiNessuna valutazione finora

- Physics GRE SolutionsDocumento338 paginePhysics GRE SolutionsDavid Latchman100% (2)

- Part E - 2 - (HVAC) Engineering DesignDocumento69 paginePart E - 2 - (HVAC) Engineering Designkeya2020Nessuna valutazione finora

- Operation Manual 2 in 1 Filling Capping Full UpdatedDocumento103 pagineOperation Manual 2 in 1 Filling Capping Full UpdatedRiyoko Fillex100% (2)

- Installation of Hvac System and Standby Generator Set For DFPC Naia T3 - Landside StoreDocumento25 pagineInstallation of Hvac System and Standby Generator Set For DFPC Naia T3 - Landside StoreScherraine Khrys CastillonNessuna valutazione finora

- AirConditioning & Ventilation TCX Methodology Rev# 1.1Documento12 pagineAirConditioning & Ventilation TCX Methodology Rev# 1.1Non Etabas GadnatamNessuna valutazione finora

- Air Diffuser Architecture PDFDocumento28 pagineAir Diffuser Architecture PDFBranislavPetrovicNessuna valutazione finora

- Pipe Support CalcDocumento73 paginePipe Support Calcmsvikhas032100% (3)

- Architectural SpecificationsDocumento12 pagineArchitectural SpecificationsRaymundo DelfinNessuna valutazione finora

- CFM CalculatorDocumento2 pagineCFM CalculatorSharon Lambert100% (3)

- Reference BooksDocumento536 pagineReference BooksAung San HtweNessuna valutazione finora

- VXC Evaporative CondenserDocumento22 pagineVXC Evaporative CondenserSenthil Murugesan100% (2)

- AHU-Volta - Submittal 04032020 - REV-02 PDFDocumento437 pagineAHU-Volta - Submittal 04032020 - REV-02 PDFRamy MahmoudNessuna valutazione finora

- Bottomgrass Engineering & HVAC Services: Indoor Section Coompressor SectionDocumento1 paginaBottomgrass Engineering & HVAC Services: Indoor Section Coompressor SectionSubodh MurkewarNessuna valutazione finora

- Tank BlanketingDocumento27 pagineTank Blanketingkhali54100% (1)

- Shop Drawing: Welcome Air-Tech (M) SDN BHDDocumento1 paginaShop Drawing: Welcome Air-Tech (M) SDN BHDKarthi KeyanNessuna valutazione finora

- HRV DaikinDocumento115 pagineHRV DaikinPityt CatalinNessuna valutazione finora

- API Spec 5CT IntroductionDocumento37 pagineAPI Spec 5CT IntroductionChandrasekhar Sonar100% (2)

- Design Calculation Sheet: Project No. DateDocumento14 pagineDesign Calculation Sheet: Project No. DatePhanhai KakaNessuna valutazione finora

- Copy of Low Side BOQ PIPING SUPPLY INSTALL ENQUIRYDocumento11 pagineCopy of Low Side BOQ PIPING SUPPLY INSTALL ENQUIRYArvnd VckyNessuna valutazione finora

- Flowtech Grilles & RegisterDocumento3 pagineFlowtech Grilles & RegisterLeomark RespondeNessuna valutazione finora

- Ventilation Design Sample For Locker Rooms and HACCPDocumento10 pagineVentilation Design Sample For Locker Rooms and HACCPerickquinto100% (1)

- VOL II - Technical-Co Boiler Dismantling PDFDocumento538 pagineVOL II - Technical-Co Boiler Dismantling PDFSteven100% (1)

- HVAC Useful Conversions ChartDocumento2 pagineHVAC Useful Conversions ChartdheerajdorlikarNessuna valutazione finora

- File 2) GRE Quant (Ignore First 85 Pages, Which Are in File 1) PDFDocumento333 pagineFile 2) GRE Quant (Ignore First 85 Pages, Which Are in File 1) PDFhuyly34100% (1)

- CP13 - 1999 MV and AC in BuildingDocumento56 pagineCP13 - 1999 MV and AC in Buildingbozow bozowlNessuna valutazione finora

- General Catalog VictaulicDocumento140 pagineGeneral Catalog VictaulicynhkngNessuna valutazione finora

- HVAC Design For Healthcare Facilities: Course No: M06-011 Credit: 6 PDHDocumento60 pagineHVAC Design For Healthcare Facilities: Course No: M06-011 Credit: 6 PDHNelson VargasNessuna valutazione finora

- BAC Brochure GeneralDocumento12 pagineBAC Brochure GeneralTran Ngoc HaNessuna valutazione finora

- Nicotra (Backward Curve)Documento95 pagineNicotra (Backward Curve)Archityrema Surya100% (1)

- Jet Fan CatalogueDocumento10 pagineJet Fan Catalogueabc3579Nessuna valutazione finora

- Android Kitchen Exhaust Calculation On AndroidDocumento5 pagineAndroid Kitchen Exhaust Calculation On AndroidPraveen SagayarajNessuna valutazione finora

- Technical Documentation Sliding DoorDocumento23 pagineTechnical Documentation Sliding DoorLe Ngoc AnhNessuna valutazione finora

- Osma Soil Waste Design Inst Guide Sept05 SW207 PDFDocumento52 pagineOsma Soil Waste Design Inst Guide Sept05 SW207 PDFLaxmana PrasadNessuna valutazione finora

- As 1725.1-2010 Chain Link Fabric Fencing Security Fences and Gates - General RequirementsDocumento8 pagineAs 1725.1-2010 Chain Link Fabric Fencing Security Fences and Gates - General RequirementsSAI Global - APAC0% (1)

- Hospital Operating Theatre PDFDocumento56 pagineHospital Operating Theatre PDFTajudeen Ibrahim80% (5)

- Flow Tech Louvers PDFDocumento10 pagineFlow Tech Louvers PDFMoriyasuNguyenNessuna valutazione finora

- Tsi Panda 341 User ManualDocumento37 pagineTsi Panda 341 User Manuala k bNessuna valutazione finora

- Technical Overview On AHUDocumento12 pagineTechnical Overview On AHUJahidul IslamNessuna valutazione finora

- Chilled Water System Introduction, MyanmarDocumento20 pagineChilled Water System Introduction, MyanmaracmvorgNessuna valutazione finora

- AHU Catalogue enDocumento68 pagineAHU Catalogue enTRISTIANDINDA PERMATANessuna valutazione finora

- AHU Technical Specification & DrawingDocumento12 pagineAHU Technical Specification & DrawingADsupermanNessuna valutazione finora

- A Study On Energy Audit of A Cold StorageDocumento5 pagineA Study On Energy Audit of A Cold StorageAshfaq Ali KhanNessuna valutazione finora

- Cooling Tower Makeup Water EstimationDocumento3 pagineCooling Tower Makeup Water EstimationMuhammad NaeemNessuna valutazione finora

- Test Report On Concrete Cube:: Department of Civil Engg., BVRITNDocumento1 paginaTest Report On Concrete Cube:: Department of Civil Engg., BVRITNsudugoudaNessuna valutazione finora

- AhuDocumento1 paginaAhuckyprianou100% (1)

- Oxycom IntrCool Brochure (2019) enDocumento20 pagineOxycom IntrCool Brochure (2019) enAnkit JainNessuna valutazione finora

- Plantroom ExhaustDocumento2 paginePlantroom ExhaustDota NgNessuna valutazione finora

- Cooling Load Calculation DetailDocumento2 pagineCooling Load Calculation DetailNikita SinhaNessuna valutazione finora

- Volume Control DampersDocumento13 pagineVolume Control Damperssreejeshkeralam100% (1)

- Grundfos Pumping Station Model-A95922154P11138 RehabilitationDocumento3 pagineGrundfos Pumping Station Model-A95922154P11138 RehabilitationMotasem AlnajjarNessuna valutazione finora

- Prima Usaha ACMV Duct Sizing Table 2017 LockedDocumento1 paginaPrima Usaha ACMV Duct Sizing Table 2017 LockedShaikh Tauseef100% (2)

- TSI PANDA 341 User ManualDocumento38 pagineTSI PANDA 341 User ManualHernan RomeroNessuna valutazione finora

- Dynair Ecology UnitDocumento12 pagineDynair Ecology Unitrid100% (1)

- Hvac Boq-07082014Documento18 pagineHvac Boq-07082014Kohilan NahivNessuna valutazione finora

- Thermal Insulation Calculation Guide - AMARINEDocumento5 pagineThermal Insulation Calculation Guide - AMARINEEddie FongNessuna valutazione finora

- York Chiller Log SheetDocumento4 pagineYork Chiller Log SheetEngr Fazal AkbarNessuna valutazione finora

- 25hp 4p 284tpa Wpi Bf37 AuDocumento15 pagine25hp 4p 284tpa Wpi Bf37 Aurhusseinpos4765Nessuna valutazione finora

- Iplv NPLVDocumento5 pagineIplv NPLVKamal HaziqNessuna valutazione finora

- Clint Cha k726p 36012p Brochure 0325 enDocumento2 pagineClint Cha k726p 36012p Brochure 0325 enDorin100% (1)

- Btec Necs 1314 3218 enDocumento82 pagineBtec Necs 1314 3218 enborodkinNessuna valutazione finora

- Chiller Selection Building A+j Cooling Only Rev 2Documento7 pagineChiller Selection Building A+j Cooling Only Rev 2Anton WelgemoedNessuna valutazione finora

- GRE 2010 by The Princeton Review Excerpt PDFDocumento46 pagineGRE 2010 by The Princeton Review Excerpt PDFhuyly34Nessuna valutazione finora

- Gre Wordlist PDFDocumento3 pagineGre Wordlist PDFhuyly34Nessuna valutazione finora

- Gre Wordlist PDFDocumento3 pagineGre Wordlist PDFhuyly34Nessuna valutazione finora

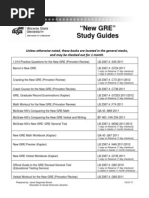

- NewGRE PDFDocumento1 paginaNewGRE PDFhuyly3450% (2)

- Crushing The GREDocumento8 pagineCrushing The GREapi-38386330% (1)

- NBWL For Web Part3Documento56 pagineNBWL For Web Part3gunalprasadgNessuna valutazione finora

- Heat PDFDocumento9 pagineHeat PDFhuyly34Nessuna valutazione finora

- File 3) GRE 2008 Database PDFDocumento265 pagineFile 3) GRE 2008 Database PDFhuyly340% (1)

- File 1) GRE 2009 From - Nov - 18 PDFDocumento84 pagineFile 1) GRE 2009 From - Nov - 18 PDFhuyly34Nessuna valutazione finora

- Warehouse Asst - Storage and Picking - JD-111112Documento2 pagineWarehouse Asst - Storage and Picking - JD-111112huyly34Nessuna valutazione finora

- Driver JD-111010Documento2 pagineDriver JD-111010huyly340% (1)

- Driver's Assistant JD-111010Documento2 pagineDriver's Assistant JD-111010huyly34Nessuna valutazione finora

- Cleaner JD 111010Documento2 pagineCleaner JD 111010huyly34Nessuna valutazione finora

- Admin Assistant Dispatch JD-111410Documento2 pagineAdmin Assistant Dispatch JD-111410huyly34Nessuna valutazione finora

- Delivery Man JD-111010Documento2 pagineDelivery Man JD-111010huyly34Nessuna valutazione finora

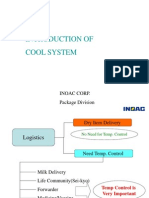

- Presentation Cool System (INOAC Corp.)Documento29 paginePresentation Cool System (INOAC Corp.)huyly34Nessuna valutazione finora

- MMH Equipment Glossary: Industrial Truck Equipment Powered, Non-PoweredDocumento4 pagineMMH Equipment Glossary: Industrial Truck Equipment Powered, Non-Poweredhuyly34Nessuna valutazione finora

- Admin Assistant Label JD-111014Documento2 pagineAdmin Assistant Label JD-111014huyly34Nessuna valutazione finora

- Mantenimiento de Brazos de CargaDocumento38 pagineMantenimiento de Brazos de CargaAlfredo BravoNessuna valutazione finora

- SOL 006 FI-FI Periodic Maintenance - Inspection and Testing 20rev. 10Documento72 pagineSOL 006 FI-FI Periodic Maintenance - Inspection and Testing 20rev. 10Dan Nicole DadivasNessuna valutazione finora

- Stainless Steel CatalogDocumento114 pagineStainless Steel CatalogSiva KumarNessuna valutazione finora

- Pipe Specification A106 Specification A106 NPS 1/8 - 48 ANSI Schedules To 160Documento1 paginaPipe Specification A106 Specification A106 NPS 1/8 - 48 ANSI Schedules To 160Denise Koh Chin HuiNessuna valutazione finora

- Final Year Project ReportDocumento89 pagineFinal Year Project ReportUsama JavedNessuna valutazione finora

- Case History of 2" Ammonia LineDocumento2 pagineCase History of 2" Ammonia LineRakesh AsukarNessuna valutazione finora

- Method Statement Jacking SystemDocumento10 pagineMethod Statement Jacking SystemHenri Purnomo SinagaNessuna valutazione finora

- Company Profil KS Dan Data Dukungnya PDFDocumento107 pagineCompany Profil KS Dan Data Dukungnya PDFRidwanda HimawanNessuna valutazione finora

- Catalog Grinnell EmeaDocumento164 pagineCatalog Grinnell EmeaGeorge RadulescuNessuna valutazione finora

- Tuf 2000m DatasheetDocumento4 pagineTuf 2000m DatasheetAngel Santos Santos0% (1)

- R/S 15F Thru R/S 30F: Air End Model BSA22, BSA21 Air CooledDocumento20 pagineR/S 15F Thru R/S 30F: Air End Model BSA22, BSA21 Air CooledAnonymous ZtXb2RO100% (1)

- 440r Manual and Parts ListDocumento90 pagine440r Manual and Parts ListBlessing OjeaburuNessuna valutazione finora

- 00 Edition 8 Catalog All PagesDocumento404 pagine00 Edition 8 Catalog All PagesRadovan KnezevicNessuna valutazione finora

- BOQ Lokwii Water Supply Project Turkana EastDocumento6 pagineBOQ Lokwii Water Supply Project Turkana EastMohamed Billow SalatNessuna valutazione finora

- TR - Type 1 - L ShapeDocumento19 pagineTR - Type 1 - L ShapeFreedom Love NabalNessuna valutazione finora

- Aseptico ADU-10 Field Dental Unit - Service ManualDocumento28 pagineAseptico ADU-10 Field Dental Unit - Service ManualluisNessuna valutazione finora