Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Untitled

Caricato da

arjunluizDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Untitled

Caricato da

arjunluizCopyright:

Formati disponibili

Manufacturing Process Brewing can be defined as the production of beer from malted barley, hops, yeast and water,

with or without the addition of other carbohydrate materials. There are six broad steps in the production of beer. It starts with the preparation of a hot liquid extract or wort from barley malt. This is referred to as mashing. This extract is then boiled with hops to impart the characteristic bitter flavour and then fermented with yeast. The fermented wort is then matured and filtered to produce a clear beer, which is filled into bottles, cans or kegs. Mashing The basic raw material of conventional brewing is malted barley, which can be described as lightly roasted sprouted barley. This malt is first milled into a fine powder referred to as grist and fed into a large vessel called the mash tun where it is mixed with hot water at around 65 degree celsius to form slurry or mash during which the slurry is stirred with a set of paddles provided in the vessel. At the end of this time, the saccharified mash is transferred into another vessel called the lauter tun (lauter in German means to clarify), which is equipped with a perforated base much like a coffee percolator. This retains the spent mash and allows the clear extract (wort) to filter through this wort is then collected in another vessel traditionally referred to as the wort kettle. The mash tun wort lauter tun and wort kettle are typically housed adjacent to each other in a section of the brewery known as brewhouse. Boiling Along with hops, the bittering ingredient in a beer recipe, the extract or wort in the kettle is boiled with either direct steam or steam coils. At the end of this, the hops are separated from the wort through a strainer or a hop back. They may also be separated in a whirlpool separator, so called because the wort is led into the vessel in a tangential flow that creates a whirlpool effect. The hops pile up in the centre of the vortex and the wort is then decanted off. Fermentation The hopped wort is subsequently cooled to fermentation temperatures, which is generally between 7-15 degree celsius depending on the type of beer to be produced. It is aerated with compressed air to provide oxygen for fermentation, pitched or mixed with the chosen yeast and then transferred into large fermentation tanks for the yeast to act. Typically, lagers are fermented between 7-9 degree celsius and ales between 10-15 degree celsius. The process of fermentation generally takes six to ten days during which the yeast multiplies and vigorously ferments the wort sugars to produce ethyl alcohol and carbon dioxide. At the end of fermentation, the yeast either rises to the top in the case of ales, or settles to the bottom as in the case of lager beers, and gas production slows down. The yeast is then separated either by skimming off or by drawing off from the bottom as the case might be and the fermented wort or beer, as it is now called, is transferred into a conditioning or maturation

tank.Maturation This is the step where ales and lagers are differentiated. Ales are traditionally conditioned in wooden casks. But it is now also being carried out in stainless steel tanks where the residual yeast is induced to carry out secondary fermentation by priming the beer with sugar. This secondary fermentation is generally carried out at 15 degree Celsius for a period of 7 to 10 days by which time it generates more carbonation after which it is sent for filtration. In the case of lagers, the fermented beer is chilled to 0 degree Celsius and transferred to lager tanks where it matures under chilled conditions for three to four weeks. During this time, a number of biochemical transformations take place to impart stable flavour characteristics to the beer and remove many of the undesirable flavours that develop during fermentation. Filtration At the end of conditioning or maturation, the beer is subjected to a process of filtration to produce clear amber liquid. This is generally carried out in two steps: a coarse filtration to remove the suspended yeast cells, and a fine filtration to remove all particulate matter. Typically, brewers use diatomoceous earth or Kieselgurh as the filtration medium. This is a special porous earth composed of siliceous marine fossils largely found on the South African shoreline. The filtration equipment used for the purpose is varied and ranges from plate and frame filters to leaf or candle filters. Many breweries also use an intermediary centrifuging step for yeast removal to augment the filtration process. Traditionally, yeast removal was brought about by the use of Isinglass or fish collagen typically obtained by dissolving swim bladders of sturgeon or cart fish in tartaric acid. A practice that is still seen in most of the British, Australian, Asian and South American breweries. In North America, tannic acid extracted from the bark of the wattle tree, is the preferred yeast clarifier. Modern brewing technology has dispensed with traditional filtration systems in favor of membrane filters and synthetic yeast clarifiers. Packaging The finished or filtered beer is now ready for packaging either in bottles, cans or kegs. Most beers packaged in bottles and cans are heated to 60 degree Celsius, a process called pasteurization in order to kill all surviving micro-organisms. Kegged or draught beers are generally unpasteurized if consumed locally but bulk pasteurized if a few days transportation and handling are involved.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Questionnaire Please Note 2Documento2 pagineQuestionnaire Please Note 2arjunluizNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- ApparelDocumento3 pagineApparelarjunluiz0% (1)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Market Overview: India: Tourism Market ScenarioDocumento5 pagineMarket Overview: India: Tourism Market ScenarioarjunluizNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The 6 Pillars of Sales Productivity Management ModelDocumento3 pagineThe 6 Pillars of Sales Productivity Management ModelarjunluizNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- RetailDocumento5 pagineRetailarjunluizNessuna valutazione finora

- ChaptersDocumento10 pagineChaptersarjunluizNessuna valutazione finora

- Mitra Samaj, Udupi: Situated Near The Krishna TempleDocumento19 pagineMitra Samaj, Udupi: Situated Near The Krishna TemplearjunluizNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Retail AssignmentDocumento35 pagineRetail Assignmentapi-316655900Nessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Basic Garments AssignmentDocumento7 pagineBasic Garments AssignmentEmdad ApmNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- 49 French Desserts - Saveur PDFDocumento112 pagine49 French Desserts - Saveur PDFBrandon Cortez100% (7)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Stihl Fs 460 C-M: Instruction Manual Manual de InstruccionesDocumento104 pagineStihl Fs 460 C-M: Instruction Manual Manual de InstruccionesDragosNessuna valutazione finora

- Brochure DPQM - Major Lean Manufacturing 2019 B IXDocumento2 pagineBrochure DPQM - Major Lean Manufacturing 2019 B IXMostafizur RahmanNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- English CompositionDocumento6 pagineEnglish Compositionparamesvary kannanNessuna valutazione finora

- Commercial ExhibitionDocumento11 pagineCommercial ExhibitionDavid Mercury HolguínNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- BrushesDocumento1 paginaBrushesHasan Juga MahmudNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Owner's Manual: Snow ThrowerDocumento49 pagineOwner's Manual: Snow ThrowerLeigh Castle DalmannNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Product Life CycleDocumento23 pagineProduct Life CycleDrArjun GawasNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Managerial Economics: No. of Unit Consumed of A Commodity Marginal Utilities Ofx Marginal Utilities OfyDocumento2 pagineManagerial Economics: No. of Unit Consumed of A Commodity Marginal Utilities Ofx Marginal Utilities OfyAASIM MUSTAFANessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Soal Ulangan Bahasa Inggris Kelas IV Semester 1Documento5 pagineSoal Ulangan Bahasa Inggris Kelas IV Semester 1IrpanNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- A Project Report On E-Commerce Sales and Operations Through MarketplaceDocumento38 pagineA Project Report On E-Commerce Sales and Operations Through MarketplaceAmit JaiswatNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

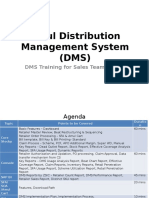

- DMSDocumento79 pagineDMSkundan0% (1)

- Strategy Assignment: Sir Shafqat HameedDocumento9 pagineStrategy Assignment: Sir Shafqat HameedMaria IftikharNessuna valutazione finora

- Lyocell Fiber: Lenzing Fibers Inc. CelluloseDocumento5 pagineLyocell Fiber: Lenzing Fibers Inc. CelluloseGrosu Marian CatalinNessuna valutazione finora

- Buy ToffyHouse Full Sleeves 3 Piece Party Suit With Bow Attached Brown For Boys (6-9months) Online in India, Shop at FirstCry - CoDocumento1 paginaBuy ToffyHouse Full Sleeves 3 Piece Party Suit With Bow Attached Brown For Boys (6-9months) Online in India, Shop at FirstCry - Codeepak vajpayeeNessuna valutazione finora

- "Consumer Behaviour of Airtel": Bachelor of Business AdministrationDocumento92 pagine"Consumer Behaviour of Airtel": Bachelor of Business AdministrationANKIT SINGHNessuna valutazione finora

- GIORGIO ARMANI - Businessman, Designer & BrandDocumento15 pagineGIORGIO ARMANI - Businessman, Designer & BrandManish Saran100% (4)

- Dole Banana Supply Chain ManagementDocumento16 pagineDole Banana Supply Chain ManagementMahesh KoliNessuna valutazione finora

- West Bengal Vat Act 2003 Amended Upto 28.05.14Documento191 pagineWest Bengal Vat Act 2003 Amended Upto 28.05.14kavi_prakash6992Nessuna valutazione finora

- Jacquard Mechanisms: Prof. Dr. Emel Önder Ass - Prof. DR - Ömer Berk BerkalpDocumento0 pagineJacquard Mechanisms: Prof. Dr. Emel Önder Ass - Prof. DR - Ömer Berk BerkalpSampurna Das100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Euromonitor Retailing in The UsDocumento33 pagineEuromonitor Retailing in The UsShriniket PatilNessuna valutazione finora

- Jacquard MachineriesDocumento15 pagineJacquard MachineriesEmdad SarkerNessuna valutazione finora

- A Norwegian CookbookDocumento27 pagineA Norwegian CookbookkaritrestakkNessuna valutazione finora

- Pastry Making BasicsDocumento4 paginePastry Making BasicsMildred C. WaltersNessuna valutazione finora

- Group-6 - Consumer Behivor Project GoProDocumento14 pagineGroup-6 - Consumer Behivor Project GoProankit100% (1)

- Manual de Usuário DS 8512 CXDocumento68 pagineManual de Usuário DS 8512 CXAndré LinharesNessuna valutazione finora

- Thinking To Export To The USA - Do You Know Your FDA Rules?Documento1 paginaThinking To Export To The USA - Do You Know Your FDA Rules?winebcNessuna valutazione finora

- ERO600 ManualDocumento1 paginaERO600 ManualClaudiu Constantin MandaNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)