Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bourdon Pressure Gauge

Caricato da

Mustafa AniDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bourdon Pressure Gauge

Caricato da

Mustafa AniCopyright:

Formati disponibili

Bourdon pressure gauge

Membrane-type manometer The Bourdon pressure gauge uses the principle that a flattened tube tends to straighten or regain its circular form in cross-section when pressurized. Although this change in cross-section may be hardly noticeable, and thus involving moderate stresses within the elastic range of easily workable materials, the strain of the material of the tube is magnified by forming the tube into a C shape or even a helix, such that the entire tube tends to straighten out or uncoil, elastically, as it is pressurized. Eugene Bourdon patented his gauge in France in 1849, and it was widely adopted because of its superior sensitivity, linearity, and accuracy; Edward Ashcroft purchased Bourdon's American patent rights in 1852 and became a major manufacturer of gauges. Also in 1849, Bernard Schaeffer in Magdeburg, Germany patented a successful diaphragm (see below) pressure gauge, which, together with the Bourdon gauge, revolutionized pressure measurement in industry.[6] But in 1875 after Bourdon's patents expired, his company Schaeffer and Budenberg also manufactured Bourdon tube gauges. In practice, a flattened thin-wall, closed-end tube is connected at the hollow end to a fixed pipe containing the fluid pressure to be measured. As the pressure increases, the closed end moves in an arc, and this motion is converted into the rotation of a (segment of a) gear by a connecting link that is usually adjustable. A small-diameter pinion gear is on the pointer shaft, so the motion is magnified further by the gear ratio. The positioning of the indicator card behind the pointer, the initial pointer shaft position, the linkage length and initial position, all provide means to calibrate the pointer to indicate the desired range of pressure for

variations in the behaviour of the Bourdon tube itself. Differential pressure can be measured by gauges containing two different Bourdon tubes, with connecting linkages. Bourdon tubes measure gauge pressure, relative to ambient atmospheric pressure, as opposed to absolute pressure; vacuum is sensed as a reverse motion. Some aneroid barometers use Bourdon tubes closed at both ends (but most use diaphragms or capsules, see below). When the measured pressure is rapidly pulsing, such as when the gauge is near a reciprocating pump, an orifice restriction in the connecting pipe is frequently used to avoid unnecessary wear on the gears and provide an average reading; when the whole gauge is subject to mechanical vibration, the entire case including the pointer and indicator card can be filled with an oil or glycerin. Tapping on the face of the gauge is not recommended as it will tend to falsify actual readings initially presented by the gauge.The Bourdon tube is separate from the face of the gauge and thus has no effect on the actual reading of pressure. Typical high-quality modern gauges provide an accuracy of 2% of span, and a special high-precision gauge can be as accurate as 0.1% of full scale.[7] In the following illustrations the transparent cover face of the pictured combination pressure and vacuum gauge has been removed and the mechanism removed from the case. This particular gauge is a combination vacuum and pressure gauge used for automotive diagnosis:

Indicator side with card and dial

Mechanical side with Bourdon tube

the left side of the face, used for measuring manifold vacuum, is calibrated in centimetres of mercury on its inner scale and inches of mercury on its outer scale. the right portion of the face is used to measure fuel pump pressure and is calibrated in fractions of 1 kgf/cm on its inner scale and pounds per square inch on its outer scale.

Mechanical details

Mechanical details

Stationary parts:

A: Receiver block. This joins the inlet pipe to the fixed end of the Bourdon tube (1) and secures the chassis plate (B). The two holes receive screws that secure the case. B: Chassis plate. The face card is attached to this. It contains bearing holes for the axles. C: Secondary chassis plate. It supports the outer ends of the axles. D: Posts to join and space the two chassis plates.

Moving Parts: 1. Stationary end of Bourdon tube. This communicates with the inlet pipe through the receiver block. 2. Moving end of Bourdon tube. This end is sealed. 3. Pivot and pivot pin. 4. Link joining pivot pin to lever (5) with pins to allow joint rotation. 5. Lever. This is an extension of the sector gear (7).

6. Sector gear axle pin. 7. Sector gear. 8. Indicator needle axle. This has a spur gear that engages the sector gear (7) and extends through the face to drive the indicator needle. Due to the short distance between the lever arm link boss and the pivot pin and the difference between the effective radius of the sector gear and that of the spur gear, any motion of the Bourdon tube is greatly amplified. A small motion of the tube results in a large motion of the indicator needle. 9. Hair spring to preload the gear train to eliminate gear lash and hysteresis

Potrebbero piacerti anche

- 2021 Moon Calendar-Cosmic RevolutionDocumento47 pagine2021 Moon Calendar-Cosmic RevolutionYahira NoeliNessuna valutazione finora

- Doors & People ManualDocumento32 pagineDoors & People ManualOscar Ayala100% (1)

- Truth Beyond Paradox (Final Download)Documento217 pagineTruth Beyond Paradox (Final Download)andreas waneyNessuna valutazione finora

- Gaugeable Tube Fittings Andadapter FittingsDocumento56 pagineGaugeable Tube Fittings Andadapter FittingsDiegoNessuna valutazione finora

- HandBook Pressure Transmitter-En PDFDocumento32 pagineHandBook Pressure Transmitter-En PDFcarloscieza100% (2)

- Bourdon Tube Pressure GaugeDocumento10 pagineBourdon Tube Pressure Gaugerexkingdom100% (1)

- Motor Operated ValveDocumento36 pagineMotor Operated ValveArie MuhardiNessuna valutazione finora

- Garlock Torque Torques en InglesDocumento6 pagineGarlock Torque Torques en InglesGustavo MardonesNessuna valutazione finora

- Computerized Embroidery MachineDocumento165 pagineComputerized Embroidery Machinehajar100% (1)

- Pressure Gauge CatalogueDocumento56 paginePressure Gauge Cataloguekutecool100% (1)

- QC System Manual PDFDocumento41 pagineQC System Manual PDFwhitebros100% (1)

- Astm D1418Documento3 pagineAstm D1418Mohamed Reda Hussein Sengar100% (2)

- ASTM E10-14 Standard Test Method For Brinell Hardness of Metallic MaterialsDocumento32 pagineASTM E10-14 Standard Test Method For Brinell Hardness of Metallic MaterialsSaya Santorno100% (2)

- O-Ring Troubleshooting Guide O-Ring Failure Analysis PDFDocumento3 pagineO-Ring Troubleshooting Guide O-Ring Failure Analysis PDFharshpatel18Nessuna valutazione finora

- Mov Specification PDFDocumento27 pagineMov Specification PDFpl_arunachalam79100% (1)

- Revenue Cycle Management Comprehensive Solutions - 0Documento4 pagineRevenue Cycle Management Comprehensive Solutions - 0avinashn1984Nessuna valutazione finora

- Manual Pressuregauges InstallationDocumento20 pagineManual Pressuregauges Installationinfo andazegiri100% (1)

- Slotter MachineDocumento20 pagineSlotter Machineshrikant100% (1)

- Ashford Gauge Manual PDFDocumento20 pagineAshford Gauge Manual PDFJoe_Merchant100% (1)

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversDa EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversValutazione: 5 su 5 stelle5/5 (2)

- Technical Data: 1. DescriptionDocumento10 pagineTechnical Data: 1. Descriptionpandi achmadan100% (1)

- Iso12944 8 PDFDocumento49 pagineIso12944 8 PDFhung_105100% (1)

- Altinbas University Industrial Engineering Ie258 Manufacturing Process Lab. Tension, Bending, Compression and Torsion TestDocumento19 pagineAltinbas University Industrial Engineering Ie258 Manufacturing Process Lab. Tension, Bending, Compression and Torsion TestHusam JARRAR100% (1)

- 09 BellevilleSpringWashersDocumento5 pagine09 BellevilleSpringWashersSteve John Poland100% (1)

- Radiography Examination ProdureDocumento29 pagineRadiography Examination ProdureNguyen Phuc100% (1)

- Arithmetic MeanDocumento9 pagineArithmetic MeanAttique HussainNessuna valutazione finora

- Increase TorqueDocumento7 pagineIncrease TorqueJohnSmithNessuna valutazione finora

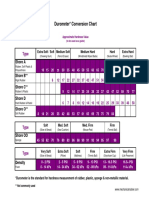

- Durometer Types & Specifications: Type Model No. Force Indenter Description ApplicationsDocumento2 pagineDurometer Types & Specifications: Type Model No. Force Indenter Description ApplicationsDarwin_Sidney100% (1)

- Shackles - CrosbyDocumento9 pagineShackles - CrosbyjsprtanNessuna valutazione finora

- Dry Coating Thickness Lab ReportDocumento9 pagineDry Coating Thickness Lab Reportwidad100% (1)

- PEEK (Polyether Ether Ketone) : PEEK Pressure vs. TemperatureDocumento2 paginePEEK (Polyether Ether Ketone) : PEEK Pressure vs. Temperaturetri_purwadiNessuna valutazione finora

- Elastomers: Dr. Dmitri KopeliovichDocumento10 pagineElastomers: Dr. Dmitri KopeliovichBara Giat PrakarsaNessuna valutazione finora

- O-Ring Manufact Defect Book MIL STD 413Documento10 pagineO-Ring Manufact Defect Book MIL STD 413Scott Kramer100% (1)

- Durometer Hardness - ASTM D2240Documento1 paginaDurometer Hardness - ASTM D2240Gürol100% (1)

- Test Bench VC25-SRVDocumento6 pagineTest Bench VC25-SRVYacine Köning100% (1)

- Durometer Conversion Table PDFDocumento1 paginaDurometer Conversion Table PDFabthakurNessuna valutazione finora

- Choke Specification - CCI PDFDocumento4 pagineChoke Specification - CCI PDFAakashRanjan100% (1)

- Spacex PDFDocumento69 pagineSpacex PDFEmerovsky ReyesNessuna valutazione finora

- Classification of ThermoplasticsDocumento9 pagineClassification of ThermoplasticsEd Willis100% (1)

- 7 PolymersDocumento25 pagine7 PolymersPrasad YarraNessuna valutazione finora

- Quality Problems OringDocumento2 pagineQuality Problems OringluisNessuna valutazione finora

- Garlock Compression Packing Catalog CMP4 41Documento34 pagineGarlock Compression Packing Catalog CMP4 41Rob CarolusNessuna valutazione finora

- 609 Awwa C504-MR - Rev00 (9-Feb-18)Documento51 pagine609 Awwa C504-MR - Rev00 (9-Feb-18)Muhammad Ridwan100% (1)

- O-Ring Failure AnalysisDocumento5 pagineO-Ring Failure Analysismoganna73Nessuna valutazione finora

- Penguard Special: Technical Data SheetDocumento5 paginePenguard Special: Technical Data Sheetajuhaseen100% (1)

- PT-Liquid Penetrant Testing Procedure R01 - 2 2Documento12 paginePT-Liquid Penetrant Testing Procedure R01 - 2 2George Ogbeche100% (1)

- Work Instruction FOR: Charpy Impact TestDocumento4 pagineWork Instruction FOR: Charpy Impact TestmahendraNessuna valutazione finora

- MSS SP 006Documento5 pagineMSS SP 006lrprete100% (1)

- Bs 1806 1989Documento22 pagineBs 1806 1989Kishor Jadhav100% (2)

- MOV Test FormDocumento1 paginaMOV Test FormAli Akbar100% (1)

- Twin SealDocumento29 pagineTwin SealJefferson De Sousa Oliveira100% (1)

- Paint Specification No.: SSPC: The Society For Protective CoatingsDocumento5 paginePaint Specification No.: SSPC: The Society For Protective CoatingsanoopkumarNessuna valutazione finora

- Arithmetic Mean 2Documento57 pagineArithmetic Mean 2Ammar Zaheer100% (1)

- Manual AUMA MOVDocumento60 pagineManual AUMA MOVBonzo DigolodogNessuna valutazione finora

- PQT Heat Treatment Tms 1Documento96 paginePQT Heat Treatment Tms 1nur wahyu dewi kusrini100% (1)

- Ball Valve PDFDocumento20 pagineBall Valve PDFRamalingam PrabhakaranNessuna valutazione finora

- Catalogue - MIDAS SafetyDocumento134 pagineCatalogue - MIDAS SafetyDelpot Castro67% (3)

- ECSS-Threaded Fasteners HandbookDocumento236 pagineECSS-Threaded Fasteners HandbookmoshiktNessuna valutazione finora

- O RingDocumento89 pagineO RingNikolat84Nessuna valutazione finora

- Anti Blow Out StemDocumento48 pagineAnti Blow Out StemimthiyazmuhammedNessuna valutazione finora

- Ansi Isa S75.19-1995Documento34 pagineAnsi Isa S75.19-1995Guillermo Ochoa100% (1)

- IQ and IQT Full ConfigurationDocumento68 pagineIQ and IQT Full Configurationivanlbraga100% (1)

- Iso 15552 2004 en PDFDocumento8 pagineIso 15552 2004 en PDFashokkumarNessuna valutazione finora

- Bourdon TubeDocumento20 pagineBourdon TubeSibabrata ChoudhuryNessuna valutazione finora

- Bourdon Tube: Prepared ByDocumento20 pagineBourdon Tube: Prepared BySaptarshi Panda100% (6)

- Reverse EnggDocumento5 pagineReverse EnggRohan MalkarNessuna valutazione finora

- حسين عامر حسين - Bourdon tubeDocumento9 pagineحسين عامر حسين - Bourdon tubeaker asdNessuna valutazione finora

- Impact of A Water JetDocumento11 pagineImpact of A Water JetDek RasalaNessuna valutazione finora

- Impact TestDocumento8 pagineImpact TestMustafa Ani100% (1)

- Tensile TestDocumento11 pagineTensile TestMustafa Ani100% (3)

- Ac ProcessesDocumento19 pagineAc ProcessesMustafa AniNessuna valutazione finora

- International Business Trade ReviewerDocumento8 pagineInternational Business Trade ReviewerCoffee VanillaNessuna valutazione finora

- Agriculture SectorDocumento66 pagineAgriculture SectorAyesha KhanNessuna valutazione finora

- Module 7 - Badminton - Fundamental SkillsDocumento45 pagineModule 7 - Badminton - Fundamental SkillsJoshua AltamiranoNessuna valutazione finora

- IO: Barriers To Entry and Exit in MarketsDocumento4 pagineIO: Barriers To Entry and Exit in MarketsSamuel Liël OdiaNessuna valutazione finora

- IvtDocumento32 pagineIvtArlhona Juana RagoNessuna valutazione finora

- Los Ángeles Times BOLIVIADocumento5 pagineLos Ángeles Times BOLIVIAMarianita Guisselle Garcia SandovalNessuna valutazione finora

- S-Block Elements: Earth Metals. These Are So Called Because Their Oxides and Hydroxides Are Alkaline in NatureDocumento8 pagineS-Block Elements: Earth Metals. These Are So Called Because Their Oxides and Hydroxides Are Alkaline in NatureAgamGoelNessuna valutazione finora

- Indra: Detail Pre-Commissioning Procedure For Service Test of Service Water For Unit 040/041/042/043Documento28 pagineIndra: Detail Pre-Commissioning Procedure For Service Test of Service Water For Unit 040/041/042/043AnhTuấnPhanNessuna valutazione finora

- Food Application Online Food Ordering SyDocumento7 pagineFood Application Online Food Ordering SyMwanje AbiyasaaliNessuna valutazione finora

- Generic List - MOH PHCs-March-2023Documento11 pagineGeneric List - MOH PHCs-March-2023drabdulrabbNessuna valutazione finora

- Marketing MixDocumento16 pagineMarketing MixGinigaddarage SudarmaNessuna valutazione finora

- "Some of Us May Never Die," by Kathleen SteinDocumento5 pagine"Some of Us May Never Die," by Kathleen SteinMark PlusNessuna valutazione finora

- Ata 21 AirconditionDocumento198 pagineAta 21 Airconditionviney1130Nessuna valutazione finora

- Find The Best Location For Your Business or For Your Rice Retailing BusinessDocumento2 pagineFind The Best Location For Your Business or For Your Rice Retailing BusinessAAAAANessuna valutazione finora

- Mock MU-BAAT Final Version Set 1Documento8 pagineMock MU-BAAT Final Version Set 1Priyanshu SinghNessuna valutazione finora

- STS Reviewer 1Documento9 pagineSTS Reviewer 1Kyle SeseNessuna valutazione finora

- M. Rahul Ananta - Rudito, BambangDocumento5 pagineM. Rahul Ananta - Rudito, BambangMuhammad Rahul AnantaNessuna valutazione finora

- With Serverless ComputingDocumento9 pagineWith Serverless Computingmha1375.1635Nessuna valutazione finora

- Nts Tevta Test 22-03-15 Paper BDocumento2 pagineNts Tevta Test 22-03-15 Paper BBeTechieNessuna valutazione finora

- Tablet Coamoxiclave (Amoxicillin +clavulanic Acid) Indications and DosDocumento2 pagineTablet Coamoxiclave (Amoxicillin +clavulanic Acid) Indications and DosShumaila Iftikhar Iftikhar AhmadNessuna valutazione finora

- Iron Ore Value-In-Use: Benchmarking and Application: Peter Hannah AnalystDocumento19 pagineIron Ore Value-In-Use: Benchmarking and Application: Peter Hannah AnalystAnkit BansalNessuna valutazione finora

- TRIAS - Master ProposalDocumento12 pagineTRIAS - Master ProposalHafidGaneshaSecretrdreamholicNessuna valutazione finora

- Form ICRA HAIs FarmasiDocumento13 pagineForm ICRA HAIs Farmasimarcella budimanNessuna valutazione finora