Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Natural Convection in A Two-Sided Lid-Driven Inclined Porous Enclosure With Sinusoidal Thermal Boundary Condition

Caricato da

IAEME PublicationDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Natural Convection in A Two-Sided Lid-Driven Inclined Porous Enclosure With Sinusoidal Thermal Boundary Condition

Caricato da

IAEME PublicationCopyright:

Formati disponibili

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

187

NATURAL CONVECTION IN A TWO-SIDED LID-DRIVEN INCLINED

POROUS ENCLOSURE WITH SINUSOIDAL THERMAL BOUNDARY

CONDITION

Sabyasachi Mondal

*1

,Tapas Ray Mahapatra

2

, Dulal Pal

3

*1

Department of Mathematics, BITM, Santiniketan-731236, West Bengal,India

2,3

Department of Mathematics, Visva Bharati (A Central University),

Santiniketan-731 235, West Bengal, India

Email:sabya.mondal.2007@gmail.com

*1

, trmahapatra@yahoo.com

2

, dulalp123@rediffmail.com

3

ABSTRACT

Natural convection in a two-sided lid-driven inclined porous enclosure with sinusoidal thermal boundary condition

on one wall using staggered grid finite-difference method is studied in this paper. The governing equations are

solved numerically for streamlines, isotherms, local Nusselt number and the average Nusselt number for various

values of the thermal radiation and heat generation parameters for three different inclination angles. The results

indicate that the flow pattern and temperature field are significantly dependent on the physical parameters.

Keywords: Natural convection; two-sided lid-driven inclined cavity; finite-difference method; thermal radiation;

heat generation.

I. INTRODUCTION

Fluid flow and heat transfer in closed cavities which are mechanically driven by tangentially moving walls

represents a basic problem in fluid mechanics. Flow of fluid in a cavity due to moving lid is a classical problem

which has wide applications in engineering such as geothermal energy, lubrication, chemical processes, drying

technologies, crude oil production, storage of nuclear waste, compacted beds for the chemical industry and thermal

insulation etc. In the past several decades, a number of experimental and numerical studies have been performed to

analyze the flow field and heat transfer characteristics of lid-driven cavity flow such as heat exchangers, solar

power collectors, packed bed catalytic reactors and so on (Nield and Bejan [1]). Furthermore, heat transfer in a lid-

driven cavity flow is widely used in applied mathematics as indicated by Bruneau and Saad [2]. The lid-driven

flows with a constant heat flux are frequently faced in the application of cooling of electronic devices (Hsu and

Wang [3]). Khanafer and Chamkha [4] studied the unsteady mixed convection flow in a lid-driven encloser filled

with Darcian fluid-saturated uniform porous medium is the presences of internal heat generation. Al-Amiri [5]

INTERNATIONAL JOURNAL OF MECHANICAL ENGINEERING

AND TECHNOLOGY (IJMET)

ISSN 0976 6340 (Print)

ISSN 0976 6359 (Online)

Volume 3, Issue 3, Septmebr - December (2012), pp. 187-202

IAEME: www.iaeme.com/ijmet.html

Journal Impact Factor (2012): 3.8071 (Calculated by GISI)

www.jifactor.com

IJMET

I A E M E

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

188

investigated the momentum and heat transfer for square lid-driven cavity filled in a porous medium heated from a

driving wall.

Roy and Basak [6] studied the influence of uniform and non-uniform heating of the bottom wall and one vertical

wall on flow and heat transfer characteristics due to natural convection within a square enclosure. Later, Basak et

al. [7] investigated a natural-convection flow in a square cavity filled with a porous medium considering both

uniform and non-uniform heating of cavity wall from below using Darcy-Forchheimer model. Oztop et al. [8]

studied numerical simulation in a non-isothermally heated square enclosure.

Also, the problem of natural convection in an inclined enclosure has considerable attention due to its relevance to a

wide variety of application area in engineering and science. The study of mixed convection in inclined lid-driven

enclosure filled with viscous fluid was studied by Sharif [9]. He observed that the average Nusselt number

increases with increase in the inclination angle. Recently, Ogut [10] investigated a laminar, mixed convection flow

in an inclined lid-driven rectangular enclosure heated from moving one side wall of the cavity with a constant speed

and cooled from the stationary adjacent side while the other sides are kept stationary and adiabatic. Sivakumar et al.

[11] analyzed numerically the mixed convection heat transfer and fluid flow in a lid-driven cavity for different

lengths of the heater and different locations of it. It is found that a better heat transfer rate is obtained on reducing

the heater length of the hot wall. Oztop and Varol [12] investigated the flow field, temperature distribution and heat

transfer in a lid-driven cavity filled with porous medium in the presence of non- uniformly heated bottom wall.

Kuhlmann et al. [13] conducted numerical and experimental studies on the steady flow in a rectangular two-sided

lid-driven cavity. Alleborn et al. [14] analyzed numerically the mixed convection in a shallow inclined two-sided

lid-driven cavity with a moving heated lid. They simulated the problem and found that both heat and mass

transports are affected from the change of cavity inclination angle. Moreover, the bifurcation topologies of different

creeping flows have been studied by Brons and Hartnack [15] for the two-sided lid-driven cavity problem by

changing the driving or geometry parameters. Understanding the mixed convection heat transfer process in inclined

cavities is thus very important for designing purposes in the event when the inclined orientation is required.

When technology processes take place at high temperatures thermal radiation heat transfer become very important.

Recent developments in hypersonic flights, missile reentry rocket combustion chambers and gas cooled nuclear

reactors have focused attention of researchers on thermal radiation and emphasize the need for inclusion of heat

transfer in these processes. Very recently, Mahapatra et al. [16] studied natural convection in a lid-driven square

cavity filled with fluid-saturated porous medium in the presence of thermal radiation considering Darcy-

Forchheimer model. Not much of attention has been given on the study of laminar natural convection flow in an

inclined two-sided lid-driven enclosure with thermal boundary conditions as far as authors knowledge. Thus the

present study deals with the unsteady laminar natural convection flow in an inclined enclosure heated non-

uniformly in the presence of thermal radiation and heat generation from the left vertical wall, heated uniformly

from bottom wall and cooled from the top wall by keeping right wall in adiabatic state. The numerical results for

streamlines, isotherms and the heat transfer rate at the heated walls in terms of local Nusselt number and average

Nusselt number are presented graphically and in tabular form.

II. GOVERNING EQUATIONS AND BOUNDARY CONDITIONS

The two-sided lid-driven inclined enclosure under investigation is filled with a fluid-saturated porous medium and

with impermeable walls. The schematic configuration of the problem is illustrated in Fig. 1, with H denoting the

length of the sides of the square enclosure. The fluid is assumed as incompressible and the porous medium is

considered to be homogeneous and isotropic. Furthermore, the porous medium is assumed to be in local thermal

equilibrium with the fluid. The top and bottom walls of the cavity are of different temperatures, the right side wall

is adiabatic and the left side wall temperature varies sinusoidally. The Brinkman-Darcy model is adopted for the

fluid flow in the porous medium.

The dimensionless governing equations take the following form:

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

189

u v

x y

+

= 0, (1)

u

t

= -

Pr p

Da x

| || |

| |

\ .\ .

+Pr

2 2

2 2

u u

x y

| |

+

|

\ .

-

| |

|

\ .

2

u uv

x y

| |

+

|

\ .

Pr u

Da

| |

|

\ .

+

*

Ra Pr

Da

| |

|

\ .

sin, (2)

v

t

= -

Pr

Da

| |

|

\ .

p

y

| |

|

\ .

+ Pr

2 2

2 2

v v

x y

| |

+

|

\ .

-

| |

|

\ .

2

v uv

y x

| |

+

|

\ .

-

Pr v

Da

| |

|

\ .

+

*

Ra Pr

Da

| |

|

\ .

cos , (3)

t

=

2 2

2 2

x y

| |

+

|

\ .

-

u v

x y

| |

+

|

\ .

+

2

2

4

3

R

N y

| |

|

\ .

+ He . (4)

Now we define the following non-dimensional variables:

x = X/H, y =Y/H, u =UH/

m

, v =VH/

m

, = (T- T

c

)/(T

h

- T

c

), p =KP /

m

, Pr =

f

/

m

, Da=K/H

2

,

N

R

=(k*/4

3

c

T ), He =QH

2

/ .

Where Pr, N

R

and He are Prandtl, thermal radiation parameter and heat generation parameter,

respectively. Here is the inclined angle of the cavity. The heat capacity ratio and Rayleigh- Darcy

number Ra

*

(Wang et al. [19]) are defined as =(c)

f

/(c)

m

, Ra

*

=gK(T

h

-T

c

) H/

f

m

.

Non-dimensional boundary conditions are

u= v=0 and = sin (y) at x=0,

u=v=0 and /x=0 at x=1,

u=A, v=0 and =1 at y=0,

u=A, v=0 and =0 at y=1

where `A(=HU

0

/

m

) is a parameter.

The heat transfer coefficient in terms of the local Nusselt number (Nu) is defined by Nu = -(/n), where

n denotes the normal direction on a plane. The local Nusselt number at the bottom wall (Nu

b

) and left

vertical wall (Nu

l

) are defined as

Nu

b

= -(/y)|

y=0

and Nu

l

= -(/x)|

x=0

.

The average Nusselt number at the hot walls is given by,

Nu

H

|

y=0

=

1

0

b Nu

dx and Nu

H

|

x=0

=

1

0

l Nu

dy.

III. SOLUTION PROCEDURE AND NUMERICAL STABILITY CRITERIA

Control-volume based finite-difference discretization of the above equation has carried out in the present work in

staggered grid, popularity known as MAC cell. In this type of grid alignment, the velocities and the pressure are

evaluated at different locations of the control volume, the pressure and temperature are evaluated at same locations

of control volume as shown in Figure 1(b). The difference equations have been derived in distinct types of cells for

the four equations, viz., (i) continuity cell, (ii) u-momentum cell, and (iii) v-momentum cell [24], (iv) temperature

cell. These distinct cells have been shown in the Figures 2(a) and 2(b). We now describe the iteration process to

obtain the solutions of the basic equations with appropriate boundary conditions. In the derivation of pressure

Poisson equation, the divergence term at n-th time level (

n

ij

D ) is retained and evaluated in the pressure-Poisson

iteration. It is done because the discretized form of divergence of velocity field, i.e, (

n

ij

D ) is not guaranteed to be

zero. The solution procedure starts with the initializing the velocity field. This is done either from the result of

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

190

previous cycle or from the prescribed initial and boundary conditions. Using this velocity field pressure-Poisson

equation is solved using Bi-CG-Stab method. Knowing pressure field u-momentum, v-momentum and equation for

temperature are updated to get u, v, at (n + 1)th time level. Using the values of u and v at (n + 1)th time level, the

value of the divergence of velocity field is for its limit. If its absolute value is less than 0.5 10

5

and steady state

reaches then iteration process stops, otherwise again pressure-Poisson equation is solved for pressure.

Linear stability of fluid flow is

1

,

| |

x y

t Min

u v

(

, which is related to the convection of fluid, i.e., fluid should not move more than one cell

width per time step (Courant, Friedrichs and Lewy condition). Also, from the Hirts stability analysis, we have

2

2

2 2 2

1 .

.

2Pr ( )

y

x

t Min

x y

(

(

(

+

.This condition roughly stated that momentum cannot diffuse more than one cell

width per time step. The time step is determined from t = FCT [Min (t

1

, t

2

)], where the factor FCT varies from

0.2 to 0.4. The upwinding parameter is governed by the inequality condition. 1 ,

u t v t

Max

x y

(

(

. As a

rule of thumb, is taken approximately 1.2 times larger than what is found from the above inequality condition.

IV. RESULTS AND DISCUSSIONS

Numerical results for contours of the streamlines and isotherms inside the inclined square cavity and the average

Nusselt number distribution at the heated surface of the cavity for various values of radiation parameter, heat

generation parameter and inclination angle have been examined and presented graphically and in tabulated form.

The working fluid is chosen as air with Prandtl number Pr = 0.7 and the value of = 0.6 are taken in the present

study. The inclination angle of the enclosure are chosen as 20

0

, 45

0

, 60

0

, 80

0

, 90

0

.

In order to get a grid independent solution to the present problem, a grid refinement study is performed for Ra

*

=

10

3

, Da = 10

-3

and = 20

0

, 45

0

, 80

0

and a parameter A (1.0 A 200). The results of grid independence test are

shown in Table 1. As observed from the results 8080 grid is sufficient to achieve good results in the entire study.

As shown in Table 2, the average Nusselt numbers are in good agreement with the Darcy-Brinkman solutions

reported by Lauriat and Prasad [20]. These comprehensive verification efforts demonstrated the accuracy of the

present numerical method. Table 3 presents the computed values of Nu

H

|

y=0

and Nu

H

|

x=0

for various values of , N

R

and He, keeping the other parameters fixed. From this table, it is seen that Nu

H

|

y=0

and Nu

H

|

x=0

decreases with

increase in N

R

and He for all the three inclination angle, = 20

0

, 45

0

, 80

0

.

Table 1: Grid independence study for Pr = 0.7, Ra

*

= 10

3

, Da = 10

-

3

, = 0.6, N

R

= 1.0 and He = 1.0.

Grid

points

2020 4040 80 80

Iteration |

min

| Iteration |

min

| Iteration |

min

|

200

450

800

17469

16475

12714

28.5321

26.9936

20.1185

34729

31954

24601

27.4674

25.7738

19.0905

101051

74572

58398

26.9837

25.1866

18.5109

Stream function and isotherm contours for various values of ,N

R

and He with non-uniform heating of the left wall

and uniform heating of the bottom wall in the two-sided driven cavity flow are displayed in Figs. 2-5. As expected,

due to hot left vertical wall, fluids rise up along the side of the hot which then flow down along the cold wall,

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

191

forming a roll with anti-clockwise rotation inside the cavity. Counter-clockwise circulations are shown with

positive sign of stream functions. Fig. 2(a) depicts the plot of the stream function for N

R

= 1.0 and He = 1.0,

keeping the other parameters fixed. It is seen from this figure that the values of stream function in the core

decreases with increasing the inclination angle of the cavity i.e, the flow rate decreases and it is also observed that

the streamlines are more concentrated near the side walls due to stronger circulation which results in lower heat

transfer rate due to convection and increase in the inclination angle. Similar flow pattern is observed in the Figs.

2(b) and 2(c). It is interesting to note that when inclination angle are fixed (for 20

0

and 80

0

), the values of stream

function in the core increases with increase in the value of N

R

i.e, the flow rate increases with increase in the

radiation parameter. But when = 45

0

there is not much change in the value of stream function in the core for the

value of N

R

> 3.0.

Table 2: Comparison of average Nusselt number predictions with the computed data of Lauriat and Prasad [20]

when Pr = 1.0 and A = 0.0.

Ra

*

Da Present Study Lauriat & Prasad

[20]

10

4

10

3

10

2

10

-4

10

-6

10

-6

0.4

0.4

0.4

25.74

13.30

3.08

25.70

13.22

3.06

Table 3: Computed values of Nu

H

|

y=0

=0 and Nu

H

|

x=0

=0 when Pr = 0.7, A = 1.0, Ra

*

= 10

3

, Da = 10

-

3

, = 0.6 for

various values of , N

R

and He.

N

R

He Nu

H

|

y=0

Nu

H

|

x=0

20

0

1.0

3.0

5.0

1.0

1.0

1.0

3.0

5.0

6.9437

5.1820

4.4149

6.9437

6.7958

6.6331

-4.2071

-5.2032

-6.0774

-4.2071

-4.3654

-4.5459

45

0

1.0

3.0

5.0

1.0

1.0

1.0

3.0

5.0

7.3142

5.3929

4.5677

7.3142

7.1752

7.0286

-3.7731

-4.8953

-5.8316

-3.7731

-3.8693

-3.9744

80

0

1.0

3.0

5.0

1.0

1.0

1.0

3.0

5.0

6.9926

5.1191

4.2956

6.9927

6.8542

6.7113

-3.1420

-4.4739

-5.5441

-3.1420

-3.1826

-3.2256

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

192

Figure 1. Geometry and the coordinate system

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

193

Figure 2. Streamlines for He=1.0, A=1.0 and (a) N

R

=1.0, (b) N

R

=3.0, (c) N

R

=5.0.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

194

Figure 3. Streamlines for N

R

=1.0, A=1.0 and (a) He=1.0, (b) He=3.0, (c) He=5.0.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

195

Figure 4. Isotherms for He=1.0, A=1.0 and (a) N

R

=1.0, (b) N

R

=3.0, (c) N

R

=5.0.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

196

Figure 5. Isotherms for N

R

=1.0, A=1.0 and (a) He=1.0, (b) He=3.0, (c) He=5.0.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

197

Figure 6. Local Nusselt number at bottom wall for different values of , N

R

and He when Pr=0.7, Ra

*

=10

3

,

Da=10

-3

, A=1.0 and =0.6.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

198

Figure 7. Local Nusselt number at left vertical wall for different values of , N

R

and He when Pr=0.7, Ra

*

=10

3

,

Da=10

-3

, A=1.0 and =0.6.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

199

Figure 8. Plot of avarage Nusselt number vs. inclination angle of the cavity

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

200

Figure 9. Local Nusselt number at bottom wall for different values of A

Fig. 3 shows that as inclination angle increases the flow patterns are different from those shown in Fig. 2. Three

cases arise when inclination angle is fixed i.e. (i) when = 20

0

, the value of stream function in the core increases

with increase the value of He (ii) when = 45

0

, there is not much flow rate change after He > 3.0 (iii) when = 80

0

,

the value of stream function in the core changes with increase in value of He, whereas not effect is seen near the

walls.

Figs. 4(a) presents isotherms are concentrated near the edges of hot walls and cold walls due to stronger circulation,

which results in higher heat transfer rate due to convection. It is seen from this figure that as inclination angle

increases, the boundary layers are relatively thick and a very small core region occurs such that the isotherms

become almost parallel to the vertical walls indicating that conduction regime is approached due to the fact that the

middle cells of the cavity get enhanced compressing shear cells generated due to moving lids. However, the shear

cells near the walls become more vigorous. The isotherm patterns realize the effect of shear cell near the walls. But

in the middle portion of the enclosure, the feature of the natural convection is maintained. Similar flow patterns are

shown in Figs 4(b), 4(c) with less concentrated streamlines near the hot and cold walls. Fig. 5 depicts the various

streamlines patterns for different values of He for fixed value of N

R

= 1.0. The flow patterns are almost similar to

those shown in Fig. 4 which shown the isotherm for different values of thermal radiation parameters. Careful

observation of Figs. 5(a) and 5(c), show that there is significant change in the streamlines pattern by increasing the

values of internal heat generation. The effect of N

R

and He on the local Nusselt numbers at the bottom and left

vertical walls (Nu

b

and Nu

l

) for different values of the inclination angle (20

0

, 45

0

and 80

0

) by keeping the other

parameters fixed are displayed in Figs. 6 and 7. In the case when uniform heating at the bottom wall (Fig. 6) is very

high at the left edge of the bottom wall due to the discontinuity present at this edge in the temperature boundary

condition then the heat transfer rate reduces towards the right corner of the bottom wall for all values of N

R

and He.

It is also seen that heat transfer rate decreases with increase in N

R

and He, for any inclination angle. It is also

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

201

observed from Fig. 7 that in the case of non-uniform heating condition at the left wall, the heat transfer rate is very

high at both left edge and right edge and it is minimum near the left corner of the left wall. The effect of the

inclination angle on average Nusselt number is investigated and demonstrates in Fig. 8. As can be seen from the

Fig. 8(a), the average Nusselt number on walls reaches its maximum value at the inclination angle of around 55

0

due to uniform heating at bottom wall. This angle is nothing but a critical angle (Nor Azwadi et al. [21]) where

the natural convection is at the maximum point. But there is no critical angle due to non-uniform heating at left

vertical wall which is seen in Fig. 8(b). It is also seen that average Nusselt number increases with increase in

inclination angle of the cavity. This phenomenon is explained in the discussion for Table 2. Fig. 9 shows that as

parameter A increases from 1 to 200, the local Nusselt number at the bottom wall (Nu

b

) increases upto a certain

value of x and thereafter opposite trend is observed. This is occurs due to change of the speed of the lid of the

cavity.

V. CONCLUSIONS

The present paper deals with the study of thermal radiation and heat generation effects on unsteady two-

dimensional laminar natural convection flow in a two-sided lid-driven inclined enclosure non-uniformly heated

from the left vertical wall, uniformly heated from bottom wall and cooled from the top wall while right vertical wall

is kept adiabatic by using staggered grid finite-difference method. Following conclusions are drawn from this

study:

(i) Flow rate decreases with increase in the inclination angle.

(ii) Increasing in the thermal radiation parameter enhances the flow rate by keeping the inclination angle fixed.

(iii) The value of stream function in the core does not change for any value of He when = 80

0

.

(iv) Average Nusselt number decreases with increasing the value of both N

R

and He.

(v) Critical angle is formed due to uniform heating at the bottom wall, whereas no Critical angle is found in the

case of non-uniform heating at the bottom wall.

REFERENCES

[1] D.A. Nield, A. Bejan, Convection in porous media, 3rd ed., Springer, New York, 2006.

[2] C.H. Bruneau, M. Saad, The 2D lid-driven cavity problem revisited, Comput. Fluids, 35

(2006) 326348.

[3] T.H. Hsu, S.G. Wang, Mixed convection in a rectangular enclosure with discrete heat sources, Numer. Heat

Transfer, Part A. 38 (2000) 627652.

[4] K.M. Khanafer, A.J. Chamkha, Mixed convection flow in a lid-driven enclosure filled with a fluid-saturated

porous medium, Int. J. Heat Mass Transf. 42 (1999) 24652481.

[5] A.M. Al-Amiri, Analysis of momentum and energy transfer in a lid-driven cavity filled with a porous medium,

Int. J. Heat Mass Transf. 43 (2000) 35133527.

[6] S. Roy, T. Basak, Finite element analysis of natural convection flows in a square cavity with non-uniformly

heated wall(s), Int. J. Engg. Sci. 43 (2005) 668680.

[7] T. Basak, S. Roy, T. Paul, I. Pop, Natural convection in square cavity filled with a porous medium: Effects of

various thermal boundary conditions, Int. J. Heat Mass Transf. 49 (2006) 14301441.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) IAEME

202

[8] H.F. Oztop, M. Oztop, V. Varol, Numerical simulation of magnetohydrodynamic buoyancy induced flow in a

non-isothermally heated square enclosure, Comm. Nonlinear Sci. Num. Simu. 14(3) (2009) 770778.

[9] M.A.R. Sharif, Laminar mixed convection in shallow inclined driven cavities with hot moving lid on top and

cooled from bottom, Appl. Therm. Engg. 27 (2007) 10361042.

[10] E.B. Ogut, Mixed convection in an inclined and lid-driven rectangular enclosure heated and cooled on

adjacent walls, CSME Transactions, 32 (2008) 213226.

[11] V. Sivakumar, S. Sivasankaran, P. Prakash, J. Lee, Effect of heating location and size on mixed convection in

lid-driven cavities, Computers and Mathematics with Applications, 59 (2010) 30533065.

[12] H.F. Oztop, A. Varol, Combined convection in inclined porous lid-driven enclosures with sinusoidal thermal

boundary condition on one wall, Progress in computational Fluid Dyanamics, 9 (2009) 127131.

[13] H.C. Kuhlmann, M. Wanschura, H.J. Rath, Flow in two-sided lid-driven cavitie: nonuniqueness, instabilities

and celular structurs, J. Fluid Mech. 336 (1997) 267299.

[14] N. Alleborn, H. Raszillier, F. Durst, Lid-driven with heat and mass transport, Int. J. Heat Mass Transf. 42

(1999) 833853.

[15] M. Brns, J.N. Hartnack, Streamline topologies near simple degenerate critical points in two-dimentional flow

away from boundaries, Phys. Fluids, 11 (1999) 314324.

[16] T.R. Mahapatra, D. Pal, S. Mondal, Natural convection in a lid-driven square cavity filled with Darcy-

Forchheimer porous medium in the presence of thermal radition, Int. J. Nonlinear Science, 11(3) (2011) 366379.

[17] T.S. Lundgren, Slow flow through stationary random beds and suspensions of spheres, J. Fluid Mech. 51

(1972) 273299.

[18] I. Zahmatkesh, Influence of thermal radiation on free convection inside a porous enclosure, Emirates J. Engg.

Research, 12(2) (2007) 4752.

[19] G. Wang, Q. Wang, M. Zeng, H. Qzoe, Numerical study of natural convection heat transfer in an inclined

porous cavity with time-periodic boundary conditions, Transp. Porous Media, 74 (2008) 293309.

[20] Lauriat, G., Prasad, V. (1989). Non-Darcian effects on natural convection in a vertical porous enclosure, Int. J.

Heat Mass Transf. 32, 21352148.

[21] C.S. Nor Azwadi, M.Y. Mohd Fairus, S. Syahrullail, Virtual study of natural convection heat transfer in an

inclined square cavity, J. of Applied Science, 10(4)(2010) 331336.

Potrebbero piacerti anche

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocumento10 pagineImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationNessuna valutazione finora

- A Study On The Reasons For Transgender To Become EntrepreneursDocumento7 pagineA Study On The Reasons For Transgender To Become EntrepreneursIAEME PublicationNessuna valutazione finora

- Broad Unexposed Skills of Transgender EntrepreneursDocumento8 pagineBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationNessuna valutazione finora

- Analyse The User Predilection On Gpay and Phonepe For Digital TransactionsDocumento7 pagineAnalyse The User Predilection On Gpay and Phonepe For Digital TransactionsIAEME PublicationNessuna valutazione finora

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocumento14 pagineModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNessuna valutazione finora

- Determinants Affecting The User's Intention To Use Mobile Banking ApplicationsDocumento8 pagineDeterminants Affecting The User's Intention To Use Mobile Banking ApplicationsIAEME PublicationNessuna valutazione finora

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocumento15 pagineAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationNessuna valutazione finora

- Gandhi On Non-Violent PoliceDocumento8 pagineGandhi On Non-Violent PoliceIAEME PublicationNessuna valutazione finora

- Voice Based Atm For Visually Impaired Using ArduinoDocumento7 pagineVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationNessuna valutazione finora

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocumento16 pagineInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationNessuna valutazione finora

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocumento7 pagineA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationNessuna valutazione finora

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocumento9 pagineFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationNessuna valutazione finora

- Visualising Aging Parents & Their Close Carers Life Journey in Aging EconomyDocumento4 pagineVisualising Aging Parents & Their Close Carers Life Journey in Aging EconomyIAEME PublicationNessuna valutazione finora

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocumento9 pagineA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationNessuna valutazione finora

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocumento10 pagineA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationNessuna valutazione finora

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocumento18 pagineRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationNessuna valutazione finora

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocumento16 pagineA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationNessuna valutazione finora

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocumento19 pagineApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationNessuna valutazione finora

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocumento10 pagineVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationNessuna valutazione finora

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDocumento13 pagineA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationNessuna valutazione finora

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocumento8 pagineDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationNessuna valutazione finora

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDocumento13 pagineAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationNessuna valutazione finora

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocumento8 pagineKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationNessuna valutazione finora

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDocumento9 pagineEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationNessuna valutazione finora

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocumento13 pagineOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationNessuna valutazione finora

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocumento7 pagineQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationNessuna valutazione finora

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDocumento7 pagineModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationNessuna valutazione finora

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDocumento9 pagineAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationNessuna valutazione finora

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDocumento13 paginePrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationNessuna valutazione finora

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocumento26 pagineA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Evaporative Cooling Equations 1589983721 PDFDocumento10 pagineEvaporative Cooling Equations 1589983721 PDFAbdulhamit KAYYALINessuna valutazione finora

- IB Lab On Hess LawDocumento7 pagineIB Lab On Hess LawBraulioMolinaFloresNessuna valutazione finora

- A Review of Heat Pipe Systems For Heat Recovery and Renewable Energy ApplicationsDocumento11 pagineA Review of Heat Pipe Systems For Heat Recovery and Renewable Energy ApplicationsJoao MinhoNessuna valutazione finora

- BITZER Output Data: Created On: 27.07.2019 08:52:49Documento7 pagineBITZER Output Data: Created On: 27.07.2019 08:52:49JcRodriguezNessuna valutazione finora

- Example Problems ConductionDocumento9 pagineExample Problems ConductionAJ100% (1)

- EURAMET Cg-13 v3.0 Temperature Block CalibratorsDocumento14 pagineEURAMET Cg-13 v3.0 Temperature Block CalibratorsNuttakarn NongpongNessuna valutazione finora

- Key Physical Variables in The Ocean Temperature, Salinity, and DensityDocumento10 pagineKey Physical Variables in The Ocean Temperature, Salinity, and DensityLeon TaufaniNessuna valutazione finora

- Comparing R1233zd and R245fa For Low Temperature ORC Applications PDFDocumento8 pagineComparing R1233zd and R245fa For Low Temperature ORC Applications PDFpancawawanNessuna valutazione finora

- HeatDocumento12 pagineHeatsitajanNessuna valutazione finora

- Triple Point CellsDocumento48 pagineTriple Point CellsGustavo SánchezNessuna valutazione finora

- Kimmco Isover-Tds-Tech Sa WM 100 0Documento2 pagineKimmco Isover-Tds-Tech Sa WM 100 0mohamedwalyNessuna valutazione finora

- Anna Univ Syllabus Chemical Engineering 3rd To 8th Sem Syllabus - WWW - Annaunivedu.infoDocumento48 pagineAnna Univ Syllabus Chemical Engineering 3rd To 8th Sem Syllabus - WWW - Annaunivedu.infosudentsideaNessuna valutazione finora

- Methods of Estimating Steam ConsumptionDocumento8 pagineMethods of Estimating Steam ConsumptionHimanshu1712Nessuna valutazione finora

- Preparatory Problems PDFDocumento2 paginePreparatory Problems PDFGerel BayrmagnaiNessuna valutazione finora

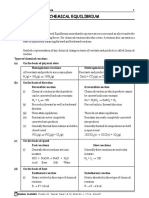

- Chemical EquilibriumDocumento68 pagineChemical Equilibriumhappy100% (1)

- 18Pph204: Statistical Mechanics and Thermodynamics: SRM Institute of Science and TechnologyDocumento3 pagine18Pph204: Statistical Mechanics and Thermodynamics: SRM Institute of Science and TechnologyVijayNessuna valutazione finora

- Improving Thermodynamic Consistency Among Vapor Pressure Heat of PDFDocumento268 pagineImproving Thermodynamic Consistency Among Vapor Pressure Heat of PDFfikriNessuna valutazione finora

- Brake Rotor ThermodynamicsDocumento13 pagineBrake Rotor ThermodynamicsMike MenosNessuna valutazione finora

- A Model Study of Thermal Characteristics of Decarburization Annealing Furnace For Silicon Steel Strip PDFDocumento8 pagineA Model Study of Thermal Characteristics of Decarburization Annealing Furnace For Silicon Steel Strip PDFد. علا محمد حداويNessuna valutazione finora

- Heat Transfer SummaryDocumento16 pagineHeat Transfer SummaryNuzhat SafdarNessuna valutazione finora

- Heat and Mass Transfer 1-5Documento209 pagineHeat and Mass Transfer 1-5karthik50% (2)

- General Equilibrium Notes CH 16 TroDocumento13 pagineGeneral Equilibrium Notes CH 16 TroVincent AllamNessuna valutazione finora

- Enthalpy of An Ideal Gas Is A Function Only of A. Entropy B. Internal Energy C. Temperature D. PressureDocumento150 pagineEnthalpy of An Ideal Gas Is A Function Only of A. Entropy B. Internal Energy C. Temperature D. PressureTed Mana-ayNessuna valutazione finora

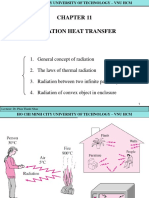

- Chapter 11 - Radiation Heat TransferDocumento22 pagineChapter 11 - Radiation Heat TransferBảo Tín TrầnNessuna valutazione finora

- KAL Pathippagam - Diploma - Heat Power Engineering (English) - 2 & 3 Marks - Important Questions - DOTE - TamilnaduDocumento45 pagineKAL Pathippagam - Diploma - Heat Power Engineering (English) - 2 & 3 Marks - Important Questions - DOTE - TamilnaduKal Pathippagam71% (21)

- Flashing Liquid Expanders For Crygenic IndustriesDocumento18 pagineFlashing Liquid Expanders For Crygenic IndustriesPeter PerezNessuna valutazione finora

- XII Phy Past PprsDocumento27 pagineXII Phy Past Pprsumairgul841Nessuna valutazione finora

- Design of An Ice Plant With 78 Tons of Block Ice CapacityDocumento33 pagineDesign of An Ice Plant With 78 Tons of Block Ice CapacityDarren Manuel Tenerife100% (7)

- Black Liquor Evaporation3-2Documento21 pagineBlack Liquor Evaporation3-2isosicaNessuna valutazione finora

- BTD Question Bank1Documento16 pagineBTD Question Bank1Mahantesh ChulakiNessuna valutazione finora