Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PVDF31508 - 0003 Data Sheet

Caricato da

soumsarkarDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PVDF31508 - 0003 Data Sheet

Caricato da

soumsarkarCopyright:

Formati disponibili

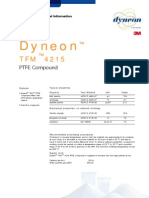

Technical Data

3M Dyneon

Features and Benefits

Copolymer of VF2 and CTFE Ultra-flexible Very low shrinkage rates Wide operating temperature window Processable using a variety of thermoplastic conversion techniques Excellent low flame and low smoke performance

Note: Data in this document are not for specification purposes.

Fluoroplastic PVDF 31508/0003

Typical Properties

Property Test Conditions Test Method

Density H2O Absorption Melt Flow Index Tensile Strength at Break Elongation at Break Flexural Modulus Melting Point (Crystallinity by DSC) Brittleness Temperature Surface Resistivity, Voltage < 1V, after 2 Minutes 500V Volume Resistivity, Intensity = 10 mA, after 2 Minutes Dielectric Constant UL - 94 Flammability Test Limiting Oxygen Index (LOI)(sheet 3 mm Thick)

24hr @ 23C 230C, 5 kg 230C, 2.16 kg 23C, 50 mm/min 23C, 50 mm/min 23C, 2 mm/min

23C 23C 1 MHz

ISO 1183 ISO 62 (method 1) ASTM D1238 ASTM D1238 ASTM D638 ASTM D638 ASTM D790 ASTM D3418 ASTM D746A ASTM D257 DIN 53483 ASTM D257 DIN 53483 ASTM D150 UL-94 ASTM D2863

1.76 g/cm3 <0.04% 15 g/10 min 5 g/10 min 22 MPa (3,190 psi) 475% 425 MPa (61,625 psi) 169C (336F) -37C (-35F) >1014 ohm.square >1014 ohm.cm 7 V-O Class 65%

Product Description

3M Dyneon PVDF 31508/0003 is a flexible copolymer of VF2 and CTFE, exhibiting very low shrinkage and excellent impact resistance. PVDF 31508/0003 also has a very low brittleness temperature, for excellent low temperature performance. This material is ideal for insulation and buffering materials for wire and cable applications and for tubing. PVDF 31508/0003 has excellent flame and smoke performance, with an LOI of 65. PVDF 31508/0003 is designed for high speed extrusion, and can be processed using a variety of conventional thermoplastic conversion techniques. As with all PVDF grades, PVDF 31508/0003 also possesses very good chemical and temperature resistance. generally does not require drying before processing unless high humidity conditions create surface moisture adsorption.

Safety/Toxicology

This is a fluoroplastic material so normal precautions observed with fluoroplastics should be followed. Before processing this product, read the product label and Material Safety Data Sheet. Follow all precautions and directions for use. General handling/processing precautions include: (1) process only in well ventilated areas, (2) do not smoke in areas contaminated with powder/residue from these products; (3) avoid eye contact; (4) after handling these products wash any contacted skin with soap and water.

Storage and Material Handling

PVDF 31508/0003 has an unlimited shelf life provided it is stored in a clean, dry place in its original, unopened container. PVDF 31508/0003 is hydrophobic, and

3M Dyneon Fluoroplastic PVDF 31508/0003

Warranty, Limited Remedy, and Disclaimer: Many factors beyond 3Ms control and uniquely within users knowledge and control can affect the use and performance of a 3M product in a particular application. User is solely responsible for evaluating the 3M product and determining whether it is fit for a particular purpose and suitable for users method of application. Unless a different warranty is specifically stated in the applicable product literature or packaging insert, 3M warrants that each 3M product meets the applicable 3M product specification at the time 3M ships the product. 3M MAKES NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY OR CONDITION ARISING OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE. If the 3M product does not conform to this warranty, then the sole and exclusive remedy is, at 3Ms option, replacement of the 3M product or refund of the purchase price. Limitation of Liability: Except where prohibited by law, 3M will not be liable for any loss or damages arising from the 3M product, whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including warranty, contract, negligence or strict liability. Technical Information: Technical information, recommendations, and other statements contained in this document or provided by 3M personnel are based on tests or experience that 3M believes are reliable, but the accuracy or completeness of such information is not guaranteed. Such information is intended for persons with knowledge and technical skills sufficient to assess and apply their own informed judgment to the information. No license under any 3M or third party intellectual property rights is granted or implied with this information.

3

3M Center St. Paul, MN 55144-1000 1-800-810-8499 www.3M.com/fluoropolymers Please recycle. Printed in USA. 3M 2011. All rights reserved. Issued: 8/11 7837HB 98-0504-1510-2 3M and Dyneon are trademarks of 3M. Used under license.

Potrebbero piacerti anche

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ADa EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANessuna valutazione finora

- 2013 Spyder ST Owners ManualDocumento171 pagine2013 Spyder ST Owners ManualMelvin Quezada67% (6)

- Drilling Rig Selection - Guidelines Only)Documento79 pagineDrilling Rig Selection - Guidelines Only)Edo Gawa77% (13)

- Adhesives Technology for Electronic Applications: Materials, Processing, ReliabilityDa EverandAdhesives Technology for Electronic Applications: Materials, Processing, ReliabilityNessuna valutazione finora

- Data, Facts and Products: Innovative Power TransmissionDocumento16 pagineData, Facts and Products: Innovative Power TransmissionHeri SetyantoNessuna valutazione finora

- Soot BlowersDocumento279 pagineSoot BlowersLALCHAND RAWANI100% (2)

- Method Statement For The Protective Coating - Corrosion Protection of Steel Structures GeneralDocumento11 pagineMethod Statement For The Protective Coating - Corrosion Protection of Steel Structures GeneralTony Nellicken100% (2)

- Airtronic D2-D4 Diagnostic Repair Manual 2013Documento33 pagineAirtronic D2-D4 Diagnostic Repair Manual 2013sdfrNessuna valutazione finora

- 3 Glass Bead Making ProjectsDocumento11 pagine3 Glass Bead Making ProjectsAngela R. Lacey100% (1)

- 3M 9731RWDocumento4 pagine3M 9731RWcbol91311Nessuna valutazione finora

- 3M Novec 1700 Electronic Grade Coating: Product InformationDocumento2 pagine3M Novec 1700 Electronic Grade Coating: Product InformationraulitoroqueNessuna valutazione finora

- 3M Adhesion Promoter 111Documento6 pagine3M Adhesion Promoter 111Marco Navarro TolentinoNessuna valutazione finora

- Loctite 5699™: Technical Data SheetDocumento3 pagineLoctite 5699™: Technical Data Sheetgazwang478Nessuna valutazione finora

- TFM 4215Documento2 pagineTFM 4215Mohit SharmaNessuna valutazione finora

- FORTRON® 1120L4 - PPS - Specialty: DescriptionDocumento2 pagineFORTRON® 1120L4 - PPS - Specialty: DescriptionAdam GordonNessuna valutazione finora

- 226N Data Sheet - FBE CoatingDocumento2 pagine226N Data Sheet - FBE Coatingbello imamNessuna valutazione finora

- Henk Multicore Macromelt Mm6208s TdsDocumento2 pagineHenk Multicore Macromelt Mm6208s TdsAbohicham AbhNessuna valutazione finora

- Amercoat 3279 DatasheetDocumento0 pagineAmercoat 3279 Datasheetmekag94Nessuna valutazione finora

- Double Coated Splicing Tapes: Technical Data March, 2008Documento3 pagineDouble Coated Splicing Tapes: Technical Data March, 2008douglas lopezNessuna valutazione finora

- VHB Acrylic Foam Tape: Technical Data March, 2001Documento2 pagineVHB Acrylic Foam Tape: Technical Data March, 2001daskhagoNessuna valutazione finora

- Pearlthane 11T93Documento2 paginePearlthane 11T93Gabriel SalomonNessuna valutazione finora

- PTFE Glass Cloth Tape: Technical Data March, 2014Documento2 paginePTFE Glass Cloth Tape: Technical Data March, 2014Lord KrsnikNessuna valutazione finora

- 3M Electrical Tape 44: Data Sheet January 2011Documento2 pagine3M Electrical Tape 44: Data Sheet January 2011Abdan ShidqiNessuna valutazione finora

- 3MScotchcast 92NBADocumento4 pagine3MScotchcast 92NBAAnalia CanosaNessuna valutazione finora

- Glass Cloth Tape: Technical DataDocumento2 pagineGlass Cloth Tape: Technical DataАндрей МошкинNessuna valutazione finora

- 3M Venture Tape 1599B TDS v12-2017Documento2 pagine3M Venture Tape 1599B TDS v12-2017Hernan Romero RomeroNessuna valutazione finora

- 3m 323 EpoxyDocumento3 pagine3m 323 EpoxyFazeel Rick MohammedNessuna valutazione finora

- 892HS PDSDocumento2 pagine892HS PDSgabriel__regioNessuna valutazione finora

- Plating Masking TapDocumento2 paginePlating Masking TapkkphadnisNessuna valutazione finora

- Polyguard PEDocumento2 paginePolyguard PEabcd1860100% (1)

- MTM44 1 Datasheet Issue6Documento6 pagineMTM44 1 Datasheet Issue6Leolix PavlixNessuna valutazione finora

- General Purpose Polyester/ Silicone Tape: 8952 8952L (Linered)Documento2 pagineGeneral Purpose Polyester/ Silicone Tape: 8952 8952L (Linered)Hardware 02Nessuna valutazione finora

- 3 100e Unersal Silicone Tds enDocumento1 pagina3 100e Unersal Silicone Tds enJames MurrayNessuna valutazione finora

- Spec 3m 375Documento2 pagineSpec 3m 375Thích Rong ChơiNessuna valutazione finora

- 3M™ Aluminum Foil Tape 425 - 20230726Documento5 pagine3M™ Aluminum Foil Tape 425 - 20230726jq9znjhswwNessuna valutazione finora

- Loctite 242: Product Description TechnologyDocumento3 pagineLoctite 242: Product Description TechnologyRuiNessuna valutazione finora

- Cinta 365 ElectricaDocumento2 pagineCinta 365 ElectricamiguelNessuna valutazione finora

- AlphaSeal PU25VLS NGDocumento3 pagineAlphaSeal PU25VLS NGMuthukumar JayaveerapandianNessuna valutazione finora

- DYMAX Ga-103Documento0 pagineDYMAX Ga-103Giosue GiacoppoNessuna valutazione finora

- 3M Scotchkote Epoxy Coating 162EP Tech DataDocumento2 pagine3M Scotchkote Epoxy Coating 162EP Tech Datajast111Nessuna valutazione finora

- 3M ScotchcastDocumento4 pagine3M ScotchcastPORT ENGINEER JAD LIFTBOATSNessuna valutazione finora

- 9 PDSDocumento2 pagine9 PDS전상문Nessuna valutazione finora

- Media Web ServerDocumento2 pagineMedia Web ServerSapari VelNessuna valutazione finora

- Dimetcote 9 PDS AIDocumento3 pagineDimetcote 9 PDS AIAmer Y KNessuna valutazione finora

- Electroplating/Anodizing Tape: Technical Data December, 2006Documento2 pagineElectroplating/Anodizing Tape: Technical Data December, 2006sanjay ukalkarNessuna valutazione finora

- Lupolen 2420 D: Features ApplicationsDocumento2 pagineLupolen 2420 D: Features ApplicationsGabs GabrielaNessuna valutazione finora

- POLYCOATDocumento2 paginePOLYCOATGeorge TsiamtsourisNessuna valutazione finora

- Cinta Teflon Cafe PTFE 5151Documento2 pagineCinta Teflon Cafe PTFE 5151rodrigoNessuna valutazione finora

- POLYTEXDocumento2 paginePOLYTEXDon AlexNessuna valutazione finora

- Technical Data: Three Bond 1207CDocumento3 pagineTechnical Data: Three Bond 1207CVictorEkaSetiawanNessuna valutazione finora

- 3M™ Fastener Adhesive 2353 and 2353Y: Technical Data SheetDocumento4 pagine3M™ Fastener Adhesive 2353 and 2353Y: Technical Data SheetanhthoNessuna valutazione finora

- Technical Data Sheet: EPIKURE™ Curing Agent 3274Documento4 pagineTechnical Data Sheet: EPIKURE™ Curing Agent 3274Kelvin Allan Soler LopezNessuna valutazione finora

- 3M Optically Clear AdhesivesDocumento5 pagine3M Optically Clear AdhesivesPanagiotis ArgyropoulosNessuna valutazione finora

- 3M Fluorinert FC-70 Electronic LiquidDocumento9 pagine3M Fluorinert FC-70 Electronic LiquidFakhrudin HalimNessuna valutazione finora

- Cable Cleaners Cleaning Wipes SpecificationDocumento2 pagineCable Cleaners Cleaning Wipes Specificationdavid.darmaji011Nessuna valutazione finora

- Flame Retardant Label Materials 7203 and 7204Documento2 pagineFlame Retardant Label Materials 7203 and 7204FAH MANNessuna valutazione finora

- 481 Preservation Sealing TapeDocumento2 pagine481 Preservation Sealing TapeSixmonNessuna valutazione finora

- Asmaco PU SealantDocumento3 pagineAsmaco PU SealantJoseph EzekielNessuna valutazione finora

- FT - Amercoat 3279Documento5 pagineFT - Amercoat 3279Rodrigo Sánchez BautistaNessuna valutazione finora

- Loctite 592™: % of Initial Strength Environment °C 720 HDocumento2 pagineLoctite 592™: % of Initial Strength Environment °C 720 HAndy ChongNessuna valutazione finora

- Loctite 648: Technical Data SheetDocumento3 pagineLoctite 648: Technical Data SheetRuiNessuna valutazione finora

- Simrit - Broșura Low Temperature Polyurethane 92 AU 21100 (The Material For Use Down To - 50°C)Documento8 pagineSimrit - Broșura Low Temperature Polyurethane 92 AU 21100 (The Material For Use Down To - 50°C)jo_rz_57Nessuna valutazione finora

- Metocene MF650X: HomopolymerDocumento1 paginaMetocene MF650X: HomopolymerParom WaikasikarnNessuna valutazione finora

- Sobitan MonoleateDocumento2 pagineSobitan MonoleateAttique AlviNessuna valutazione finora

- Loctite 641: Technical Data SheetDocumento3 pagineLoctite 641: Technical Data SheetRuiNessuna valutazione finora

- 3M Scotchkote Parts A and BDocumento16 pagine3M Scotchkote Parts A and BGilberto YoshidaNessuna valutazione finora

- RX 6-8 PDFDocumento30 pagineRX 6-8 PDFCyrusNessuna valutazione finora

- Aryan 170206134129Documento21 pagineAryan 170206134129api-402308093Nessuna valutazione finora

- ANUBISPapercraft Maskby NtanosDocumento12 pagineANUBISPapercraft Maskby NtanosandrescardonaNessuna valutazione finora

- 5000M MotionSetup 70000420C Nov09 PDFDocumento32 pagine5000M MotionSetup 70000420C Nov09 PDFspeedtunningNessuna valutazione finora

- Procurement & Distribution Logistics: Tutor: Mr. Michael KleinDocumento14 pagineProcurement & Distribution Logistics: Tutor: Mr. Michael KleinRiya OberoiNessuna valutazione finora

- About Dissimilar MetalsDocumento1 paginaAbout Dissimilar MetalsIsabel Christina Gonzalez MoralesNessuna valutazione finora

- C2 Quantitative Chemistry HigherDocumento12 pagineC2 Quantitative Chemistry HigherdownendscienceNessuna valutazione finora

- PNS 40 2020 Steel RebarsDocumento9 paginePNS 40 2020 Steel RebarscesuquilangNessuna valutazione finora

- Armoured Unarmoured: Size (MM)Documento3 pagineArmoured Unarmoured: Size (MM)Bonaventure NzeyimanaNessuna valutazione finora

- BDA30403 Gas TurbinesDocumento56 pagineBDA30403 Gas TurbinesShishajimooNessuna valutazione finora

- Bomba Vacio C Lateral FPZ TDDocumento52 pagineBomba Vacio C Lateral FPZ TDchristian_ignacioNessuna valutazione finora

- L5PNFDocumento2 pagineL5PNFmajdjasonNessuna valutazione finora

- ROHS Compliance TestingDocumento13 pagineROHS Compliance TestingVedang BhagwatNessuna valutazione finora

- Hot WireDocumento3 pagineHot WirewaleedfoxxNessuna valutazione finora

- TeslaDocumento6 pagineTeslaSharif EisaNessuna valutazione finora

- Pyro ValveDocumento5 paginePyro Valvehkr0101Nessuna valutazione finora

- Line Index Table For Miano-18 Wellhead CompressionDocumento2 pagineLine Index Table For Miano-18 Wellhead CompressionHafiz AkhtarNessuna valutazione finora

- Intro To Gears & Gear TrainsDocumento20 pagineIntro To Gears & Gear TrainsBrettNessuna valutazione finora

- Electric Conductivity (EC) MeterDocumento3 pagineElectric Conductivity (EC) MeterThanh NguyênNessuna valutazione finora

- PRV Catlogue-Samson (09!06!09)Documento6 paginePRV Catlogue-Samson (09!06!09)pkrishna984Nessuna valutazione finora

- Synthotech e BrochureDocumento14 pagineSynthotech e BrochurePeter FormanNessuna valutazione finora

- Spectrapak 309Documento2 pagineSpectrapak 309WahyuNessuna valutazione finora

- Klueber Paraliq-91 DsDocumento2 pagineKlueber Paraliq-91 DsZulkiflee IsmailNessuna valutazione finora