Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Placing Concrete From Rome To SCC

Caricato da

mafran1602Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Placing Concrete From Rome To SCC

Caricato da

mafran1602Copyright:

Formati disponibili

PLACING CONCRETE: FROM ROME TO SCC

Massimo Coli1 & Marco Francini2

1

Dep. Earth Science, Un. of Florence, Italy -

Betonval SpA, Buzzi Unicem Group, Italy

Roman Age

Photo: Fikret Yegul

XXI Century

PLACING

PLACING

MAN ENERGY

WORK FLOW

Photo: Fikret Yegul

COMPACTION GRADE

Observing the self-adjustement of SCC

MACHINE ENERGY

GRAVITY FLOW

MAN ENERGY

COMPONENTS HIGHLIGHTS

Photo: Judith A: Geary

- POZZOLANA - SLAKED LIME - RUBBLES

TEXTURE

AGGREGATE VOLUME

WATER CONTENT

AGGREGATE Dmax

Photo: G. Giunti

Photo: Fikret Yegul

WORK FLOW

Slaves hand working stiff concrete. They mixed a semidry mortar in a box and carried it to the job site in baskets, pounding it into a previously prepared layer of stones

COMPACTION GRADE

MACHINE ENERGY

GRAVITY FLOW

TEXTURE Rome - the Arch of Septimius Severus

AGGREGATE VOLUME

Pozzolana did react with lime and water to solidify into a rocklike mass, even when water submerged

COMPONENTS HIGHLIGHTS

- ACRYLIC ADMIXTURES - MINERAL FILLER

The self compacting concrete runs into the moulds, leading to an excellent conpaction degree due to the endless belt-like effect of the finest solid fraction Rome - the Pantheon

Roman concrete was placed in layers and faced on both sides with clay bricks that had little structural value

Middle Age

Photo: M.Francini

Since 300 B.C. the Romans were able to build up strong edifices and to vault large ceilings by using a mixture of slaked lime, volcanic ash (Pozzolana), sand, crock, rubbles and organic admixtures. The high performances and durability of roman concrete were due to the volcanic ash, as well as to the wide availability of low-cost manpower (slaves) that permitted the use of high viscosity fresh mixture with a very low water/cement ratio. Placing concrete meant to hard compress it between huge walls locked with brick rows. The high cost of cement due to the restricted supply of the volcanic ash did not allow for a wide use of concrete, that was Durability confined to large public buildings which was paid directly by the Imperial Treasury or by rich important citizens, who also supplied many necessary slaves to place the concrete.

Strenght

ete cr on C t n ie c n

A recent revolutionary change has lead to the SCC, a very high strength, high durable Self Compacting Concrete were the smallest solid phase, that till now was only the cement, is more enhanced by a well graded filler in the range 040 mm.

Futu re Co nc re

te

P la c in g c o n c r e t e will m e a n t o o b s e r ve i t self-adjusting in t o t h in n e r a n d t h in n e r - o r s p e c ia l s h a p e d - m o u ld s .

The SCC technology together with a large reuse of industrial waste now can make concrete an environmental friendly, low-cost, very durable, widespread and easy making building material.

The decline of concrete utilization in the middle-age was almost complete

Moulding After the collapse of the Roman Empire the use of such a viscous material declined and stone or brick masonry continued to be used as building materials for many centuries. The first change was in the early XIX Century with the introducton of Portland cement, that was produced with widespread and cheap materials (limestone and clay) allowing a better workable and relatively high-strength concrete. P l a c i n g c onc re t e me a nt to c o m p a c t i t in t o s i m p l e moul d s .

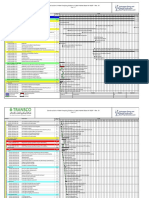

EQUAL CEMENT CONTENT TRENDS

The second notable improvement was in the middle 1900s with the introduction of chemical admixtures, that allowed for a very fluid yet high-strength concrete.

COMPONENTS HIGHLIGHTS

Placing concrete means to guide it into more complex moulds. Since the early 1900s landscape has been deeply marked by concrete use -buildings, bridges, tunnels, dams-, some of which are works of art.

- CHEMICAL ADMIXTURES - COMPOSITE CEMENTS

Mo

der

n Co n cr ete

TEXTURE TEXTURE

Co ay Tod

re nc

te

Today keywords are workability and durability, often associated with high mechanical strenght

PLACING

PLACING COMPACTION GRADE MACHINE ENERGY Florence - the Autostrade Church

GRAVITY FLOW

MAN ENERGY

AGGREGATE VOLUME

AGGREGATE VOLUME

COMPACTION GRADE

AGGREGATE Dmax

MACHINE ENERGY

MAN ENERGY

- PORTLAND CEMENT - REINFORCEMENT STEEL

With the use of steel reiforcements an homogeneous and more plastic mix became necessary

WORK FLOW

COMPONENTS HIGHLIGHTS

GRAVITY FLOW

WATER CONTENT

WATER CONTENT

AGGREGATE Dmax

XIX-XX Century

Year 2000

WORK FLOW

WATER CONTENT

AGGREGATE Dmax

Potrebbero piacerti anche

- NBSC 2019 MfranciniDocumento15 pagineNBSC 2019 Mfrancinimafran1602Nessuna valutazione finora

- Acti-Gel - SCC StabilizerDocumento2 pagineActi-Gel - SCC Stabilizermafran1602Nessuna valutazione finora

- Guide To Image SharpeningDocumento13 pagineGuide To Image Sharpeningmafran1602Nessuna valutazione finora

- Self-Compacting ConcreteDocumento68 pagineSelf-Compacting ConcreteMisgun SamuelNessuna valutazione finora

- Predictive Analysis of Components To Obtain An Aimed RobustnessDocumento6 paginePredictive Analysis of Components To Obtain An Aimed Robustnessmafran1602Nessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Precast Concrete Technician Study GuideDocumento37 paginePrecast Concrete Technician Study Guidefree4bruceNessuna valutazione finora

- Voorbeeld: Internatio N Al Standard 2186Documento10 pagineVoorbeeld: Internatio N Al Standard 2186Pansawut WanitwanakornNessuna valutazione finora

- Mebs6000 1011 06 Sewage DisposalDocumento72 pagineMebs6000 1011 06 Sewage DisposalJack LiNessuna valutazione finora

- Flexural Strength of Reinforced Polymer Concrete Made With Recycled Plastic WasteDocumento7 pagineFlexural Strength of Reinforced Polymer Concrete Made With Recycled Plastic WastepicottNessuna valutazione finora

- Static Structural and Fatigue Analysis of SpannerDocumento17 pagineStatic Structural and Fatigue Analysis of Spannerprashant kottalagiNessuna valutazione finora

- Tolerances and Jacking Force PDFDocumento2 pagineTolerances and Jacking Force PDFAbu BiduNessuna valutazione finora

- ETABS 2016 Shear Wall Design: ETABS 2016 16.2.1 License # 1VT4JZ6NBETB3BFDocumento1 paginaETABS 2016 Shear Wall Design: ETABS 2016 16.2.1 License # 1VT4JZ6NBETB3BFArmando CasasNessuna valutazione finora

- 1Documento3 pagine1Jose Fernando GemperleNessuna valutazione finora

- Design Calculation For Column 750Kn, 140Knm, 20Knm Parameter Unit Column Segment 1 2 3Documento12 pagineDesign Calculation For Column 750Kn, 140Knm, 20Knm Parameter Unit Column Segment 1 2 3mudithaNessuna valutazione finora

- Cold-Formed Steel Design DocumentsDocumento12 pagineCold-Formed Steel Design DocumentsTarek-Aziz BihiNessuna valutazione finora

- POW - CCJE 2 STOREY REHABILITATION Final 101720Documento51 paginePOW - CCJE 2 STOREY REHABILITATION Final 101720Mark Stephen FelipeNessuna valutazione finora

- A Study On Composite Structures - A Solution For High Rise Structures in IndiaDocumento5 pagineA Study On Composite Structures - A Solution For High Rise Structures in IndiaHealer AVNessuna valutazione finora

- Caso de Estudio Estabilidad de Taludes RS en ChinaDocumento14 pagineCaso de Estudio Estabilidad de Taludes RS en ChinaVivi AbelloNessuna valutazione finora

- Lord You Know All Things, You Can Do All Things and You Love Me Very MuchDocumento4 pagineLord You Know All Things, You Can Do All Things and You Love Me Very Muchal bentulanNessuna valutazione finora

- 3) Project ScheduleDocumento7 pagine3) Project ScheduleunnicyriacNessuna valutazione finora

- Directional Drilling PDFDocumento48 pagineDirectional Drilling PDFdionNessuna valutazione finora

- Fluid Mechanics - Lecture 7 - 9 - Viscous + NNF Pipe FlowxDocumento61 pagineFluid Mechanics - Lecture 7 - 9 - Viscous + NNF Pipe Flowxking4lifeNessuna valutazione finora

- Experiment 1: Forces in A Roof Truss With A Central and Wind LoadDocumento5 pagineExperiment 1: Forces in A Roof Truss With A Central and Wind LoadAinur NasuhaNessuna valutazione finora

- Chapter II-Branching and Pipe NetDocumento39 pagineChapter II-Branching and Pipe NetArah Louise ApostolNessuna valutazione finora

- Chapter 2 Introduction To HydraulicsDocumento46 pagineChapter 2 Introduction To HydraulicsEdwin Perez100% (1)

- Calculations For Tower Crane 2Documento12 pagineCalculations For Tower Crane 2Susi UmarohNessuna valutazione finora

- Brief For Geotechnical Investigations Maitama AbujaDocumento6 pagineBrief For Geotechnical Investigations Maitama AbujaAdakole ObekaNessuna valutazione finora

- Checklist For Fabrication & Installation of Tensile Fabric ShadesDocumento1 paginaChecklist For Fabrication & Installation of Tensile Fabric ShadesSun ShadeNessuna valutazione finora

- Formulas: Determining Weld Size Using AllowablesDocumento1 paginaFormulas: Determining Weld Size Using Allowablesgv Sathishkumar KumarNessuna valutazione finora

- Daily Checklist Bulldozerpdf PDF FreeDocumento1 paginaDaily Checklist Bulldozerpdf PDF FreeRama Asmara TariganNessuna valutazione finora

- Uel Sugarcrete Slab Report - 7 Nov 2022Documento85 pagineUel Sugarcrete Slab Report - 7 Nov 2022Eng_RochaNessuna valutazione finora

- Comparing Effects of Openings in Concrete Shear WallsDocumento10 pagineComparing Effects of Openings in Concrete Shear WallsIrshadAhmedNessuna valutazione finora

- Properties of Torsion Springs Before and After Heat TreatmentDocumento8 pagineProperties of Torsion Springs Before and After Heat TreatmentPrihastya WishnutamaNessuna valutazione finora

- Blue Book: Fire Resisting DuctworkDocumento20 pagineBlue Book: Fire Resisting DuctworkMadan TiwariNessuna valutazione finora

- House Construction Calculations For BegginersDocumento67 pagineHouse Construction Calculations For BegginersBernard DavidNessuna valutazione finora