Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tank Inspection

Caricato da

Subbarayan SaravanakumarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tank Inspection

Caricato da

Subbarayan SaravanakumarCopyright:

Formati disponibili

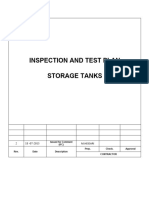

Tank/Container Inspection Standard Operating Procedures

This Standard Operating Procedure describes the steps that University units that manage aboveground oil storage tanks (ASTs) or containers must follow to perform visual tank inspections. Checklists are attached. Tank Inspection (e.g., Aboveground Storage Tanks, Generator Tanks): Use and complete the Tank Inspection Checklist Designate an individual to inspect tanks according to the attached checklist or an equivalent method pre-approved by Environmental Compliance. Monthly Inspect aboveground tanks and associated valves, piping, and appurtenances. Visually assess the general condition of the tank or container and its appurtenances such as flange joints, expansion joints, valve glands and bodies, catch pans, pipeline supports, locking of valves, and metal surfaces. Also observe shells for signs of leaks or potential leaks, such as cracks, holes, rust, bulges, dents, residues, stains or other visual evidence. For oil/fuel containers that lack secondary containment and cannot be inspected or viewed on all sides for the presence of leaks, accurately inventory quantities at least monthly. Reconcile the amount of product used with the amount of product purchased to account for all inventory and confirm that product is not slowly leaking from the container. Keep written procedures and a record of inspections, inventories and tests, signed by the appropriate supervisor or inspector, with the SPCC Plan at your unit for 3 years. For certain integrity tests, records may be retained for the life of the tank. Report problems to the Unit Coordinator for corrective action. If you witness or discover a release of a petroleum product or any other hazardous material that can not be safely cleaned up immediately by University personnel, call 9-911.

Short-Term Container Inspection (e.g., drums 55 gallons or more): Short-term containers are containers 55 gallons or greater that are used for storage of oil for less than 10 years. Short-term containers must be visually inspected at least monthly and the visual inspection must be documented. Use and complete the Short-Term Container Inspection Checklist Designate an individual to conduct container inspections according to the attached checklist (SOP-5b) or preapproved equivalent. At least monthly Inspect the top, bottom and sides of the container to observe for exterior dents, bulges, holes, missing bungs or caps, rust or other signs that might indicate leakage or potential leakage of contents. Ensure that the container is not in contact with the ground surface. If in contact with ground, note on checklist and immediately notify The Division of Safety and Compliance. Remove from service any short-term container that appears to pose risk of oil discharge and replace with an approved container if a substitute container is considered necessary. Remove from service all short-term containers prior to ten years of age. Document the inspection on the attached Short-Term Container Inspection Checklist (SOP-5b) and keep with the SPCC Plan at your unit for 3 years. Report problems to the appropriate person for corrective action.

Page 1 of 3 http://safetyandcompliance.fs.illinois.edu Last Updated: Mar 09 217-265-9828

Last updated by: T Malvestuto University of Illinois at Urbana-Champaign

Tank/Container Inspection Standard Operating Procedures

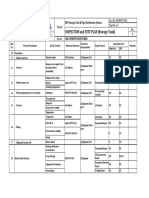

Tank Inspection Checklist Unit: _________________________________________ Date of Inspection: _____________ Container/System:______________________________________________________________ Inspection Criteria Visible leaks from any part of apparatus? Tank is dented, bulging, rusted, damaged, or deteriorated? Bolts, rivets, or seams are cracked or damaged? Tank supports are deteriorated or buckled? Tank foundations have eroded or settled? Level gauges or alarms are inoperative? Vents are obstructed? Valve seals or gaskets are leaking? Cracks in hosing present? Pipelines or supports are damaged or deteriorated? Buried pipelines exposed? Double-walled tanks Space between inner and outer walls is free of oil? Secondary containment or ground is damaged or stained? Dike drainage valves are open? Oil/water separator is functioning properly? Security fencing, gates, locks, lighting are functional? Remarks:______________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ Signature (Inspector or Supervisor)

Last updated by: T Malvestuto University of Illinois at Urbana-Champaign Page 2 of 3 http://safetyandcompliance.fs.illinois.edu

Yes

No

N/A

Comments

Date:_____________

Last Updated: Mar 09 217-265-9828

Tank/Container Inspection Standard Operating Procedures

University Unit: _________________ _ _____________ Container/System (drum, contents, etc): ________ ** Visually inspect the top, bottom and sides of the container. Container must not have exterior dents, bulges, holes, missing bungs or caps, rust or other signs that might indicate leakage or potential leakage of contents. Container expiration/replacement date must be present on the container. ** Container Passes Inspection (Y/N see criteria above) Container in Contact with the Ground Surface (Y/N) __ Storage Location (bldg/room): _ ____ _

Date

Name of Inspector

Amount Stored

Diversionary Equipment Adequate (Y/N)

Evidence of Release (Y/N)

Deficiencies Reported to Supervisor (list)

Fore more information, please contact the Division of Safety and Compliance at (217) 265-9828.

Last updated by: T Malvestuto University of Illinois at Urbana-Champaign

Page 3 of 3 http://www.fs.uiuc.edu

Last Updated: Mar 09 217-265-9828

Potrebbero piacerti anche

- AST ChecklistsDocumento16 pagineAST ChecklistsGary WoodsideNessuna valutazione finora

- Example of Tank Field ErectionDocumento12 pagineExample of Tank Field Erectionfazeel mohammedNessuna valutazione finora

- Tank Inspection NotesDocumento5 pagineTank Inspection Notesaneeshjose013Nessuna valutazione finora

- Itco Repair ProcedureDocumento29 pagineItco Repair Procedureelvis1979Nessuna valutazione finora

- Above Ground Storage Tank Inspection GuidelinesDocumento7 pagineAbove Ground Storage Tank Inspection GuidelinesTina Miller100% (1)

- 2015 Container Exam BulletinDocumento14 pagine2015 Container Exam BulletinAndrés Falla VictoriaNessuna valutazione finora

- New Bottom PlateDocumento9 pagineNew Bottom PlateEmmanuel kusimo100% (1)

- API 653 - Annex B - 10 TermsDocumento2 pagineAPI 653 - Annex B - 10 TermsSERFORTEC CIA. LTDA.Nessuna valutazione finora

- Shackle InspectionDocumento3 pagineShackle InspectionArfanAliNessuna valutazione finora

- Checklist Tank NewDocumento11 pagineChecklist Tank NewamevaluacionesNessuna valutazione finora

- STS Co. storage tank fabrication methodologyDocumento15 pagineSTS Co. storage tank fabrication methodologypurshottam GHNessuna valutazione finora

- API Tank Estimate SheetDocumento3 pagineAPI Tank Estimate SheetKjunwolf100% (1)

- AST Nozzle Repair Req.Documento10 pagineAST Nozzle Repair Req.Irvansyah RazadinNessuna valutazione finora

- Inspection & Test Plan TankDocumento3 pagineInspection & Test Plan TankJOSHUA SULLEGUE100% (1)

- Reconstruction of Pakistan Refinery Tank T-53Documento16 pagineReconstruction of Pakistan Refinery Tank T-53javaidahmedshaikh100% (1)

- API 650 12th - 2013Documento4 pagineAPI 650 12th - 2013mohamedNessuna valutazione finora

- Tam-Sc-2-B Doorsheet Removal and Reinstallation: February 2003 © Chevrontexaco 1 of 9Documento9 pagineTam-Sc-2-B Doorsheet Removal and Reinstallation: February 2003 © Chevrontexaco 1 of 9Herlys Pereira100% (1)

- Tank Erection Itp Org ChartDocumento34 pagineTank Erection Itp Org Chartvasantha kumar100% (1)

- Shell and Tube Heat Exchanger TPIDocumento9 pagineShell and Tube Heat Exchanger TPIpstechnical_43312697Nessuna valutazione finora

- Repairing Corroded Tank Bottoms Safely and Cost EffectivelyDocumento5 pagineRepairing Corroded Tank Bottoms Safely and Cost EffectivelylsatchithananthanNessuna valutazione finora

- Pickling Procedure 20 - 08Documento2 paginePickling Procedure 20 - 08Siriepathi SeetharamanNessuna valutazione finora

- External Floating Roof Tank Design & ComponentsDocumento2 pagineExternal Floating Roof Tank Design & Componentsarif99pakNessuna valutazione finora

- PSV TestingDocumento26 paginePSV Testingmanoj thakkar100% (1)

- British Standard 5289: 1976: Visual InspectionDocumento10 pagineBritish Standard 5289: 1976: Visual InspectionMarcelo Rodriguez FujimotoNessuna valutazione finora

- MONITOR STORAGE TANK FABRICATION & ERECTIONDocumento9 pagineMONITOR STORAGE TANK FABRICATION & ERECTIONRyanto Sirait100% (1)

- Process Tank Fabrication Work StepsDocumento4 pagineProcess Tank Fabrication Work StepsMuhammad ZubairNessuna valutazione finora

- 3LPE Repair ProcedureDocumento3 pagine3LPE Repair Procedurelhanx2Nessuna valutazione finora

- Tank Calibration:, Surveys & InspectionsDocumento2 pagineTank Calibration:, Surveys & InspectionsIETqatarNessuna valutazione finora

- API 653 NotesDocumento10 pagineAPI 653 Notesamine bouizarNessuna valutazione finora

- Fall 2019 Container Information BulletinDocumento11 pagineFall 2019 Container Information BulletinTJANDIROSONessuna valutazione finora

- Ground Steel Crude Oil Storage Tank Location and FoundationDocumento20 pagineGround Steel Crude Oil Storage Tank Location and Foundationliz aldanaNessuna valutazione finora

- Annular Plate RemovalDocumento2 pagineAnnular Plate RemovalVishvjeet Prakash TiwariNessuna valutazione finora

- QCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.Documento6 pagineQCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.abdul aziz100% (1)

- API Repair ProcedureDocumento1 paginaAPI Repair ProcedurejacquesmayolNessuna valutazione finora

- Roundness Check Record of 1St Shell CourseDocumento1 paginaRoundness Check Record of 1St Shell CourseRhannie GarciaNessuna valutazione finora

- Third Party Inspection For Storage TankDocumento8 pagineThird Party Inspection For Storage TankGeroldo 'Rollie' L. QuerijeroNessuna valutazione finora

- Inspection TankDocumento22 pagineInspection Tanksbmmla100% (1)

- API-653 Now Permits Lap-Welded Patch Plates For Shell Repairs - Carmagen EngineeringDocumento2 pagineAPI-653 Now Permits Lap-Welded Patch Plates For Shell Repairs - Carmagen Engineeringmohsen_267100% (1)

- Stub Onin ConnectionsDocumento4 pagineStub Onin ConnectionsMehman NasibovNessuna valutazione finora

- Shell Plate Dimension CheckDocumento7 pagineShell Plate Dimension Checksetak0% (1)

- Air Testing TanksDocumento2 pagineAir Testing TanksTatiana CruzNessuna valutazione finora

- Above Ground Storage Tank InspectionDocumento9 pagineAbove Ground Storage Tank InspectionbeqsNessuna valutazione finora

- Scissor Shoe Installation Guide Jan 2005 PDFDocumento32 pagineScissor Shoe Installation Guide Jan 2005 PDFMohsen Halweni50% (2)

- 1113 Maintenance of PRVDocumento63 pagine1113 Maintenance of PRVhardito sussatrioNessuna valutazione finora

- Technical Manual - 2000 USG Horizontal Lined Acid TankDocumento20 pagineTechnical Manual - 2000 USG Horizontal Lined Acid TankGade JyNessuna valutazione finora

- Niigata - Replacing Bottom Plates of Oil Storage TanksDocumento7 pagineNiigata - Replacing Bottom Plates of Oil Storage TanksJohnson Olarewaju100% (2)

- Floating Head Heat Exchanger Hydrotest ProcedureDocumento15 pagineFloating Head Heat Exchanger Hydrotest ProcedureDoğuhan DenizgezNessuna valutazione finora

- Tank Procedure by Conventional MethodDocumento8 pagineTank Procedure by Conventional Methodsatish04Nessuna valutazione finora

- Sky Climber SparesDocumento7 pagineSky Climber SparesshambhoiNessuna valutazione finora

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDocumento13 pagineJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNessuna valutazione finora

- Safety Alert Space HeatersDocumento2 pagineSafety Alert Space HeatersRamadan KareemNessuna valutazione finora

- GTS-PP-120: 3 LayerDocumento2 pagineGTS-PP-120: 3 Layershoaib1985100% (1)

- 14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFDocumento11 pagine14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFVladimir Rodriguez LeonNessuna valutazione finora

- Shop Fabrication and Inspection Procedure for Gasoline and Engine Oil TankDocumento7 pagineShop Fabrication and Inspection Procedure for Gasoline and Engine Oil TankGATOTNessuna valutazione finora

- How To Calculate Hydrostatic Test Height in TanksDocumento4 pagineHow To Calculate Hydrostatic Test Height in TanksEric MagnayeNessuna valutazione finora

- Storage Tank Weld JointsDocumento16 pagineStorage Tank Weld JointsDilip Varadharajan100% (1)

- Tank Inspection Standard Operating Procedures PDFDocumento3 pagineTank Inspection Standard Operating Procedures PDFIfroz KhanNessuna valutazione finora

- API 653 Tank Inspection GuideDocumento53 pagineAPI 653 Tank Inspection GuideWàhränî Là Cläşş100% (3)

- Tank Inspection Standard Operating ProceduresDocumento12 pagineTank Inspection Standard Operating ProceduresJosé Nunes100% (1)

- Tank and Tank Farm InspectionDocumento5 pagineTank and Tank Farm InspectionAjao Joseph Olayinka100% (1)

- BearingsDocumento3 pagineBearingsSubbarayan SaravanakumarNessuna valutazione finora

- Top Discharge Vertical Basket Centrifuge Operating PrincipleDocumento2 pagineTop Discharge Vertical Basket Centrifuge Operating PrincipleSubbarayan SaravanakumarNessuna valutazione finora

- AWS ClassificationsDocumento6 pagineAWS ClassificationsSubbarayan SaravanakumarNessuna valutazione finora

- AWS ClassificationsDocumento6 pagineAWS ClassificationsSubbarayan SaravanakumarNessuna valutazione finora

- Manuals CentrifugeDocumento30 pagineManuals CentrifugeSubbarayan Saravanakumar100% (1)

- Lead Acid Battery Instruction Sheet (f5)Documento4 pagineLead Acid Battery Instruction Sheet (f5)FaycelmekadminiNessuna valutazione finora

- Cooling Tower LessonsDocumento26 pagineCooling Tower Lessonssmidhum7470100% (1)

- Bearing ArrangementDocumento5 pagineBearing ArrangementSubbarayan SaravanakumarNessuna valutazione finora

- What Is ThermowellDocumento2 pagineWhat Is ThermowellaminNessuna valutazione finora

- BurjDocumento39 pagineBurjarjunmurali1993Nessuna valutazione finora

- All About FansDocumento1 paginaAll About FansSubbarayan SaravanakumarNessuna valutazione finora

- Centrifuge Preventative Maintenance Schedule: EBA 20, EBA 20S, MIKRO 120 See Lower Chart Centrifuge Bowl SealDocumento1 paginaCentrifuge Preventative Maintenance Schedule: EBA 20, EBA 20S, MIKRO 120 See Lower Chart Centrifuge Bowl SealSubbarayan SaravanakumarNessuna valutazione finora

- Compressed Air: A Common Sense Approach To Its Use and AbuseDocumento27 pagineCompressed Air: A Common Sense Approach To Its Use and AbuseSubbarayan SaravanakumarNessuna valutazione finora

- Chiller BasicsDocumento2 pagineChiller BasicsSubbarayan Saravanakumar100% (1)

- Specification For Ducting of Ac PlantDocumento7 pagineSpecification For Ducting of Ac PlantSubbarayan SaravanakumarNessuna valutazione finora

- Specification For Ducting of Ac PlantDocumento7 pagineSpecification For Ducting of Ac PlantSubbarayan SaravanakumarNessuna valutazione finora

- Number StoryDocumento14 pagineNumber Storybigstrand447645% (11)

- Good Centrifuge PracticeDocumento1 paginaGood Centrifuge PracticeSubbarayan SaravanakumarNessuna valutazione finora

- PNEUMATIC TEST CALCULATIONSDocumento3 paginePNEUMATIC TEST CALCULATIONSSubbarayan Saravanakumar57% (7)

- MS Word Short Cut KeyDocumento24 pagineMS Word Short Cut KeyRajesh BabuNessuna valutazione finora

- The Line of FateDocumento2 pagineThe Line of FateSubbarayan SaravanakumarNessuna valutazione finora

- General Centrifuge MaintenanceDocumento2 pagineGeneral Centrifuge MaintenanceSubbarayan SaravanakumarNessuna valutazione finora

- The Line of FateDocumento2 pagineThe Line of FateSubbarayan SaravanakumarNessuna valutazione finora

- Pneumatic TestDocumento6 paginePneumatic TestSubbarayan SaravanakumarNessuna valutazione finora

- Pneumatic TestDocumento6 paginePneumatic TestSubbarayan SaravanakumarNessuna valutazione finora

- Pneumatic TestDocumento6 paginePneumatic TestSubbarayan SaravanakumarNessuna valutazione finora

- Pneumatic TestDocumento6 paginePneumatic TestSubbarayan SaravanakumarNessuna valutazione finora

- PNEUMATIC TEST CALCULATIONSDocumento3 paginePNEUMATIC TEST CALCULATIONSSubbarayan Saravanakumar57% (7)

- TNT SheetDocumento1 paginaTNT SheetSubbarayan SaravanakumarNessuna valutazione finora

- PNEUMATIC TEST CALCULATIONSDocumento3 paginePNEUMATIC TEST CALCULATIONSSubbarayan Saravanakumar57% (7)

- Serto Up To Date 33Documento7 pagineSerto Up To Date 33Teesing BVNessuna valutazione finora

- Surface Coating ProcessesDocumento7 pagineSurface Coating ProcessesSailabala ChoudhuryNessuna valutazione finora

- Reading in Philippine History (Chapter 3)Documento14 pagineReading in Philippine History (Chapter 3)AKIO HIROKINessuna valutazione finora

- Leica CS10 CS15 GSSensors QG v3.0.1 en PDFDocumento16 pagineLeica CS10 CS15 GSSensors QG v3.0.1 en PDFMohammad Saiful AzamNessuna valutazione finora

- Falling Weight Deflectometer Bowl Parameters As Analysis Tool For Pavement Structural EvaluationsDocumento18 pagineFalling Weight Deflectometer Bowl Parameters As Analysis Tool For Pavement Structural EvaluationsEdisson Eduardo Valencia Gomez100% (1)

- History of English Prose PDFDocumento21 pagineHistory of English Prose PDFMeisyita QothrunnadaNessuna valutazione finora

- OS9000 AOS 6.1.5 R01 Network Configuration GuideDocumento846 pagineOS9000 AOS 6.1.5 R01 Network Configuration GuideclaupasinaNessuna valutazione finora

- Theory Is An Explanation Given To Explain Certain RealitiesDocumento7 pagineTheory Is An Explanation Given To Explain Certain Realitiestaizya cNessuna valutazione finora

- Biomérieux 21342 Vitek 2 GP: Intended UseDocumento19 pagineBiomérieux 21342 Vitek 2 GP: Intended UserezaNessuna valutazione finora

- Gujarat Technological University: Emester ViDocumento4 pagineGujarat Technological University: Emester ViPradeep SutharNessuna valutazione finora

- Project Planning and Management Unit 1Documento13 pagineProject Planning and Management Unit 1Savant100% (1)

- The Secret Language of AttractionDocumento278 pagineThe Secret Language of Attractionsandrojairdhonre89% (93)

- Lazo v. Judge TiongDocumento9 pagineLazo v. Judge TiongKing BadongNessuna valutazione finora

- Joel Werner ResumeDocumento2 pagineJoel Werner Resumeapi-546810653Nessuna valutazione finora

- Preparatory Lights and Perfections: Joseph Smith's Training with the Urim and ThummimDocumento9 paginePreparatory Lights and Perfections: Joseph Smith's Training with the Urim and ThummimslightlyguiltyNessuna valutazione finora

- What Are Universities ForDocumento19 pagineWhat Are Universities ForBikash Ranjan MishraNessuna valutazione finora

- D2DDocumento2 pagineD2Dgurjit20Nessuna valutazione finora

- Transformer InsulationDocumento14 pagineTransformer InsulationcjtagayloNessuna valutazione finora

- SCM PPT (Supply Chain Management)Documento19 pagineSCM PPT (Supply Chain Management)Mairaj NaseemNessuna valutazione finora

- LM385Documento14 pagineLM385vandocardosoNessuna valutazione finora

- Telegra Manual - DatasheetDocumento79 pagineTelegra Manual - DatasheetNilanjan Chakravortty100% (1)

- Download 12,000 Shed PlansDocumento27 pagineDownload 12,000 Shed PlansRadu_IS100% (2)

- T Cells & Autoimmunity, s3Documento21 pagineT Cells & Autoimmunity, s3LiaAriestaNessuna valutazione finora

- Complimentary JournalDocumento58 pagineComplimentary JournalMcKey ZoeNessuna valutazione finora

- Effect of Dust On The Performance of Wind Turbines PDFDocumento12 pagineEffect of Dust On The Performance of Wind Turbines PDFJallal ArramachNessuna valutazione finora

- 740 (Q50, V40, Awa 4Documento10 pagine740 (Q50, V40, Awa 4rawat2583Nessuna valutazione finora

- The Diary of Anne Frank PacketDocumento24 pagineThe Diary of Anne Frank Packetcnakazaki1957Nessuna valutazione finora

- YSUUSYs NiCd Battery RepairDocumento6 pagineYSUUSYs NiCd Battery Repairrwesseldyk50% (2)

- Primary 2 (Grade 2) - GEP Practice: Contest Problems With Full SolutionsDocumento24 paginePrimary 2 (Grade 2) - GEP Practice: Contest Problems With Full Solutionswenxinyu1002100% (1)

- Process of Producting High Carbon Ferro ChromeDocumento5 pagineProcess of Producting High Carbon Ferro ChromeSantosh Kumar MahtoNessuna valutazione finora