Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Foldrite Furniture Company: CASE Study

Caricato da

Japkirat OberaiDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Foldrite Furniture Company: CASE Study

Caricato da

Japkirat OberaiCopyright:

Formati disponibili

CASE Study:

FOLDRITE FURNITURE COMPANY

Submitted to:

Submitted by:

Dr. P.K Dash Professor, Operations Management

Japkirat Singh Oberai Roll no : 012 PGDM 2102

FoldRite Furniture Company

FoldRite Furniture Company spent the last two years improving manufacturing quality and efficiency and now they produce stylish, environmentally friendly folding and stackable chairs and tables. Sales interest in the new products is higher than the forecast and a new plan is needed to meet its high demand while controlling manufacturing and inventory costs and mitigating risk.

1. What are the Manufacturing Options available with Mr. Martin Kelsey ? (10 marks)

Ans :

There can be many options available with Mr Martin Kesley . Some of them are:Ask the staff to work an extra shift (10 Hours) on Fridays, increasing staff temporarily to take the advantage of the idle production capacity.

Increasing the amount of inventory by maintaining a constant level of production

i.

ii.

iii. iv. v.

Change in Design of assembly line Hiring of new employees Hire all workers needed and ask them to work overtime . and by making use of the hired persons make extra amount of production in april. Subcontracting part of the work, such as the manufacture of seats for stackable chairs. Though this option would add an extra 20% to the cost of labour for the products, but given the current economy, FoldRite would not need to pay a set-up fee or commit to minimum orders.

2.What are the financial implications of each option ? What is the impact on lead-time ? (50 marks) Ans : Financial implications of these each options are as follows:

Wages (Skilled) = 19 + 33% of 19 = 25.27 Wages (Unskilled) = 9 + 10% of 9=9.9

Continued overtime is expensive as the overtime wage rates are 1.5 times the normal rate. Which come out to be: Full time: Wages (skilled): (19+33% of 19)*1.5=25.27*1.5=37.90 Wages (unskilled): (9+10% of 9)*1.5=9.9*.15=14.85

So an extra wages of 17.58 would be incurred for every Friday. Subcontracting strategy at 20% extra cost of labor will also be expensive:

Subcontracting cost (unskilled) = 120% of wages = 11.88 Subcontracting cost (skilled) = 120% of wages = 30.324. Change of design of assembly line: o A change in design would cost the company a onetime cost of $15000 and would take one month time to be fully operational on the factory floor. o But these changes would not affect the durability of the product. Hiring of New employees: o A new skilled worker would cost $1500 in recruiting and administrative expenses. o Two supervisors interviewed the unskilled the workers, each spending one hour on one worker, supervisors earned $25 per hour plus 33% benefits. o All newly inducted staff showed an efficiency of about 80% in the first week. Lead time will definitely improve if more skilled people start working extra hours but for the subcontracting strategy lead time will increase as inexperienced people with less knowledge will impact the operations initially as what happened in 2006 when lead time increased to 6-8 weeks.

3.What are the risks ? How does each of the options accommodates changes in economy and environment ? (20 marks) Ans: The risks are enormous in this process. To highlight certain pressing issues :

Under the overtime working conditions, overtime wages were 1.5 times higher than the normal wage rates, which includes the benefits. Similarly hiring new employees was a costly affair and will require management and supervision resources. Overtime also introduced fatigue, leading to declines in quality and yield. If demand did not materialize, laying-off these new workers would demoralize the remaining workforce and cost the company in added unemployment insurance. In any case, given the scarcity and expense of credit, the cost of carrying inventory beyond the normal two weeks demand would be a major concern.

4.Weighing options in term of non-financial implications. (20 marks)

Ans : If we weigh the options in terms of the non-financial implications we can say that:

If demand did not materialize, laying off new workers would Demoralize the remaining workforce Added unemployment insurance The cost of carrying inventory beyond two weeks would be major headache

Some of the options would be Using the green technology Using degradable plastic material. Giving emphasis to optimum efficiency.

Overtime Strategy effects: Advantages: o No need to lay off the superfluous labours and thus suffer from the demoralization and high unemployment insurance after the surge in demand. o Flexibility: can make change according to the change of the demand Disadvantages: High cost: overtime wages were 1.5 times the normal fully loaded rates. Decline in quality and yield: overtime may lead to labours fatigue Potential risk: may not able to meet the demand if the demand continues to increase Negative effect on potential labours: the long-lasting overtime may discourage other labour join in the company.

Subcontracting Strategy effects: Advantages: Least manufacture cost Save of its labour force and administrative resource Flexibility: can have relatively flexible change according to the demand Disadvantages: Inventory cost would be Extra 20% to the cost of labour for the product . No guarantee of the quality for product

Potrebbero piacerti anche

- Blanchard Importing and Distributing Co. Inc.: Production Planning and ControlDocumento24 pagineBlanchard Importing and Distributing Co. Inc.: Production Planning and ControlJo James100% (1)

- Integrated Siting SystemDocumento8 pagineIntegrated Siting SystemSahrish Jaleel Shaikh100% (4)

- OM - Case - Analysis - Donner Company Case ReportDocumento8 pagineOM - Case - Analysis - Donner Company Case Reportpusparghya pakrasiNessuna valutazione finora

- Genentech Case SubmissionDocumento2 pagineGenentech Case SubmissionArijit MajiNessuna valutazione finora

- Davey MukullDocumento6 pagineDavey MukullMukul Kumar SinghNessuna valutazione finora

- FoldRite Furniture Co.Documento4 pagineFoldRite Furniture Co.Hualu Zhao0% (1)

- Group1 Sec A OM CasestudyDocumento8 pagineGroup1 Sec A OM CasestudyUpdesh ChauhanNessuna valutazione finora

- Om Case Kulicke and Soffa Industries, IncDocumento11 pagineOm Case Kulicke and Soffa Industries, Incsili core100% (1)

- Operation ManagementDocumento20 pagineOperation ManagementKelvin_1369100% (2)

- FoldRite Furniture CoDocumento5 pagineFoldRite Furniture CoAmit Roy0% (1)

- Eli LDocumento6 pagineEli LKaruna GaranNessuna valutazione finora

- Scientific Glass IncDocumento17 pagineScientific Glass IncSakshi Sharda100% (1)

- Store24 DataDocumento8 pagineStore24 DatajujuNessuna valutazione finora

- Executive Shirt CompanyDocumento13 pagineExecutive Shirt CompanySandeep Chowdhury100% (1)

- Sales Force Management Baria Planning Solutions Assignment Submitted To: Miss Mehrukh SalmanDocumento6 pagineSales Force Management Baria Planning Solutions Assignment Submitted To: Miss Mehrukh SalmannomanNessuna valutazione finora

- David - Fletcher - Case StudyDocumento2 pagineDavid - Fletcher - Case StudyGangadhar BituNessuna valutazione finora

- Executive Shirts CompanyDocumento12 pagineExecutive Shirts CompanyAnonymous thwanV100% (1)

- Labour CostsDocumento17 pagineLabour Costszeebee17100% (1)

- Changing Landscape of WorkDocumento8 pagineChanging Landscape of WorkA K Azad SumanNessuna valutazione finora

- Fold Rite HintsDocumento7 pagineFold Rite HintsAdeela Binte Abbas0% (1)

- Planning To Meet A Surge in DemandDocumento19 paginePlanning To Meet A Surge in DemandAbhi0% (1)

- FoldriteDocumento6 pagineFoldriteAbhiNessuna valutazione finora

- Fold RiteDocumento5 pagineFold RiteNilay KumarNessuna valutazione finora

- OM2 LeitaxCase GroupE7Documento9 pagineOM2 LeitaxCase GroupE7Ashfaq Shaikh50% (2)

- Risk Management FoldRite Furniture AssignmentDocumento8 pagineRisk Management FoldRite Furniture AssignmentAbhra Debroy100% (1)

- Leitax 19110207Documento2 pagineLeitax 19110207Ghulam Mehr Ali ShahNessuna valutazione finora

- Foldrite Furniture CaseDocumento7 pagineFoldrite Furniture CaseJoe Joy0% (2)

- Mos Game Writeup b10Documento2 pagineMos Game Writeup b10Siddharth BathlaNessuna valutazione finora

- Oberoi Hotels: Train Whistle in The Tiger Reserve: Assignment Case ReportDocumento7 pagineOberoi Hotels: Train Whistle in The Tiger Reserve: Assignment Case ReportJyotsna JeswaniNessuna valutazione finora

- OM Foldrite 1Documento9 pagineOM Foldrite 1Rohit Kiran0% (1)

- Transcript of Hewlett-Packard: The Flight of The Kittyhawk: Target MarketDocumento7 pagineTranscript of Hewlett-Packard: The Flight of The Kittyhawk: Target Marketprerna004Nessuna valutazione finora

- Executive Shirt Company IncDocumento14 pagineExecutive Shirt Company IncUtkarsh Singh50% (2)

- AssgmintDocumento4 pagineAssgmintArooj HectorNessuna valutazione finora

- Dore Dore CaseDocumento5 pagineDore Dore CaseDIshant KulwalNessuna valutazione finora

- Scientific GlassDocumento9 pagineScientific GlassLajwanti M Jethwani100% (1)

- Genentech Answer 2Documento1 paginaGenentech Answer 2Navnee RajputNessuna valutazione finora

- Barilla Case CDocumento5 pagineBarilla Case CKenneth ChuaNessuna valutazione finora

- The Morning Star Company: Self-Management at WorkDocumento8 pagineThe Morning Star Company: Self-Management at WorkRomali DasNessuna valutazione finora

- Toyota Motor Manufacturing USA., inDocumento5 pagineToyota Motor Manufacturing USA., inmudasserNessuna valutazione finora

- What Are The Ethical and Privacy Issues That Harrah's Should Be Concerned AboutDocumento5 pagineWhat Are The Ethical and Privacy Issues That Harrah's Should Be Concerned AboutVarun BangotraNessuna valutazione finora

- How Does The Internal Market For Innovation at Nypro FunctionDocumento2 pagineHow Does The Internal Market For Innovation at Nypro Functionprerna004Nessuna valutazione finora

- G6 Moore MDocumento4 pagineG6 Moore MAKNessuna valutazione finora

- Case-Sports ObermeyerDocumento56 pagineCase-Sports ObermeyerSiddharth MehtaNessuna valutazione finora

- Executive Shirts - Solution 2Documento10 pagineExecutive Shirts - Solution 2Bernard EugineNessuna valutazione finora

- Decision Report On Technotronics 1979: MemorandumDocumento9 pagineDecision Report On Technotronics 1979: MemorandumKandarp PandeNessuna valutazione finora

- Merrimack Tractors and MowersDocumento10 pagineMerrimack Tractors and MowersAtul Bhatia0% (1)

- Lesser Antilles Lines - The Island of San Huberto Case Solution and Analysis, HBR Case Study Solution & Analysis of Harvard Case StudiesDocumento5 pagineLesser Antilles Lines - The Island of San Huberto Case Solution and Analysis, HBR Case Study Solution & Analysis of Harvard Case Studiesthetpainghein one0% (1)

- Executive Shirt CompanyDocumento6 pagineExecutive Shirt CompanyPramod kNessuna valutazione finora

- BlanchardDocumento9 pagineBlanchardtwinkle kumariNessuna valutazione finora

- LSCM Group 2 Scientific Glass Case AnalysisDocumento10 pagineLSCM Group 2 Scientific Glass Case AnalysisArshpreet SinghNessuna valutazione finora

- Kanthal CaseDocumento5 pagineKanthal CaseMonica Rosa LinaNessuna valutazione finora

- Dore Dore1Documento5 pagineDore Dore1yuveesp5207Nessuna valutazione finora

- James R Steiner Case 2Documento4 pagineJames R Steiner Case 2api-285459465Nessuna valutazione finora

- Executive SummaryDocumento17 pagineExecutive SummaryAzizki WanieNessuna valutazione finora

- Case Study 2: Blanchard Importing and Distributing Co., IncDocumento3 pagineCase Study 2: Blanchard Importing and Distributing Co., IncMansi MundhraNessuna valutazione finora

- Oilwell Cable CompanyDocumento4 pagineOilwell Cable CompanyPrathibha Vemulapalli100% (1)

- 1.what Are The Pros and Cons of Switching From Wage Rates To Piece-Rate Pay?Documento5 pagine1.what Are The Pros and Cons of Switching From Wage Rates To Piece-Rate Pay?Shanaya SinghaniyaNessuna valutazione finora

- Case FoldRite FurnitureDocumento3 pagineCase FoldRite FurniturePhạm Thị Trúc LinhNessuna valutazione finora

- Aggregate PlanningDocumento54 pagineAggregate PlanningAndrea CoxNessuna valutazione finora

- Q1. People's Productivity Key To Indian Manufacturing Competitiveness: BostonDocumento8 pagineQ1. People's Productivity Key To Indian Manufacturing Competitiveness: Bostonaryanboxer786Nessuna valutazione finora

- Cost Planning For The Product Life Cycle: Target Costing, Theory of Constraints, and Strategic PricingDocumento38 pagineCost Planning For The Product Life Cycle: Target Costing, Theory of Constraints, and Strategic PricingWatikah SururiNessuna valutazione finora

- Strategy Formulation - Kingfisher AirlinesDocumento18 pagineStrategy Formulation - Kingfisher AirlinesJapkirat OberaiNessuna valutazione finora

- Pre-Course Assignment: Submitted To Dr. Suprti Mishra Associate Professor (Strategy) IMI BhubaneswarDocumento23 paginePre-Course Assignment: Submitted To Dr. Suprti Mishra Associate Professor (Strategy) IMI BhubaneswarJapkirat OberaiNessuna valutazione finora

- Strategy Formulation - Kingfisher AirlinesDocumento18 pagineStrategy Formulation - Kingfisher AirlinesJapkirat OberaiNessuna valutazione finora

- Dig ValnkmmDocumento4 pagineDig ValnkmmJapkirat OberaiNessuna valutazione finora

- Ethical Issues Involved in Host Country OperationsDocumento3 pagineEthical Issues Involved in Host Country OperationsJapkirat OberaiNessuna valutazione finora

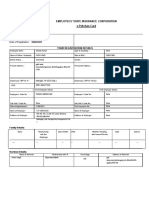

- Work Breakdown Structure Template For Project Name: Prepared By: Japkirat Date: 03-08-2013Documento1 paginaWork Breakdown Structure Template For Project Name: Prepared By: Japkirat Date: 03-08-2013Japkirat OberaiNessuna valutazione finora

- Ethical Issues Involved in Host Country OperationsDocumento3 pagineEthical Issues Involved in Host Country OperationsJapkirat OberaiNessuna valutazione finora

- Parle-G Roll No.12-JapkiratDocumento9 pagineParle-G Roll No.12-JapkiratJapkirat OberaiNessuna valutazione finora

- Assignment 200812 ITDMDocumento3 pagineAssignment 200812 ITDMJapkirat OberaiNessuna valutazione finora

- Parle-G Roll No.12-JapkiratDocumento9 pagineParle-G Roll No.12-JapkiratJapkirat OberaiNessuna valutazione finora

- General and Commercial Short NotesDocumento21 pagineGeneral and Commercial Short Notesshweta_namaya11Nessuna valutazione finora

- Autocratic Leadership - Characteristics, Benefits and DownsidesDocumento1 paginaAutocratic Leadership - Characteristics, Benefits and DownsidesKale KunalNessuna valutazione finora

- 4 Functions of Management ProcessDocumento6 pagine4 Functions of Management ProcessShadaab Farooq0% (1)

- Reading Comprehension UnemploymentDocumento2 pagineReading Comprehension Unemploymentabalde0506Nessuna valutazione finora

- Meidner (1992) - Rise and Fall of The Swedish ModelDocumento13 pagineMeidner (1992) - Rise and Fall of The Swedish ModelmarceloscarvalhoNessuna valutazione finora

- Labor Review 2020-21 (2nd Sem) Atty. Paciano F. Fallar Jr. Sscr-Col Bar Questions On Employer-Employee Relationship and Jurisdiction Q1Documento3 pagineLabor Review 2020-21 (2nd Sem) Atty. Paciano F. Fallar Jr. Sscr-Col Bar Questions On Employer-Employee Relationship and Jurisdiction Q1RVirayNessuna valutazione finora

- MIRPM Prospectus & Syllabus Autonomous-1Documento30 pagineMIRPM Prospectus & Syllabus Autonomous-1Kanchan DewalNessuna valutazione finora

- Diversity and DiscriminationDocumento14 pagineDiversity and DiscriminationZurulNessuna valutazione finora

- Human Resource Management: Muhammad Salman Arshad Lecturer-Business Studies UCP-FSDDocumento31 pagineHuman Resource Management: Muhammad Salman Arshad Lecturer-Business Studies UCP-FSDWadOod KhAnNessuna valutazione finora

- Financial Express German Mittelstand 20191010 MBarveDocumento1 paginaFinancial Express German Mittelstand 20191010 MBarveManoj BarveNessuna valutazione finora

- Training and Employee Retention Khalid FinalDocumento27 pagineTraining and Employee Retention Khalid FinalKhalid HussainNessuna valutazione finora

- ASSIGNMENT1chapter 2Documento1 paginaASSIGNMENT1chapter 2rita sinhaNessuna valutazione finora

- 07 The Impact of AI On Human LaborDocumento19 pagine07 The Impact of AI On Human Laborjillian llanesNessuna valutazione finora

- Insular Life Assurance Co vs. NLRCDocumento2 pagineInsular Life Assurance Co vs. NLRCXavier BataanNessuna valutazione finora

- Employee Separation Agreement - WUBurger - Sao Pedro AiltonDocumento3 pagineEmployee Separation Agreement - WUBurger - Sao Pedro AiltonNhowgNessuna valutazione finora

- Ntroduction To ToxicologyDocumento27 pagineNtroduction To Toxicologyrostaminasab100% (1)

- Manifesto For Douglas EastDocumento4 pagineManifesto For Douglas EastMatthew RobinsonNessuna valutazione finora

- Application Form 1Documento11 pagineApplication Form 1ThabisoNessuna valutazione finora

- AP The Conundrum Case StudyDocumento8 pagineAP The Conundrum Case StudyRupal RawatNessuna valutazione finora

- Illinois Secretary of State Document Requirements To Obtain A Driver S License/State ID CardDocumento2 pagineIllinois Secretary of State Document Requirements To Obtain A Driver S License/State ID CardEric RadulovichNessuna valutazione finora

- Sustainable Livelihood Program in The Resettlement Sites - Aljon MiloDocumento3 pagineSustainable Livelihood Program in The Resettlement Sites - Aljon MiloAljon MiloNessuna valutazione finora

- Day 1 Schedule of 6th Research ForumDocumento9 pagineDay 1 Schedule of 6th Research ForumTrisha Ann BarteNessuna valutazione finora

- FWP Reporting FormDocumento6 pagineFWP Reporting FormCfc-sfc Naic ChapterNessuna valutazione finora

- Empowering The Handicraft Artisans Through ODL ModeDocumento11 pagineEmpowering The Handicraft Artisans Through ODL ModeAshutosh SrivastavaNessuna valutazione finora

- Ajwan HablainDocumento11 pagineAjwan HablainHuuiiNessuna valutazione finora

- Job Evaluation and Merit RatingsDocumento19 pagineJob Evaluation and Merit RatingsDeekshaomar100% (2)

- Case StudyDocumento27 pagineCase Studypushpender gargNessuna valutazione finora

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationDocumento3 pagineEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationMuni ArumilliNessuna valutazione finora

- Bradley ReportDocumento3 pagineBradley ReportThe London Free Press100% (1)

- Finals Admin LawDocumento12 pagineFinals Admin LawJai Noreena Balili100% (2)