Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Wisconsin DOT Chapter - 4 CCTV

Caricato da

acabadingDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Wisconsin DOT Chapter - 4 CCTV

Caricato da

acabadingCopyright:

Formati disponibili

Wisconsin Department of Transportation

Intelligent Transportation Systems (ITS) Design Manual

CHAPTER 4

CLOSED CIRCUIT TELEVISION (CCTV) CAMERAS

December, 2004

Wisconsin Department of Transportation

Intelligent Transportation Systems (ITS) Design Manual

4.

Closed-Circuit Television (CCTV) Cameras

4.1. Introduction and Usage

Closed circuit television (CCTV) cameras are a key part of traffic management systems. The primary benefit of CCTV is the ability to provide visual information required to make informed decisions. CCTV cameras are used for roadway surveillance, verification of incidents detected by other means (e.g., cellular calls, speed detectors, etc.), and for assistance in determining appropriate responses to an unplanned event or incident. Beyond these tasks, cameras can be utilized for: Monitoring traffic movements on the mainline and ramps. Changeable Message Sign (CMS) verification. Verification of stranded motorists and incidents. Observing localized weather and other hazardous conditions. Use of CCTV images has expanded outside of Traffic Operation and Management Centers. When local agencies are granted access to the images, CCTV assists in the coordination and efficient use of available resources, such as emergency vehicle deployment. Motorists can access CCTV via the local television stations or the Internet to look at current travel conditions and plan alternate routes to avoid delays caused by incidents, construction, and special events.

4.2.

CCTV Types

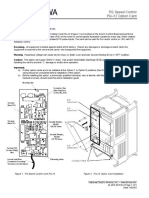

Five elements are included in a typical CCTV installation, and include the camera, camera cables, camera pole and concrete base, camera lowering system, and video CODEC. Features for the camera components can be found in Figure 4-1.

CCTV Element Camera CCTV Features Barrel or Dome Enclosure Pan/Tilt Unit Washer/wiper assembly required with barrel camera Control Cable Power Cable Video Cable 30-ft (arterial applications) with Type 2 Concrete Base 50-ft with Special Concrete Base 80-ft with Engineered Concrete Base for each site Interior or Exterior to Pole Recommended for 50-ft and 80-ft Poles 30-ft Pole Optional Encoder on Site Decoder at Operation Center

Camera Cables

Camera Pole and Concrete Base

Camera Lowering System

Video CODEC

Figure 4-1: CCTV Components

December, 2004

4-1

Wisconsin Department of Transportation

Intelligent Transportation Systems (ITS) Design Manual

4.3.

CCTV Design Process

In the CCTV design process, the designer must follow several steps to ensure successful implementation and proper operational capabilities. Many of these steps, such as power and communication requirements, must be addressed early in the design process. 1) 2) 3) 4) 5) 6) 7) 8) Collect initial data required for the proposed CCTV location. Determine the CCTV type required for the design location. Determine the location of the controller cabinet and meter service pedestal. Prepare the underground infrastructure, including camera pole, conduit, and pullboxes or vaults. Perform cable routing to provide hardwire interconnection between the controller cabinet and CCTV station devices. Determine the communications medium used for the proposed location (See Chapter 8, Communication Systems). Revisit steps 3 through 6 until final design is complete. Begin the process to establish electrical service for the proposed location with the local power company. This should be done early in the design process to establish an acceptable electrical service location. Utilizing Figure 4-3 found at the back of this chapter and the information contained within the ITS Design Manual Documents: Chapter 4 CCTV Cameras Construction Details and Worksheets folders, determine the construction details needed for the proposed design, details which need to be modified, and new details which need to be created to provide a complete construction plan. Utilizing Figure 4-4 found at the back of this chapter and the information contained within the ITS Design Manual Documents: Chapter 4 CCTV Cameras Special Provisions and Worksheets folders, determine the special provisions needed for the proposed design, special provisions which need to be modified, and new special provisions which need to be created to provide a complete construction plan. Utilizing Figure 4-5 found at the back of this chapter and the information contained within the ITS Design Manual Documents: Chapter 4 CCTV Cameras Worksheets folder determine the standard specification bid items and procurement items that will need to be included in the estimate and miscellaneous quantities to provide a complete construction plan.

9)

10)

11)

4.4.

Initial Data Collection

Prior to determining the location of a CCTV camera, various data needs to be collected, such as: Corridor spacing requirements (1 -mile spacing is typically used in urban areas, where full freeway or arterial coverage is desired. Spot location CCTV surveillance may be used in rural interchanges where sight distance is greater and surveillance is needed for incident verification, crash investigation sites, ramp meter operation, or variable message sign verification). Site-specific issues or concerns based on an initial site visit (right-of-way, utilities, landscape)

December, 2004

4-2

Wisconsin Department of Transportation

Intelligent Transportation Systems (ITS) Design Manual

To save on construction costs, CCTV and system detector stations or ramp meters are typically combined whenever possible.

4.5.

Determination of CCTV Type

Guidelines for choosing the type of CCTV equipment are listed below. Dome Cameras: Should be used for most CCTV applications. All moving parts (including pan/tilt/zoom) are internal to the dome, so there is less mechanical failure and maintenance due to weather conditions. Water slides off of the dome exterior so special wiper blades are not needed. Barrel Cameras: Should be used when extended vertical viewing is necessary (a dome camera can only see to the top of the clear part of the dome) or if there is a special mounting consideration that precludes the use of a dome camera. 30 Foot Camera Poles: Should be used for arterial applications, where a 50-ft or 80-ft camera pole height is not needed to see the roadway corridor. These poles have the option for special powder coat paint (color determined by vendor catalogue at time of procurement) to match existing aesthetic plans. 50 Foot Camera Poles: Should be used for most freeway CCTV applications. The height facilitates seeing the roadway for 1/2 mile in any direction, and is typically high enough to be above most tree foliage. 80 Foot Camera Poles: Should be used for locations where terrain and land availability do not allow for the 50-ft camera to view enough of the roadway. These poles are typically deployed in Interchanges. Also, new technology for cameras is allowing visual distance to be more than mile in a direction (added distance can be from 1-3 miles in a direction) and having a taller pole may reduce the amount of camera pole sites needed for corridor camera coverage. Camera Lowering System: Should be used for poles taller than 30 feet. This allows for maintenance of the camera without deploying a bucket truck, and one person can perform the maintenance. The Statewide Procurement has 50-ft and 80-ft camera poles equipped with lowering systems. External lowering systems can be applied to camera poles that are currently deployed and do not have an internal camera lowering system (any pole height). Video CODEC: This equipment is necessary to facilitate the data transfer from the camera to the Operation Center. Video transmission is accomplished through an encoder (deployed at the camera site) and a decoder (deployed at the Operation Center). Communication is facilitated through an ethernet/fiber communication link or a leased line telephone link (See Chapter 8, Communication Systems). Most Video CODEC utilize MPEG2/MPEG4/MJPEG technology for full motion video using 1.5 to 5.0 MB of bandwidth for each camera site. For specific procurement product information, see ITS Design Manual Documents: Chapter 4 CCTV Cameras Product Cut Sheets and Worksheets folders. Use the worksheets to find the reference number for the product cut sheet file related to the procurement item. Also, if you have any questions about a procurement item that the cut sheets or manual cannot answer, please contact the product vendor (as listed in the procurement worksheet).

December, 2004

4-3

Wisconsin Department of Transportation

COLLECT INITIAL DATA

Intelligent Transportation Systems (ITS) Design Manual

DETERMINE CCTV TYPE

DETERMINE LOCATION OF CONTROLLER CABINET

ESTABLISH POWER SERVICE

PREPARE UNDERGROUND INFRASTRUCTURE

DETERMINE COMMUNICATIONS MEDIUM

PERFORM CABLE ROUTING

MODIFY, AND CREATE CONSTRUCTION DETAILS

MODIFY, AND CREATE SPECIAL PROVISIONS

1

Refer to Chapter on Refer to Chapter 9 8 on Communications for Communications for further information further information.

CCTV DESIGN COMPLETE

Figure 4-2: CCTV Design Process

December, 2004

4-4

Wisconsin Department of Transportation

Intelligent Transportation Systems (ITS) Design Manual

4.6.

Camera Placement

Camera placement is based largely on the spacing requirements as documented under the Initial Data Collection section of this chapter. Placing cameras involves field verification of camera sites using a video recorder and bucket truck. When performing this video review, the following issues must be kept in mind when placing a camera: Foliage - Whenever possible, the video review should be done while trees are in full foliage. If this is not done, the view from installed CCTV sites may be minimized since foliage has a detrimental effect on sight distance. Right-of-way- If the camera is being placed on a local arterial, right-of-way restraints are critical. Arterial right-of-way is much narrower than typically found on the freeway. If the camera is placed outside of WisDOT right-of-way, permits and easements will be required to construct the site. Maintenance - The camera must be able to be maintained via a bucket truck. If the designer is unable to access the proposed location with a bucket truck during design, future maintenance (and installation) of the site may be cumbersome. Site distance to other ITS equipment - It is desirable for CCTV cameras to be capable of viewing nearby ramp meters or variable message signs. Cross-street viewing - Whether the proposed camera is being placed along the freeway or along an arterial, coverage of major cross streets is desirable. Cross street video surveillance is very important if an entrance ramp is being metered, or if the street is typically used as an alternate route. Viewing of other features - It is desirable for CCTV cameras to be capable of viewing features surrounding the freeway, such as park-and-ride lots and crash investigation sites. Future Construction Find out if there is any planned construction (1-10 years) in the area where the camera will be placed. You may need to coordinate with the plan designer or construction manager of the projects to ensure that the camera, or any of its components, will not need to be relocated or replaced during the construction process. Blind Spots - When a camera-lowering device is used there will be a blind spot at the pole. It is very important that the pole be orientated so the blind spot is located in the least desirable viewing sector. A pole orientation detail should be included in the plan set, so the contractor places the anchor bolts correctly in the concrete base.

4.7.

Cabinet and Equipment Placement

Placement of equipment for camera sites involves the controller cabinet, camera pole, and electrical service. Cabinet Placement The placement of the controller cabinet includes the following: Visibility of the camera from the controller cabinet. Distance between the controller cabinet and the camera. Off-freeway accessibility for maintenance vehicles whenever possible. Safety of the cabinet location.

December, 2004

4-5

Wisconsin Department of Transportation Grades.

Intelligent Transportation Systems (ITS) Design Manual

For maintenance considerations, it is very important that the camera be visible from the controller cabinet. The slope of the terrain for cabinet placement must be no steeper than 4:1. Placement of the cabinet on 3:1 slopes or steeper require grading provisions to provide a level area around the cabinet. Pole Mount Cabinets may be used if a controller cabinet size or capability is not needed. These cabinets are mounted directly to the pole. The pole mount cabinet has enough space to house electric service, a video encoder, and other communication equipment. Conduit is run from the bottom of the pole mount cabinet to the nearest pullbox or vault. Camera Pole Placement The camera pole should be placed within 350-ft of the controller cabinet. Extending beyond this distance requires re-design of the camera power cable size (gauge) and size of the coaxial cable, which transmits the video images. Placement of the camera pole must be outside of the clear zone (as determined by AASHTO: A Policy On Geometric Design of Highways and Streets or the AASHTO Roadside Design Guide, latest editions). The poles also must be accessible for maintenance vehicles, including large bucket trucks, unless using a lowering system, in which case maintenance may be performed with smaller vehicles.

4.8.

Underground Infrastructure

When the controller cabinet, electrical service and camera pole site have been placed, the underground conduit infrastructure can be designed. Issues to keep in mind when designing the conduit infrastructure include: Pull Box Spacing - Pull boxes should be spaced within 200 feet. Terrain - Conduit infrastructure should be designed on relatively flat (4:1 slope or flatter) terrain. For steeper sloped terrain (3:1 or greater) , conduit may be run perpendicular to (i.e., up or down) the slope to locations where the terrain is more suitable for conduit installation. Conduit Size - 4-Inch conduit is typically used for camera cable raceways. Conduit entering electrical service pedestals must be sized per pedestal requirements. Conduit Fill - The size and number of conduits along a run is dependent on percentage of fill as established by the National Electric Code (NEC). For new conduit installation, the percent fill must not exceed 31%. For installation of cable in existing conduit, 40% of the available area may be used. Conduit in Camera Base Two 4-inch conduits, and one 2-inch conduit or three 2inch conduits should be placed in the cameras concrete base. This will allow one conduit for electrical wire, one conduit for communication wire, and one conduit for coaxial cable (which is sensitive to electric-magnetic fields).

4.9.

Cable Routing

General Cable routing for camera sites typically involves the connection of all equipment, December, 2004 4-6

Wisconsin Department of Transportation

Intelligent Transportation Systems (ITS) Design Manual

including the camera pole and the electrical service, to the controller cabinet or pole mount cabinet. Other devices such as ramp meters or system detector stations (Chapters 2 and 3) may be added to a camera site, and require cable routing as described in their respective chapters. The power distribution cable running between the controller cabinet or pole mount cabinet and the electrical service should be in a separate conduit. Power and communication cables should not be mixed together. Camera Cables Camera cables consist of two different types: conductor cables for power and control, and coaxial cable for transmission of the video image between the camera and the video encoder. The maximum distance between the camera and controller for these cables must be kept within 350 feet. If this 350-ft maximum distance requirement is unobtainable, the size of the camera cables (for power, control, and video) must be redesigned and incorporated appropriately. Electrical service The power distribution wires running between the electrical service and the controller cabinet consists of stranded copper single conductors, cross-linked polyethylene (XLP), USE rated. Section 655 of the standard specifications provides guidance on additional requirements. The bid items for Electrical Wire Lighting (gauge #) AWG will meet the requirements. The gauge of conductors must be calculated per the requirements of the National Electric Code. Electrical Wire Routing The conduit system for camera sites needs to be bonded together, due to the fact that power cables are running within the system. Bonding all metallic components of the system together assures that there will be no difference in voltage potential across two points in that system. In addition, grounded conductor needs to be run with current-carrying cables (such as traffic signal conductors, power distribution wires, etc.), which returns the circuits current at zero voltage. The bonding/grounding wires in system typically use Electrical Wire Traffic Signals 10 AWG (Item 655.0515) in the States Standard Specifications. The gauge of grounded conductor must be calculated per the requirements of the National Electric Code. There is a distinct method required for the bonding system. Examples of this method can be found in Chapters 2 and 3. The pull boxes do not require grounding if the total voltage encountered in the pull box is 50 volts or less. In some Districts, a policy has been made to bond and ground all conduit systems, since equipment is frequently added to various locations in the future. For assistance in bonding and grounding of underground systems, consult the State Electrical Engineer.

4.10.

Communication Requirements

Closed-circuit television cameras require communication methods offering larger bandwidth than that required for typical ramp meter or detector station controllers. Communication requirements also are contingent upon whether full-motion video is desired, or if slow-scan images are adequate. The communication medium selected for camera sites is open to the following communication types as described in Chapter 8, Communication System. Leased Communications - Either leased analog video (fiber optics) for full-motion video or leased high-speed data lines (ISDN, 56k) for slow-scan images.

December, 2004

4-7

Wisconsin Department of Transportation

Intelligent Transportation Systems (ITS) Design Manual

State-Owned Communications - Fiber optic communications for full-motion video. Wireless Ethernet Radio- full motion video or slow scan images, capable of bandwidth between 3MB to 20 MB.

4.11. Power Requirements

A 100 Amp, 120/240 volt, single phase, three wire underground electrical service is required for electrical service installation. Typically, two controller cabinets can be powered by a single 100-amp service. The electrical service will be furnished and installed by the local power company up to a demarcation point, which consists of an electrical service (meter) pedestal. The electrical service must conform to the requirements of the local power company. The location of the electrical service must receive approval from the utility company. The electrical service will include two 50-amp circuit breakers rated at 22,000 AIC. The requirements for power cable between the electrical service and controller cabinet can be found under the Cable Routing section of this chapter. At locations which require a remotely located electrical service, a 100 Amp outside rated breaker box with space for 6 circuits, but no main breaker, will be attached to the side of the cabinet. Also, a 50 Amp single circuit breaker rated at 22,000 AIC will be installed within the breaker box to serve as a local electrical service disconnect point.

4.12.

CCTV Construction Details

Construction details (Adobe Acrobat format and Microstation DGN format) previously used during construction of CCTV sites are listed in Figure 4-3. These detail files can be found in ITS Design Manual Documents: Chapter 4 CCTV Cameras Construction Details folder.

4.13. CCTV Special Provisions

Special provisions (Adobe Acrobat format and Microsoft Word format) for items used in previous contracts containing CCTV sites are listed in Figure 4-4. These specification files can be found in ITS Design Manual Documents: Chapter 4 CCTV Cameras Special Provisions folder.

4.14.

CCTV Bid Items and Procurement Items

Bid items and procurement items are listed in Figure 4-5. Worksheets for developing estimates and miscellaneous quantities can be found in ITS Design Manual Documents: Chapter 4 CCTV Cameras Worksheets folder. Procurement product cut sheets can be found in ITS Design Manual Documents: Chapter 4 CCTV Cameras Product Cut Sheets folder. Bid and contract documents for procurement items can be found in ITS Design Manual Documents: Chapter 4 CCTV Cameras Bid and Contract Documents folder.

December, 2004

4-8

Wisconsin Department of Transportation

Intelligent Transportation Systems (ITS) Design Manual

Figure 4-3: CCTV Construction Details

File Name cabbase cabdetaila cabdetailb breaker meter1 polecond idplaque pmcab cctv30 cctv50&80a cctv50&80b vault Description CONCRETE BASE, CONTROLLER CABINET FIELD CABINET (1 OF 2) FIELD CABINET (2 OF 2) CABINET BREAKER DISCONNECT INSTALLATION FREE STANDING METER BREAKER PEDESTAL CONDUIT INSTALLATION ON POLE, POST, OR INTO CABINET CABINET/POLE IDENTIFICATION PLAQUE POLE MOUNTED CABINET CAMERA POLE DETAIL, 30-FT (FUTURE DETAIL) CAMERA POLE DETAIL, 50-FT/80-FT (1 OF 2) CAMERA POLE DETAIL, 50-FT/80-FT (2 OF 2) COMMUNICATION VAULT

Figure 4-4: CCTV Special Provisions Filename

camcable pmcabinet videocodec camparapet relcampole ctrlmultiplx

Description

CABLE CAMERA ASSEMBLY INSTALL POLE MOUNTED CABINET INSTALL VIDEO ENCODER CAMERA, PARAPET MOUNT (OLD FORMAT) RELOCATE CAMERA POLE (OLD FORMAT) VIDEO CONTROL MULTIPLEXER (OLD FORMAT)

Figure 4-5: CCTV Bid Items and Procurement Items

Bid Item Number / Commodity Code

550-91-039139 677.0200 SPV.0090 550-91-039138 677.0200 SPV.0090 677.0100 550-85-039120 550-85-039121 550-85-039123 550-85-039122 654.0102 672.0230 550-85-039136 677.0100 672.0250 FURNISH DOME CAMERA Install Camera Assembly Cable Camera Assembly BARREL CAMERA FURNISH BARREL CAMERA Install Camera Assembly Cable Camera Assembly 30-FT CAMERA POLE Install Camera Pole FURNISH ARTERIAL POLE, 30 FEET, GALVANIZED, FOR BARREL CAMERA FURNISH ARTERIAL POLE, 30 FEET, GALVANIZED, FOR DOME CAMERA FURNISH ARTERIAL POLE, 30 FEET, POWDER COAT PAINTED, FOR BARREL CAMERA FURNISH ARTERIAL POLE, 30 FEET, POWDER COAT PAINTED, FOR DOME CAMERA Concrete Bases Type 2 Base Camera Pole 30-FT 50-FT CAMERA POLE FURNISH FREEWAY POLE, 50 FEET, WITH LOWERING SYSTEM Install Camera Pole Base Camera Pole 50-FT EACH EACH EACH EACH EACH EACH EACH EACH EACH EACH EACH EACH LF

CCTV CAMERA ITEMS

DOME CAMERA

UNIT

EACH EACH LF

December, 2004

4-9

Wisconsin Department of Transportation

Intelligent Transportation Systems (ITS) Design Manual

Figure 4-5: CCTV Bid Items and Procurement Items, Continued

80-FT CAMERA POLE 550-85-039164 677.0100 672.0280 550-85-039163 550-85-039126 550-85-039124 550-85-039125 550-85-039322 SPV.0060 550-81-039146 672.0100 675.0200 653.0135 653.0180 673.0105 656.0200 656.0500 655.0515 655.0625 655.0630 655.0635 655.0640 655.0645 550-91-039177 550-91-039180 550-91-039735 550-91-039735 550-91-39895 550-91-039894 550-91-039907 SPV.0060 550-91-039177 550-91-039180 550-91-039735 550-91-039735 550-91-039736 550-91-039736 FURNISH FREEWAY POLE, 80 FEET, WITH LOWERING SYSTEM Install Camera Pole Base Camera Pole 80-FT HINGED POLE FURNISH HINGED POLE, 50 FEET LOWERING SYSTEM FURNISH EXTERNAL MOUNT CAMERA LOWERING SYSTEM FURNISH CAMERA LOWERING TOOL, MANUAL FURNISH CAMERA LOWERING TOOL, MOTORIZED CABINETS FURNISH CCTV POLE MOUNTED CABINET Install Pole Mounted Cabinet FURNISH FIELD CABINET Base ITS Controller Cabinet Install Controller Detector Processor Assembly PULL BOX / VAULT Pull Boxes Steel 24x36-Inch Pull Boxes Steel Communications (inch) Communication Vault Type 1 ELECTRICAL Electrical Service Meter Breaker Pedestal (location) Electrical Service Breaker Disconnect Box (location) Electrical Wire Traffic Signals 10 AWG (for Bonding and Grounding) Electrical Wire Lighting 6 AWG Electrical Wire Lighting 4 AWG Electrical Wire Lighting 2 AWG Electrical Wire Lighting 1 AWG Electrical Wire Lighting 1/0 AWG VIDEO ENCODER FURNISH LEASED LINE VIDEO ENCODER FURNISH LEASED LINE VIDEO ENCODER, ENVIRONMENTALLY RUGGEDIZED FURNISH ETHERNET VIDEO ENCODER FURNISH ETHERNET VIDEO ENCODER, ENVIRONMENTALLY RUGGEDIZED FURNISH LEASED LINE VIDEO CODEC PLUG-IN MODULE - ENCODER FURNISH ETHERNET VIDEO CODEC PLUG-IN MODULE - ENCODER FURNISH VIDEO CODEC CONTROL SOFTWARE-WATCHDOG Install Video Encoder VIDEO DECODER FURNISH LEASED LINE VIDEO DECODER FURNISH LEASED LINE VIDEO DECODER, ENVIRONMENTALLY RUGGEDIZED FURNISH ETHERNET VIDEO DECODER FURNISH ETHERNET VIDEO DECODER, ENVIRONMENTALLY RUGGEDIZED FURNISH VIDEO CODEC CHASSIS - LEASED LINE FURNISH VIDEO CODEC CHASSIS - ETHERNET EACH EACH EACH EACH EACH EACH EACH EACH EACH EACH EACH EACH EACH EACH LS LS LF LF LF LF LF LF EACH EACH EACH EACH EACH EACH EACH EACH EACH EACH EACH EACH EACH EACH EACH

December, 2004

4-10

Wisconsin Department of Transportation

550-91-39895 550-91-039894 SPV.0060

Intelligent Transportation Systems (ITS) Design Manual

EACH EACH EACH

FURNISH LEASED LINE VIDEO CODEC PLUG-IN MODULE - DECODER

Figure 4-5: CCTV Bid Items and Procurement Items, Continued

FURNISH ETHERNET VIDEO CODEC PLUG-IN MODULE - DECODER Install Video Decoder (FUTURE) VIDEO TRANSMITTER / RECEIVER 725-23-040050 962-18-040030 725-23-040061 725-23-040062 962-18-040029 924-10-039169 924-10-039170 924-10-039167 924-10-039168 924-10-039181 670.0100 670.0200 FURNISH VIDEO TRANSMITTER INSTALL VIDEO TRANSMITTER VIDEO RECEIVER RACK, 14 SLOT FURNISH VIDEO RECEIVER INSTALL VIDEO RECEIVER TRAINING TRAINING, LOWERING SYSTEM WITH LOWERING TOOL TRAINING, HINGED POLE, 50 FEET TRAINING, DOME CAMERA TRAINING, BARREL CAMERA TRAINING, LEASED LINE VIDEO CODEC'S INTEGRATOR Field System Integrator ITS Documentation LS LS DAY DAY DAY DAY DAY EACH EACH EACH EACH EACH

December, 2004

4-11

Potrebbero piacerti anche

- Digital Video Processing for Engineers: A Foundation for Embedded Systems DesignDa EverandDigital Video Processing for Engineers: A Foundation for Embedded Systems DesignNessuna valutazione finora

- Industrial Process Automation Systems: Design and ImplementationDa EverandIndustrial Process Automation Systems: Design and ImplementationValutazione: 4 su 5 stelle4/5 (10)

- CCTV Design Manual Chapter on Camera InstallationDocumento9 pagineCCTV Design Manual Chapter on Camera InstallationAhmed KhattabNessuna valutazione finora

- Bticino CCTV GuideDocumento58 pagineBticino CCTV GuideH_REZAPANANessuna valutazione finora

- CCTV StudymateDocumento56 pagineCCTV Studymatesubhayanmanna1234Nessuna valutazione finora

- RDSO CCTV System Specification for Indian Rail CoachesDocumento16 pagineRDSO CCTV System Specification for Indian Rail CoachesShailendra KumarNessuna valutazione finora

- DPD Video Surveillance System SpecsDocumento102 pagineDPD Video Surveillance System SpecsDallasObserverNessuna valutazione finora

- GD Ipsurv Design 32568 en 0807 LoDocumento50 pagineGD Ipsurv Design 32568 en 0807 LodgrsriNessuna valutazione finora

- CCTV IP Camera GuideDocumento50 pagineCCTV IP Camera GuideRehan Shahid QureshiNessuna valutazione finora

- Dcs StandardDocumento6 pagineDcs Standardsina20795Nessuna valutazione finora

- T02 - Audiovisual Systems 2022Documento23 pagineT02 - Audiovisual Systems 2022naveedfndNessuna valutazione finora

- CCTV Over IP IIDocumento36 pagineCCTV Over IP IIshahzad pervezNessuna valutazione finora

- CCTVDocumento12 pagineCCTV27051977100% (2)

- CCTV Camera System RequirementDocumento2 pagineCCTV Camera System RequirementIrosh GunasekaraNessuna valutazione finora

- Document PDFDocumento128 pagineDocument PDFMUBASHIRNessuna valutazione finora

- Surveillance System DesignDocumento24 pagineSurveillance System Designmostafa HusseinNessuna valutazione finora

- BS 8418 CCTV GUIDEDocumento2 pagineBS 8418 CCTV GUIDEmmhaq1975Nessuna valutazione finora

- CCTV Technical Advice for Public and Private SpacesDocumento60 pagineCCTV Technical Advice for Public and Private Spacesmatthew02012010100% (2)

- Introduction To CCTV SystemDocumento10 pagineIntroduction To CCTV SystemCRISTINE ABARIAL ANGCANessuna valutazione finora

- Alcatel-Lucent IPTV Test and Measure WhitePaperDocumento23 pagineAlcatel-Lucent IPTV Test and Measure WhitePaperTungust SiberianNessuna valutazione finora

- 66-08 Retrieval of Video Ev12835Documento32 pagine66-08 Retrieval of Video Ev12835jonykhanNessuna valutazione finora

- Tecnical For CCTVDocumento25 pagineTecnical For CCTVsakthisriniNessuna valutazione finora

- PARKING40Documento11 paginePARKING40Roshan ShanmughanNessuna valutazione finora

- CCNA Discovery 4 Module 4 Exam Answers Version 4Documento7 pagineCCNA Discovery 4 Module 4 Exam Answers Version 4विनोद कुमार भाष्करNessuna valutazione finora

- CCTV System StandardsDocumento17 pagineCCTV System StandardsCyrene MamaradloNessuna valutazione finora

- CCTV ProjectDocumento15 pagineCCTV Projectmicos8150% (2)

- Closed Circuit TelevisionDocumento10 pagineClosed Circuit TelevisionGirish SahareNessuna valutazione finora

- F-Spot Preliminary Design ReportDocumento23 pagineF-Spot Preliminary Design Reportcrabpot8Nessuna valutazione finora

- CCTV Code of PracticeDocumento20 pagineCCTV Code of PracticeMeijin Senjin100% (1)

- CCTV Surveillance System Technical SpecificationDocumento23 pagineCCTV Surveillance System Technical SpecificationsakthisriniNessuna valutazione finora

- Telemetry SIHDocumento8 pagineTelemetry SIHsoham bhattacharyaNessuna valutazione finora

- Fo Optral CatalogoDocumento20 pagineFo Optral CatalogoSergio SanchezNessuna valutazione finora

- CCTV Guide To Bs8418Documento5 pagineCCTV Guide To Bs8418Dan DimitriuNessuna valutazione finora

- Video Surveillance Solution Over The Aruba Infrastructure: EnterpriseDocumento15 pagineVideo Surveillance Solution Over The Aruba Infrastructure: EnterpriseBayuSutawijayaNessuna valutazione finora

- Data-Driven CCTV SpecificationDocumento22 pagineData-Driven CCTV SpecificationsakthisriniNessuna valutazione finora

- M1M OP ManualDocumento111 pagineM1M OP ManualDavide SestiNessuna valutazione finora

- Code of Practice For Digital Recording Systems For The Purpose of Image Export To Be Used As EvidenceDocumento11 pagineCode of Practice For Digital Recording Systems For The Purpose of Image Export To Be Used As EvidenceAmine DidiNessuna valutazione finora

- Technical ReportDocumento9 pagineTechnical Report27051977100% (3)

- Review of Closed Circuit Television CCTV Technique PDFDocumento8 pagineReview of Closed Circuit Television CCTV Technique PDFFaiq NukhaNessuna valutazione finora

- Electrical Spec.'S CCTV System 16782-1Documento12 pagineElectrical Spec.'S CCTV System 16782-1Waleed Abd El-HamiedNessuna valutazione finora

- CCTV GuidelinesDocumento21 pagineCCTV Guidelinesalexandra_rigo100% (1)

- RFQDocumento9 pagineRFQOmarMohsen1989Nessuna valutazione finora

- Navigation Search: Purchasing CCTVDocumento5 pagineNavigation Search: Purchasing CCTVrosninikmat100% (1)

- CCTV12 CCTV Systems Explained in Under 40Documento6 pagineCCTV12 CCTV Systems Explained in Under 40Professor GowthamNessuna valutazione finora

- Requirements for CCTV InstallationDocumento20 pagineRequirements for CCTV InstallationRaj RamachandranNessuna valutazione finora

- Dipol Polska, PrimerDocumento6 pagineDipol Polska, PrimerJohnNessuna valutazione finora

- IDE20 Series Sarix IP Indoor Fixed Dome: Product SpecificationDocumento6 pagineIDE20 Series Sarix IP Indoor Fixed Dome: Product Specificationgat_leeNessuna valutazione finora

- Request Technical Commercial Info Mobile Cellular ArmyDocumento12 pagineRequest Technical Commercial Info Mobile Cellular ArmyUgyenKpNessuna valutazione finora

- BAS Security AccessDocumento19 pagineBAS Security AccessSayed HashemNessuna valutazione finora

- CCTV (Closed Circuit Television)Documento39 pagineCCTV (Closed Circuit Television)Aizel Jacob Roncejero100% (1)

- Control System For Security Enhancement of CCTV Camera Maintenance DevicesDocumento6 pagineControl System For Security Enhancement of CCTV Camera Maintenance Devicesyeshrine levishaNessuna valutazione finora

- Intelligent Video Surveillance System PDFDocumento29 pagineIntelligent Video Surveillance System PDFWafa BenzaouiNessuna valutazione finora

- Installing Digital Cinema in Your Theater: A Technical GuideDocumento52 pagineInstalling Digital Cinema in Your Theater: A Technical GuideTunde RennerNessuna valutazione finora

- Closed Circuit Tele VisionDocumento13 pagineClosed Circuit Tele VisionApril Belza PelonioNessuna valutazione finora

- Multi-Camera Networks: Principles and ApplicationsDa EverandMulti-Camera Networks: Principles and ApplicationsHamid AghajanValutazione: 3 su 5 stelle3/5 (1)

- Intelligent Transport Systems: Technologies and ApplicationsDa EverandIntelligent Transport Systems: Technologies and ApplicationsAsier PerallosNessuna valutazione finora

- Alcatel-Lucent Service Routing Architect (SRA) Self-Study Guide: Preparing for the BGP, VPRN and Multicast ExamsDa EverandAlcatel-Lucent Service Routing Architect (SRA) Self-Study Guide: Preparing for the BGP, VPRN and Multicast ExamsNessuna valutazione finora

- IPTV Delivery Networks: Next Generation Architectures for Live and Video-on-Demand ServicesDa EverandIPTV Delivery Networks: Next Generation Architectures for Live and Video-on-Demand ServicesSuliman Mohamed FatiNessuna valutazione finora

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneDa EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNessuna valutazione finora

- CCP Express Admin GuideDocumento30 pagineCCP Express Admin GuidePepe PerezaNessuna valutazione finora

- DMS MasterplanDocumento71 pagineDMS MasterplanacabadingNessuna valutazione finora

- Manual On Uniform Traffic Control DevicesDocumento864 pagineManual On Uniform Traffic Control DevicesRightHandViking100% (4)

- Key Features 35Documento9 pagineKey Features 35acabadingNessuna valutazione finora

- Installation guide for ZXDU68 B201 DC power systemDocumento4 pagineInstallation guide for ZXDU68 B201 DC power systemclaudio100% (1)

- MR-J3-B-RJ004U LM-H2 LM-U2 LM-F: SeriesDocumento212 pagineMR-J3-B-RJ004U LM-H2 LM-U2 LM-F: SeriesJorge MorenoNessuna valutazione finora

- Mini Metal Lathe 7x12 Owner's Manual Safety GuideDocumento13 pagineMini Metal Lathe 7x12 Owner's Manual Safety GuideVicente Banda ZuñigaNessuna valutazione finora

- Samsung LCD TV Le27t51b (ET)Documento121 pagineSamsung LCD TV Le27t51b (ET)Mohamed Salah100% (1)

- PGX2 IngDocumento5 paginePGX2 IngpiabNessuna valutazione finora

- Code of Practice For Earthing LV Networks and HV Distribution Substations IMP010011Documento89 pagineCode of Practice For Earthing LV Networks and HV Distribution Substations IMP010011SatyaNessuna valutazione finora

- Distance Protection RelayDocumento27 pagineDistance Protection RelaycallkalaiNessuna valutazione finora

- Terminal Blocks: KasugaDocumento6 pagineTerminal Blocks: KasugaKs MuraliNessuna valutazione finora

- Quad Channel High Side Driver: So-28 (Double Island)Documento20 pagineQuad Channel High Side Driver: So-28 (Double Island)julianNessuna valutazione finora

- Atv68 Usersmanual enDocumento40 pagineAtv68 Usersmanual enDarius YorimNessuna valutazione finora

- Product Manual 25805 (Revision D 4/2003) : Governor Test StandDocumento76 pagineProduct Manual 25805 (Revision D 4/2003) : Governor Test StandAnonymous V9fdC6Nessuna valutazione finora

- Ams Manual Sensit3 Snack VCB VCF Vcbe LBX Food LCX ComboDocumento57 pagineAms Manual Sensit3 Snack VCB VCF Vcbe LBX Food LCX ComboGustavo EsquivelNessuna valutazione finora

- Epson AL M300-M400 SMDocumento546 pagineEpson AL M300-M400 SMLH TanNessuna valutazione finora

- Emerson EWT19S2Documento50 pagineEmerson EWT19S2dreamyson1983100% (1)

- PD-42DX CH - MK (sm-52088)Documento140 paginePD-42DX CH - MK (sm-52088)Roberd MihailovNessuna valutazione finora

- Gast Lubricated 0211 Series Rotary Vane Vacuum Pumps & Compressors O & M MDocumento8 pagineGast Lubricated 0211 Series Rotary Vane Vacuum Pumps & Compressors O & M MTiam StoneNessuna valutazione finora

- Magnetic Effect of Electric Current Notes Chpt2Documento11 pagineMagnetic Effect of Electric Current Notes Chpt2Sarathrv Rv100% (2)

- Prophet 10 Synthesizer Operation Manual PDFDocumento92 pagineProphet 10 Synthesizer Operation Manual PDFPhasma3027Nessuna valutazione finora

- Application Note: Transformer-Less Power-One Inverters and Parallel UseDocumento9 pagineApplication Note: Transformer-Less Power-One Inverters and Parallel UsenisteriNessuna valutazione finora

- E-Series Manual (N00-807-00) PDFDocumento130 pagineE-Series Manual (N00-807-00) PDFMaxwel SenaNessuna valutazione finora

- 02-Sedecal Instalacion HF IN1005R5iDocumento91 pagine02-Sedecal Instalacion HF IN1005R5ijaime munozNessuna valutazione finora

- Ssa3000x User Manual Um0703x E02bDocumento83 pagineSsa3000x User Manual Um0703x E02bHANSENNessuna valutazione finora

- Power Sector Overview in India - EARTHING DESIGN CALCULATIONDocumento3 paginePower Sector Overview in India - EARTHING DESIGN CALCULATIONnavneetNessuna valutazione finora

- 1st Radio Book For Boys Morgan PDFDocumento207 pagine1st Radio Book For Boys Morgan PDFsantiago962Nessuna valutazione finora

- System Neutral Resistance GroundingDocumento7 pagineSystem Neutral Resistance Grounding1japs2014Nessuna valutazione finora

- How To Become A Laptop Technician - From Zero To Hero Kang Solihin 9781980416357 Tre Media 2018 142 $44-0 - 94 PDFDocumento142 pagineHow To Become A Laptop Technician - From Zero To Hero Kang Solihin 9781980416357 Tre Media 2018 142 $44-0 - 94 PDFSofiane Mourad50% (2)

- Maintenance: Base Station Controller MMN:BSCDocumento233 pagineMaintenance: Base Station Controller MMN:BSCRachidNessuna valutazione finora

- SGPD SMDocumento83 pagineSGPD SMAdityaBeheraNessuna valutazione finora

- 93c26-A KR BS La PR PDFDocumento58 pagine93c26-A KR BS La PR PDFronoro450Nessuna valutazione finora

- Prodigy Eng-Sp Owners ManualDocumento44 pagineProdigy Eng-Sp Owners ManualAlejandro Paz PerazzaNessuna valutazione finora