Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Banner QL55 Luminescence Sensors

Caricato da

Memik TylnDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Banner QL55 Luminescence Sensors

Caricato da

Memik TylnCopyright:

Formati disponibili

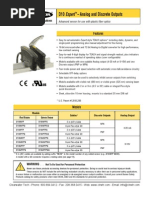

QL55 Series Luminescence Sensor

Self-contained, microprocessor-based luminescence sensor

Features

Self-contained design in a robust, compact metal housing High sensitivity Microprocessor-controlled Senses luminescent marks, even on luminescent backgrounds Senses luminescence on reflective surfaces, such as ceramic, metal, or mirrored glass Easy-to-set sensing threshold Fast 250-microsecond sensing response time; high 2 kHz switching frequency Switch-selectable NPN or PNP discrete output, plus 0 to 5.5V dc analog output Switch-selectable output OFF-delay 3-position swivel QD connector

Models

Models Sensing Range Cable/ Connector* Supply Voltage Outputs

Relative Received Signal

Sensor Performance

100% 80% 60% 40% 20% 0 0 10 mm (0.4") 20 mm (0.8") 30 mm (1.2") 40 mm (1.6") 50 mm (2.0")

QL55M6XD15BQ

9 to 18 mm (0.35" to 0.71")

Sensing Distance

QL55M6XD30BQ

20 to 40 mm (0.79" to 1.57")

4-pin Euro-style (M12) QD connector with 3-position swivel (locking screw-secured)

10 to 30V dc

One selectable NPN or PNP discrete plus one 0 to 5.5V dc analog

Relative Received Signal

100% 80% 60% 40% 20% 0 0 10 mm (0.4") 20 mm (0.8") 30 mm (1.2") 40 mm (1.6") 50 mm (2.0")

Sensing Distance Relative Received Signal

100% 80% 60% 40% 20% 0 30 mm (1.2") 40 mm (1.6") 50mm (2.0") 60 mm (2.4") 70 mm (2.8") 80 mm (3.2")

QL55M6XD50BQ

40 to 75 mm (1.57" to 2.95")

Sensing Distance

* Mating cable required; see back cover for cable options.

These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current Banner Safety Products catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

WARNING . . .

Not To Be Used for Personnel Protection

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

QL55 Series Luminescence Sensor

Overview

The QL55 Series Sensor is an easy-to-use, extremely sensitive microprocessor-based luminescence sensor that emits ultraviolet light from a high-power LED and scans for luminescence in materials. The QL55 senses the luminescence inherent in a material, or it can sense luminophores added to a material in process to make it luminescent. The sensor can be set to accurately sense a wide range of luminescence intensities and background conditions. The two-step QL55 Sensor programming procedure sets the threshold for target luminescence and background. The Luminescent Target condition is taught first, followed by the Luminescent Target Absent (background) condition. During operation, the sensor outputs will be ON when the luminescent target object is present, and OFF for the background condition. (The sensor may instead be taught to respond to the Background condition; see page 3.) Located within the QL55 Sensor, two selector switches may be used to enable an output OFF-delay option and for setting the discrete output to NPN or PNP (see Figure 5). The QL55 is available with one of three operating ranges, to a maximum of 75 mm (2.95"), depending on the model. The sensor housing has two push buttons, Mark and Background, for easy programming; it has two LEDs, Ready/Overload and Output, for easy monitoring during operation. See Figure 1. For easier understanding, the sensor faces are described in this data sheet as labeled in Figure 2. The key pad is considered the sensor back, and the lens is on the bottom.

Green Ready/ Overload LED (Power ON Indicator) Mark Push Button

READY

OUT

Red Output LED

MARK

BKGD

Background Push Button

Figure 1. QL55 Luminescence Sensor features (sensor back)

Luminescence Sensing

Luminescence sensing detects a form of electromagnetic radiation, caused by the shining of UV light (black light, invisible to the human eye) on a luminescent substrate material, such as a petroleum-based adhesive. When the UV light shines on the adhesive, the light excites electrons in the material (effecting a change of state), causing it to reflect visible light. Thus an invisible light source can produce a visible reflection. Because it emits UV light but detects visible waves, the sensor can distinguish between the fluorescent material and other highly reflective materials.

Top Back Key Pad Front

Cost Factors

When comparing luminescence sensors to make a selection, it is important to consider whether luminophores must be added to the product sensed, in order for the sensor to detect luminescence. Generally speaking, the more sensitive the sensor, the lower the level of luminescence required for detection. Less sensitive (and usually less expensive) sensors may require an additional step in the production process, and a substantial cost over time, to add luminophores. For information on less expensive, less sensitive luminescence sensor models, refer to data sheet p/n 112151, Model QL50 Luminescence Sensor, or contact a Banner applications engineer for more information (see back page for addresses).

Bottom Lens

Blanking Plug

Figure 2. QL55 orientation of features

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

QL55 Series Luminescence Sensor

Light Operate

Less Luminescent Condition

Output OFF

Sensor Configuration

In this simple two-step procedure, the sensor samples the luminescence levels of both the target (Mark) and the background (Background) conditions. The sensor automatically selects light operate or dark operate (see Figure 3) based on the relative luminescence of the two conditions. Using the procedure described below, sensing the more luminescent condition (in this case the target to be sensed) will close the normally open output, turn on the red Output LED, and cause the output to conduct current (light operate). If the application requires the output to conduct for a less luminescent condition, reverse the procedure (dark operate): Present the less luminescent condition first (Mark push button) and then Present the more luminescent condition (Background push button).

More Luminescent Condition

Output ON

Least Luminescent

Most Luminescent

Dark Operate

Less Luminescent Condition More Luminescent Condition

Output ON

Output OFF

Least Luminescent

Most Luminescent

Figure 3. Sensor automatically selects light operate or dark operate, when configured as described below

Procedure

Result

SET Output ON Condition

Position luminescent target in front of sensing lens. Press Mark push button (approx. 4 sec.) until green Ready LED turns OFF.

Green Ready LED: turns OFF Red Output LED: OFF

READY OUT MARK BKGD

Green Ready LED stays OFF, and sensor stores the Output ON condition.

READY

OUT

MARK

BKGD

SET Output OFF Condition

Remove luminescent target from sensors field of view. Press and hold Background push button (approx. 4 sec.) until green blinks.

Programming Accepted Green Ready LED: Flashes 1x, then ON Red Output LED: OFF Green Ready LED stays ON, and sensor stores the Output OFF (background) condition.

READY OUT MARK BKGD

READY

OUT

READY

OUT

then

MARK BKGD MARK BKGD

Programming Error (Due to insufficient contrast between target and background luminescence) Green Ready LED: flashes slowly (approx. 2 Hz)

Repeat programming procedure from the beginning. If programming fails again, increase the target luminescence or subdue the background.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

QL55 Series Luminescence Sensor

Sensor Setup Output OFF-Delay

Setting an output OFF-delay extends the duration of the QL55 sensors ON output by 20 ms. See Figure 4. The sensor default is for no OFF-delay. NOTE: Take precautions against potential static discharge. To activate the output OFF-delay option: 1. Remove power from sensor. 2. Remove the four cover screws and the sensor side cover. 3. Slide DIP switch 2 (shown in Figure 5) to the ON position. NOTE: Leave DIP switch 1 in its factory-set position. 4. Change NPN/PNP output selection, if applicable. 5. Replace the sensor side cover and screws.

ON 1 2

Sensor Output Output Starts OFF-Delay (20 ms) Output Ends

Figure 4. Output OFF-delay: Output continues for 20 ms after sensing stops

Setting NPN / PNP Output

The QL55 has a selector switch for setting the output to NPN (current sinking) or PNP (current sourcing). The sensor is pre-set with the output set to NPN. If the sensor will be operating with an NPN output (and no output OFF-delay), the sensor housing does not need to be opened. NOTE: Take precautions against potential static discharge. To set NPN or PNP output: 1. Remove power from sensor. 2. Access the red sliding NPN/PNP selector switch by removing the four cover screws and the sensor side cover. The switch is located deep within the sensor housing; do not confuse it with the bank of two DIP switches. The NPN/PNP selector switch is visible below the circuit board, next to the exposed mounting screw location (see Figure 5). 3. Carefully use a small screwdriver (preferably non-metallic) to select the NPN or PNP switch position. 4. Replace the sensor side cover and screws before installing the sensor. NOTE: If a cover screw is lost, contact the Banner applications group for a free replacement (see back page for addresses).

NPN (default)

ON 1 2

OFF-delay Active PNP OFF-delay Inactive (default) NPN/PNP Selector (recessed below top board)

DIP Switch 2: Output OFF-Delay Selector DIP Switch 1: For factory use only; leave in OFF position

Figure 5. Selector switches: Output OFFDelay and NPN/PNP output select

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

QL55 Series Luminescence Sensor

Sensor Installation

Do not attempt to change the lens position on the sensor housing. The sensor will work only with the lens in the bottom port (see Figure 2). No optical components exist behind the blanking plug on the sensor front; do not remove the blanking plug. 1. Loosen the connector locking screw (several turns), and position the QD connector as needed (back, side, or bottom of the sensor). Tighten the locking screw after the connector is properly positioned. 2. Measure the appropriate operating distance from the front surface of the sensor optics to the surface or object to be sensed. Do not exceed the sensing range for your model (see page 1 for sensor model and range). 3. Fasten the sensor to its intended location using two to four M5 mounting screws and washers. There are four mounting holes on the bottom (lens side) of the sensor and two on each side (see page 7). NOTE: Proper mounting screw length depends on mounting bracket thickness. Additional washers may be necessary to make sure the screws do not exceed the thread depth. 4. Attach the QD cable to the sensors connector; see hookups on page 7.

Sensor Operation

Power up the QL55 Sensor after programming, setup, and installation. The green Ready LED turns ON to indicate that the sensor is in RUN mode and ready to sense the luminescent target as programmed. When configured as described on page 3, sensing the target object will cause the normally-open output to close and the red Output LED to turn ON. If the sensor experiences an output overload condition during operation, the green Ready LED will flash fast (approx. 4 Hz). Verify that output current is less than 200 mA.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

QL55 Series Luminescence Sensor

Specifications

Sensing Beam Supply Voltage Supply Protection Circuitry Output Configuration Output Rating Output Protection Output Response Time Adjustments Ultraviolet high-power LED (370 nm) 10 to 30V dc, 2 V pp max ripple 80 mA max, exclusive of load Protected against reverse polarity Discrete NPN or PNP Analog 0 to 5.5V dc 10%, ripple 40 mV pp max. Saturation Voltage: 1V max. NPN / 2V max PNP Leakage Current: <100 A 200 mA maximum load NPN/PNP: Protected against reverse polarity, overload, and short circuit (pull down/up resistance 10 k) Analog: Protected against short circuit (output resistance 2.2 k) 250 microseconds 2 push buttons (MARK and BKGD) determine switching threshold and Light/Dark operate (see page 3) 2 selector switches (see Figure 5) 20 ms Output OFF-delay NPN/PNP output Red Output LED ON: output is conducting Green Ready/Overload LED ON: normal operating condition, RUN mode Flashing 2 Hz: setup failure due to insufficient contrast Flashing 4 Hz: output overload condition (verify output current 200 mA) Housing: zinc, aluminum, and magnesium alloy Lens: glass IEC IP62 4-pin Euro-style (M12) QD connector. See back cover for required accessory cable options.

Temperature: -10 to +55C (+14 to +131F) Max. Relative Humidity: 85% at 50C (non-condensing)

Indicators

Construction Environmental Rating Connections Operating Conditions Data Retention Scanning Range

EEPROM nonvolatile memory QL55M6XD15BQ: 9 to 18 mm (0.35" to 0.71") QL55M6XD30BQ: 20 to 40 mm (0.79" to 1.57") QL55M6XD50BQ: 40 to 75 mm (1.57" to 2.95") QL55M6XD15BQ: 2 mm (0.08") QL55M6XD30BQ: 3 mm (0.12") QL55M6XD50BQ: 4 mm (0.16") According to EN 60947-5-2 30 G; 3 shocks per axis; 11 ms duration 0.5 mm (0.02") amplitude; 10 to 60 Hz frequency, 30 minutes for each X, Y, Z axis

Spot Diameter Ambient Light Rejection Shock Resistance Vibration Certifications

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

QL55 Series Luminescence Sensor

Dimensions

Connector swivels to 3 positions

READY

OUT

READY

OUT

READY OUT

31.0 mm (1.22")

81.2 mm (3.20") 77.0 mm (3.03")

MARK

BKGD

MARK

BKGD

16.0 mm (0.63")

M12 Connector

Loosen locking screw to rotate connector

READY OUT

Blanking Plug Only No optical axis in this location Do Not Remove

39.8 mm (1.57")

58.0 mm (2.28")

MARK BKGD

Model QL55M6XD15BQ

25 mm (0.98") 4.3 mm (0.17")

36.6 mm (1.44")

28.0 mm (1.10")

Model QL55M6XD30BQ

28.6 mm (1.13")

28 mm (1.10")

Model QL55M6XD50BQ

21.6 mm (0.85")

33 mm (1.30")

21.0 mm (0.83")

14.1 mm (0.56")

28.2 mm (1.10") 27.5 mm (1.08")

Hookups

NPN

bn bu bk wh Load 10 to 30V dc

Analog Out 0 to 5.5V dc

PNP

bn bu bk wh Load 10 to 30V dc

Analog Out 0 to 5.5V dc

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

QL55 Series Luminescence Sensor

Quick-Disconnect Cables

Style

4-Pin Straight Euro-style

Model

MQDC-406 MQDC-415 MQDC-430

Length

2 m (6.5') 5 m (15') 9 m (30')

Dimensions

15 mm (0.6") 44 mm max. (1.7") M12 x 1

Pinout

White Wire Brown Wire Blue Wire Black Wire

Accessory Mounting Brackets

SMB55A 15 offset bracket 12-gauge stainless steel

SMB55RA Right-angle bracket 12-gauge stainless steel

SMB55F Flat-mount bracket 12-gauge stainless steel

SMB55S 15 offset bracket 12-gauge stainless steel

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair or replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty period. This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any other warranty either expressed or implied.

P/N 112153 rev. C

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Potrebbero piacerti anche

- Banner QL50 Luminescence SensorsDocumento8 pagineBanner QL50 Luminescence SensorsMemik TylnNessuna valutazione finora

- Installation Instructions Series 9000 Lasersight Photoelectric SensorsDocumento4 pagineInstallation Instructions Series 9000 Lasersight Photoelectric Sensorsy0o0o0Nessuna valutazione finora

- D12 ExpertDocumento12 pagineD12 ExpertaeduardocgNessuna valutazione finora

- TMP 8479-LR-ZB250AN AP IM 96M12305 GB WW 1014-1b-796519325Documento4 pagineTMP 8479-LR-ZB250AN AP IM 96M12305 GB WW 1014-1b-796519325Isra MarNessuna valutazione finora

- Tài liệu cảm biến bắt màu BANNER R58 Expert - R58ECRGB1Documento12 pagineTài liệu cảm biến bắt màu BANNER R58 Expert - R58ECRGB1Nguyễn Văn Dũng100% (4)

- Q5X Laser Triangulation Sensor With Analog Outputs: Quick Start GuideDocumento12 pagineQ5X Laser Triangulation Sensor With Analog Outputs: Quick Start GuideJose Luis Gutierrez MartinezNessuna valutazione finora

- Manual Sensor de LiquidoDocumento16 pagineManual Sensor de LiquidoLuis Alberto Vera ZamoraNessuna valutazione finora

- WORLD-BEAM QS18E Clear Object Detection: Quick Start GuideDocumento4 pagineWORLD-BEAM QS18E Clear Object Detection: Quick Start GuideDébora Dos SanttosNessuna valutazione finora

- Honeywell Is2500lt Install GuideDocumento2 pagineHoneywell Is2500lt Install GuideAlarm Grid Home Security and Alarm MonitoringNessuna valutazione finora

- Sensor Banner - BarreiraDocumento4 pagineSensor Banner - BarreiraAdailton FreitasNessuna valutazione finora

- LX Series Part-Sensing Light Screen: FeaturesDocumento4 pagineLX Series Part-Sensing Light Screen: Featuresduonghieu8xNessuna valutazione finora

- Lab - 13 - PhotoInterupter and Proximity SensorDocumento9 pagineLab - 13 - PhotoInterupter and Proximity SensorRahman ShafiqueNessuna valutazione finora

- Assignment: Course Code Microcontroller Computer Peripherals and Interfacing LabDocumento17 pagineAssignment: Course Code Microcontroller Computer Peripherals and Interfacing LabAll OneNessuna valutazione finora

- Shockgard SS101 - 102 Installation Instructions PDFDocumento2 pagineShockgard SS101 - 102 Installation Instructions PDFPastor Díaz C.Nessuna valutazione finora

- SmartScan 8000 Installation GuideDocumento20 pagineSmartScan 8000 Installation GuideRoboHDNessuna valutazione finora

- Sick KT5W-2 - 6Documento4 pagineSick KT5W-2 - 6Barba LuisNessuna valutazione finora

- R58E Series Expert Registration Mark Sensors: DatasheetDocumento11 pagineR58E Series Expert Registration Mark Sensors: DatasheetVikaas JainNessuna valutazione finora

- Installation Instructions Photoswitch Bulletin 42Ft Selfćteach Fiber OpticDocumento4 pagineInstallation Instructions Photoswitch Bulletin 42Ft Selfćteach Fiber OpticFito RahNessuna valutazione finora

- Circuit Analysis Project ReportDocumento4 pagineCircuit Analysis Project ReportBushra KhanNessuna valutazione finora

- Installation Instructions 45LMS Laser Measurement Sensor: Important: Save These Instructions For Future UseDocumento4 pagineInstallation Instructions 45LMS Laser Measurement Sensor: Important: Save These Instructions For Future UseDiauoliver RendersNessuna valutazione finora

- Honeywell IS2535 Install GuideDocumento2 pagineHoneywell IS2535 Install GuideAlarm Grid Home Security and Alarm MonitoringNessuna valutazione finora

- Course Code Microcontroller Computer Peripherals and Interfacing LabDocumento17 pagineCourse Code Microcontroller Computer Peripherals and Interfacing LabAll OneNessuna valutazione finora

- Siemens 3RG7404 0CH00 DatasheetDocumento54 pagineSiemens 3RG7404 0CH00 DatasheetManea George-CristianNessuna valutazione finora

- Banner Q3X Laser Contrast SensorDocumento33 pagineBanner Q3X Laser Contrast SensorMark R.Nessuna valutazione finora

- Fs10 R, RN Spec (Sp330c)Documento5 pagineFs10 R, RN Spec (Sp330c)theloniussherekNessuna valutazione finora

- Banner Qs30Documento12 pagineBanner Qs30alen_c405833Nessuna valutazione finora

- Banner SL-30 Series PDFDocumento6 pagineBanner SL-30 Series PDFdirkz26Nessuna valutazione finora

- Q4X Stainless Steel Analog Laser Sensor: Quick Start GuideDocumento11 pagineQ4X Stainless Steel Analog Laser Sensor: Quick Start Guidepracmci automatizacion3Nessuna valutazione finora

- Ah 00212Documento17 pagineAh 00212maithuong8567% (6)

- GXUSB1000-18GK-E5-V1 ManualDocumento3 pagineGXUSB1000-18GK-E5-V1 ManualDaniel Antonio AzócarNessuna valutazione finora

- Project ReportDocumento14 pagineProject ReportNoah100% (7)

- User's Manual - Compact Omnidirectional Laser ScannerDocumento20 pagineUser's Manual - Compact Omnidirectional Laser ScannerKia GalatiNessuna valutazione finora

- Decentlab DL SHT35 DatasheetDocumento16 pagineDecentlab DL SHT35 Datasheeteugen.lok0813Nessuna valutazione finora

- EN - Lamp Change VCP ECP HCP NP IW1 IR ENDocumento14 pagineEN - Lamp Change VCP ECP HCP NP IW1 IR ENDeniMestiWidiantoNessuna valutazione finora

- Instruction ManualDocumento8 pagineInstruction Manualana carolina PereiraNessuna valutazione finora

- SQ-2800 Manual PDFDocumento56 pagineSQ-2800 Manual PDFLuz MarinoNessuna valutazione finora

- Banner R58 Color Mark SensorsDocumento11 pagineBanner R58 Color Mark SensorsMemik TylnNessuna valutazione finora

- Sisense Xu Xukt1ksmm12-797657Documento3 pagineSisense Xu Xukt1ksmm12-797657Muhammad Noman MehboobNessuna valutazione finora

- AGLS Light Sensor: Luminance AdapterDocumento4 pagineAGLS Light Sensor: Luminance AdapterDavid MartínezNessuna valutazione finora

- Q10 Series: FeaturesDocumento4 pagineQ10 Series: FeaturesAbdalla FarisNessuna valutazione finora

- Automatic Room Light Controller With Bidirectional Visitor CounterDocumento20 pagineAutomatic Room Light Controller With Bidirectional Visitor CounterpraneethNessuna valutazione finora

- SPECTRO-UV/V-16/18: Instruction Manual ForDocumento31 pagineSPECTRO-UV/V-16/18: Instruction Manual ForArbjan RusiNessuna valutazione finora

- Minor ProjectDocumento22 pagineMinor Project205.Vyshnavi GrandhiNessuna valutazione finora

- LC-103PIMSK: Professional Passive Infrared & Microwave Detector With Anti-Mask With Pet ImmunityDocumento2 pagineLC-103PIMSK: Professional Passive Infrared & Microwave Detector With Anti-Mask With Pet ImmunityAndrei PantaNessuna valutazione finora

- LT40 UM-enDocumento9 pagineLT40 UM-enferdecoNessuna valutazione finora

- Dkg-605 Alarm Annunciator Unit: DKG-605 User Manual V-04Documento9 pagineDkg-605 Alarm Annunciator Unit: DKG-605 User Manual V-04Happy Photography Page 0Nessuna valutazione finora

- Manual-Vis Spect - Jenus V1100Documento15 pagineManual-Vis Spect - Jenus V1100bashirNessuna valutazione finora

- MP+Technical+Data enDocumento2 pagineMP+Technical+Data enRodrigo Alvarez EspejelNessuna valutazione finora

- FS-V30 31CM Im 96M11291 GB 1070-1Documento6 pagineFS-V30 31CM Im 96M11291 GB 1070-1Santi ElisahNessuna valutazione finora

- CDJ2000NXS2 RRV4645 SMDocumento82 pagineCDJ2000NXS2 RRV4645 SMQiguang WuNessuna valutazione finora

- Hikvision Day Night High-Definition Color Camera V2.1.0Documento42 pagineHikvision Day Night High-Definition Color Camera V2.1.0J.Vicente GonzálezNessuna valutazione finora

- Im PDC 360i 8 12 Mini KNX GB 1110Documento13 pagineIm PDC 360i 8 12 Mini KNX GB 1110Alex KnezNessuna valutazione finora

- Uv VisDocumento56 pagineUv VisDiego Antonio Paredes ValenciaNessuna valutazione finora

- CDJ-900NXS Service ManualDocumento143 pagineCDJ-900NXS Service ManualalexNessuna valutazione finora

- 601P (En)Documento2 pagine601P (En)Radu BucuresteanuNessuna valutazione finora

- Eye BlinkDocumento31 pagineEye BlinkPoorva Gupta67% (3)

- DS KRTL3B en P PDFDocumento8 pagineDS KRTL3B en P PDFAnonymous GGwiHdL8Nessuna valutazione finora

- Obstacle Sensed Switching in Industrial ApplicationsDocumento68 pagineObstacle Sensed Switching in Industrial ApplicationsAbhijit PattnaikNessuna valutazione finora

- Gold Spectrumlab 54Documento17 pagineGold Spectrumlab 54Korsarito100% (1)

- CONTRINEX Safety Screen CatalogDocumento23 pagineCONTRINEX Safety Screen CatalogMemik TylnNessuna valutazione finora

- Contrinex RfidDocumento51 pagineContrinex RfidMemik TylnNessuna valutazione finora

- CONTRINEX Series 600 Proximity Sensors PDFDocumento38 pagineCONTRINEX Series 600 Proximity Sensors PDFMemik TylnNessuna valutazione finora

- CONTRINEX Cable Distribution SystemDocumento19 pagineCONTRINEX Cable Distribution SystemMemik TylnNessuna valutazione finora

- CONTRINEX Fiber Optic SolutionsDocumento23 pagineCONTRINEX Fiber Optic SolutionsMemik TylnNessuna valutazione finora

- Banner Vision SensorsDocumento32 pagineBanner Vision SensorsMemik TylnNessuna valutazione finora

- CONTRINEX Capacitive Proximity SwitchesDocumento15 pagineCONTRINEX Capacitive Proximity SwitchesMemik TylnNessuna valutazione finora

- Banner STB Touch ButtonsDocumento26 pagineBanner STB Touch ButtonsMemik TylnNessuna valutazione finora

- Banner T18 Compact Photoelectric SensorsDocumento37 pagineBanner T18 Compact Photoelectric SensorsMemik TylnNessuna valutazione finora

- CONTRINEX Background Suppression SensorsDocumento17 pagineCONTRINEX Background Suppression SensorsMemik TylnNessuna valutazione finora

- Banner VALU BEAM Series SensorsDocumento48 pagineBanner VALU BEAM Series SensorsMemik TylnNessuna valutazione finora

- Banner R GAGE Radar SensorsDocumento4 pagineBanner R GAGE Radar SensorsMemik TylnNessuna valutazione finora

- Banner Midsize Photo EyesDocumento41 pagineBanner Midsize Photo EyesMemik TylnNessuna valutazione finora

- Banner PICO AMP MD14 AmplifiersDocumento8 pagineBanner PICO AMP MD14 AmplifiersMemik TylnNessuna valutazione finora

- Banner R58 Color Mark SensorsDocumento11 pagineBanner R58 Color Mark SensorsMemik TylnNessuna valutazione finora

- Banner QC50 True Color SensorsDocumento8 pagineBanner QC50 True Color SensorsMemik TylnNessuna valutazione finora

- Banner Mounting BracketsDocumento9 pagineBanner Mounting BracketsMemik TylnNessuna valutazione finora

- Banner Q45 Photoelectric SensorsDocumento11 pagineBanner Q45 Photoelectric SensorsMemik TylnNessuna valutazione finora

- Banner MINI BEAM Photo EyesDocumento37 pagineBanner MINI BEAM Photo EyesMemik TylnNessuna valutazione finora

- Banner Miniature Photo EyesDocumento20 pagineBanner Miniature Photo EyesMemik TylnNessuna valutazione finora

- Banner Measuring SensorsDocumento57 pagineBanner Measuring SensorsMemik TylnNessuna valutazione finora

- Banner Fullsize Photo EyesDocumento34 pagineBanner Fullsize Photo EyesMemik TylnNessuna valutazione finora

- Banner D10 Analog Discrete OutputsDocumento15 pagineBanner D10 Analog Discrete OutputsMemik TylnNessuna valutazione finora

- Answers Questions 3d-PrintingDocumento9 pagineAnswers Questions 3d-PrintingBongani MaphumuloNessuna valutazione finora

- Photo Diode Photo Transistor Light Dependent ResistorDocumento1 paginaPhoto Diode Photo Transistor Light Dependent Resistortntntn86Nessuna valutazione finora

- VMC260 CollimationDocumento2 pagineVMC260 CollimationJose Salvador Moral SorianoNessuna valutazione finora

- 2001 BESSY BorisenkoDocumento2 pagine2001 BESSY BorisenkoXan TolusNessuna valutazione finora

- Optical Sensors For Multi-Axis Angle andDocumento33 pagineOptical Sensors For Multi-Axis Angle andAnant PatilNessuna valutazione finora

- PN Mitsubishi dpm2340 - 072308 PDFDocumento122 paginePN Mitsubishi dpm2340 - 072308 PDFLODELBARRIO RDNessuna valutazione finora

- Sheet 1A IE304 Material TechnologyDocumento5 pagineSheet 1A IE304 Material TechnologyAhmedAhmedNessuna valutazione finora

- PresentationofcDocumento17 paginePresentationofcKavita KamerikarNessuna valutazione finora

- LanguagesDocumento4 pagineLanguagesKelly Teotonio BritoNessuna valutazione finora

- EDU OT1 M EnglishManualDocumento66 pagineEDU OT1 M EnglishManuallibra76kNessuna valutazione finora

- Andrew Britecell Plus User ManualDocumento241 pagineAndrew Britecell Plus User ManualFemi OketokiNessuna valutazione finora

- NexION 300 BrochureDocumento12 pagineNexION 300 BrochureJhamal SalazarNessuna valutazione finora

- Special Tools Kom Secc 2Documento21 pagineSpecial Tools Kom Secc 2Anonymous g1Uh7kzLvb100% (1)

- 9.4 Process AdjustmentDocumento11 pagine9.4 Process AdjustmentHugo Luis Escalante100% (1)

- 10 Science TP 10 1Documento6 pagine10 Science TP 10 1Rajput rockNessuna valutazione finora

- Ch04 Ppts Callister7e Imperfection Is SolidsDocumento32 pagineCh04 Ppts Callister7e Imperfection Is SolidsOdarie HunterNessuna valutazione finora

- Photo TransistorsDocumento15 paginePhoto TransistorsAditi JaNessuna valutazione finora

- Government College of EnggDocumento18 pagineGovernment College of EnggSanket KadwadeNessuna valutazione finora

- Radar PrinciplesDocumento49 pagineRadar PrinciplesPranayKrishnapNessuna valutazione finora

- Il 1000Documento140 pagineIl 1000Jesus Roberto RomoNessuna valutazione finora

- CHP 19Documento3 pagineCHP 19hongling240% (1)

- Solved HT ProblemsDocumento34 pagineSolved HT ProblemsRavichandran GNessuna valutazione finora

- Water Level MonitoringDocumento36 pagineWater Level MonitoringNunnaAgni TejaNessuna valutazione finora

- Is 16101 2012Documento17 pagineIs 16101 2012gayathrikanduriNessuna valutazione finora

- Film BadgesDocumento2 pagineFilm BadgesxrijlovNessuna valutazione finora

- Computer Memory Based On Protein Bacterio-Rhodopsin - Full ReportDocumento23 pagineComputer Memory Based On Protein Bacterio-Rhodopsin - Full ReportAbdul Wahid KhanNessuna valutazione finora

- Light SourcesDocumento5 pagineLight Sources123vidyaNessuna valutazione finora

- AssignmentDocumento2 pagineAssignmentUtkarsh ShrivatavaNessuna valutazione finora

- TerahertzGuidezomega Ebook PDF 1206 SR PDFDocumento84 pagineTerahertzGuidezomega Ebook PDF 1206 SR PDFrazpizdeniNessuna valutazione finora

- IEC 62471 SummaryDocumento4 pagineIEC 62471 SummaryZuhaili BZNessuna valutazione finora