Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

QP Blasting JSA

Caricato da

Mohammed MujahidDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

QP Blasting JSA

Caricato da

Mohammed MujahidCopyright:

Formati disponibili

QFM-DKN-25-01 JOB SAFETY ANALYSIS Rev: 0 Date: 19.11.

2012 Page : 1 of 6

PETROSERV LIMITED

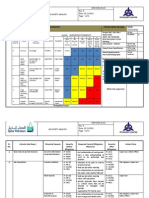

RISK MATRIX

PROJECT/JOB DETAILS

Project Ref./ Job Title / Work Order:

E Occurs several times a year at this site Low 3475 / GC 12104700

DATE: 19/11/2012

JSA No: REVISION:

INCREASING PROBABILITY

Potential Severity People Asset / Production Environment Reputation A Never heard of in industry B Has Occurred in Industry C Has Occurred in QP D Occurs several times a year in QP Low

Brief Description of job: Blasting Job Location : Dukhan Hazard Area Classification: Permit Requirements: Hot/cold/Radiography Participants(parties involved in JSA)

No Injury

No damage

No affect

No Impact

No Risk

Low

Low

Sponsoring Department: Performing Department: Permit Authority JSAApproved by

Slight injury or health effects Minor injury or health effects Major Fatality or permanent total disability Single fatality or permanent total disability Multiple fatalities

Slight damage, No disruption to operation

Slight effect

Slight impact

Low

Low

Low

Low

Low

Minor damage (=QR 250,000)

Minor effect

Limited impact

Low

Low

Medium

Medium

Medium

Major damage (=QR 1,300,000)

Localized Effect

National impact

Low

Medium

Medium

Medium

High

All the mitigation measures identified in JSA are in place before starting the activates

Major damage (=25,000,000)

Major effect

Regional Impact

Low

Medium

Medium

High

High

Work site supervisor

Extensive damage(=25,000,000)

Massive Effect

International Impact

Medium

Medium

High

High

High

Probability Factor

QFM-DKN-25-01 JOB SAFETY ANALYSIS Rev: 0 Date: 19.11.2012 Page : 2 of 6

PETROSERV LIMITED

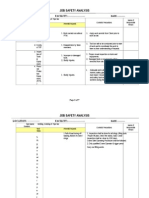

Sl. No. 1

Activity (Job Steps )

Potential Hazards

Severity Before Mitigation

P= 3C(M) A=2B (M) E= 2B(M) R= 2C(M) P= 2C (M) A= 0B (L) E= 0A(NR) R= 1B(L)

Required Control/Mitigation Measures

Get Authorization of work permit Have a clear understanding of work to be performed and location Attention to be paid on uneven terrain structure. Hold pre-job safety meeting Get Authorization of work permit Site safety rules shall be followed Hold pre-job safety meeting Check with operations Identify potential Plant Hazards i.e. (critical valves that can be knocked or damaged while passing gear or erecting & dismantling scaffold). Appropriate PPE shall be used Get Authorization of work permit Carry out gas test before entry. Use personal H2S monitor in hazardous area If required, go for continuous gas test. Maintain gas leak awareness by location and wind direction. If monitor warning actuates leave area and use a predetermined escape route across wind

Severity After Mitigation

P= 1C(L) A= 1A(L) E= 1A(L) R= 1C(L) P= 1C(L) A= 0A(NR) E= 0A(NR) R= 0B(L)

Action Party

Raise relevant permit clearance

Incorrect information on permit/clearance

Supervisor, Safety Officer

Site Preparation

Ground conditions

Supervisor.

Plant Hazards

P= 2C (M) A= 0B (L) E= 0A(NR) R= 1B(L)

P= 1C(L) A= 0A(NR) E= 0A(NR) R= 0B(L)

Exposure to Hazardous gases

P= 3C(M) A= 0A(NR) E= 0A(NR) R= 2C(M)

P= 1C(L) A= 0A(NR) E= 0A(NR) R= 1C(L)

Supervisor, Safety Officer.

QFM-DKN-25-01 JOB SAFETY ANALYSIS Rev: 0 Date: 19.11.2012 Page : 3 of 6

PETROSERV LIMITED

Transportation

P= 3C (M) A= 3C (M) E= 2C(M) R= 2C(M)

Incompetent workers

Material Handling (Manual)

P= 3C (M) A= 2C (M) E= 1C(L) R= 1B(L) P= 3C (M) A= 2C (M) E= 1C(L) R= 1B(L)

Traffic rules & regulations shall be followed Inspection and maintenance of vehicle shall be done periodically All loads transported in a pick-up (or utility) truck or other cargo vehicle shall be securely fastened and shall not exceed the manufacturers load specifications and legal limits for the vehicles Shut off the engine and hand brake shall be applied when leaving the vehicle, the driver must leave his vehicle and not return to it until the loading / unloading activity is complete. Ensure that sub-contractors shall follow traffic Rules & Regulations Ensure fire extinguisher is available in vehicle. Supervisor shall ensure that workers involved in blasting are trained & competent to carry out the work safely. Try to use trolleys or wheelbarrows if possible. If required use lifting equipment to unload materials from vehicle. Personnel shall follow proper lifting techniques When lifting a load with another person(s), communicate with the other person(s) before lowering

P= 1C (L) A= 1C (L) E= 1C(L) R= 1B(L)

Supervisor, Driver.

P= 1C (L) A= 1B (L) E= 0A(NR) R= 0A(NR) P= 1C (L) A= 0B (L) E= 0A(NR) R= 0A(NR)

supervisor

Supervisor, worker.

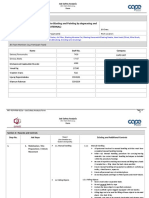

QFM-DKN-25-01 JOB SAFETY ANALYSIS Rev: 0 Date: 19.11.2012 Page : 4 of 6

PETROSERV LIMITED

your end of the load. Do not try lifting a load that is too heavy ask for help Do not twist your body while carrying a heavy load Appropriate PPE shall be used Defective Tools / Equipment P= 3C (M) A= 2C (M) E= 2C(M) R= 2B(M) Only QP approved material & Equipment shall be used for blasting operations. Ensure the respiratory equipment such as air line hose, pressure regulator, filter is free from defect. Ensure flexible hose clamps & joints for blasting is suitable for pressure rating of the system and shall be fastened. The equipment and tools are adequately grounded to prevent electrostatic charges. Supervisor shall ensure the maintenance of equipment & tools are being done periodically. Required PPE shall be used. Work shall be done by certified personnel Enclose the blasting area with sheets and post warning notice. Sprinkle water prior to blasting activity on nearby surface. Ensure continuous supply of breathing air to the blast hood. Do not leave the grit blast equipment un- attended with air P= 1C (L) A= 0B (L) E= 1B(L) R= 1B(L) Supervisor, Blaster

Blasting

Dust

P= 3C (M) A= 2B(M) E= 2C(M) R= 2B(M)

P= 1C (L) A= 1A (L) E= 1B(L) R= 1B(L)

Supervisor, Blaster

QFM-DKN-25-01 JOB SAFETY ANALYSIS Rev: 0 Date: 19.11.2012 Page : 5 of 6

PETROSERV LIMITED

supply on. Wear the required PPE (Long Sleeve Coverall, earplug, Apron, Face Shield & suitable respiratory protection etc.). Ensure proper ventilation of the area. Noise P= 3C (M) A= 0A (NR) E= 3C(M) R= 2C(M) Ear muffs / ear plugs shall be used. If possible place screens / sheets around blasting area. Maintenance of vehicle shall be done regularly Check all pipe work / equipment to be blasted is adequately grounded to prevent accumulation of electrostatic charges. Never allow any spray painting at the location; where blasting is in progress. Stop mobile compressor while fueling. Keep the suitable fire extinguishers ready Isolate the equipment from all source of energy when not in use. Fire fighting & first aid training shall be provided Supervisor shall ensure that adequate lighting is available during blasting activity. If required appropriate temporary lighting shall be P= 1C (L) A= 0A(NR) E= 1C(L) R= 1B(L) Supervisor, safety Officer

Static Electricity

P= 3C (M) A= 0A (NR) E= 0A (NR) R= 2C(M) P= 3C (M) A= 3C (M) E= 3C(M) R= 2C(M)

P= 1C (L) A= 0A(NR) E= 0A (NR) R= 1B(L) P= 1C (L) A= 1C (L) E= 1B(L) R= 1B(L)

Supervisor, safety officer

Fire & Explosion

Supervisor, safety officer

Illumination

P= 2C (M) A= 2C (M) E= 0A (NR) R= 1C(M)

P= 1C (L) A= 1A(L) E= 0A(NR) R= 1A(L)

supervisor

QFM-DKN-25-01 JOB SAFETY ANALYSIS Rev: 0 Date: 19.11.2012 Page : 6 of 6

PETROSERV LIMITED

provided.

Windup & Housekeeping

Scattered Material

P= 2C (M) A= 2C (M) E= 2C(L) R= 1C(M)

Arrange the recovery and safe disposal of spent grit/sand. Ensure proper wind up of equipment, tools & tidiness of the work area. Keep walk ways, aisle clear of materials, equipments and other items

P= 1C (L) A= 1A(L) E= 1B(L) R= 1A(L)

supervisor

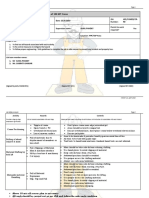

JOB SAFETY ANALYSIS Job steps: List the main sequential steps. Each step should be analyzed with the associated risk involved and its severity Alternative Considered: What are the possible means of achieving the job outcome with less risks Now undertake the JAS and record in the table above. Using JSA Hazard Checklist, Critical Question & Risk Assessment tables.

Potrebbero piacerti anche

- QP Painting JSADocumento6 pagineQP Painting JSAMohammed Mujahid100% (2)

- JsaDocumento39 pagineJsajithin shankar100% (3)

- Jsa Grit BlastingDocumento2 pagineJsa Grit BlastingHenryOdoh100% (3)

- 1 - Scaffolding WorkDocumento16 pagine1 - Scaffolding WorkPerwez21100% (14)

- Jsa Grinding W Angle GrinderDocumento2 pagineJsa Grinding W Angle GrinderMichael Angelo SanteNessuna valutazione finora

- Guide To Inspecting and Maintaining CranesDocumento8 pagineGuide To Inspecting and Maintaining CranesMohammed MujahidNessuna valutazione finora

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocumento2 pagineJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- How Chin Engineering: Job Safety AnalysisDocumento5 pagineHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNessuna valutazione finora

- Risk Assessment For Sand BlastingDocumento8 pagineRisk Assessment For Sand BlastingRochdi Bahiri71% (17)

- JSA For Working at HeightDocumento2 pagineJSA For Working at HeightXUE JIANNessuna valutazione finora

- Jsa SKDocumento10 pagineJsa SKEngr Tahir UL Haq100% (2)

- Jsa Welding Cutting and Grinding at Closing AreaDocumento7 pagineJsa Welding Cutting and Grinding at Closing AreaDedy Kurniawan100% (2)

- JSA For Welding GrindingDocumento7 pagineJSA For Welding GrindingBabar78% (9)

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocumento1 paginaJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNessuna valutazione finora

- Jsa For WeldingDocumento2 pagineJsa For WeldingMohamed Samir50% (2)

- JSA G17 Lift Container With CraneDocumento4 pagineJSA G17 Lift Container With CraneYosep Sapto Rahyudi100% (3)

- JSA 08 Gas WeldingDocumento1 paginaJSA 08 Gas Weldingmuthuswamy77Nessuna valutazione finora

- JSA Shut Down and Tie in Work PDFDocumento6 pagineJSA Shut Down and Tie in Work PDFpjosesm80% (5)

- 02.JHA-Site Survey, Between 33kV Swgr. and MV Substation For Cable LayingDocumento5 pagine02.JHA-Site Survey, Between 33kV Swgr. and MV Substation For Cable LayingFrancis Enriquez Tan100% (1)

- Jsa Lifting of PitsDocumento8 pagineJsa Lifting of PitseslamNessuna valutazione finora

- Confined Space Entry Procedure WorksheetDocumento5 pagineConfined Space Entry Procedure WorksheetToma AdrianaNessuna valutazione finora

- JSA-009 Sand Blasting - Coating 2Documento6 pagineJSA-009 Sand Blasting - Coating 2Omar DhiebNessuna valutazione finora

- JSA - Cable Trench ExcavationDocumento9 pagineJSA - Cable Trench Excavationfrancis_e_tan75% (4)

- Jsa-Jha For Using of Hand ToolsDocumento2 pagineJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- JSA-Steel Structure Erection-NDocumento4 pagineJSA-Steel Structure Erection-NVivek Naik100% (2)

- QP Cutting JSADocumento6 pagineQP Cutting JSAMohammed MujahidNessuna valutazione finora

- QP Cutting JSADocumento6 pagineQP Cutting JSAMohammed MujahidNessuna valutazione finora

- JSA Formet New Structural Steel FabricationDocumento7 pagineJSA Formet New Structural Steel Fabricationsakthi venkatNessuna valutazione finora

- Site Inspection and Test Plan For Architectural Work Rev-1Documento23 pagineSite Inspection and Test Plan For Architectural Work Rev-1Mohammed MujahidNessuna valutazione finora

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocumento9 pagineHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- JSA Blasting and Coating KP 69.4Documento5 pagineJSA Blasting and Coating KP 69.4shinto Lawrence100% (6)

- JSA For Cutting, Grinding and WeldingDocumento4 pagineJSA For Cutting, Grinding and Weldingyc safety100% (3)

- Manual Tig Welding (RRC) - Job ProcedureDocumento3 pagineManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- JSA For Coating and Raping Activity in TankDocumento7 pagineJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatNessuna valutazione finora

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocumento16 pagineSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh60% (5)

- JSA - Sand Blasting and PaintngDocumento8 pagineJSA - Sand Blasting and PaintngJohn100% (1)

- JSA - Blasting - EXTERNALDocumento13 pagineJSA - Blasting - EXTERNALAzad pravesh khanNessuna valutazione finora

- JSA For Working at HeightDocumento1 paginaJSA For Working at HeightSafety& Security Supervisor100% (1)

- CSP Exam Essential Practice Simply and Thoroughly Explained: August 2020Documento26 pagineCSP Exam Essential Practice Simply and Thoroughly Explained: August 2020Gamal Abd-ElnaserNessuna valutazione finora

- 972 99 100 (Mobile) : Job Safety AnalysisDocumento8 pagine972 99 100 (Mobile) : Job Safety AnalysisSreeraj Reghunathan Nair VanmazhyNessuna valutazione finora

- ITP For ASPHALT CONCRETE PAVINGDocumento4 pagineITP For ASPHALT CONCRETE PAVINGMohammed MujahidNessuna valutazione finora

- Crane Jsa TGPDocumento2 pagineCrane Jsa TGPSuryakant SurajNessuna valutazione finora

- Jsa For Complete Erection of Tank-001Documento52 pagineJsa For Complete Erection of Tank-001Ashutosh80% (10)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocumento17 pagineSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh0% (1)

- JHA For Tie-In at PCR14-02Documento7 pagineJHA For Tie-In at PCR14-02Francis Enriquez TanNessuna valutazione finora

- Duqm Refinery Project EPC Package One: JSA For Confined Space Rev.0Documento8 pagineDuqm Refinery Project EPC Package One: JSA For Confined Space Rev.0balasubramaniamNessuna valutazione finora

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocumento4 pagineJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- Job Safety Analysis (Rolling For MS Plates)Documento1 paginaJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- Job Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdDocumento3 pagineJob Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdTeodoro EsquilloNessuna valutazione finora

- JSA For Painting Inside TankDocumento2 pagineJSA For Painting Inside TankDilshad aliNessuna valutazione finora

- Musings On A Rodin CoilDocumento2 pagineMusings On A Rodin CoilWFSCAO100% (1)

- FINAL-ITP Earthwork-Rev. 1 13-09-2014Documento10 pagineFINAL-ITP Earthwork-Rev. 1 13-09-2014Mohammed Mujahid100% (1)

- Job Safety Analysis Sheet: FacilityDocumento1 paginaJob Safety Analysis Sheet: Facilitywahyu nugrohoNessuna valutazione finora

- Ss1169 - Telecom Frameworx l1TMFDocumento65 pagineSs1169 - Telecom Frameworx l1TMFPrince SinghNessuna valutazione finora

- Jsa For Steel Structure For Off PlotDocumento13 pagineJsa For Steel Structure For Off PlotKhuda BukshNessuna valutazione finora

- Risk Assesment For Sand Blasting and PaintingDocumento6 pagineRisk Assesment For Sand Blasting and PaintingRochdi Bahiri100% (10)

- JSA For Fab Erec of STRL Steel StackDocumento5 pagineJSA For Fab Erec of STRL Steel StackkrishnakumarNessuna valutazione finora

- Sika Saudi Arabia: Safety Data SheetDocumento4 pagineSika Saudi Arabia: Safety Data Sheetusman khalid100% (1)

- Midterm Exam StatconDocumento4 pagineMidterm Exam Statconlhemnaval100% (4)

- Spare Parts ManagementDocumento21 pagineSpare Parts Managementdajit1100% (1)

- 052 Sand BlastingDocumento2 pagine052 Sand Blastingwilson mantilla100% (1)

- FINAL-ITP For Concreting Work Rev.2 25-Oct-2014Documento12 pagineFINAL-ITP For Concreting Work Rev.2 25-Oct-2014Mohammed MujahidNessuna valutazione finora

- Construction AuditDocumento5 pagineConstruction AuditMohammed Mujahid100% (1)

- JSA-009a Drilling and Mon Well Construction-SonicDocumento4 pagineJSA-009a Drilling and Mon Well Construction-SonicDedi Apriadi83% (6)

- Barangay Tanods and The Barangay Peace and OrderDocumento25 pagineBarangay Tanods and The Barangay Peace and OrderKarla Mir74% (42)

- 4 - Hydro Jetting and Sludge RemovalDocumento18 pagine4 - Hydro Jetting and Sludge RemovalPerwez21100% (2)

- Lifting Operatio in Progress PDFDocumento1 paginaLifting Operatio in Progress PDFsubhanmusadiq100% (1)

- JHA For Blasting Painting Works FinalDocumento7 pagineJHA For Blasting Painting Works Finalrosevelvet50% (10)

- Tank Cleaning ConsiderationsDocumento1 paginaTank Cleaning ConsiderationsAdele PollardNessuna valutazione finora

- Refueling JSA 4 08 2019 Rev.03 Near WaterDocumento9 pagineRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariNessuna valutazione finora

- Ig1 Igc1 0005 Eng Obe Answer Sheet v1Documento8 pagineIg1 Igc1 0005 Eng Obe Answer Sheet v1Mohammed MujahidNessuna valutazione finora

- International Health and Safety at Work The Handbook For The NEBOSH International General Certificate 2nd Edition Paperback Routledge PDFDocumento2 pagineInternational Health and Safety at Work The Handbook For The NEBOSH International General Certificate 2nd Edition Paperback Routledge PDFMohammed Mujahid0% (1)

- Crane JSADocumento5 pagineCrane JSAPungky Tri WijayaNessuna valutazione finora

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Documento4 pagine0017 JS A Hot Job (Welding, Grinding & Cutting)Positivesolution100% (2)

- Job Safety AnalysisDocumento1 paginaJob Safety AnalysisWati KaNessuna valutazione finora

- Employee Incident Report Form 1 1Documento3 pagineEmployee Incident Report Form 1 1api-459048769100% (1)

- APPLE - Extra SaudiDocumento1 paginaAPPLE - Extra SaudiMohammed MujahidNessuna valutazione finora

- M6UMTYDocumento3 pagineM6UMTYMohammed MujahidNessuna valutazione finora

- Mohammed MujahidDocumento3 pagineMohammed MujahidMohammed MujahidNessuna valutazione finora

- Redemption Details: Your Egift Card Value Egift CodeDocumento1 paginaRedemption Details: Your Egift Card Value Egift CodeMohammed MujahidNessuna valutazione finora

- Text 2Documento1 paginaText 2Mohammed MujahidNessuna valutazione finora

- Mujahid CVDocumento8 pagineMujahid CVMohammed MujahidNessuna valutazione finora

- Arrival Registration R5932222Documento1 paginaArrival Registration R5932222Mohammed MujahidNessuna valutazione finora

- ITP For Structural Work-1Documento5 pagineITP For Structural Work-1Mohammed MujahidNessuna valutazione finora

- 10 Sustainable Development Management Plan 1Documento15 pagine10 Sustainable Development Management Plan 1Mohammed MujahidNessuna valutazione finora

- HummusDocumento4 pagineHummusMohammed MujahidNessuna valutazione finora

- Mens Black Wax Lambskin Biker Style Leather Jacket - Jild-New LeatherinnDocumento1 paginaMens Black Wax Lambskin Biker Style Leather Jacket - Jild-New LeatherinnMohammed MujahidNessuna valutazione finora

- ون مليون ONE MILLION - FLOWER FACTORYDocumento1 paginaون مليون ONE MILLION - FLOWER FACTORYMohammed MujahidNessuna valutazione finora

- Apple Watch Series 7Documento1 paginaApple Watch Series 7Mohammed MujahidNessuna valutazione finora

- UMRAH GuideDocumento23 pagineUMRAH GuideAnggi WardhaniNessuna valutazione finora

- Aqeeda of Tableegh Jamaat - Najdi Shaitan.Documento9 pagineAqeeda of Tableegh Jamaat - Najdi Shaitan.Tariq Mehmood Tariq0% (1)

- 965 CapDocumento29 pagine965 CapMohammed MujahidNessuna valutazione finora

- Cooking Time: 15-20 Minutes Servings: 4: Sprouted Moong KhichdiDocumento2 pagineCooking Time: 15-20 Minutes Servings: 4: Sprouted Moong KhichdiMohammed MujahidNessuna valutazione finora

- Elb v2 ApiDocumento180 pagineElb v2 ApikhalandharNessuna valutazione finora

- Computer System Sevicing NC Ii: SectorDocumento44 pagineComputer System Sevicing NC Ii: SectorJess QuizzaganNessuna valutazione finora

- Sem 4 - Minor 2Documento6 pagineSem 4 - Minor 2Shashank Mani TripathiNessuna valutazione finora

- Ks 1609Documento5 pagineKs 1609krish dabhiNessuna valutazione finora

- Chap 06 Ans Part 2Documento18 pagineChap 06 Ans Part 2Janelle Joyce MuhiNessuna valutazione finora

- Strength and Microscale Properties of Bamboo FiberDocumento14 pagineStrength and Microscale Properties of Bamboo FiberDm EerzaNessuna valutazione finora

- Statable 1Documento350 pagineStatable 1Shelly SantiagoNessuna valutazione finora

- Tle 9 Module 1 Final (Genyo)Documento7 pagineTle 9 Module 1 Final (Genyo)MrRightNessuna valutazione finora

- AdvertisingDocumento2 pagineAdvertisingJelena ŽužaNessuna valutazione finora

- Cara Membuat Motivation LetterDocumento5 pagineCara Membuat Motivation LetterBayu Ade Krisna0% (1)

- ADS Chapter 303 Grants and Cooperative Agreements Non USDocumento81 pagineADS Chapter 303 Grants and Cooperative Agreements Non USMartin JcNessuna valutazione finora

- Vocabulary Practice Unit 8Documento4 pagineVocabulary Practice Unit 8José PizarroNessuna valutazione finora

- Apst GraduatestageDocumento1 paginaApst Graduatestageapi-253013067Nessuna valutazione finora

- Expected MCQs CompressedDocumento31 pagineExpected MCQs CompressedAdithya kesavNessuna valutazione finora

- Tecplot 360 2013 Scripting ManualDocumento306 pagineTecplot 360 2013 Scripting ManualThomas KinseyNessuna valutazione finora

- Fin 3 - Exam1Documento12 pagineFin 3 - Exam1DONNA MAE FUENTESNessuna valutazione finora

- To Syed Ubed - For UpdationDocumento1 paginaTo Syed Ubed - For Updationshrikanth5singhNessuna valutazione finora

- Eclipsecon MQTT Dashboard SessionDocumento82 pagineEclipsecon MQTT Dashboard Sessionoscar.diciomma8446Nessuna valutazione finora

- Completed NGC3 ReportDocumento4 pagineCompleted NGC3 ReportTiCu Constantin100% (1)

- Enumerator ResumeDocumento1 paginaEnumerator Resumesaid mohamudNessuna valutazione finora

- POM 3.2 Marketing Management IIDocumento37 paginePOM 3.2 Marketing Management IIDhiraj SharmaNessuna valutazione finora

- Scheme Bidirectional DC-DC ConverterDocumento16 pagineScheme Bidirectional DC-DC ConverterNguyễn Quang KhoaNessuna valutazione finora

- Chapter03 - How To Retrieve Data From A Single TableDocumento35 pagineChapter03 - How To Retrieve Data From A Single TableGML KillNessuna valutazione finora

- For Email Daily Thermetrics TSTC Product BrochureDocumento5 pagineFor Email Daily Thermetrics TSTC Product BrochureIlkuNessuna valutazione finora