Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Self Cleaning Basket Strainers

Caricato da

Bossman Instruments TechnologyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Self Cleaning Basket Strainers

Caricato da

Bossman Instruments TechnologyCopyright:

Formati disponibili

R

Bossmanfilter

Ultimate in Filtration & Purification Technology

Self Cleaning Basket Strainer

Filtering Process : The water flow through the cylindrical filter element inside-out, creating minimum pressure loss. During accumulation of filtration cake on inner surface of the screen,pressure loss is created accordingly. Cleaning Process : When the pressure drop between the inlet and outlet of the filter reached 0.5 bar,cleaning of the filtration cylinder is operated automatically.This operation consists of opening an exhaust valve located on the housing lid and starting the electric motor which revolving brushes and flushed out through the open exhaust valve.The cleaning duration is around 15 seconds.The service flow of the filtered water is continuous during the cleaning cycle.

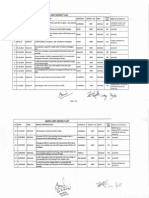

Self Cleaning Basket Strainer Matl - Carbon Steel ( Horizontal Type )

Self Cleaning Basket Strainer Matl - Stainless Steel ( Horizontal Type )

Technical Specifications

ss m

* Design pressure: 10 or 16 Bar. * Minimum working pressure 1 Barg. * Maximum temperature: 200 . * Control & Power supply- 220/440V AC, 50/60 Hz ,Three phase. * Delta P , Timer control with Manual flushing. * Applications: -Water supply systems. -Cooling water. -Waste water. -Fuel oil,crude oil. In : oil refinery ,power plant,steel mill , pulp & paper,etc.

an

fil t

D1

2 2 3 4 6 8 10 12 14 16 20 24

Control System : The differential pressure switch transmits an electric signal to the electric control board when the pressure differential across the screen reached the pre-set value.The control board activates the motor and opens the exhaust valve.If due to some fault the pressure drop over the filter is not eliminated by cleaning,the interval between successive cleaning operations is limited by control board to a minimum of 5 minutes.

* Flow rates up to 1200 m3 /H * Size 2 ~ 14. * Reduce maintenance costs on down stream equipment. * Filter area 3000,6000,8000,1000 cm2. * No interruption of flow during flushing. * Wedge wire screen AISI 316 L . * Stainless Steel 304,316,316L construction. * Filtration Degree: From 3500 ~ 50 Micron. * Suitable for high load filtration requirements and heavy duty conditions. * Minimum waste water :less than 1% of total flow .

er

C

15 15 20 19 27 32 39 46 50 53 88 122

Model

A

21 21 25 27 32 40 50 58 59 61 94 140

B

12 12 16 17 20 24 30 36 38 40 64 62

D

5 5 8 10 10 11 13 15 16 19 22 32

D2

1 1 2 2 2 3 4 4 4 4 6 8

E

8 8 9 10 10 12 14 15 16 19 28 36

F

41 41 44 52 58 78 87 100 99 120 152 186

BOSS-SLF 50 BOSS-SLF 65 BOSS-SLF75 BOSS-SLF100 BOSS-SLF150 BOSS-SLF200 BOSS-SLF250 BOSS-SLF300 BOSS-SLF350 BOSS-SLF400 BOSS-SLF500 BOSS-SLF600

Weight LBS 60 73 90 105 172 230 370 425 650 950 3420 4840

LPM min - max

133 - 750 133-750 250 - 1333 666 - 2100 833 - 4975 1666 - 8330 2666 - 13328 3332 - 18326 4998 - 24990 6664 - 33320 13328 - 49980 19992 - 66640

Flushing Volume

1.3 1.6 1.7 2 4 11 25 46 54 94 198 281

Flush outlet

G - Height for removing Strainer

Bo

A F

Bossmanfilter reserves the right to modify, in any moment technical details without notice. Accessories shown in the pictures are not a part of the equipments

Inlett outlet

B

Ordering Example : B3000 - Closer Style - Pressure - Dsgn Std - Mesh Size - Seals Type - Accessories B3000 - LS 04 A 80 - 001 G0

Closure Style LS Blind Flange SW Blind Flange with Swing Arm Assist Working Pressure 01 PN 10 or 150 PSI 02 PN 16 or 232 PSI 03 PN 25 or 362 PSI 04 PN 40 or 580 PSI Dsgn Std A - ASME B - DIN STD C - EN STD Mesh Size 10 10 Mesh 20 20 Mesh 40 40 Mesh 80 80 Mesh Elastomer Seals 001 - Buna - N 002 - Silicon 003 - Viton 004 - Others Miscellaneous Options G0 - Not Required G1 - Differential Pressure G2 - Other Gauge

B2000 Series- Offset Single Basket Strainer

For further details,Please contact

Bossmanfilter

Ultimate in Filtration & Purification Technology

Bossman Instruments Technology

An ISO 9001:2008 Certified Company

No. 401/2, G/8 (A), Swastik Manandi Arcade,Ground Floor, S.C. Road, Bangalore - 560 020. INDIA . Ph : 91-80-2346 3313, Telefax : 91-80-2346 3313 Web site : www.bossmaninternational.com , www.bossmanfilter.com , E-mail : bossmanfilter@bossmaninternational.com,info@bossmanfilter.com

Potrebbero piacerti anche

- Pre FiltersDocumento1 paginaPre FiltersBossman Instruments TechnologyNessuna valutazione finora

- Hydraulic FiltersDocumento1 paginaHydraulic FiltersBossman Instruments TechnologyNessuna valutazione finora

- Compact Heatless Air DryersDocumento1 paginaCompact Heatless Air DryersBossman Instruments TechnologyNessuna valutazione finora

- Bag Filters G4Documento1 paginaBag Filters G4Bossman Instruments TechnologyNessuna valutazione finora

- Automatic Control ValvesDocumento1 paginaAutomatic Control ValvesBossman Instruments TechnologyNessuna valutazione finora

- Basket StrainersDocumento1 paginaBasket StrainersBossman Instruments TechnologyNessuna valutazione finora

- Duplex StrainersDocumento1 paginaDuplex StrainersBossman Instruments TechnologyNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Wind Energy Systems ClassificationsDocumento16 pagineWind Energy Systems ClassificationsSubheesh KTNessuna valutazione finora

- Report Nova VarosDocumento75 pagineReport Nova VarosSrbislav GenicNessuna valutazione finora

- Biomass To Bioethanol - Second Generation Technology by PrajDocumento38 pagineBiomass To Bioethanol - Second Generation Technology by Prajjpsingh75Nessuna valutazione finora

- 13 Stoic ProbDocumento3 pagine13 Stoic ProbdeNessuna valutazione finora

- Failure Evaluation On A High-Strength Alloy SA213-T91 Super Heater Tube of A Power GenerationDocumento6 pagineFailure Evaluation On A High-Strength Alloy SA213-T91 Super Heater Tube of A Power Generationabet_singkong8930Nessuna valutazione finora

- Dragsted History Booklet 2013Documento98 pagineDragsted History Booklet 2013ozakyusNessuna valutazione finora

- Building Envelope Audit: Naufal Aulia Aziz Teknik Fisika, Institut Teknologi BandungDocumento16 pagineBuilding Envelope Audit: Naufal Aulia Aziz Teknik Fisika, Institut Teknologi Bandungmalikakbaar0% (1)

- Meeting With Dr. MushtaqDocumento6 pagineMeeting With Dr. MushtaqashianamNessuna valutazione finora

- Cisco CSR ReviewDocumento4 pagineCisco CSR ReviewVikram JeetNessuna valutazione finora

- Tanaji Jadhav: Project EngineerDocumento2 pagineTanaji Jadhav: Project EngineerTanaji JadhavNessuna valutazione finora

- GEOG1016: Non-Renewable and Renewable ResourcesDocumento62 pagineGEOG1016: Non-Renewable and Renewable ResourcesChing LeoNessuna valutazione finora

- Chemical Kinetics Type 1Documento32 pagineChemical Kinetics Type 1DeependraNessuna valutazione finora

- Fta Eta Hazop ExerciseDocumento3 pagineFta Eta Hazop ExerciseMarouane AdamNessuna valutazione finora

- Two-Axis Solar Tracker Analysis and Control For Maximum Power GenerationDocumento6 pagineTwo-Axis Solar Tracker Analysis and Control For Maximum Power GenerationIonDodonNessuna valutazione finora

- Overpressure Protection and Relief Valves: Process Training School 2004/5Documento62 pagineOverpressure Protection and Relief Valves: Process Training School 2004/5Ekundayo JohnNessuna valutazione finora

- 4 Hydro Power LDocumento76 pagine4 Hydro Power LTibebu MerideNessuna valutazione finora

- The Role of Hydropower in MyanmarDocumento8 pagineThe Role of Hydropower in MyanmarKo NgeNessuna valutazione finora

- Basics Steam BoilersDocumento29 pagineBasics Steam BoilersZia Ul HassanNessuna valutazione finora

- Gas WeldingDocumento6 pagineGas WeldingEdggar PiinelittopNessuna valutazione finora

- அறிவியல் ஆண்டு 5 மணவோட்டவரைவுDocumento41 pagineஅறிவியல் ஆண்டு 5 மணவோட்டவரைவுvargan_ramoNessuna valutazione finora

- Geothermal Energy Development in The Philippines: Country UpdateDocumento9 pagineGeothermal Energy Development in The Philippines: Country Updatejenixson tamondongNessuna valutazione finora

- Shell and TubeDocumento66 pagineShell and TubeEdgar Enrique Diaz Marquina0% (1)

- ManualDocumento108 pagineManualCamiloNogueraRiascosNessuna valutazione finora

- Industrial Training Template BasicsDocumento65 pagineIndustrial Training Template BasicsFaiz IbrahimNessuna valutazione finora

- Defects Captured During RRTDocumento37 pagineDefects Captured During RRTdreamboy87Nessuna valutazione finora

- HindalcoDocumento29 pagineHindalcoTANVEER AHMED100% (1)

- Ventilation FanDocumento7 pagineVentilation FanadamzulkarnainNessuna valutazione finora

- Durst Malz Case StudyDocumento3 pagineDurst Malz Case StudyHamada KhamisNessuna valutazione finora

- Microgrid Controller 600 en LR (Dic2013)Documento16 pagineMicrogrid Controller 600 en LR (Dic2013)riki187100% (1)

- Group 06 Assignment 2Documento28 pagineGroup 06 Assignment 2Amna ArifNessuna valutazione finora