Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Risk Manag. Policy 2

Caricato da

Samantha WilliamsDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Risk Manag. Policy 2

Caricato da

Samantha WilliamsCopyright:

Formati disponibili

POLYBRITE RISK MANAGEMENT POLICY

MUHAMMAD TAHIR LIAQUAT

SUPERIOR UNIVERSITY LAHORE

2011

COMPANYS PORTFOLIO To discover & and to check the business risk severity of the Manufacturing concern / branded industrial products (industrial products are those products which are used by manufacturers) we choose industrial brand POLYBRITE which are the pioneer manufacturer of Master batches, Free Flow in Pakistan (used in plastic industry, medicine manufacturer, manufacturer of bottles, manufacturer of shoes industry and Tyre industry, plastic bags, computer manufacturer as well as automotive, consumer products, and in electronics appliances and in packaging and fiber products etc as a coloring material). POLYBRITE was established in early nineties with the technical assistance of Euro base multinational and has specialized in development & manufacturing of colors in all forms i.e. Master batches, Free Flow Colorants and Compounds. metric tons POLYBRITE (500 MT) per have month manufacturing capacity of Five hundred comprises of two manufacturing units in Lahore. In current period POLYBRITE is working on his half capacity due to energy crisis in Pakistan and due to recession in the economy worldwide. POLYBRITE major market is divided into two category i.e. local market and foreign market or export. POLYBRITE also has research & development facility due to which they are able to develop the material or Master batch according to the specification of the market or customer needs. POLYBRITE market share in local market is almost forty five percent. POLYBRITE also has a variety of product which is classified according to the standards or quality and price. POLYBRITE also a big user of waste recycles (plastic material which can be reprocessed and can be used in other form) and also involved in the trading of various types of plastic raw material and additives in Lahore. POLYBRITE uses the forward integration policy (forward integration policy is a policy in which manufacturer sold his product directly to the user or consumer of the product) in marketing because of the nature of the products and

to maintain or facilitate our customer about the best utilization of his product & To increase the efficiency of marketing department POLYBRITE also establish his factory outlets in local market as well as in the foreign markets. POLYBRITE also a large scale exporter with the name of COLOUR LINE. The major market of COLOUR LINE is UAE, Australia, England, USA and Canada. COLOUR LINE also adopts forward integration policy in his marketing strategy. The major competitor in this industry is Clariant company. which is a multinational Clariant is considering a

If we want to measure the success of the POLYBRITE brand we can observed that the business forecasting, and efficient business decisions making & superior marketing strategy according to the nature of the brand play a vital role in the success of Business. The most competitive advantage POLYBRITE has over his competitors is research and development facility, quality & Standard of product and marketing forward integration policy (forward integration policy is a policy in which manufacturer sold his product directly to the user or consumer of the product) and the human resource management (job specialization policy putting the right person on the right place according to his capabilities). After my swot analysis the human resource management is the backbone of the success of POLYBRITE brand because it is not easy to handle industrial brand and target market of the industrial brand & to maintain the standard and quality of the industrial product which requires extra efforts and commitment of the employees to compete with the market competition and to survive in the market which is

market leader of this Master batch industry because of his standard, quality, price and distribution network all over the world. Clariant gives a tough competition to the local manufacturer of Master batches in Pakistan and India and U.A.E as well as in the local and foreign markets last five years. POLYBRITE and other manufacturer of Master batches compete with Clariant by offering credit facility to our business customers and other distribution dealers to survive and to maintain his market share of the business.

achieved management

by

the through

POLYBRITE his efficient

High Market Shares Quality Products Customers Satisfaction Technically business Advantage

decisions making, future forecasting and innovations in the Master batch industry. COMPANYS VISION To be the leader in the field of Master batches and Compounds through constant growth and innovation this will be achieved by putting every effort to ensure the growth of our customers COMPANYS MISSION To be the most technically advanced manufacturer of Master batches and Compounds ensuring the highest quality at the most economical prices. There will be a constant drive in us to continuously improve processes, R & D and technology. To our business we stakeholders a and customers, promise mutually

PRODUCTS & APPLICATIONS At POLYBRITE, we manufacture master batches catering to the all of the following processing methods: Bi-axially Oriented Film Blow Molding Blown Film Cast Film Continuous Filament/Spinning Double-Bubble Film Extrusion Blow Molding Extrusion Coating Extrusion Film Extrusion Flat Films (T-Die) Extrusion Fiber spinning (POY / FDY) Injection Molding Oriented Flat Film Pipe Extrusion Profile Extrusion Raffia (Woven Sacks) Sheet Extrusion

beneficial business relationship. To our employees we shall offer a pleasant working environment with positive reinforcements for tasks well performed. Together, we will grow with the promise to be successful in all our future endeavors. COMPANYS STRATGIC GOALS Market Leader

Spun Bonded Non Wovens Thermoforming

batches for various exterior & interior parts of the car/trucks such as Dashboards Bumpers Armrests grip handles consoles Other interior decoration etc

The main principle of manufacturing the master batches to facilitate the industrialist from coloring point of view and to control dust & safety measures for health Agriculture: The agricultural business is a major consumer of plastics with a very diverse range of applications. These applications cover the entire value chain from, for instance, soil conditioning to packaging of foodstuffs. such as: Mulch Films Geomembranes Drip Irrigation Irrigation Pipes Water Sprinklers Greenhouse films Agrotextiles You will find our masterbatches in various end applications

Infrastructure, Construction & Road Traffic Indicators: As Pakistan progresses the use of plastics in this sector is continuously increasing at a much faster pace. We supply master batches that are used for producing: Roofing Geomembranes Geotextiles Drainage Water & Gas pipes Tanks (Chemicals & Water) Barricades Dividers Manhole covers Tarpaulins

Automotive: To make the cars more fuel efficient & safer there has been an increasing use of plastics in cars. We can supply master

Consumer Products: This is something that anyone can relate to. Even without knowing we use umpteen numbers of products which are made out

of plastics. To make the product more attractive, producers use coming up with more & more colorful solutions to entice customers. From toothbrushes to your telephones and TV cabinets every plastic item is colored using master batches. A few of the various items in which you will find our master batches are as follows through which you can easily understand: Buckets, Bottles, toys etc. Disposable Trays, cups & cutlery Filing cabinets, pens Television, Air conditioners etc. Toothbrush, Hair dryers

of shampoo brands in a consumer store? One of the key factors affecting your decision would be the attractive packaging. As the retail concept is now taking place there is tremendous onus on attractive packaging. This pushes master batch and film manufacturers into innovation and developments of new concepts. You will find our master batches Raffia (Woven sacks) FIBC (Flexible Intermediate Bulk Containers) / Jumbo Bags Drums, Shopping bags Tubes Containers (for food items) Jerry Cans Caps & Closures Material Handling (Pallets/Crates/Holders) Bottles (shampoo/cosmetics) Jabla Bags Liners Protective films PET bottles

Electrical: Ever wondered the wires in your house are made of what? Yes, it is plastics. Electrical wires are coated in plastic to prevent conduction of electricity to people or other metallic and conductive materials. Plastic is also flexible and will bend around tight corners and through narrow spaces We supply master batches for various electrical applications such as : Wires & Cables, Switchboards Packaging: It is packed with potential. What would make you differentiate between numbers

Healthcare, Hygiene & Medicine: Non-woven fabrics are extensively used in disposable medical garments. Doctors and

nurses

around

the

world

wear

the

Ropes Textiles

disposable facemasks which are made from non woven fabrics. We manufacture master batches for applications such as : Disposable masks Bottles (for storing medicines) Sanitary napkins Diapers Disposable headrests

ACCREDITIONS AND AFFILIATION ISO 9001:14000 Certification UKAS Conformance to standards and making standardization a way of life is an integral part of our working environment. Our ISO 9001:14000 certification is a proof of our commitment to quality and Working Place environments which we adopt in our org. Affiliations and Memberships At POLYBRITE, we understand the value of being associated to organizations that work for the good of the industry. Here are a few organizations that we are a member of and work closely with, to share and exchange information and help promote the importance of plastics.

1)

Fibers: You may not have realized that the handle of the school bag that you were carrying all those years or the seat belt in your car was made of plastics. Multifilament yarns which are dope dyes using color master batches are woven to form these. We have been suppliers of master batches for end uses such as: Stitching threads Narrow woven fabrics Handles Luggage belts Socks Webbing belts Fishing nets Filter cloth

4) 5)

Organization of Plastic Processors of India (OPPI) Indian Plastics Institute (IPI) Plastics & Linoleum Export Promotion Council of India (PLEXCONCIL) Platindia Foundation Society for Plastics Industry, USA

2) 3)

6) 7)

Society of Plastics Engineers, USA Lahore Chamber of Commerce

competitors in the line of machinery & Equipments and to to maintain survive his and technology & technical edge over his

POLYBRITE also have many other membership associations to of Engineering compete with the

competitors

increase to increase his market.

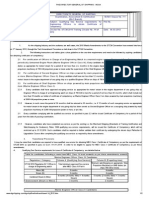

List of trustworthy Customers L o c a l l y Customers ___ 1). ___ 2). ___ 1). ___ 3). ___ 4). ___ 5). ___ 6). ___ 7). ___ 8). ___ 9). ___ 10). ___ 15). ___ 11). ___ 12). ___ 13). ___ 14). ___ 16). ___ 17). ___ 18). ___ 19). Services Industries Footwear Firhaj Footwear Industries (Hush Puppies) Stylo Shoes Industries. Pak China (Ali Akbar Group) Four Brothers (4Bs Group) Synthetic Products Enterprise Limited (SPEL) ICI Chemical Industries Descon Chemical Industries (Polybrite Customer & Supplier) NAYYER Group Of Ind. GOURMET (Bakers & Foods) MASTER Ballpoint Ind. BIO AMLA Ind. WELCON Chemical Industries (formerly Known as Warda pesticides) Automotive Components (Pvt.) Ltd. (Supplier of Atlas Honda) Lucky Plastic (Manufacturer of Plastic Furniture etc.) BURHANI STS Ind. Karachi KOLACHI International Ind. COASTAL SYNTHETICS FINE CRYSTOPLASTS (Formerly Known as FINE GAS) BTS Plastic (Manufacturer of Homeopathy Medicies in Pakistan)

___ 20). ___ 1). ___ 2). ___ 3). ___ 4). ___ 5).

Steel Craft Industries (Manufacturer of BML Motorcycles) Foreign Customers USA UAE Canda Australia England BUSINESS SWOT ANALYSIS

Strength of Business ___ 1).Technologically & Technical Edge ___ 2).Customer Satisfaction ___ 3).Quality and Standard ___ 4).Research & Development Facilities ___ 5).Business Credit Policy ___ 6).Trustworthy Customers ___ 7).Trustworthy Suppliers ___ 8).Skilled Labour of Masterbatch ___ 9).Business Exports ___ 10).Business Manufacturing Capacity ___ 11).Recycling Waste facilities ___ 12).Variety of Products / Price Levels according to Standard Weaknesses of Business ___ 1).Financial force ___ 2).Business Decisions Policy ___ 3).Business Credit Policy ___ 4).No Succession Business Policy ___ 5).Employee Turnover

___ 6).Less healthy Working Environment ___ 7).Employee Motivation Concerned ___ 8).High Small & Medium Customers Turnovers ___ 9).Not Potentional Usage of Manufacturing Capacity ___ 10).Facing Energy Crisis ___ 11).Long Term Decision Making ___ 12).Business Achievements ___ 13).Not Best focus on Local Market Shares BUSINESS SWOT ANALYSIS Opportunities of Business ___ 1).Master batches Demands i-e. Local & Foreign ___ 2).Pending Business Customer Orders\Purchase Orders ___ 3).Market Leader ___ 4).Increase Business Productivity ___ 5).Fruitful Usage of Skilled Labour ___ 6).Best Utilization of Waste Recycling Capacity ___ 7).Product & Price Diversity ___ 8).Reduced Local Customers Turnover ___ 9).Strength Business Financial Force through Capital Market Institutions ___ 10).Explore new Potent ional Buyer of Master batches ___ 11).Fruitful Utilization of technology & Technical Business Edge ___ 12).High POLYBRITEs Product Applications Threats of Business ___ 1).Business Competitors ___ 2).Up & Down in Cost of Goods Sold (Raw Material) ___ 3).Govt. Taxation Policy (Removal of Zero Rated Tax Policy) ___ 4).Lack of Research & Development Govt. Facilities / Facilities

___ 5).Skilled Labors Turnover ___ 6).Less Govt. Facilities for Exporters ___ 7).Energy Crisis (Electricity and Gas) ___ 8).Recession in Business World ___ 9).High Cost of Capital in Pakistan ___ 10).Threat from Business Credit Policy ___ 11).Product Quality and Standard ___ 12).Political Instability results Short term planning and decisions making ___ 13).Unstable Per unit Price affecting Business Contracts. Why I have chosen POLYBRITE for business risk assessment policy??? ___ 1).The major theme behind this that I want to do some more practical work other than to create fiction or estimation about sample / selected Organization because I have some business exposure in POLYBRITE which I have gain during job by working as a Accounts Officer. ___ 2).Another smart objective to chose POLYBRITE is industrial branded product I want to identified, measurement and evaluation of business risks & challenges facing by the manufacturing brands and want to differentiate from the other types of organizations ___ 3).The another major objective is to identify what types of business challenges facing by the best local organizations in Pakistan and what types of business threats facing by these local organizations as I mentioned in Business SWOT Analysis above. ___ 4).I also wants to identified and evaluate the day to day business Operational issues facing by best local business organizations in Pakistan or want to discover the local businesses planning and decision making in terms of long term & short term. ___ 5).From Business Customers we can also evaluate the business success of any particular business by choosing that organization I want to identified & estimate business customer policy and business Succession policy of the organization that playing a vital role in the success of POLYBRITE business.

___ 6).We also chose POLYBRIT to know, what are the main reasons of Customers Confidence on the organization ___ 7).To discover what types of planning the organization have to achieve his organizations vision, mission statements as well as organizations smart goals. ___ 8).In Last the most important for organizations what are the major reasons of employees turnover as well as local customers turnover in best local organization as I also stated in the weaknesses and threats of business(SWOT Analysis). Keeping in view the all above points in mind I try my best to write fruitful risk assessment policy that helpful to me and for my organization in future for better decisions making.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Handbook On Productivity 2015 PDFDocumento30 pagineHandbook On Productivity 2015 PDFHélio René Lopes da RochaNessuna valutazione finora

- Auce10082 11 PDFDocumento9 pagineAuce10082 11 PDFBabar AliNessuna valutazione finora

- Accenture Goods and Service TaxDocumento20 pagineAccenture Goods and Service Taxagarwal.rmNessuna valutazione finora

- Raisoni Industrial Hinjewadi Mechanical CopaniesDocumento5 pagineRaisoni Industrial Hinjewadi Mechanical CopaniesGp MishraNessuna valutazione finora

- Technical Development Program For Process Performance Engineers, 2008-2009Documento20 pagineTechnical Development Program For Process Performance Engineers, 2008-2009vikubhardwaj9224Nessuna valutazione finora

- Scientific Glass EquipmentDocumento28 pagineScientific Glass EquipmentJuan P RuizNessuna valutazione finora

- Vaisakh Resume of Mechanical Project Engineer With Five Years ExperienceDocumento3 pagineVaisakh Resume of Mechanical Project Engineer With Five Years ExperienceEngr Tahir UL HaqNessuna valutazione finora

- Work Instruction - Loading-TamilDocumento28 pagineWork Instruction - Loading-Tamilshanmugam86100% (2)

- Chapter 11Documento11 pagineChapter 11poNessuna valutazione finora

- A Review of Steel Production and Consumption in South American Countries, Other Than BrazilDocumento29 pagineA Review of Steel Production and Consumption in South American Countries, Other Than BrazilJorge MadiasNessuna valutazione finora

- A3 Civil WorksDocumento28 pagineA3 Civil WorksNonsoufo ezeNessuna valutazione finora

- Care LabellingDocumento26 pagineCare LabellingShashi PrakashNessuna valutazione finora

- Cement Concrete PavementDocumento8 pagineCement Concrete Pavementgtarun22guptaNessuna valutazione finora

- ArchitecturalDocumento51 pagineArchitecturalShoukat Ali Shaikh0% (1)

- CIVIL Daily Construction Report DCR FormatDocumento6 pagineCIVIL Daily Construction Report DCR FormatXozanNessuna valutazione finora

- PlasticDocumento48 paginePlasticRaihanHaronNessuna valutazione finora

- Cross Laminated Timber CEUDocumento12 pagineCross Laminated Timber CEUHasan Žera TalićNessuna valutazione finora

- Stock ShapesDocumento12 pagineStock ShapesandhikabpNessuna valutazione finora

- CHAPTER 1 - History of Kaizen & Lean ManagementDocumento8 pagineCHAPTER 1 - History of Kaizen & Lean Managementsam100% (1)

- Topic 1: Production Possibility Frontiers (PPF/PPB)Documento21 pagineTopic 1: Production Possibility Frontiers (PPF/PPB)some oneNessuna valutazione finora

- Rumusan 3Documento42 pagineRumusan 3Den limboongNessuna valutazione finora

- Quality Engineering Operations Director in Toledo OH Resume Kelly OkdieDocumento2 pagineQuality Engineering Operations Director in Toledo OH Resume Kelly OkdieKellyOkdieNessuna valutazione finora

- Welding Metalwork Fabrication Services Sample ProposalDocumento9 pagineWelding Metalwork Fabrication Services Sample ProposalDouglas OngomNessuna valutazione finora

- China Outsourcing Magazine Interview With Mr. Gagan SabharwalDocumento7 pagineChina Outsourcing Magazine Interview With Mr. Gagan SabharwalNASSCOMNessuna valutazione finora

- Me Troll Brochure 2017Documento44 pagineMe Troll Brochure 2017KantishNessuna valutazione finora

- AllaboutDocumento13 pagineAllaboutRohan JindalNessuna valutazione finora

- Ultra Thin WhitetoppingDocumento36 pagineUltra Thin WhitetoppingAnil Kumsr T B100% (1)

- Material Requirement PlanningDocumento13 pagineMaterial Requirement PlanningAhsan IftikharNessuna valutazione finora

- Class 1 Sea TimeDocumento2 pagineClass 1 Sea TimeAnonymous 4ylE57C6Nessuna valutazione finora

- The Next Generation of Manufacturing Automation It's All About ProductivityDocumento9 pagineThe Next Generation of Manufacturing Automation It's All About ProductivityDeddy SagalaNessuna valutazione finora