Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fluid Power Application - Introduction

Caricato da

Darnalis A RahmanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fluid Power Application - Introduction

Caricato da

Darnalis A RahmanCopyright:

Formati disponibili

UNiSEL (KMD 3133)

Fluid Power Application

Hydraulics & Pneumatics KMD 3133

By,

Mohd Darnalis A.Rahman

dARNALis

What is Fluid Power?

Deals with the generation, control, and transmission of power using pressurized fluids. The muscle that moves industry. Most modern machines driven by it. Applications,

fluid power steering & brakes automobiles, drives machine tools, controls airplanes, moves earth (excavation), even drills teeth.

dARNALis 2

Fluid Transport? or Fluid Power?

Should be realized that there are actually 2(two) different types of fluid systems.

1.

Fluid transport

Sole objective is to deliver a fluid from one location to another to accomplish some useful purpose.

2.

Fluid power

Designed specifically to perform work.

dARNALis

darnalis '10

UNiSEL (KMD 3133)

Fluid Power

The work is accomplished by a pressurized fluid acting on a fluid cylinder or fluid motor.

A fluid cylinder produces a force. A fluid motor produces a torque. Fluid cylinders & motors provide the muscle to do desired work.

dARNALis

Fluid Power - History

Known as hydraulics & pneumatics due to the working fluid can either be liquid or gas. Working on the Pascals Law

Pressure is transmitted undiminished in a confined body of fluid Pascal found that when he rammed a cork into a jug completely full of wine, the bottom of the jug broke and fell out.

dARNALis

Fluid Power - History

Pressure Acting Area 1

Acting Area 2 Pressure Transmitted

Pascals law indicated that the pressures were equal at the top and bottom of the jug, however, the jug has a small opening area at the top and a large area at the bottom, thus the bottom absorbs greater force due to its larger area.

dARNALis 6

darnalis '10

UNiSEL (KMD 3133)

Fluid Power - History

While Bernoulli developed his law of conservation of energy for a fluid flowing in a pipeline. Pascals & Bernoullis law is the working principle of all fluid power applications and are used for analysis purposes.

dARNALis

Fluid Power Hydraulics

Hydraulics Systems

Uses liquids such as mineral oils, water, synthetic oils, even molten metals. Water was the 1st hydraulic fluids Not very suitable due to several deficiencies, such as freezes, poor lubricant & corrosive characteristics. Oils are superior and widely used. Liquids provides very rigid medium (uncompressible) for transmitting power & thus provides huge forces moving loads (with accuracy & precision)

dARNALis

Fluid Power Pneumatics

Pneumatics Systems

Uses air as the gas medium due to abundant supply and can be readily exhausted to the atmosphere. Other gasses are not favorable due to cost, efficiency reasons but might be considered for special/critical purposes, should there be. Gas exhibits spongy characteristics due to compressibility of gas. However it is less expensive to build, operate & maintained.

dARNALis 9

darnalis '10

UNiSEL (KMD 3133)

Applications

dARNALis

10

Applications

dARNALis

11

dARNALis

12

darnalis '10

UNiSEL (KMD 3133)

Advantages of Fluid Power

3 basic methods of transmitting power;

Electrical Mechanical Fluid Power

Efficient overall system using combination of all above. Fluid systems can transmit power more economically over greater distance than mechanical system. However, restricted to shorter distances compared to electrical systems

dARNALis 13

Advantages of Fluid Power

Fluid power secret is its versatility and manageability. Not constrain to the physical geometry of the machine compared to mechanical systems. E.g. automotive braking systems. Power transmitted in almost limitless quantities. Not constrained by the physical limitation of materials such in an electrical systems. (E.g. Electromagnets, depends on saturation limit of steel)

dARNALis 14

Advantages of Fluid Power

Main advantages of Fluid Power systems are:

1. 2. 3. 4.

Ease and accuracy of control. Multiplication of force. Constant force or torque. Simplicity, safety & economy.

dARNALis

15

darnalis '10

UNiSEL (KMD 3133)

Drawbacks of Fluid Power

In spite of all highly desirable of fluid power, it is not the answer of all power transmission problems.

Hydraulics oil are messy. Leakage is virtually impossible to eliminate completely. Safety issue hydraulics lines might burst resulting to injuries if proper design are not implemented.

dARNALis 16

Applications of Fluid Power

dARNALis

17

Applications of Fluid Power

dARNALis

18

darnalis '10

UNiSEL (KMD 3133)

Applications of Fluid Power

dARNALis

19

Applications of Fluid Power

dARNALis

20

Applications of Fluid Power

dARNALis

21

darnalis '10

UNiSEL (KMD 3133)

Applications of Fluid Power

dARNALis

22

Applications of Fluid Power

dARNALis

23

Applications of Fluid Power

Pneumatic powered Dextrous articulated artificial limb

Courtesy of , Shadow Robot Company

dARNALis 24

darnalis '10

UNiSEL (KMD 3133)

Applications of Fluid Power

dARNALis

25

Applications of Fluid Power

Pneumatic powered artificial muscle. Air Muscle, Courtesy of Shadow Robot Company

dARNALis

26

Components of a Fluid Power System (Hydraulic System)

There are 6(six) basic components

1. 2. 3. 4. 5.

Tank (reservoir) holding the liquid (hydraulic oil). Pump forcing liquid through the system. Electric motor or other power source to drive the pump. Valves controlling liquid direction, pressure & flow rate. Actuators convert energy of liquid into mechanical force / torque providing useful work. Cylinders linear motions. Motors rotary motions. Piping Carries the liquid from one location to another.

dARNALis 27

6.

darnalis '10

UNiSEL (KMD 3133)

Components of a Fluid Power System (Hydraulic System)

Figure 1-21

dARNALis

28

Components of a Fluid Power System (Hydraulic System)

Figure 1-20

dARNALis

29

Components of a Fluid Power System (Hydraulic System)

Complexity of hydraulic systems will vary depending on the specific applications Each unit is a complete, packaged power system containing,

Electric motor Pump Shaft coupling Reservoir (oil tank) Miscellaneous piping, pressure valves and Other components as required for proper operation such as pressure gages.

dARNALis 30

darnalis '10

10

UNiSEL (KMD 3133)

Components of a Fluid Power System (Hydraulic System)

Figure 1-22

dARNALis

31

Components of a Fluid Power System (Pneumatic System)

There are also 6(six) basic components

1. 2. 3. 4. 5.

6.

Air Tank (reservoir) storing a given volume of compressed air. Compressor Compresses air from the atmosphere. Electric motor or other prime mover to drive the compressor. Valves controlling liquid direction, pressure & flow rate. Actuators convert energy of liquid into mechanical force / torque providing useful work. Cylinders linear motions. Motors rotary motions. Piping distribute the pressurized air from one location to another.

dARNALis 32

Components of a Fluid Power System (Pneumatic System)

Fig 1-23

dARNALis

33

darnalis '10

11

UNiSEL (KMD 3133)

Components of a Fluid Power System (Pneumatic System)

Complexity of pneumatic systems will vary depending on the specific applications. Self-contained pneumatic power unit is consist of,

Electric motor Compressor Shaft coupling Reservoir (Air tank) Miscellaneous piping, pressure valves and Other components as required for proper operation such as pressure gages.

dARNALis

34

Components of a Fluid Power System (Pneumatic System)

Should be noted;

In pneumatic systems after pressurized air is spent driving actuators, it is then exhausted back to the atmosphere.

While,

In hydraulic systems, the spent oil drains back to the reservoir and is repeatedly reused after being re-pressurized & filtered by the system.

dARNALis 35

Closed-Loop vs. Open Loop System

Fluid power can either be using the closed-loop or open-loop type. Closed-loop System

Using feedback. Output from system is automatically sampled and compared (fed back) to the input / command signal by means of a device known as feedback transducer. If there is significance difference between command signal and feedback signals, action will be taken automatically to correct the system output. A.K.A servo systems, valves used to direct fluid are systems typically called servo valves.

dARNALis 36

darnalis '10

12

UNiSEL (KMD 3133)

Closed-Loop vs. Open Loop System

Open-loop System Not using feedback. Performance solely depends on individual components and how they interact in the circuit. No input / output compensation occur. Most hydraulic circuits are of the open-loop type, which generally not so complex / precise as closed-loop. Errors due to slippage (oil leakage which somehow depends on the pressure & temperature.) Example,

Leakage past seals inside pumps due to viscosity change of fluid which affected to the rise of operating temperature. Leading to pressure and speed of actuators to drop.

dARNALis

37

Closed-Loop vs. Open Loop System

dARNALis

38

darnalis '10

13

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- PC Hardware Servicing Teacher's GuideDocumento7 paginePC Hardware Servicing Teacher's GuidedanballaisNessuna valutazione finora

- Final Exam Review Questions Funds of SecurityDocumento65 pagineFinal Exam Review Questions Funds of Securityidk80% (5)

- Water System Validation ExampleDocumento6 pagineWater System Validation Exampledvdynamic1100% (2)

- Management Information System KFCDocumento29 pagineManagement Information System KFCTamilSelvan0% (1)

- Report - MillingDocumento8 pagineReport - MillingMaarij Anjum50% (2)

- 2016 Smart City PresentationDocumento22 pagine2016 Smart City PresentationDeshGujarat80% (5)

- Betriebsanleitung Engl PDFDocumento812 pagineBetriebsanleitung Engl PDFotipi100% (3)

- Performance and Emission Characteristics of Di Diesel Engine Fuelled With Camphor Oil-Diesel BlendsDocumento4 paginePerformance and Emission Characteristics of Di Diesel Engine Fuelled With Camphor Oil-Diesel BlendsRam KrishNessuna valutazione finora

- Eletrical Motor OffshoreDocumento38 pagineEletrical Motor OffshoreandreisraelNessuna valutazione finora

- StarbucksDocumento19 pagineStarbucksNimah SaeedNessuna valutazione finora

- PresPrescient3 Extinguishing Control Panelcient 3 SLDocumento4 paginePresPrescient3 Extinguishing Control Panelcient 3 SLIgor NedeljkovicNessuna valutazione finora

- Mempower Busduct - PG - EN - 6 - 2012 PDFDocumento38 pagineMempower Busduct - PG - EN - 6 - 2012 PDFAbelRamadhanNessuna valutazione finora

- A88JY ManualDocumento6 pagineA88JY ManualionmocanuNessuna valutazione finora

- Kinematic Analysis of 5 Dof Lynx ArmDocumento6 pagineKinematic Analysis of 5 Dof Lynx ArmsathyaNessuna valutazione finora

- Installation, Operation, and Maintenance Manual: Ansi Process PumpDocumento56 pagineInstallation, Operation, and Maintenance Manual: Ansi Process Pumpfaundes100% (1)

- CONTRIBN MADE by Deming, Juran and CrosbyDocumento14 pagineCONTRIBN MADE by Deming, Juran and CrosbySachin Methree100% (1)

- What Is A Bioclimatic Chart - EHowDocumento2 pagineWhat Is A Bioclimatic Chart - EHowonkhgfg kjhh jghNessuna valutazione finora

- Educational Design Research: Introduction and Illustrative CasesDocumento24 pagineEducational Design Research: Introduction and Illustrative Casespatterson nji mbakwaNessuna valutazione finora

- 6.3. Example of Transmission Ratio Assessment 6.3.1. Power-Split Hydro-Mechanical TransmissionDocumento2 pagine6.3. Example of Transmission Ratio Assessment 6.3.1. Power-Split Hydro-Mechanical TransmissionNita SebastianNessuna valutazione finora

- Aerocon BlocksDocumento5 pagineAerocon BlocksLeigh Hudson100% (2)

- Featuring:: ISO 9001:2008 CertifiedDocumento59 pagineFeaturing:: ISO 9001:2008 CertifiedClaudio AzevedoNessuna valutazione finora

- PKG 101 Principles of Packaging Quiz 1ADocumento2 paginePKG 101 Principles of Packaging Quiz 1AuknowgaryNessuna valutazione finora

- Appendix A.ivankova, Et Al.2006Documento34 pagineAppendix A.ivankova, Et Al.2006Ismet EliskalNessuna valutazione finora

- Himmlischer Adventjodler StringsDocumento2 pagineHimmlischer Adventjodler StringsSibille HuberNessuna valutazione finora

- Tyre RetradingDocumento4 pagineTyre RetradingdskjajkdsaNessuna valutazione finora

- Booz Allen - Strategy & BusinessDocumento18 pagineBooz Allen - Strategy & BusinessPaul AllenNessuna valutazione finora

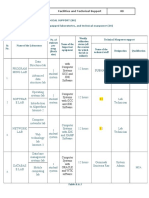

- Criterion 6 Facilities and Technical Support 80: With Computer Systems GCC and JDK SoftwareDocumento6 pagineCriterion 6 Facilities and Technical Support 80: With Computer Systems GCC and JDK SoftwareVinaya Babu MNessuna valutazione finora

- 2015 Lanzar Web Optimized PDFDocumento58 pagine2015 Lanzar Web Optimized PDFrecursowebNessuna valutazione finora

- Manual Do Usuario de Automatizadores Deslizantes CE2017 InglesDocumento2 pagineManual Do Usuario de Automatizadores Deslizantes CE2017 InglesTasso ParteliNessuna valutazione finora

- Unit 1 Module 2 Air Data InstrumentsDocumento37 pagineUnit 1 Module 2 Air Data Instrumentsveenadivyakish100% (1)