Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Accelerated Curing Techniques

Caricato da

Mohamed MeraounaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Accelerated Curing Techniques

Caricato da

Mohamed MeraounaCopyright:

Formati disponibili

PROPERTIES OF STEAM CURED RECYCLED AGGREGATE FLY ASH CONCRETE

S. C. Kou (1), Chi S. Poon (1) and Dixon Chan (1) (1)Department of Civil and Structural Engineering, The Hong Kong Polytechnic University, Hung Hom, Kowloon, Hong Kong Abstract ID Number : 200

Author contacts Authors Shi C. Kou Chi S. Poon Dixon Chan

E-Mail 01902042r@polyu.deu.hk cecspoon@polyu.edu.hk cechancw@polyu.edu.hk

Fax 852 2334 6389 852 2334 6389 852 2334 6389

Postal address Department of Civil and Structural Engineering, The Hong Kong Polytechnic University

Contact person for the paper : Chi S. Poon Presenter of the paper during the Conference : Chi S. Poon Total number of pages of the paper: 10

PROPERTIES OF STEAM CURED RECYCLED AGGREGATE FLY ASH CONCRETE

Shi C. Kou (1), Chi S. Poon (1) and Dixon Chan (1) (1) Department of Civil and Structural Engineering, The Hong Kong Polytechnic University, Hung Hom, Kowloon, Hong Kong Abstract The effects of steam curing on the hardened properties of recycled aggregate concrete prepared with fly ash as a partial replacement of cement were investigated. The concrete mixtures were prepared with a water-to-binder (W/B) ratio of 0.45. The recycled aggregate was used as 0, 20, 50 and 100 % by weight replacements of natural aggregate. In addition, fly ash was used as 0, 25 and 35 % by weight replacements of cement. The concrete specimens underwent standard water curing and steam curing regimes. The test results showed that the strength of concrete decreased as the recycled aggregate content increased. An initial steam curing regime increased the 1-day strength of the concrete but the corresponding 28 and 90day strengths decreased. Furthermore, steam curing reduced the static modulus of elasticity of concrete compared to that of the water cured concrete. However, the negative effect of steam curing diminished as the recycled aggregate and fly ash contents increased. Moreover, steam curing reduced the drying shrinkage and increased the resistance against chloride ion penetration of the recycled aggregate concrete prepared with fly ash. The results show that one of the practical ways to utilize a higher percentage of recycled aggregates in structural concrete is by incorporating 25-35 percents of fly ash and with steam curing. Key words: Steam curing; Fly ash; Recycled aggregate concrete; Precast concrete, Hardened properties. 1. INTRODUCTION

Recycled aggregate has been used as a replacement of the natural aggregate for a number of years. The potential benefits and drawbacks of using recycled aggregate in concrete have been extensively studied [1-7]. The use of recycled aggregate generally increases the drying shrinkage, creep and water sorptivity and decreases the compressive strength and modulus of elasticity of concrete compared to those of natural aggregate concrete [8-11]. The negative effects of recycled aggregate on concrete quality limit the use of this material in structural concrete. However, the shortcomings of using recycled aggregate can be mitigated by incorporating a certain amount of fly ash into the concrete mixture since fly ash is known to be able to reduce the drying shrinkage and creep of concrete [12-16]. Moreover, the disadvantages can be further minimized when recycled aggregate concrete is employed in the precast concrete industry since it is easier to ensure the quality of such products due to the presence of an existing quality assurance system. The curing method used for precast concrete products differs from the normal curing method where steam curing is usually employed because it accelerates the rate of strength development. However, this curing method alters the properties of the resulting concrete [18-22]. Although plenty information is already available on the effect of steam curing on conventional concrete properties, there is limited data relating to steam cured recycled aggregate concrete prepared with fly ash.

This paper presents the results of a current study on the use of fly ash as a cement replacement in steam cured recycled aggregate concrete. In the study, the effects of fly ash on the compressive strength, the tensile splitting strength, the static modulus of elasticity, the drying shrinkage and the chloride penetrability on the prepared steam cured recycled aggregate concrete were investigated. 2. EXPERIMENTAL DETAILS

2.1 Materials ASTM Type I Portland cement and ASTM Class F low-calcium fly ash were used in the concrete mixtures. The chemical and physical properties of cement and fly ash are given in Tables 1 - 2. Table 1 Chemical compositions of cement and fly ash COMPOSITION (%) LOI SiO2 Fe2O3 Al2O3 CEMENT 2.97 19.61 3.32 7.33 FLY ASH 3.90 56.79 5.31 28.21 Table 2 Physical properties of cement and fly ash MATERIALS CEMENT 3 DENSITY (g/cm ) 3.16 SPECIFIC SURFACE AREA 3519.5 (cm2/g)

CaO 63.15 <3

MgO 2.54 5.21

SO3 2.13 0.68

FLY ASH 2.31 3960

Natural and recycled aggregates were used as the coarse aggregate in the concrete mixtures. In this study, crushed granite was used as the natural aggregate, and recycled aggregate sourced from a recycling facility in Hong Kong was used. The nominal sizes of the natural and recycled coarse aggregates were 20 and 10 mm and their particle size distributions conformed to the requirements of BS 812 [23]. The physical and mechanical properties of the coarse aggregate are shown in Table 3. The porosity of the aggregates was determined using mercury intrusion porosimetry (MIP). River sand was used as the fine aggregate in the concrete mixtures. Table 3 Properties of natural and recycled coarse aggregates WATER NOMINAL DENSITY ABSORPTION SIZE (kg/m3) (%) CRUSHED 10mm 2.62 1.12 GRANITE 20mm 2.62 1.11 RECYCLED 10mm 2.49 4.26 AGGREGATE 20mm 2.57 3.52 STRENGTH MIP (10% fine POROSITY values) kN (%) 159 126 1.62 8.69

2.2 Concrete mixtures The concrete mixtures were prepared with a water-to-binder (W/B) ratio of 0.45. Fly ash was used as a partial replacement of cement and recycled aggregate was used as a replacement of the natural coarse aggregate. In this study, fly ash was used as 0, 25 and 35%

by weight replacements of cement, and recycled aggregate was used as 0, 20, 50 and 100% by weight replacements of natural coarse aggregate. The absolute volume method was adopted to design the mix proportions of the concrete mixtures as shown in Tables 4. In the concrete mixture, the 10 and 20 mm coarse aggregates were used in a ratio of 1:2. Table 4 Proportioning of concrete mixtures CONSTITUTES (kg/m3) FLY RECYCLED NOTATION ASH AGGREGATE Total Sand (%) (%) Water cementitious material R0 0 0 180 400 708 R20 0 20 180 400 708 R50 0 50 180 400 708 R100 0 100 180 400 708 R0 F25 25 0 180 400 688 R20F25 25 20 180 400 688 R50F25 25 50 180 400 688 R100F25 25 100 180 400 688 R0F35 35 0 180 400 668 R20F35 35 20 180 400 668 R50F35 35 50 180 400 668 R100F35 35 100 180 400 668

Granite 1108 886 554 0 1108 886 554 0 1108 886 554 0

Recycled aggregate 0 215 538 1075 0 215 538 1075 0 215 538 1075

2.3 Specimens casting and curing For each concrete mix, 100 mm cubes, 70 x 70 x 285 mm prisms and 200 x 100 mm diameter cylinder specimens were cast. The cubes and the prisms specimens were used to test the compressive strength and the drying shrinkage respectively. The cylinders were used to evaluate the splitting tensile strength, the static modulus of elasticity and the chloride-ion penetration of concrete. All specimens were cast in steel moulds and compacted using a vibrating table. In this study, normal water curing and initial steam curing were used. For the water-cured specimens, the specimens were cured in air for a period of 24 hours before they were demolded. After demolding, three cubes and three cylinders were immediately tested for the 1-day compressive and splitting tensile strengths and the rest of the specimens were cured in a water tank at 27 1C until other test ages were reached. For steam curing, the concrete specimens immediately after casting (without demolding) were initially cured in a steam bath at 65oC for 8 hours. The steam curing cycle is shown in Figure 1. After the steam curing stage, the specimens were demolded and three cubes and three cylinders were tested for the 1day compressive and splitting tensile strengths. The rest of the specimens were further cured in a water tank at 27 1C until other test ages were reached.

70 60

Temperature (C)

50 40 30 20 10 0 0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hour)

Fig.1 One-day steam curing cycle 3. TESTS

3.1 Compressive and splitting tensile strengths The compressive and splitting tensile strengths of concrete were determined using a Denison compression machine with a loading capacity of 3000 kN. The loading rates for the compressive and splitting tensile tests were 0.2-0.4 N/mm.s and 57 kN/min respectively. The compressive and splitting tensile strength tests were carried out at the ages of 1, 4, 7, 28 and 90 days. 3.2 Static modulus of elasticity The static modulus of elasticity of concrete was determined in accordance with ASTM C 469-65. In this study, this test was carried out on the concrete specimens at the ages of 28 and 90 days. 3.3 Drying shrinkage test A modified British Method (BS1881, part 5: 1970) was used for the test. After removing the concrete prisms from the curing tank, the initial length of each specimen was measured. The specimens were then stored in an environmental chamber with a temperature of 55C and a relative humidity of 95 % until the next measurements at 1, 4, 7, 28, 56, 90 and 112 days. Before each measurement was taken on the scheduled day, the specimens were first removed from the environmental chamber and conveyed to a second cooling chamber for about 4 hours at a controlled temperature of 25C and a relative humidity of 75 %. The length of each specimen was then measured within 15 minutes before delivering the specimens back to the environmental chamber for the subsequence drying process. The procedure of drying, cooling and measuring continued until the final length measurement at 112 day was recorded. 3.4 Chloride penetrability The chloride ion penetrability of concrete was determined in accordance with ASTM C1202-94 using a 50 mm thick x 100 diameter concrete disc cut from the 100 x 200 mm concrete cylinders. The resistance of concrete against chloride ion penetration is represented by the total charge passed in coulombs during a test period of 6 hour. In this study, the chloride penetrability test was carried out on the concrete specimens at the ages of 28 and 90 days. 4. 4.1 RESULTS AND DISCUSSIONS Compressive strength 4

The compressive strengths of the concrete mixtures are shown in Tables 5 6. Each presented value is the average of three measurements. The results showed that the compressive strengths of concrete at all curing ages decreased with an increase in the recycled aggregate content. The 1-day compressive strengths of the steam cured concrete were higher than those of the water cured concrete. However, the corresponding 28 and 90-day compressive strengths of the steam cured concrete were lower than those of water cured concrete. The early day (1, 4 and 7-day) compressive strengths of concrete were significantly reduced as the fly ash content increased. However, at 90 days, the beneficial effects of the incorporation of fly ash became evident. The 90-day compressive strengths (regardless of the curing methods) of concrete containing fly ash as a 25 % replacement of cement were comparable to or higher than those of the concrete prepared with no fly ash. 4.2 Splitting tensile strength The splitting tensile strengths of the concrete are given in Tables 7 - 8. Each presented value is the average of three measurements. The results showed that an increase in the recycled aggregate content decreased the splitting tensile strength of the concrete. Similarly, steam curing increased the 1-day tensile strength. However, as oppose to the compressive strengths, the 28 and 90-day splitting tensile strengths of steam cured concrete were comparable to or higher than those of water cured concrete. However, at the same recycled aggregate replacement level, the use of fly ash reduced the tensile splitting strengths of the concrete. Table 5 Compressive strength of concrete mixtures with standard water curing COMPRESSIVE STRENGTH (MPa) FLY ASH RECYCLED NOTATION (%) AGGREGATE 1-day 4-day 7-day 28-day 90-day (%) R0 0 0 25.8 45.8 53.8 66.8 72.3 R20 0 20 23.6 43.2 51.2 62.4 68.0 R50 0 50 21.1 40.3 44.8 55.8 61.5 R100 0 100 15.5 26.8 36.2 42.0 50.2 R0 F25 25 0 17.6 32.6 39.9 54.4 69.0 R20 F25 25 20 13.2 28.9 34.1 49.7 68.7 R50 F25 25 50 11.6 25.7 31.3 44.3 65.2 R100F25 25 100 11.1 21.4 28.6 39.5 52.3 R0 F35 35 0 12.8 25.6 30.6 45.9 56.6 R20 F35 35 20 11.6 23.6 28.5 43.6 55.8 R50 F35 35 50 10.9 21.2 26.3 40.4 52.3 R100F35 35 100 9.9 20.5 25.3 38.3 50.9 4.3 Static modulus of elasticity The static modulus of elasticity values of concrete are presented in Table 9 and Fig. 2. Similarly, each presented value is the average of three measurements. The results showed that the static modulus of elasticity of concrete decreased with an increase in the recycled aggregate content. The static modulus of elasticity of concrete prepared with 100% recycled aggregate was more than 20 % lower than that of natural aggregate concrete at the curing ages of 28 and 90 days. Although steam curing had a detrimental effect on the static modulus of elasticity of natural aggregate concrete, it did not affect the modulus of elasticity of recycled aggregate concrete. On the other hand, steam curing increased the modulus of elasticity of recycled aggregate concrete prepared with fly ash (Fig. 2) when compared to that of water cured concrete. However, at the same recycled aggregate replacement level, the use of fly ash slightly 5

reduced the static modulus of elasticity values of concrete at both 28 and 90 days with the exception of the steam cured concrete prepared with 100 % recycled aggregate.

Table 6 Compressive strength of concrete mixtures with steam curing FLY ASH RECYCLED COMPRESSIVE STRENGTH (MPa) NOTATION (%) AGGREGATE 1-day 4-day 7-day 28-day 90-day (%) R0 0 0 41.8 49.6 53.2 58.1 63.9 R20 0 20 41.9 47.9 50.3 57.4 65.9 R50 0 50 38.0 41.9 46.7 55.1 62.2 R100 0 100 28.1 32.1 35.7 41.4 48.4 R0 F25 25 0 37.0 41.9 46.2 55.3 66.4 R20 F25 25 20 33.3 37.1 42.2 51.6 63.1 R50 F25 25 50 30.0 34.5 37.6 48.3 58.0 R100F25 25 100 26.8 30.7 33.6 42.1 52.0 R0 F35 35 0 30.4 33.6 36.4 46.2 52.2 R20 F35 35 20 28.5 30.5 33.7 44.1 51.1 R50 F35 35 50 26.3 28.9 32.1 42.3 47.2 R100F35 35 100 22.9 29.5 30.3 39.5 44.9 Table 7 Splitting tensile strengths of concrete mixtures with standard water curing FLY RECYCLED SPLITTING TENSILE STRENGTH (MPa) NOTATION ASH AGGREGATE 1-day 4-day 7-day 28-day 90-day (%) (%) R0 0 0 2.15 2.89 2.92 3.43 3.81 R20 0 20 1.91 2.28 2.85 3.16 3.62 R50 0 50 1.64 2.19 2.66 2.97 3.17 R100 0 100 1.41 2.15 2.59 2.84 3.02 R0 F25 25 0 1.40 2.06 2.39 3.42 3.50 R20 F25 25 20 1.08 1.69 2.05 3.14 3.21 R50 F25 25 50 1.03 1.84 2.13 3.10 3.16 R100F25 25 100 0.99 1.75 2.04 2.85 2.99 R0 F35 35 0 0.95 1.33 1.48 2.30 3.15 R20 F35 35 20 0.84 1.29 1.41 2.21 3.02 R50 F35 35 50 0.82 1.49 1.35 2.19 2.98 R100F35 35 100 0.79 0.98 1.48 2.19 2.99 4.4 Drying shrinkage The drying shrinkage values (tested at 112 days) of the concrete mixtures are shown in Fig. 3. It can be shown that the drying shrinkage values increased with an increase in recycled aggregate content. However, an initial steam curing regime reduced the drying shrinkage of concrete. Also, the incorporation of fly ash as a partial replacement of cement decreased the drying shrinkage value of the concrete.

Table 8 Splitting tensile strengths of concrete mixtures with steam curing FLY RECYCLED SPLITTING TENSILE STRENGTH (MPa) NOTATION ASH AGGREGATE 1-day 4-day 7-day 28-day 90-day (%) (%) R0 0 0 2.28 2.77 2.80 3.06 3.72 R20 0 20 2.37 2.65 2.76 3.58 3.96 R50 0 50 2.35 2.47 2.67 3.24 3.62 R100 0 100 2.13 2.31 2.47 3.08 3.22 R0 F25 25 0 1.83 2.59 2.82 3.65 4.06 R20 F25 25 20 2.18 2.37 2.80 3.35 3.60 R50 F25 25 50 2.11 2.14 2.51 3.05 3.84 R100F25 25 100 1.72 1.88 2.16 2.89 3.29 R0 F35 35 0 1.79 1.96 2.37 2.71 3.24 R20 F35 35 20 1.76 1.92 2.24 2.56 3.12 R50 F35 35 50 1.73 1.87 2.21 2.46 3.09 R100F35 35 100 1.67 1.85 2.36 2.46 2.99 Table 9 Static elasticity modulus values of concrete mixtures ELASTICITY MODULUS (GPa) NOTATION FLY RECYCLED ASH AGGREGATE Standard water cured Steam cured (%) (%) 28-day 90-day 28-day 90-day R0 0 0 38.7 39.5 32.3 34.3 R20 0 20 29.1 36.5 30.4 34.3 R50 0 50 26.0 33.2 26.6 31.0 R100 0 100 23.4 28.5 22.8 27.6 R0F25 25 0 36.3 34.6 32.0 33.6 R20F25 25 20 29.3 31.6 28.5 31.9 R50F25 25 50 27.1 29.1 30.2 30.6 R100F25 25 100 23.2 26.2 25.5 26.5 R0F35 35 0 31.3 33.9 29.6 32.3 R20F35 35 20 26.3 30.5 29.8 31.0 R50F35 35 50 23.2 25.9 23.8 31.6 R100F35 35 100 23.2 28.9 27.4 29.2 4.5 Chloride penetrability The resistances against chloride-ion penetration of concrete are given in Table 10. It was found that the use of fly ash as a partial replacement of cement increased the resistance against chloride ion penetration. The improvement was significant at 90 days for both curing methods. Furthermore, it was found that steam curing increased the resistance against chloride-ion penetration of recycled aggregate concrete with and without fly ash. However, the resistance decreased with an increase in the recycled aggregate content.

40

28-day Static Modulus of Elasticity (GPa)

35

Recycled Aggregate Replacement Levels 0% (water cured) 0% (steam cured) 20% (water cured) 20% (steam cured) 50% (water cured) 50% (steam cured) 100% (water cured) 100% (steam cured)

30

25

20 0 10 20 30 40 50

Fly Ash Content (%)

Fig. 2 - 28-day static modulus of elasticity of concrete prepared with different fly ash contents

500

Drying Shrinkage at 112 days (x10^-6)

450

Recycled Aggregate Replacement Levels

400

0% (water cured) 0% (steam cured) 20% (water cured) 20% (steam cured) 50% (water cured) 50% (steam cured) 100% (water cured) 100% (steam cured)

350

300

250 0 10 20 30 40 50

Fly Ash Content (%)

Fig. 3 - Drying shrinkage (at 112 days) of concrete prepared with different fly ash contents Table 10 Chloride-ion penetrations of concrete mixtures TOTAL CHARGE PASSED (Coulombs) NOTATION FLY RECYCLED ASH AGGREGATE Standard water cured Steam cured (%) (%) 28-day 90-day 28-day 90-day R0 0 0 3239 2427 2680 1485 R20 0 20 3643 2528 2956 1600 R50 0 50 4620 2609 3276 1740 R100 0 100 4957 3562 3940 2807 R0F25 25 0 2599 715 1552 317 R20F25 25 20 3038 937 1865 479 R50F25 25 50 3263 1275 1838 548 R100F25 25 100 3818 1759 2047 978 R0F35 35 0 2500 1109 971 510 R20F35 35 20 2981 1456 918 530 R50F35 35 50 3795 1066 1483 430 R100F35 35 100 3969 1789 1488 539 8

5.

CONCLUSIONS

The test results showed that the compressive and splitting tensile strengths of concrete decreased with an increase in the recycled aggregate content. The early-age compressive and splitting tensile strengths of concrete significantly decreased as the fly ash content increased. However, at longer curing ages, the beneficial effects of fly ash became evident. The static modulus of elasticity values of concrete decreased as the recycled aggregate and fly ash contents increased. However, the influence of fly ash on the static modulus of elasticity of concrete prepared with 100 % recycled aggregate was not significant. It was found that steam curing at 65 C increased the 1-day strengths of the concrete compared to those of the water cured concrete. However the corresponding 28 and 90-day compressive strengths of the steam cured concrete were lower than those of the water cured concrete. The drying shrinkage value of concrete increased with an increase in the recycled aggregate content but the shrinkage of concrete decreased with an increase in the fly ash content. The reduction was about 10 % for the steam cured concrete prepared with 25 % fly ash and 100 % recycled aggregate. The resistance of concrete against chloride ion penetration decreased as the recycled aggregate content increased. However, this reduction could be counteracted by the use of fly ash. Moreover, an initial steam curing regime significantly increased the resistance of the recycled aggregate fly ash concrete against chloride-ion penetration at 28 and 90 days. The results show that one of the practical ways to utilize a higher percentage of recycled aggregates in structural concrete is by incorporating 25-35 percents of fly ash and with an initial steam curing step. ACKNOWLEDGEMENTS The authors would like to thank the Environment and Conservation Fund and The Hong Kong Polytechnic University for funding support. REFERENCES

[1] [2] [3] [4] [5] [6] [7] Dhir R.K. AND Jappy T.G. (edit), 1999, Proceedings of the International Conference on Exploiting Wastes in Concrete, Thomas Telford, UK. Hansen, T. C., RILEM REPORT 6., Recycling of Demolished Concrete and Masonry, published by E&FN Spon, Bodmin, UK, 1996. Collins, R.J. The Use of Recycled Aggregates in Concrete, BRE Information Paper IP 5/94, Building Research Establishment, Watford, UK. 1994. Dhir, R.K., Henderson, N.A. AND Limbachiya, M.C (edit), Proceedings of the International Conference on the Use of Recycled Concrete Aggregates, Thomas Telford, UK. 1998. RILEM, Proceedings of the 1st ETNRecy.net/RILEM workshop on Use of Recycled Materials as Aggregates in the Construction Industry, 11-12 September, 2000, Paris. Sagoe-Crentsil, K.K., Brown, T. AND Taylor, A.H., Performance of concrete made with commercially produced coarse recycled concrete aggregate, Cem. Conr. Res. 31. 707-712, 2001. Poon, C. S., Shui, Z. H. Lam, L. Fok H. AND Kou, S. C., Influence of moisture states of natural and recycled aggregates on the properties of fresh and hardened concrete, Cem. Conr. Res. 34 (2004) 31-36.

[8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23]

Hasaba, S., Kawamura, M., KazuyukI,T. AND Kunio,T., Drying shrinkage and durability of concrete made from recycled concrete aggregates, Transactions of Japan Concrete Institute, Tokyo, Vol 3, 1981, pp.55-60. Hansen, T. C. AND Begh, E., Elasticity and drying shrinkage of recycled aggregate concrete, Journal of American Concrete Institute, 82 (5), pp. 648-652, 1985. Olorunsogo, F.T. AND Padayachee. N., Performance of recycled aggregate concrete monitored by durability indexes, Cement and Concrete Research, 32 (2002)179-185. Dhir, R. K. Limbachiya, M. Leelawat, C. T., Suitability of recycled concrete aggregate for use BS 5328 designated mixes, Proc. Inst. Civ. Engrs & Bldgs, 1999, 134, Aug., 257-274. Haque, M. N., Langan, B. W. AND Ward, M. A., High fly ash concrete, ACI Mater. J., 81 (1), 54-60. Hansen, K. D., AND Reinhardt, W. G., Roller-compacted concrete dams, McGraw-Hill, New York. Nanni, A., Ludwig, D., AND Shoenberger, J., Roller compacted concrete for highway pavements, Concr. Int., 18(5) 33-39. Delagrave, A., Marchand, J., Pigeon, M., AND Boisvert, J., Deicer salt scaling resistance of roller compacted concrete pavements, ACI Mater. J., 96 (2), 164-169. Pittman, D. W., AND Ragan, S. A., Drying shrinkage of roller compacted concrete for pavement applications, ACI Mater. J., 95 (1), 19-25. Costabile, S., Recycled aggregate concrete with fly ash: A preliminary study on the feasibility of a sustainable structural material, The first international conference on ecological building structure, San Rafael California, July, 5-9, 2001. American Concrete Institute, Pressure steam curing, ACI Journal, Vol. 60, No 8, August 1963, pp 953-986. Brooks, J.J. AND Wainwright, P.J., Influences of steam curing on strength, shrinkage and creep of OPC and slag concretes, Proceeding of the International Conference held at the University of Dundee, Scotland, UK on 27-28 June 1996. pp 367-374. Boukendakdji, M. Brooks J. J. AND Wainwright, P.J., Influences of steam curing on strength, shrinkage and creep of OPC and slag concrete, Proceeding of the International Conference held at the University of Dundee, Scotland, UK on 27-28 June 1996, pp 367-374. Ho, D. W. S. Chua, C.W. AND Tam, C. T., Steam-cured concrete incorporating mineral admixtures, Cement and Concrete Research, 33 (2003) 595-601. Erdem, T.K. Turanli, L. Erdogan, T.Y., Setting time: An important criterion to determine the length of the delay period before steam curing of concrete, Cement and Concrete Research, 33 (2003) 741-745. British Standard Institute, BS 812: Part 103.1, Methods for determination of particle size distribution, 1985.

10

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- ASTM C1552 Capping Concrete Masonry Units, Related Units and Masonry Prisms For Compression TestingDocumento5 pagineASTM C1552 Capping Concrete Masonry Units, Related Units and Masonry Prisms For Compression TestingMohamed MeraounaNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- IBA Test Prep MaterialDocumento3 pagineIBA Test Prep MaterialAmmar Hassan67% (9)

- Chapter 4 - Drains and SwalesDocumento23 pagineChapter 4 - Drains and SwalesFadhlullah Abu Bakar100% (1)

- Understanding BatteriesDocumento258 pagineUnderstanding Batteriesramprabhakarj100% (8)

- Design and Calculation AgitationDocumento18 pagineDesign and Calculation AgitationDavid Lambert67% (3)

- ANSI-ASNT CP-105 (2016 Edition)Documento129 pagineANSI-ASNT CP-105 (2016 Edition)aun.muhd2100% (1)

- Shear Wave Velocity: Comparison Between Centrifuge and Triaxial Based MeasurementsDocumento6 pagineShear Wave Velocity: Comparison Between Centrifuge and Triaxial Based MeasurementsLuciano JuniorNessuna valutazione finora

- Radiation Dose Limits: Appendix BDocumento6 pagineRadiation Dose Limits: Appendix BVaradha RajanNessuna valutazione finora

- ASTM C1782 PavingSlabsDocumento6 pagineASTM C1782 PavingSlabsMohamed MeraounaNessuna valutazione finora

- ASTM C140 Sampling and Testing Concrete Masonry Units and RelatedDocumento24 pagineASTM C140 Sampling and Testing Concrete Masonry Units and RelatedMohamed MeraounaNessuna valutazione finora

- Wideslab LayoutDocumento1 paginaWideslab LayoutMohamed MeraounaNessuna valutazione finora

- Initial Time of Set of Fresh Concrete: Test Procedure ForDocumento3 pagineInitial Time of Set of Fresh Concrete: Test Procedure ForMohamed MeraounaNessuna valutazione finora

- Density of States - MSE 5317 PDFDocumento8 pagineDensity of States - MSE 5317 PDFJohn AllenNessuna valutazione finora

- 2008 10 08 Product Show Mixing SpeakersDocumento18 pagine2008 10 08 Product Show Mixing SpeakersyhjhzzjNessuna valutazione finora

- MAG8000 Manual PDFDocumento137 pagineMAG8000 Manual PDFHanks EpphNessuna valutazione finora

- MRG - D R.sirDocumento30 pagineMRG - D R.sirPLASTIC LAB CBDNessuna valutazione finora

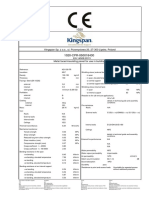

- A.7.a.1CE Mark - KS1150 FR - Panou Perete Rez Foc 180 Min C2Documento1 paginaA.7.a.1CE Mark - KS1150 FR - Panou Perete Rez Foc 180 Min C2Agnes SzaboNessuna valutazione finora

- Basic Analysis 1Documento312 pagineBasic Analysis 1MahaNessuna valutazione finora

- A Computational Fluid Dynamics Model of Algal Growth Development and ValidationDocumento11 pagineA Computational Fluid Dynamics Model of Algal Growth Development and ValidationsuyyinNessuna valutazione finora

- Adnan Aljarallah 1988 Kinetic of MTBE Over AmberlystDocumento6 pagineAdnan Aljarallah 1988 Kinetic of MTBE Over AmberlystJason NunezNessuna valutazione finora

- Australia Shell Spirax S6 AXME 80W-140 TDSDocumento2 pagineAustralia Shell Spirax S6 AXME 80W-140 TDSfdpc1987Nessuna valutazione finora

- KrishnaDocumento9 pagineKrishnaKrishna KashyapNessuna valutazione finora

- Nonlinear Disturbance Observer Based Robust Control With With Mismatch Disturbances/uncertaintiesDocumento25 pagineNonlinear Disturbance Observer Based Robust Control With With Mismatch Disturbances/uncertaintiesHazal Demir100% (1)

- RH98Documento2 pagineRH98Arun Jacob CherianNessuna valutazione finora

- Activity No. 13 - 2016 St6ar Finding With A Star FinderDocumento4 pagineActivity No. 13 - 2016 St6ar Finding With A Star FinderCristina AguinaldoNessuna valutazione finora

- Maths Grade 9 Ujian SekoahDocumento10 pagineMaths Grade 9 Ujian SekoahKopi LuwakNessuna valutazione finora

- Rotary CompressorDocumento24 pagineRotary Compressorvijayns_250355172Nessuna valutazione finora

- Lx400 PDFDocumento3 pagineLx400 PDFbalab2311Nessuna valutazione finora

- SOM 2-2 (Students Note)Documento15 pagineSOM 2-2 (Students Note)HasmitthaNessuna valutazione finora

- TS PGECET Civil Engineering Exam Syllabus & PatternDocumento3 pagineTS PGECET Civil Engineering Exam Syllabus & PatternpavaniNessuna valutazione finora

- ASTM D5147 - Sampling and Testing Modified Bituminous Sheet Material1Documento5 pagineASTM D5147 - Sampling and Testing Modified Bituminous Sheet Material1jothi vel muruganNessuna valutazione finora

- One-Factor Short-Rate Models: 4.1. Vasicek ModelDocumento8 pagineOne-Factor Short-Rate Models: 4.1. Vasicek ModelbobmezzNessuna valutazione finora

- ACI 350-06 ErrataDocumento7 pagineACI 350-06 ErrataLuis Ariel B. MorilloNessuna valutazione finora

- Arlon Microwave MaterialsDocumento18 pagineArlon Microwave MaterialsFelipe RabeloNessuna valutazione finora

- ANSYS 10.0 Workbench Tutorial - Description of TutorialsDocumento7 pagineANSYS 10.0 Workbench Tutorial - Description of TutorialssangeethsreeniNessuna valutazione finora