Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Metal & Plastic Forming Process

Caricato da

nurin_irdina_126332Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Metal & Plastic Forming Process

Caricato da

nurin_irdina_126332Copyright:

Formati disponibili

UNIT 6 FORMING PROCESS 1 Introduction Forming means changing the shape of existing solid body.

. In forming processes, the starting material may be in the shape of a plate, sheet, bar, rod, wire or tubing of various cross-sections. Plastic deformation of the material occurs in the forming process. This happened by stresses applied in the process exceed the yield strength of the material caused the material to take shape of the die. Learning points o Metal forming o Types of metal forming process o Plastic forming

Learning Outcomes Upon completion of this module, you would be able to: 1. Explain what is metal forming process 2. Describe different types of forming process 3. Identify the application of each forming process 4. Notify the basic plastic forming and shaping process

Teaching Materials 3.1 METAL FORMING PROCESS In metal forming process, it can be divided into three categories:

a) bulk deformation processes: for example to change the shape of a steel block. Types of bulk deformation processes are rolling, forging, extrusion and drawing. b) sheet metal working process: process that carried out on metal sheets, strips and coils (thickness is range from 0.4 to 6 mm). Sometimes this process known as stamping. Types of sheet metal working processes are bending, drawing and shearing.

3.2

TYPES OF METAL FORMING 3.2.1 Rolling It is a process of reducing the thickness or changing the crosssection of a long workpiece by compressive force applied through a set of rolls (Figure 6.1).

Figure 6.1: Various flat-rolling and shape rolling processes. Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition The rolling process can be divided into two types: a) Flat rolling: this process will reduce the thickness and increase the width of the workpiece (Figure 6.2). It is used to roll the slabs, strips, sheets and plates.

Figure 6.2: Decrease the thickness and increase in width Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition b) Shape roll: in this process the rectangular cross-section is changed to other shapes as I-beam, L-beam and U-channels. The workpiece passes through rolls that have the desired shape. Example of shape process is shown in Figure 6.3.

Figure 6.3: Steps in the shape rolling of an I-beam part. Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition

3.2.2 Forging process It is a process where the workpiece is deformed by compressing it between two dies either applying impact or gradual pressure to shape the part. It is used to make crankshaft, gears, turbine shaft and tools such as spanar. There are several types of forging process such as open-die forging, closed die forging and flash-less forging. a) Open-die forging: in this process workpiece is compressed between two flat dies as shown in Figure 6.4.

Figure 6.4: The open-die forging process Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition

b) Closed-die forging: It is carried out by using dies that have the inverse of the desired shape of the part. As in Figure 6.5, the force is applied to rectangular shape workpiece and it will deform according to the shape of cavity. This process is not suitable to produce parts with good dimensional accuracy.

Figure 6.5: The closed-die forging process Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition c) Flashless forging: It is a type of closed-die forging with no flash is formed (Figure 6.6).

Figure 6.6: The flashless forging process Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition 3.2.3 Extrusion processes In this process, a cylindrical billet is forced through a die (similar to squeezing toothpaste from a tube (Figure 6.7). Typical products made by extrusion are sliding doors, window frames, aluminum ladders and etcs. It is used to extrude material as aluminum, copper, magnesium and other metals and alloys. Extrusion can be economical for large production runs.

Figure 6.7: The extrusion process Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition There are two types of extrusion: a) Hot: It is carried out at high temperature. In hot extrusion, firstly the billet is heated to above the recrytallization temperature. This will assist the material to lower its strength and increases its ductility. b) Cold: It is a combination of extrusion and forging (Figure 6.8). Examples of part produced by this process are components for automobiles. The advantages of this process are better mechanical properties, dimensional accuracy, surface finish and the disadvantage is high magnitude of stresses.

Figure 6.8: The cold extrusion process Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition 3.2.4 Drawing processes It is a process where the cross section of a rod or wire is reduced or change by pulling through a die (draw die) (Figure 6.9). This process is used to produce shafts, bolts and rivets, cables and

etcs. The advantages of drawing are good surface finish, dimensional accuracy and improved mechanical properties.

Figure 6.9: The drawing process Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition 3.2.5 Sheet metal bending process The most common sheet metal forming processes. It is used to increase the stiffness of a part. Bending is defined as the straining of metal a round a straight axis. Die and punch is used in the bending process to perform the force which will plastically deformed the sheet metal and the bend takes a permanent once the forces are removed (Figure 6.10). The bending machine (press brake) is used in this process (Figure 6.11).

Figure 6.10: The bending process Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition

Figure 6.11: The bending machine (press brake) Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition

3.2.6 Sheet metal drawing process Drawing is done by placing a piece of sheet metal (blank), over a die cavity and pushing the metal into cavity using a punch (Figure 6.12). In this process, the workpiece will having a complex stresses and strains and slowly formed according to the shape of the die cavity and punch.

Figure 6.12: The sheet metal drawing process Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition 3.2.7 Sheet metal shearing process It is a cutting process using shearing action between two sharp cutting edges, similar in cutting a paper using a pair of scissors. In this process, the sheet metal will have plastic deformation, penetration and fractures (Figure 6.13).

Figure 6.13: The sheet metal shearing process Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition

3.3

PLASTIC FORMING Nowadays most products such as computers, automobiles, toys are made from plastic. Plastic is categorised as a polymeric material. For each type of plastics, they are differing from each other in terms of their mechanical properties and chemicals. There is various form of plastic similar to metals, for example sheets, tubes, rods etcs. In plastic shaping process, plastic powders or pellets will be melted just before the shaping process. Types of plastic forming process are:

a) Injection molding b) Compression molding c) Transfer molding 3.3.1 Injection molding This process is done by firstly plastic pellet is heated and after the plastic pellet melted, it will flow into the mold cavity under a high pressure. Injection molding machine is used to carry out the process.

Figure 6.14: Injection molding with (a) plunger, (b) reciprocating rotating screw Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition

Figure 6.15: Typical products made by injection molding Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition

Figure 6.15: Injection-molding machine Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition

3.3.2 Compression molding The oldest molding process for making especially rubber tires. In this process, two mold halves will close to

compress the charge (compound) which will flow into the cavity.

Figure 6.16: Types of compression melding, a process similar to forging: (a) positive, (b) semipositive, and (c) flash. The flash in part (c) has to be trimmed off. (d) Die design for making a compression-molded part with undercuts. Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition

3.3.3 Transfer molding This process is done by loading the charge into the chamber and heated before the soften charge is given pressure to flow into the heated mold.

Figure 6.17: Sequence of operations in transfer molding for thermosetting plastics. Source: Serope Kalpakjian and Steven R. Schmid, Manufacturing Engineering and Technology, 5th Edition

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Tabela Diametro Furo para Fazer RoscaDocumento2 pagineTabela Diametro Furo para Fazer Roscajotacosmico50% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

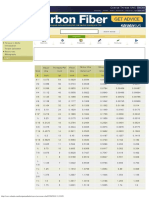

- Carbon Steel Hand Taps Metric PDFDocumento30 pagineCarbon Steel Hand Taps Metric PDFchikoopandaNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Fundamentals of Metal Casting Phase DiagramsDocumento10 pagineFundamentals of Metal Casting Phase Diagramsneetu_deep624Nessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- NPT Thread DimensionsDocumento1 paginaNPT Thread DimensionsNeil Louis60% (5)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Re Gi Stock 24.03..........Documento6 pagineRe Gi Stock 24.03..........SUMANTANessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- TC Thread Measuring FormulasDocumento1 paginaTC Thread Measuring FormulasVikas PatilNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Retail Price List: Padi UnitDocumento16 pagineRetail Price List: Padi Unitsalil kumar padhyNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- MT Casting Part 1Documento115 pagineMT Casting Part 1Ahad RazzNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Din 931Documento1 paginaDin 931Showkath Ali100% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- Tightening TorqueDocumento2 pagineTightening TorqueMiguel QueirosNessuna valutazione finora

- Feeding and Risering of High-Alloy Steel CastingsDocumento20 pagineFeeding and Risering of High-Alloy Steel CastingsHusen TaufiqNessuna valutazione finora

- Sess 9 (Ceramic Mould - Pressure Die Casting - Centrifugal Casting)Documento7 pagineSess 9 (Ceramic Mould - Pressure Die Casting - Centrifugal Casting)Prakash RagupathyNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Metal Casting Technology: DR Srinivasan NarayananDocumento95 pagineMetal Casting Technology: DR Srinivasan NarayananAkshita MuskanNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- PTB profile rod seal dimensions and specificationsDocumento10 paginePTB profile rod seal dimensions and specificationsAditiyo Umara WijayantoNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Navoji - PodatciDocumento88 pagineNavoji - PodatciNikolat84Nessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Unit 1 - Casting-1Documento17 pagineUnit 1 - Casting-1Yuvaraj SNessuna valutazione finora

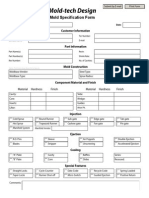

- Mold Design Spec SheetDocumento1 paginaMold Design Spec Sheetomerscheen0% (1)

- Die Casting Machines Core Pins & Ejector PinsDocumento1 paginaDie Casting Machines Core Pins & Ejector PinsJayden BarnesNessuna valutazione finora

- Asme B1.11-1958 (2016)Documento12 pagineAsme B1.11-1958 (2016)vijay pawarNessuna valutazione finora

- Chapter 13 - Extrusion-Based Processes (Part 1)Documento45 pagineChapter 13 - Extrusion-Based Processes (Part 1)hirenpatNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- STPB740Documento12 pagineSTPB740Antônio Rafael BatistaNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Casting DefectsDocumento5 pagineCasting DefectsNayeem pashaNessuna valutazione finora

- Foundry BasicsDocumento30 pagineFoundry BasicsDr. B. Ramesh100% (1)

- Area BoltsDocumento2 pagineArea Boltsivan bolañosNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Press Tools BasicsDocumento7 paginePress Tools BasicsAnonymous pMVR77x1Nessuna valutazione finora

- Introduction To Casting Processes: BackgroundDocumento5 pagineIntroduction To Casting Processes: BackgroundSubhasis BiswalNessuna valutazione finora

- Metal-Casting Tomo 15Documento8 pagineMetal-Casting Tomo 15CamilaAndreaGrijalbaNessuna valutazione finora

- Harga Printer LBPDocumento1 paginaHarga Printer LBPngomah klipangNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Nut Washer DimensionsDocumento1 paginaNut Washer DimensionszfrlNessuna valutazione finora

- Decimal Equivalents Tap Drill Size ChartDocumento1 paginaDecimal Equivalents Tap Drill Size ChartAlejandro CollinsNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)