Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1gr Fe Vvtisystem

Caricato da

Gepenx AriesDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1gr Fe Vvtisystem

Caricato da

Gepenx AriesCopyright:

Formati disponibili

NEW FEATURES 1GR-FE ENGINE

55

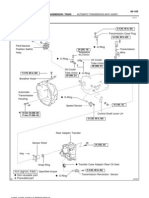

8. VVT-i (Variable Valve Timing-intelligent) System

General D The VVT-i system is designed to control the intake camshaft within a range of 50_ (of Crankshaft Angle) to provide valve timing that is optimally suited to the engine condition. This improves torque in all the speed ranges as well as increasing fuel economy, and reducing exhaust emissions.

VVT Sensor (Right Bank) Camshaft Timing Oil Control Valve

Engine Coolant Temp. Sensor

Throttle Position Sensor

NF

ECM

Camshaft Timing Oil Control Valve

VVT Sensor (Left Bank) Crankshaft Position Sensor

Mass Air Flow Meter

238EG60

D Using the engine speed, intake air volume, throttle position and engine coolant temperature, the ECM can calculate optimal valve timing for each driving condition and controls the camshaft timing oil control valve. In addition, the ECM uses signals from the camshaft position sensor and the crankshaft position sensor to detect the actual valve timing, thus providing feedback control to achieve the target valve timing.

ECM Crankshaft Position Sensor Mass Air Flow Meter Throttle Position Sensor Engine Coolant Temp. Sensor VVT Sensors Vehicle Speed Signal

221EG16

Target Valve Timing Duty-cycle Control Feedback Correction Actual Valve Timing

Camshaft Timing Oil Control Valve

56

NEW FEATURES 1GR-FE ENGINE Effectiveness of the VVT-i System

Operation State

TDC

Objective

Latest Timing

Effect

During Idling

EX

IN

Eliminating overlap to reduce blow back to the intake side

D Stabilized idling rpm D Better fuel economy

BDC

188EG51

to Retard Side

At Light Load

EX

IN

Decreasing overlap to eliminate blow back to the intake side.

Ensured engine stability

188EG64

to Advance Side

At Medium Load

EX

IN

Increasing overlap to increase internal EGR to reduce pumping loss

D Better fuel economy D Improved emission control

188EG65 TDC

In Low to Medium Speed Range with Heavy Load

EX

IN

Advancing the intake valve close timing for volumetric efficiency improvement

Improved torque in low to medium speed range

to Advance Side

BDC 188EG66

In High Speed Range with Heavy Load

EX

IN

Retarding the intake valve close timing for volumetric efficiency improvement

Improved output

to Retard Side

188EG67

Latest Timing

At Low Temperatures

EX

IN

188EG53

Eliminating overlap to prevent blow back to the intake side leads to the lean burning condition, and stabilizes the idling speed at fast idle

D Stabilized fast idle rpm D Better fuel economy

Latest Timing

D Upon Starting D Stopping the Engine

EX

IN

Eliminating overlap to minimize blow back to the intake side

Improved startability

188EG53

NEW FEATURES 1GR-FE ENGINE Construction 1) VVT-i Controller

57

This controller consists of the housing driven from the timing chain and the vane coupled with the intake camshaft. The oil pressure sent from the advance or retard side path at the intake camshaft causes rotation in the VVT-i controller vane circumferential direction to vary the intake valve timing continuously. When the engine is stopped, the intake camshaft will be in the most retarded state to ensure startability. When hydraulic pressure is not applied to the VVT-i controller immediately after the engine has been started, the lock pin locks the movement of the VVT-i controller to prevent a knocking noise.

NF

Lock Pin Housing Timing Rotor Intake Camshaft

Sprocket Vane (Fixed on Intake Camshaft)

Oil Pressure

238EG61

In Operation

At a Stop

Lock Pin 2) Camshaft Timing Oil Control Valve This camshaft timing oil control valve controls the spool valve position in accordance with the duty-cycle control from the ECM. This allows hydraulic pressure to be applied to the VVT-i controller advance or retard side. When the engine is stopped, the camshaft timing oil control valve is in the most retarded state.

To VVT-i Controller (Advance Side) Sleeve Sleeve

To VVT-i Controller (Retard Side)

Drain

Drain

Coil Spool Valve

Plunger

238EG62

Oil Pressure

58 Operation 1) Advance

NEW FEATURES 1GR-FE ENGINE

When the camshaft timing oil control valve is positioned as illustrated below by the advance signals from the ECM, the resultant oil pressure is applied to the vane chamber of advance side to rotate the camshaft in the timing advance direction.

Vane

ECM

Oil Pressure Rotation Direction IN Drain

238EG63

2) Retard When the camshaft timing oil control valve is positioned as illustrated below by the retard signals from the ECM, the resultant oil pressure is applied to the vane chamber of retard side to rotate the camshaft in the timing retard direction.

Rotation Direction

ECM

Oil Pressure Vane Drain IN

238EG64

3) Hold After reaching the target timing, the valve timing is held by keeping the camshaft timing oil control valve in the neutral position unless the traveling state changes. This adjusts the valve timing at the desired target position and prevents the engine oil from running out when it is unnecessary.

Potrebbero piacerti anche

- Volvo Penta 7748089 5.0-5.7 Engine ManualDocumento176 pagineVolvo Penta 7748089 5.0-5.7 Engine ManualJohn Dahl88% (26)

- Technical Documentation: M57TU EngineDocumento89 pagineTechnical Documentation: M57TU EngineIongornistu100% (5)

- Ih Navistar Dt466e 530e Service ManualDocumento206 pagineIh Navistar Dt466e 530e Service Manualaviseur100% (3)

- Volvo F9Q EngineDocumento42 pagineVolvo F9Q EngineAoife Fitzgerald100% (2)

- A4 LDDocumento1 paginaA4 LDOmar Molina100% (1)

- Timing Kit Instructions - 50 DegreesDocumento5 pagineTiming Kit Instructions - 50 DegreesMike Apple100% (1)

- LCR 200 Wiring Routing and Connector PDFDocumento397 pagineLCR 200 Wiring Routing and Connector PDFYannick de WalqueNessuna valutazione finora

- Toyota 2azfe Valve Clearance PDFDocumento9 pagineToyota 2azfe Valve Clearance PDFMarcos EmmanuelNessuna valutazione finora

- Suzuki Grand Vitara 1999Documento2 pagineSuzuki Grand Vitara 1999Olga PlohotnichenkoNessuna valutazione finora

- Porsche ECU Pins....Documento4 paginePorsche ECU Pins....José BenavidesNessuna valutazione finora

- RE4R03ADocumento2 pagineRE4R03AAbbode HoraniNessuna valutazione finora

- T1 Cam Trigger Instructions 1Documento10 pagineT1 Cam Trigger Instructions 1Initial_BG100% (1)

- Throttle Body Dan TPS Corolla 88-97Documento4 pagineThrottle Body Dan TPS Corolla 88-97Fitri Wibowo100% (1)

- 1mz Ecu Wiring DiagramDocumento7 pagine1mz Ecu Wiring Diagram12volt bayNessuna valutazione finora

- 1MZ-FE Engine Control SystemRX300 99Documento11 pagine1MZ-FE Engine Control SystemRX300 99Jose Calle100% (1)

- Polo No. 31 / 1: Current Flow DiagramDocumento11 paginePolo No. 31 / 1: Current Flow DiagramIgnacio Rifo NochezNessuna valutazione finora

- PWKsetting OLDocumento1 paginaPWKsetting OLGod BornNessuna valutazione finora

- Toyota 2az FeDocumento9 pagineToyota 2az FeFerran AlfonsoNessuna valutazione finora

- DTC P0120/41 Throttle/Pedal Position Sensor/Switch "A" Circuit MalfunctionDocumento6 pagineDTC P0120/41 Throttle/Pedal Position Sensor/Switch "A" Circuit MalfunctionMiguel ruizNessuna valutazione finora

- SD313-10 Engine Control System (G4KJ: THETA-II 2.4L GDI)Documento1 paginaSD313-10 Engine Control System (G4KJ: THETA-II 2.4L GDI)Luis GarcíaNessuna valutazione finora

- 1Gr-Fe Engine: DescriptionDocumento4 pagine1Gr-Fe Engine: DescriptionRenat VeedgamNessuna valutazione finora

- Transmissions - A - T Circuit (Transmission and Drivetrain) - ALLDATA RepairDocumento2 pagineTransmissions - A - T Circuit (Transmission and Drivetrain) - ALLDATA RepairManuel AyalaNessuna valutazione finora

- Lubrication System 1. General: Engine - 2Tr-Fe Engine EG-16Documento2 pagineLubrication System 1. General: Engine - 2Tr-Fe Engine EG-16Maxi SardiNessuna valutazione finora

- Engine Temperature Control Actuator - N493-, CHECKING: General DescriptionDocumento3 pagineEngine Temperature Control Actuator - N493-, CHECKING: General Descriptionbyungchul kimNessuna valutazione finora

- P0405-96 P0406-96 Taken From 2KD Manual - To Be CheckedDocumento4 pagineP0405-96 P0406-96 Taken From 2KD Manual - To Be CheckedBiniyam BekeleNessuna valutazione finora

- AVEO 2007-2010/wave - 07-10/engine Mechanical - 1.5L/Repair Instructions - On VehicleDocumento86 pagineAVEO 2007-2010/wave - 07-10/engine Mechanical - 1.5L/Repair Instructions - On VehicleArley HernandezNessuna valutazione finora

- 1Nz-Fe Engine Mechanical: Service DataDocumento3 pagine1Nz-Fe Engine Mechanical: Service Dataalbert phiriNessuna valutazione finora

- 1gr-Fe Engine Control System4Documento7 pagine1gr-Fe Engine Control System4mike chenNessuna valutazione finora

- Captiva Control Valve Body Removal PDFDocumento2 pagineCaptiva Control Valve Body Removal PDFBurhan udinNessuna valutazione finora

- CVT - F1cja PDFDocumento38 pagineCVT - F1cja PDFShaneel PrasadNessuna valutazione finora

- Cd4e Automatic TransmissionDocumento5 pagineCd4e Automatic TransmissioncossatotNessuna valutazione finora

- Electronic Controlled Automatic Transmission (ECT) (A750e-A750f) Cip0751Documento1 paginaElectronic Controlled Automatic Transmission (ECT) (A750e-A750f) Cip0751limadacarlosNessuna valutazione finora

- Timing Chain - 2003 Toyota Camry Sedan l4-2Documento10 pagineTiming Chain - 2003 Toyota Camry Sedan l4-2ftafedeNessuna valutazione finora

- VVT-i (Variable Valve Timing-Intelligent) System: GS430/300 - NEW FEATURES 41Documento5 pagineVVT-i (Variable Valve Timing-Intelligent) System: GS430/300 - NEW FEATURES 41Luqman AzamNessuna valutazione finora

- GF4AX-EL Documents - Tips - Automatic-Transaxle-Service-Gf4ax-El PDFDocumento53 pagineGF4AX-EL Documents - Tips - Automatic-Transaxle-Service-Gf4ax-El PDFkallekuhlaNessuna valutazione finora

- 031 - Engine - Igniter Circuit Malfunction (No. 1)Documento6 pagine031 - Engine - Igniter Circuit Malfunction (No. 1)Ayun AhmNessuna valutazione finora

- 2011 SAP Catalog 2011-10-07 Email VerDocumento208 pagine2011 SAP Catalog 2011-10-07 Email VerTransmisiones Guero100% (2)

- DTC P1128 Throttle Control Motor Lock Malfunction: Circuit DescriptionDocumento1 paginaDTC P1128 Throttle Control Motor Lock Malfunction: Circuit DescriptionWillian Jane100% (1)

- Re4F04A and Re4F04V Automatic Transmission (A/T) - Solenoid Valve Replacement ProceduresDocumento3 pagineRe4F04A and Re4F04V Automatic Transmission (A/T) - Solenoid Valve Replacement ProceduresfulltransmissionNessuna valutazione finora

- Engine Control (1Mz-Fe) : System OutlineDocumento10 pagineEngine Control (1Mz-Fe) : System OutlineDust100% (1)

- w58 RebuildDocumento49 paginew58 RebuildtfphoenixNessuna valutazione finora

- MIL ON DTC P2820 2014 - 2017 Corolla Transmission(s) CVT 2017 Im Transmission(s) CVTDocumento10 pagineMIL ON DTC P2820 2014 - 2017 Corolla Transmission(s) CVT 2017 Im Transmission(s) CVTSajjad HussainNessuna valutazione finora

- Fuse Box Diagram Toyota Alphard 1G and Relay With Assignment and LocationDocumento1 paginaFuse Box Diagram Toyota Alphard 1G and Relay With Assignment and LocationSiu Kit YauNessuna valutazione finora

- Auto Mat Ice Trans - Auto Trans F ComponentsDocumento4 pagineAuto Mat Ice Trans - Auto Trans F Componentstonek9Nessuna valutazione finora

- Atf Drain & Fill & Leveling - Camry U760eDocumento13 pagineAtf Drain & Fill & Leveling - Camry U760echuck8726842667% (3)

- DTC Troubleshooting: Before You Troubleshoot, Review The General Troubleshooting InformationDocumento32 pagineDTC Troubleshooting: Before You Troubleshoot, Review The General Troubleshooting InformationpaniyaNessuna valutazione finora

- 2Uz-Fe Engine 1. General: 4runner - New Features 317Documento5 pagine2Uz-Fe Engine 1. General: 4runner - New Features 317goNessuna valutazione finora

- PCM Terminal Information SD313-8 Engine Control System (G4KJ: THETA-II 2.4L GDI)Documento1 paginaPCM Terminal Information SD313-8 Engine Control System (G4KJ: THETA-II 2.4L GDI)Luis GarcíaNessuna valutazione finora

- Brake Control PDFDocumento410 pagineBrake Control PDFClod HopperNessuna valutazione finora

- 10-Automatic Transmission PDFDocumento192 pagine10-Automatic Transmission PDFLakzana Budhy100% (2)

- CHEVROLET (DAEWOO) Lacetti (J200) 1.8 16V F18D3: Timing Belt: Removal/installationDocumento7 pagineCHEVROLET (DAEWOO) Lacetti (J200) 1.8 16V F18D3: Timing Belt: Removal/installationJuan Jesus FernandesNessuna valutazione finora

- BYD S6-Owner's Manual20110615-ENDocumento114 pagineBYD S6-Owner's Manual20110615-ENMouyaser KodabNessuna valutazione finora

- Kia-Sorento 2009 en Manual de Taller Caja Automatica c487cc7398Documento1.577 pagineKia-Sorento 2009 en Manual de Taller Caja Automatica c487cc7398wilmersarmiento3101Nessuna valutazione finora

- Mustan 05-09 AutomaticDocumento6 pagineMustan 05-09 AutomaticJohn MooreNessuna valutazione finora

- DTC P2714 Pressure Control Solenoid "D" Performance (Shift Solenoid Valve SLT)Documento7 pagineDTC P2714 Pressure Control Solenoid "D" Performance (Shift Solenoid Valve SLT)Igor MarkovicNessuna valutazione finora

- Technical Service Information: FORD 5R55N, 5R55W/SDocumento8 pagineTechnical Service Information: FORD 5R55N, 5R55W/SJose garcua vargas 2006401321Nessuna valutazione finora

- 2003-2006 Kia Opirus - Engine Mechanical System PDFDocumento131 pagine2003-2006 Kia Opirus - Engine Mechanical System PDFprueba2Nessuna valutazione finora

- DTC P0045/34 Turbo/Super Charger Boost Control Solenoid Circuit / OpenDocumento4 pagineDTC P0045/34 Turbo/Super Charger Boost Control Solenoid Circuit / OpenYani Yani0% (1)

- Caja Automatica Optra Ingles-Libre 1Documento50 pagineCaja Automatica Optra Ingles-Libre 1Plinio SuarezNessuna valutazione finora

- BYD G3-Owner's Manual20110610-EN PDFDocumento160 pagineBYD G3-Owner's Manual20110610-EN PDFamer100% (1)

- Mazda 5 EngineDocumento143 pagineMazda 5 EngineAngel CastNessuna valutazione finora

- DownloadPdf PDFDocumento5 pagineDownloadPdf PDFbelchiorNessuna valutazione finora

- 2uztrd PDFDocumento33 pagine2uztrd PDFbob loblawNessuna valutazione finora

- VVT Sensor PDFDocumento4 pagineVVT Sensor PDFDoDuyBac100% (1)

- VVT-i (Variable Valve Timing-Intelligent) System: GeneralDocumento5 pagineVVT-i (Variable Valve Timing-Intelligent) System: GeneralsadiksnmNessuna valutazione finora

- VVT-i (Variable Valve Timing-Intelligent) SystemDocumento4 pagineVVT-i (Variable Valve Timing-Intelligent) SystemJorge Armando VelázquezNessuna valutazione finora

- VVT (Variable Valve Timing)Documento26 pagineVVT (Variable Valve Timing)PramodPradhan100% (1)

- 1.577 81 1.655 66 77 KW TDI CR Engine (CAYA CAYB CAYC CLNA CWXB CWXC)Documento577 pagine1.577 81 1.655 66 77 KW TDI CR Engine (CAYA CAYB CAYC CLNA CWXB CWXC)Kunji ManiNessuna valutazione finora

- Tadano Faun Tf90g 4 Spare Parts ListDocumento20 pagineTadano Faun Tf90g 4 Spare Parts Listwilliam100% (48)

- Altronic V Installation Manual (FORM AV II)Documento12 pagineAltronic V Installation Manual (FORM AV II)francis_mouille_iiNessuna valutazione finora

- Motor L60F-70F-90F PDFDocumento60 pagineMotor L60F-70F-90F PDFRenato Almeida100% (2)

- DPF Check List: Part 1Documento4 pagineDPF Check List: Part 1NachoNessuna valutazione finora

- Diagram 4 Accelerator Pedal P... - 1Documento1 paginaDiagram 4 Accelerator Pedal P... - 1Misa GamezNessuna valutazione finora

- 62 11052Documento32 pagine62 11052jgokey100% (2)

- Ve Pump Removal and InstallationDocumento5 pagineVe Pump Removal and InstallationMiguel MartinezNessuna valutazione finora

- 854 Fe 34 TaDocumento27 pagine854 Fe 34 TapepppeNessuna valutazione finora

- Piston Position IndicatorDocumento3 paginePiston Position IndicatorRobertNessuna valutazione finora

- Toggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintDocumento2 pagineToggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintGhianny AndresNessuna valutazione finora

- Doosan Basic EngineDocumento67 pagineDoosan Basic EngineJuan Guzmán100% (4)

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 31R877-0018-B1Documento27 pagineParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 31R877-0018-B1Adrian RiosNessuna valutazione finora

- Wartsila New X Series EnginesDocumento48 pagineWartsila New X Series Enginesvran7775% (4)

- 3516B LocoDocumento4 pagine3516B LocomarcosNessuna valutazione finora

- GSX-R1000 (UF/Z/ZUF) L3: Parts CatalogueDocumento277 pagineGSX-R1000 (UF/Z/ZUF) L3: Parts CatalogueRea Cleare TampusNessuna valutazione finora

- Internal Combustion EngineDocumento54 pagineInternal Combustion EngineBagas Satriya PrayogaNessuna valutazione finora

- Herramientas Puesta A Tiempo Motor Crafter 2.5LDocumento7 pagineHerramientas Puesta A Tiempo Motor Crafter 2.5Lferran_alfonso100% (1)

- Aeroplanes Test 1, Øvingsoppgaver: Klaus Bjørnar Noddeland (Dokumenttittel)Documento4 pagineAeroplanes Test 1, Øvingsoppgaver: Klaus Bjørnar Noddeland (Dokumenttittel)Pavlos TsitswnisNessuna valutazione finora

- Ed220629 PDFDocumento896 pagineEd220629 PDFPaul TadiwaNessuna valutazione finora

- Pistons and Connecting Rods - DisassembleDocumento4 paginePistons and Connecting Rods - Disassembleeshopmanual limaNessuna valutazione finora

- Engine Performance Data at 1500 RPM: QSL 1 Cummins IncDocumento4 pagineEngine Performance Data at 1500 RPM: QSL 1 Cummins IncOjhal RaiNessuna valutazione finora

- GTSIO 520 H OperatorsDocumento84 pagineGTSIO 520 H OperatorscarlNessuna valutazione finora