Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MBA Sem2 Fall 2012 Assignment

Caricato da

Rajdeep KumarCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MBA Sem2 Fall 2012 Assignment

Caricato da

Rajdeep KumarCopyright:

Formati disponibili

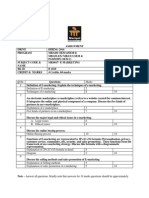

Fall / August 2012 Master of Business Administration - MBA Semester 2 MB0044 Productions & Operations Management Assignment Set-

- 1 Q1. What do you understand by Vendor-Managed Inventory (VMI)? Some firms have successfully improved their supply chain performance by implementing an approach known as Vendor Managed Inventory (VMI). With VMI, the vendor specifies delivery quantities sent to customers through the distribution channel using data obtained from EDI. Vendor Managed Inventory, Just-in-Time Distribution (JITD), and Efficient Consumer Response (ECR) all refer to similar concepts, but applied to different industries. For example, the grocery and apparel industries tend to use ECR, whereas the automobile industry tends to use VMI and JITD. The Vendor Managed Inventory Approach VMI reduces stock-outs and reduces inventory in the supply chain. Some features of VMI include:

Shortening of the supply chain Centralized forecasting Frequent communication of inventory, stock-outs, and planned promotions. Electronic Data Interchange (EDI) linkages facilitate this communication. No manufacturer promotions Trucks are filled in a prioritized order. For example, items that are expected to stock out have top priority, then items that are furthest below targeted stock levels, then advance shipments of promotional items (promotions allowed only in transition phase), and finally, items that are least above targeted stock levels. Relationship with downstream distribution channels Result: Inventory reduction and stock-out reduction

VMI Implementation Challenges VMI can be made to work, but the problem is not just one of logistics. VMI often encounters resistance from the sales force and distributors. At issue are roles and skills, trust, and power shifts. Some of the sales force concerns are:

Loss of control

Roll No. XXXX

Effect on compensation - incentive bonuses may depend on how much is sold, but sales force has less influence under VMI. Possible loss of job Skepticism that it will function well - technical problems Concern that reduced inventory will result in less shelf space and therefore loss of market share. This concern can be addressed by filling the shelf space with other stock keeping units from the same vendor.

Distributors also may have concerns about vendor managed inventory, including:

Inventory will be pushed on them No more promotions, discounts, and forward buying With less inventory, more risk of disruptions due to strikes, adverse weather, etc. The vendor enjoys the benefits while the distributor gives up its only lever of power data on what the retailers want. Danger of being replaced - vendor may decide to forward integrate.

Addressing Concerns For a VMI system to work, the concerns of distributors and the sales force must be addressed. They can be at least partially addressed by the following:

Transform the sales role into one of marketing. For example, bonuses can be given based on the number of new clients. Distributor skepticism can be addressed by implementing a pilot program with vendorowned warehouses in order to demonstrate that the system works. Introduce system in distributor-owned warehouses on a pilot basis. Engage a neutral consultant in meetings among the vendor, distributor, and sales force. Allow some manufacturer promotions in the transition. Extensively simulate the system off-line before implementing. Don't exaggerate the benefits of VMI; otherwise, any delay in realizing the benefits may cause the supply chain to lose faith in the system.

Roll No. XXXX

Q2. Explain briefly the four classification of scheduling strategies & its approaches. Types of Scheduling Strategies Burst Campaigns: often associated with the awareness objective, the burst campaign compacts media activities into a series of relatively short time frames, with relatively long periods of absence from media activity in between. This pattern may be used when a new product is being introduced. Flighting: Wave method or the flighting method is another kind of scheduling. In flighting, advertisements are bunched with the intention of providing a concentrated impact. is another method of creating an advertising schedule. The phrase advertising flight describes the time when commercials are aired. When flighting is used in relation to a scheduling technique, it refers to a method that has advertising going on and off the air. The advantage of the flighting technique is that it allows a campaign that does not have funds for running spots continuously to conserve money and maximize the impact of the commercials by airing them at key strategic times during the campaign. Frequently when flighting is employed, radio or cable TV will be used to supplement the advertising campaign during the times when television commercials are off the air. This method of media planning allows the messages and themes of the campaign to reach the voter through radio or cable TV, less costly alternatives to broadcast TV. Overview: Henko Stain Champion Powder (HSCP) was launched in July 1994 in South India. It was clearly positioned as a brand in the premium segment of detergents among HLLs Surf Wash Booster (todays Surf Multi-Action). Battling consumer inertia to try out this new brand was its toughest challenge and carving out pride of association was the other issue. Continuous Campaign: Another approach mostly associated with reminder campaigns, is to extend the time frame of the advertising message over a long period. The campaign provides continuity of the message, although at the cost of the impact. These continuous patterns are often used for mature products, where reminder advertising is appropriate. Over a long term .this strategy is more appropriate for products and services where the demand is constant or there is a long purchase cycle. There can be perfect continuous advertising, rising continuity or falling continuity.

Roll No. XXXX

1. Rising continuity: this pattern is used when the advertising circles around a particular event. E.g. the advertisement for Paints generally increases during the festive seasons like divali. 2. Falling continuity: this pattern may follow an initial burst to launch a new product or to inform a product modification. Pulsing Campaign: A compromise between the burst and the continuous strategy is the development of the pulsing campaign. Here a comparatively low level of media activity is maintained over long period of time, with periodic increases in the expenditure patterns. It is often associated with seasonal or other influences on buyer activities. Normally, scheduling is done for a 4-week period. The six types of schedules available are: 1. Steady pulse: it is the easiest. For instance, one ad/week for 52 weeks or one ad/month for 12 months. 2. Seasonal pulse: ads are scheduled to meet seasonal peaks by appearing in concentrated doses ahead of buying season. Products like Vicks Balm, Glycodin TerpVasaka Syrup, and Ponds cold cream follow this approach. 3. Period pulse: Scheduling follows a regular pattern, e.g., media scheduling of consumer durables, non-durables, etc. 4. Erratic pulse: The ads are spaced irregularly. Perhaps, we want to change the typical purchase cycles. 5. Start-up pulse: It is concentrated media scheduling. It launches a new product or a new campaign. 6. Promotional pulse: A one-shot affair it suits only particular promotional theme. Heavy concentration during a period is the characteristic of this scheduling. For instance, financial advertising of companys issue.

Roll No. XXXX

Q3. Define production management. What are the various functions involved in production management? Production management means planning, organising, directing and controlling of production activities. Production management deals with converting raw materials into finished goods or products. It brings together the 6M's i.e. men, money, machines, materials, methods and markets to satisfy the wants of the people. Production management also deals with decision-making regarding the quality, quantity, cost, etc., of production. It applies management principles to production. Production management is a part of business management. It is also called "Production Function." Production management is slowly being replaced by operations management. The main objective of production management is to produce goods and services of the right quality, right quantity, at the right time and at minimum cost. It also tries to improve the efficiency. An efficient organisation can face competition effectively. Production management ensures full or optimum utilisation of available production capacit Functions of Production Management Functions of production management are depicted, listed & explained below.

Roll No. XXXX

The components or functions of production management are as follows: 1. 2. 3. 4. 5. 6. 7. 8. Selection of Product and Design, Selection of Production Process, Selecting Right Production Capacity, Production Planning, Production Control, Quality and Cost Control, Inventory Control, and Maintenance and Replacement of Machines

The above functions of production management are briefly discussed below. 1. Selection of Product and Design Production management first selects the right product for production. Then it selects the right design for the product. Care must be taken while selecting the product and design because the survival and success of the company depend on it. The product must be selected only after detailed evaluation of all the other alternative products. After selecting the right product, the right Roll No. XXXX

design must be selected. The design must be according to the customers' requirements. It must give the customers maximum value at the lowest cost. So, production management must use techniques such as value engineering and value analysis. 2. Selection of Production Process Production management must select the right production process. They must decide about the type of technology, machines, material handling system, etc. 3. Selecting Right Production Capacity Production management must select the right production capacity to match the demand for the product. This is because more or less capacity will create problems. The production manager must plan the capacity for both short and long term's production. He must use break-even analysis for capacity planning. 4. Production Planning Production management includes production planning. Here, the production manager decides about the routing and scheduling. Routing means deciding the path of work and the sequence of operations. The main objective of routing is to find out the best and most economical sequence of operations to be followed in the manufacturing process. Routing ensures a smooth flow of work. Scheduling means to decide when to start and when to complete a particular production activity. 5. Production Control Production management also includes production control. The manager has to monitor and control the production. He has to find out whether the actual production is done as per plans or not. He has to compare actual production with the plans and finds out the deviations. He then takes necessary steps to correct these deviations. 6. Quality and Cost Control Production management also includes quality and cost control. Quality and Cost Control are given a lot of importance in today's competitive world. Customers all over the world want goodquality products at cheapest prices. To satisfy this demand of consumers, the production manager must continuously improve the quality of his products. Along with this, he must also take essential steps to reduce the cost of his products.

Roll No. XXXX

7. Inventory Control Production management also includes inventory control. The production manager must monitor the level of inventories. There must be neither over stocking nor under stocking of inventories. If there is an overstocking, then the working capital will be blocked, and the materials may be spoiled, wasted or misused. If there is an understocking, then production will not take place as per schedule, and deliveries will be affected. 8. Maintenance and Replacement of Machines Production management ensures proper maintenance and replacement of machines and equipments. The production manager must have an efficient system for continuous inspection (routine checks), cleaning, oiling, maintenance and replacement of machines, equipments, spare parts, etc. This prevents breakdown of machines and avoids production halts.

Roll No. XXXX

Q4. Explain the various phases in project management life cycle.

Remaining answers are available in the full assignments.

For full assignments contact us:

Global Education

Rajdeep: 098662 48187 / 077958 40110 Email: support@smuassignments.com / global.education_smu@yahoo.in Website: www.smuassignments.com

NOTE: The diagonally marked watermark (Sample Assignment of smuassignments.com) will not appear in the paid assignments.

Roll No. XXXX

Potrebbero piacerti anche

- Sample SMU MBA Sem4 Fall 2015Documento4 pagineSample SMU MBA Sem4 Fall 2015Rajdeep KumarNessuna valutazione finora

- Project Guidelines For BBA - SMUDocumento9 pagineProject Guidelines For BBA - SMURahul DewanNessuna valutazione finora

- BBA203 Financial AccountingDocumento3 pagineBBA203 Financial AccountingRajdeep KumarNessuna valutazione finora

- 597183Documento1 pagina597183Smu DocNessuna valutazione finora

- BBA201 Research MethodsDocumento1 paginaBBA201 Research MethodsRajdeep KumarNessuna valutazione finora

- 597183Documento2 pagine597183Smu DocNessuna valutazione finora

- Solved Assignments of SMU MBA Semester 3 Spring 2015Documento4 pagineSolved Assignments of SMU MBA Semester 3 Spring 2015Rajdeep KumarNessuna valutazione finora

- Solved Assignments of SMU BBA Semester 3 Spring 2015Documento3 pagineSolved Assignments of SMU BBA Semester 3 Spring 2015Rajdeep Kumar0% (1)

- Sample SMU MBA Sem3 Fall 2015Documento4 pagineSample SMU MBA Sem3 Fall 2015Rajdeep KumarNessuna valutazione finora

- Solved Assignments of SMU BBA Semester 1 Spring 2015Documento4 pagineSolved Assignments of SMU BBA Semester 1 Spring 2015Rajdeep KumarNessuna valutazione finora

- Solved Assignments of SMU BBA Semester 2 Spring 2015Documento3 pagineSolved Assignments of SMU BBA Semester 2 Spring 2015Rajdeep KumarNessuna valutazione finora

- SMU MBA Semester 4 Spring 2014 Solved AassignmentsDocumento3 pagineSMU MBA Semester 4 Spring 2014 Solved AassignmentsRajdeep KumarNessuna valutazione finora

- Sample MBA Sem2 Fall 2015Documento4 pagineSample MBA Sem2 Fall 2015Rajdeep KumarNessuna valutazione finora

- Solved Assignments of SMU MBA Semester 4 Spring 2015Documento3 pagineSolved Assignments of SMU MBA Semester 4 Spring 2015Rajdeep KumarNessuna valutazione finora

- SMU BBA Semester 2 Summer 2014 AssignmentDocumento4 pagineSMU BBA Semester 2 Summer 2014 AssignmentRajdeep KumarNessuna valutazione finora

- Solved Assignments of SMU MBA Semester 1 Spring 2015Documento3 pagineSolved Assignments of SMU MBA Semester 1 Spring 2015Rajdeep KumarNessuna valutazione finora

- Solved Assignments of SMU MBA Semester 2 Spring 2015Documento4 pagineSolved Assignments of SMU MBA Semester 2 Spring 2015Rajdeep KumarNessuna valutazione finora

- Solved Assignments of SMU MBA Semester 4 Summer 2014 Are Available.Documento3 pagineSolved Assignments of SMU MBA Semester 4 Summer 2014 Are Available.Rajdeep KumarNessuna valutazione finora

- Solved Assignments of SMU MBA Semester 3 Summer 2014 Are Available.Documento4 pagineSolved Assignments of SMU MBA Semester 3 Summer 2014 Are Available.Rajdeep KumarNessuna valutazione finora

- Solved Assignments of SMU MBA Semester 2 Summer 2014 Are Available.Documento4 pagineSolved Assignments of SMU MBA Semester 2 Summer 2014 Are Available.Rajdeep KumarNessuna valutazione finora

- SMU MBA Semester 1 Spring 2014 Solved AssignmentsDocumento3 pagineSMU MBA Semester 1 Spring 2014 Solved AssignmentsRajdeep KumarNessuna valutazione finora

- SMU MBA Semester 2 Spring 2014 Solved AssignmentsDocumento3 pagineSMU MBA Semester 2 Spring 2014 Solved AssignmentsRajdeep KumarNessuna valutazione finora

- SMU MBA Semester 3 Spring 2014 Solved AssignmentsDocumento4 pagineSMU MBA Semester 3 Spring 2014 Solved AssignmentsRajdeep KumarNessuna valutazione finora

- Solved Assignments of SMU MBA Semester 1 Summer 2014 Are Available.Documento4 pagineSolved Assignments of SMU MBA Semester 1 Summer 2014 Are Available.Rajdeep KumarNessuna valutazione finora

- Solved Assignments of SMU BBA Semester 1 Summer 2014 Are Available.Documento4 pagineSolved Assignments of SMU BBA Semester 1 Summer 2014 Are Available.Rajdeep KumarNessuna valutazione finora

- SMU BBA Semester 1 Spring 2014 AssignmentsDocumento3 pagineSMU BBA Semester 1 Spring 2014 AssignmentsRajdeep KumarNessuna valutazione finora

- SMU BBA Semester 5 Spring 2014 Solved AssignmentsDocumento4 pagineSMU BBA Semester 5 Spring 2014 Solved AssignmentsRajdeep KumarNessuna valutazione finora

- SMU MBA Sem1 Summer 2013 Sooved AssignmentDocumento4 pagineSMU MBA Sem1 Summer 2013 Sooved AssignmentRajdeep KumarNessuna valutazione finora

- MK0017Documento2 pagineMK0017Rajdeep KumarNessuna valutazione finora

- MK0018Documento2 pagineMK0018Rajdeep KumarNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Mega StructuresDocumento2 pagineMega StructuresSanthosh KumarNessuna valutazione finora

- Optical Scattering of Gold NanosphereDocumento24 pagineOptical Scattering of Gold NanosphereParas KumarNessuna valutazione finora

- AS and A Level: ChemistryDocumento11 pagineAS and A Level: ChemistryStingy BieNessuna valutazione finora

- ETR Series: A Full Spectrum of Products To Solve Your Application NeedsDocumento106 pagineETR Series: A Full Spectrum of Products To Solve Your Application Needs周小安Nessuna valutazione finora

- Concrete Super Structure ReportDocumento43 pagineConcrete Super Structure ReportLivian TeddyNessuna valutazione finora

- Pitot/Static Systems: Flight InstrumentsDocumento11 paginePitot/Static Systems: Flight InstrumentsRoel MendozaNessuna valutazione finora

- ELS 06 Maret 223Documento16 pagineELS 06 Maret 223Tri WinarsoNessuna valutazione finora

- Pusheen With Donut: Light Grey, Dark Grey, Brown, RoséDocumento13 paginePusheen With Donut: Light Grey, Dark Grey, Brown, RosémafaldasNessuna valutazione finora

- Preview: Proquest Dissertations and Theses 2002 Proquest Dissertations & Theses Full TextDocumento24 paginePreview: Proquest Dissertations and Theses 2002 Proquest Dissertations & Theses Full TextFelipe AguilarNessuna valutazione finora

- Chillers VoltasDocumento4 pagineChillers Voltasanil shuklaNessuna valutazione finora

- Gondola CalculationDocumento6 pagineGondola CalculationBudi SusantoNessuna valutazione finora

- Chapter 7 - Stress - TransformationsDocumento21 pagineChapter 7 - Stress - TransformationsroselleNessuna valutazione finora

- Tabla de Avances de AcesoriosDocumento3 pagineTabla de Avances de AcesoriosPedro Diaz UzcateguiNessuna valutazione finora

- B737-3 ATA 23 CommunicationsDocumento112 pagineB737-3 ATA 23 CommunicationsPaul RizlNessuna valutazione finora

- TheBasicsofBrainWaves - RS PDFDocumento4 pagineTheBasicsofBrainWaves - RS PDFOnutu Adriana-LilianaNessuna valutazione finora

- 1.1.3.12 Lab - Diagram A Real-World ProcessDocumento3 pagine1.1.3.12 Lab - Diagram A Real-World ProcessHalima AqraaNessuna valutazione finora

- Nomenclatura SKFDocumento1 paginaNomenclatura SKFJuan José MeroNessuna valutazione finora

- LinkageDocumento9 pagineLinkageHarshu JunghareNessuna valutazione finora

- Flow Zone Indicator Guided Workflows For PetrelDocumento11 pagineFlow Zone Indicator Guided Workflows For PetrelAiwarikiaar100% (1)

- 3 Curvilinear MotionDocumento50 pagine3 Curvilinear Motiongarhgelh100% (1)

- Coding Decoding Sheet - 01 1678021709186Documento9 pagineCoding Decoding Sheet - 01 1678021709186Sumit VermaNessuna valutazione finora

- Conceptual Artist in Nigeria UNILAGDocumento13 pagineConceptual Artist in Nigeria UNILAGAdelekan FortuneNessuna valutazione finora

- Reynold A. Nicholson - The Mystics of IslamDocumento65 pagineReynold A. Nicholson - The Mystics of IslamLuminon SamanNessuna valutazione finora

- Surface Finish Measurement NotesDocumento32 pagineSurface Finish Measurement NotesAneez ShresthaNessuna valutazione finora

- Project ReportDocumento14 pagineProject ReportNoah100% (7)

- 1F-Korean-Nami Mun - Miles From NowhereDocumento4 pagine1F-Korean-Nami Mun - Miles From NowhereNeil PatelNessuna valutazione finora

- ff2023 Web 0 0Documento2 pagineff2023 Web 0 0khaing khantNessuna valutazione finora

- Ecological Quality RatioDocumento24 pagineEcological Quality RatiofoocheehungNessuna valutazione finora

- Kami Export - Subject Complements-1 PDFDocumento3 pagineKami Export - Subject Complements-1 PDFkcv kfdsaNessuna valutazione finora

- Pharmalytica Exhibitor List 2023Documento3 paginePharmalytica Exhibitor List 2023Suchita PoojaryNessuna valutazione finora