Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lyncole Ground Test Methods

Caricato da

evaristoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lyncole Ground Test Methods

Caricato da

evaristoCopyright:

Formati disponibili

Soil Resistivity Testing

Lyncole XIT Grounding www.Lyncole.com

Soil Resistivity Testing

Where Grounding Bonds With Sciencetm

www.Lyncole.com 1-800-962-2610

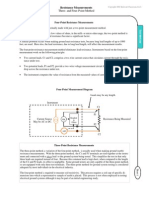

Four Point Wenner Method

LEP-1001

Table of Contents 1. General

1.1 Purpose 1.2 Scope 1.3 Introduction 1.4 Theory 2 2 2 3

2. Testing Procedure

2.1 Equipment 2.2 Procedure 5 6

List of Figures

1-1 Principle of Operation 2-1 Testing Layout 2-2 Resistivity Report Form 5 7 8

LEP-1001

Revised 9/09/05

Soil Resistivity Testing

Lyncole XIT Grounding www.Lyncole.com

1. General 1.1 Purpose

This document was developed as a guideline and process for understanding the concepts of, and determining soil resistivity.

1.2 Scope

This document presents the theory and methodology of soil resistivity testing, the equipment required, a detailed test procedure and forms. It also explains the use of the soil resistivity data in designing grounding systems to meet specific performance requirements.

1.3 Introduction

Soil resistivity data is the key factor in designing a grounding system for a specific performance objective. All soil conducts electrical current, with some soils having good electrical conductivity while the majority has poor electrical conductivity. The resistivity of soil varies widely throughout the world and changes dramatically within small areas. Soil resistivity is mainly influenced by the type of soil (clay, shale, etc.), moisture content, the amount of electrolytes (minerals and dissolved salts) and finally, temperature. When designing a grounding system for a specific performance objective, it is necessary to accurately measure the soil resistivity of the site where the ground is to be installed. Grounding system design is an engineering process that removes the guesswork and art out of grounding. It allows grounding to be done right, the first time. The result is a cost savings by avoiding change orders and ground enhancements.

LEP-1001

Revised 9/09/05

Soil Resistivity Testing

Lyncole XIT Grounding www.Lyncole.com

1.4 Theory

The best method for testing soil resistivity is the Wenner Four Point method. It uses a 4-pole digital ground resistance meter, such as the Megger 5/4 or the AEMC 4500 meters, probes, and conductors. It requires inserting four probes into the test area. The probes are installed in a straight line and equally spaced (See Figure 1-1). The probes establish an electrical contact with the earth. The four pole test meter injects a constant current through the ground via the tester and the outer two probes. The current flowing through the earth (a resistive material) develops a voltage / potential difference. This voltage drop resulting from the current flow is then measured between the two inner probes. The meter then knows the amount of current that is flowing through the earth and the voltage drop across the two center probes. With this information the meter uses ohms law (R=E/I) to calculate and display the resistance in ohms This displayed resistance value is in ohms and must be converted to ohms-meter, which are the units of measure for soil resistivity. Ohms-meter is the resistance of a volume of earth that is one meter by one meter by one meter, or one cubic meter. To convert from the displayed ohms to ohms-meter, the meter reading is multiplied by 1.915 and the result multiplied times the probe spacing. The following shows the calculation in a formula.

(ohms-m) = 1.915 x R x A

= soil resistivity in ohm-m (-m ). 1.915 constant R = digital readout in ohms (). A = distance between electrodes in ft.

LEP-1001

Revised 9/09/05

Soil Resistivity Testing

Lyncole XIT Grounding www.Lyncole.com

1.4 Theory (continued)

Readings are usually taken at probe spacings of 5, 10, 15, 20, 30, and 40, 60, 80 and 100 feet. If the testing is being performed for the purposes of ground potential rise (GPR) studies or for substation design, readings up to 150 foot probe spacing should be performed. The calculated soil resistivity is the average of the soil resistivity from the surface to a depth equivalent to the probe spacing. For example, a probe spacing of 20 feet between each probe will provide the average soil resistivity between the surface and a depth of 20 feet. Probe Spacing 5 10 20 30 40 60 80 100 Avg. Soil Resistivity From Surface to: 5 10 20 30 40 60 80 100

Several readings at the different probe spacings and at different areas of the site are required. The more data available to the design agency, the more accurately they will be able to design and predict the grounding system performance. The benefits to the customer are that the job is done right the first time. Readings should be taken along at least two sides of the site and diagonally from one corner to another. A pipe or some underground structure could influence the readings. The more data available and used in the design provides more confidence in the outcome.

LEP-1001

Revised 9/09/05

Soil Resistivity Testing

Lyncole XIT Grounding www.Lyncole.com

Figure 1-1: Principle of Operation

Ground Resistance Tester

C1 P1

Voltage Drop Current Flow

C2 P2

2. Testing Procedures 2.1 Equipment Required

A 4-Pole Digital - Ground Resistance Tester At least four probes Four insulated wire conductors Measuring tape Hammer (to drive probes) Users Manual for Meter

LEP-1001

Revised 9/09/05

Soil Resistivity Testing

Lyncole XIT Grounding www.Lyncole.com

2.2 Procedure

The following procedure is generic and will work with all meters. The meters manual should be consulted for operational details. Step 1. Verify that the metal strip between the meters C1 and P1 terminals is disconnected (used for for 3-Point testing). Step 2. Install the 4 test probes in the ground equally spaced in a straight line. Generally the shorter spacing is done first (I.e. 5). Step 3. Using the conductors, connect the C1, P1, P2 and C2 terminals to the electrodes. The electrodes must be connected in order from the end, to the C1, P1, P2 and C2 terminals. The test results will be invalid If the electrodes are not connected properly. Step 4. Press the test button and read the digital display. Record the reading on the worksheet at the appropriate location. If the reading is not stable or displays an error indication, doublecheck the connections. For some meters, the RANGE and TEST CURRENT settings may be changed until a combination that provides a stable reading without error indications is reached. Also, an effective way of decreasing the electrode resistance to ground is by pouring water around it. The addition of moisture is insignificant for the reading; it will only achieve a better electrical connection and will not influence the overall results. Also a longer probe or multiple probes (within a short distance) may help. Step 5. Place the probes at each of the spacings indicated above and record the readings on the worksheet (See Figure 2-1). Steps 1-5 of this procedure must be repeated at multiple locations on the site to obtain a reliable soil profile. Step 6. Fax, phone or email these readings to Lyncole Technical Services or insert the reading in the formula described earlier (p=191.5 X R X A) to obtain your soil resistivity readings.

NOTE:

If an AEMC 4500 meter is used, first select the highest RANGE (20K-ohms) and the lowest test current (2 ma). When a resistance reading is displayed, adjust the RANGE to the lowest setting that still provides a stable reading without error indications.

6 Revised 9/09/05

LEP-1001

Soil Resistivity Testing

Lyncole XIT Grounding www.Lyncole.com

Procedure (continued)

Stray currents, buried water pipes, cable sheaths and other factors may interfere and distort the readings. Measurements should be taken along 3 directions at each site as a minimum. Sometimes this may not be feasible, but the more data that can be obtained, the more accurate the generated soil model will be.

Figure 2-1: Testing Layout

Building A Soil Resistivity Profile A minimum of 3 Lines of testing should be performed.

Property line

A minimum of readings from three areas (two along the sides and one through the center) is recommended.

If you have any questions, do not hesitate to give us a call on the Lyncole Technical Services Hotline: (800) 962-2610. Fax: 310-214-1114. Email: support@lyncole.com.

LEP-1001

Revised 9/09/05

Soil Resistivity Testing

Lyncole XIT Grounding www.Lyncole.com

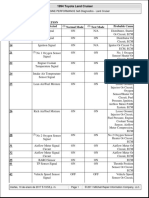

Figure 2-2: Recording Soil Resistivity

Lyncole Technical Services 3547 Voyager St. #204 Torrance, CA 90503 800-962-2610 Tel 310-214-1114 Fax www.lyncole.com

Soil Resistivity Field Report

COMPANY CONFIDENTIAL

Project Number:

LEF-1001.01

TECHNICAL SERVICES

Where Grounding Bonds With Science TM

Client: Conditions: Test Completed by: Test Instrument:

Project Name: Soil: Test Method: Serial Number: Testing Results Test Location Probe Spacing (ft) 5 ft 10 ft 15 ft 20 ft 30 ft 40 ft 60 ft 80 ft 100 ft Meter Reading ( )

Date Of Test:

Calibration Date:

Calculation: Soil resistivity ( -m) = 1.915 x Probe Spacing (ft) x R( ) Calculated Soil Resistivity ( -m)

5 ft 10 ft 15 ft 20 ft 30 ft 40 ft 60 ft 80 ft 100 ft

5 ft 10 ft 15 ft 20 ft 30 ft 40 ft 60 ft 80 ft 100 ft

LEP-1001

Revised 9/09/05

Ground System Testing (Clamp-On Method)

Lyncole XIT Grounding www.Lyncole.com

Ground System Testing

Where Grounding Bonds With ScienceTM

www.lyncole.com 1-800-962-2610

Clamp-On Meter Method

LEP-1002

2

2 2 2 3 5 5

Table of Contents 1. General

1.1 Purpose 1.2 Scope 1.3 Introduction 1.4 Principle of Operation 1.5 Advantages of Clamp-On Meter

1.6 Determining the Correct Measuring Point

2. Testing Procedures

2.1 Setting Up For The Test 2.2 Taking The Measurement 2.3 Interpreting The Results 8 8 8

List of Figures

1-1 Principle of Operation 1-2 Testing Location Overview 1-3 Field Report Form 4 7 10

LEP-1002

Revised: 09/09/05

Ground System Testing (Clamp-On Method)

Lyncole XIT Grounding www.Lyncole.com

1. General

1.1 Purpose

This document provides a procedure and explains the equipment operation for the Clamp-On resistance test and should be used as a guideline.

1.2 Scope

This document lists the procedures and equipment required to perform a Clamp-on test utilizing the AEMC Model 3711 / 3731 and the Megger Model DET10C / 20C. The procedures and theory of operation are the same for all Clamp-On ground test meters.

1.3 Introduction

The Clamp-on Ground Resistance Tester is designed to measure ground rod and ground grid resistance without the use of the auxiliary electrodes. It can also verify the continuity of the grounding connections and enable the evaluation of neutral currents or currents flowing to ground. The Clamp-On method was developed as an alternative to the Fall of Potential test and has some distinct advantages. One benefit over the Fall of Potential method is that the Clamp-On test requires that the ground system be connected to the utility neutral, versus the requirement that it be isolated as with the Fall of Potential. The ground system is normally connected to the utility neutral through the ground-neutral bond at the service entrance. The isolation required by the Fall of Potential method is most often difficult or impossible but if not done will result in an invalid test.

LEP-1002

Revised: 09/09/05

Ground System Testing (Clamp-On Method)

Lyncole XIT Grounding www.Lyncole.com

1.4 Principle of Operation

The typical site or facility has its own equipment grounding system which is connected to the utility multi grounding neutral conductor at the service entrance panel. This grounded neutral from the power utility is common to all utility customers in the region with the result being that the neutral ties innumerable grounds together, all in parallel. Because of the numerous parallel grounds, the effective earth resistance of the utility grounds at the low frequencies typical with power and testing, is virtually zero. (See Figure 1-1). The meter head contains two control transformers. One transformer induces a small fixed voltage (at approximately 2khz) on the grounding conductor. If a path exists, the voltage will result in current flow. The path normally consists of the ground system under test, the utility neutral wire and the utility ground system, (figure 1-1). The second transformer in the meter head then senses the amount of current (a unique frequency) flowing in the path. The amount of current flow is determined by the voltage induced and the amount of resistance in the path. The resistance is made up of the resistance of the ground system under test and the resistance of the utility neutral grounds. The meter knows the amount of voltage it induces and measures the current on the path; it now has two unknowns of ohms law and simply reads out in resistance. With the near zero grounding resistance from the utility side, the meter measurement shows the site ground resistance only.

LEP-1002

Revised: 09/09/05

Ground System Testing (Clamp-On Method)

Lyncole XIT Grounding www.Lyncole.com

Figure 1-1: Principle of Operation

Utility Neutral Line

NeutralGround Bond Grounding Conductor

R = E/I

Current Flow

???

LEP-1002

Revised: 09/09/05

Ground System Testing (Clamp-On Method)

Lyncole XIT Grounding www.Lyncole.com

1.5 Advantages of Using the Clamp-On Hand Held Meter

The Clamp-On meter offers many advantages over the traditional method of testing. Much testing done with this method is invalid due to the operator not understanding the principles of operation and lack of training. When properly utilized, the following are a minimum of benefits: No need to disconnect the utility or isolate the grounding system. The meter can also be used with the equipment powered up. No probes to be driven or long conductors to be utilized. Access to large a area is not required. Safe, non-contact measurement system reduces risk. Easy to use, accurate, one step measurement.

1.6 Determining The Correct Measuring Point

Finding the proper location to install the Clamp-On tester can be challenging in some facilities or sites. With a good understanding of the meter operation, the chances are much better that a successful test can be performed. Refer to the operators manual for safety and other precautions. If the facility has a single point ground, normally determining the proper test point is very easy. Also, if you are testing a single driven rod or other single electrode, it should be relatively easy.

LEP-1002

Revised: 09/09/05

Ground System Testing (Clamp-On Method)

Lyncole XIT Grounding www.Lyncole.com

1.6 Determining The Correct Measuring Point (Continued)

Figure 1-2 illustrates one good and two bad locations to test with the Clamp-On meter. Position 1 would not work because the path for the current flow caused by the meter would not be through the earth. The current would flow to the air duct and most likely the air duct would have electrical contact with building steel which is tied to the bus bar. It would essentially be a short circuit. Position 2 also would not work due to the current flowing to the equipment which should be isolated from the floor. It should read an open loop. The current in Position 3 would go through the ground and return via the utility neutral grounds to the facility and grounding conductor. Caution The operating manual for the Clamp-On meter should be thoroughly reviewed prior to meter use. Anytime work is performed involving electrical systems and / or equipment and subsystems extreme caution must be exercised and all appropriate precautions must be observed.

LEP-1002

Revised: 09/09/05

Ground System Testing (Clamp-On Method)

Lyncole XIT Grounding www.Lyncole.com

1.6 Determining The Correct Measuring Point (continued)

Figure 1-2 Test Location

Position 2 Position 1

Position 3

Equipment

`

LEP-1002

Revised: 09/09/05

Ground System Testing (Clamp-On Method)

Lyncole XIT Grounding www.Lyncole.com

2. Testing Procedures 2.1 Setting up the Meter for Measurement

Check that the surfaces of the jaws are properly aligned and free from contamination. Check the calibration of the meter with the calibration loop (provided by the meter manufacturer), ensuring that the readings are within the tolerances indicated in the user manual.

2.2 Taking the Measurement

Rubber gloves are recommended for added safety. Select the current option (A) on the meter and clamp around the conductor. If the ground currents exceeds 5 A or noise exceeds 50 V, resistance measurements cannot be taken. Note this for maintenance. Select the ground resistance option (), clamp around the grounding conductor as described in Figure 1-2 for the reading.

2.3 Interpreting the Results

The display indicates the correct resistance of the system under test. Clamp-On meters will generally read accurately down to 0.1 ohm or less. It is very unusual to have a correct reading less than 1.0 ohm. Not many ground systems are below two ohms, certainly without a design and construction effort. If an unexpected low reading is observed the operating principles of the meter should be reviewed and the connection point should be reconsidered. Low resistance grounds do exist, they are just pretty rare.

LEP-1002

Revised: 09/09/05

Ground System Testing (Clamp-On Method)

Lyncole XIT Grounding www.Lyncole.com

2.3 Interpreting the Results (Continued)

If the reading on the meter is <1 ohm, there may be a continuity loop present and the test may have been performed at an incorrect location. Perform a visual inspection of the system under test to determine if any downstream neutral to ground bonds exist. If the reading on the meter is OL (OverLoad) the system under test does not have a complete conductive path, or loop for the current to flow in.

LEP-1002

Revised: 09/09/05

Ground System Testing (Clamp-On Method)

Lyncole XIT Grounding www.Lyncole.com

TECHNICAL SERVICES

Lyncole Technical Services 3547 Voyager St. #104 Torrance, CA 90503 800-962-2610 Tel 310-214-1114 Fax www.lyncole.com

Clamp-On Resistance Field Report

COMPANY CONFIDENTIAL

LEF-1002.01

Where Grounding Bonds With Science TM

Date of Test: Client: Project Name: Conditions: Test Completed By: Test Method: Clamp-On Resistance Test Test Instrument:

Project Number:

Copy To: Soil:

Serial Number:

Calibration Date:

Comments: * This test measures ground currents, resistance to earth for ground electrodes and ground path resistance (determines whether or not the grounding conductor under test is electically continuous through a multiple grounding path). CAUTION It is not common that ground resistance be under 2 ohms. If a low reading occurs, you should ensure that the meter is being used properly. If the reading is below 1 ohm, it is likely a reding of continuity, not ground resistance.

Testing Results:

Description of Systems Tested Test Point A: Test Point B: Test Point C: Test Point D: Test Point E: Test Point F: Test Point G: Current Measurement Resistance Measurement

Field Report Form

LEP-1002

10

Revised: 09/09/05

Ground System Testing (Fall of Potential Method)

Lyncole XIT Grounding www.Lyncole.com

Where Grounding Bonds With Sciencetm

www.lyncole.com 1-800-962-2610

Ground System Testing Fall of Potential Method

LEP-1003

2

2 2 2 3

Table of Contents 1. General

1.1 Purpose 1.2 Scope 1.3 Introduction 1.4 Theory

2. Testing Procedures

2.1 Safety Information 2.2 Equipment 2.3 Procedures 6 6 7 3 5 9 9 10 11

List of Figures

1-1 1-2 2-1 2-2 2-3 2-4 Principle of Operation Ground Resistance Testing Valid Test Graph Invalid Test Graph 1 Invalid Test Graph 2 Sample Report Form

LEP-1003

Revised: 09/09/05

Ground System Testing (Fall of Potential Method)

Lyncole XIT Grounding www.Lyncole.com

1. General 1.1 Purpose

The purpose of this document is to provide the ability to properly test an installed grounding system utilizing the Fall Of Potential method.

1.2 Scope

This document lists the ground test meters, ancillary equipment and detailed procedures for performing a proper 3 Point Fall of Potential Test. It also provides the ability to determine the validity of the test results and shows examples of proper and invalid test results.

1.3 Introduction

The Fall Of Potential method is the most recognized method for measuring the resistance to earth of a grounding system, or the ground system performance. It is based on an IEEE standard and when properly performed, it is a very accurate test. Although most people recognize that grounding is required for personnel protection, the grounding system also serves as the basis for the electrical protection of your site or facility. It determines the effectiveness of the lightning protection and surge suppression systems. Without good grounding, these systems do not function. Grounding also serves as the path for system noise to be dissipated from equipments. Grounding systems should be tested upon installation and then annually during their service life. The initial testing establishes a performance baseline, confirms that the design specification is met and validates the quality of the installation. Annual testing ensures the continued integrity of the system and provides protection against degradation prior to equipment damage or performance problems.

LEP-1003

Revised: 09/09/05

Ground System Testing (Fall of Potential Method)

Lyncole XIT Grounding www.Lyncole.com

1.4 Theory

In the fall of potential test, three points of ground contact are considered: 1. The grounding system under test (X) 2. A current probe (Z) placed some distance from the ground system under test. 3. A voltage probe (Y) that is inserted at various distances between the system under test and the current probe. Ideally the X-Z distance should be 10 times the ground rod length or grid width (i.e. 10 ft. rod, 100 ft. spacing).

Figure 1-1: Principle of Operation

Current Flow

Ground System Under Test (X)

Auxiliary Voltage Probe (Y) Voltage Drop

Remote Current Probe (Z)

Earth

LEP-1003

Revised: 09/09/05

Ground System Testing (Fall of Potential Method)

Lyncole XIT Grounding www.Lyncole.com

1.4 Theory (Continued)

Note: Lyncoles experience has shown that the (Z) probe may be placed at a minimum 5 times the length of the ground rod under test (i.e.10 foot rod, 50 ft spacing). If a grid is being tested, the minimum distance is 5 times the widest point of the grid. However, always go 10 times if the space is available. Evaluating the test results is the only way of validating the results and determining if the distance was adequate.

With this method of test, the meter injects a current into the ground system under test (X). The current flows through the earth to the remote current probe (Z) and returns to the meter. As the current flows through the resistive material (earth) a voltage drop is created. This voltage drop is proportional to the amount of current flow and the resistance of the ground system to earth. The voltage probe (Y) is used to measure this voltage drop. The meter then knows both the amount of current flow and the resulting voltage drop. It simply uses Ohms law to calculate and display the resistance. The resistance is measured at several locations moving the voltage probe (Y) at regular intervals, each of them equal 10% distance XZ. The resistance measurements are then plotted along with the distance between the ground system and the Y probe. From this graph the actual ground system resistance can be determined along with the validity of the test. See Figure 2-1, pg. 9. The grounding system must be electrically isolated for the 3 Point Test to be valid. If not isolated, the readings will reflect all the grounding systems in the area hooked in parallel. The reading will always be very low and have no bearing on the actual ground system resistance. The result is not an inaccurate test, but an invalid one. The fall of potential method is the most reliable method of ground resistance testing. However, in about 95 % out of the cases, the test is invalid because. Once again, we have to emphasize the fact that this method is based on ideal test conditions including complete electrical isolation of the grounding system and proper

LEP-1003

Revised: 09/09/05

Ground System Testing (Fall of Potential Method)

Lyncole XIT Grounding www.Lyncole.com

spacing of the current probe.

1.4 Theory (Continued)

It is also important to emphasize that this is a ground test, performed on a circuit controlled by many factors as well as by their interdependence and interference. The current going into ground via a buried electrode is not following a straight line path as in a typical conventional electric circuit. Fault current radiates in all directions around the electrode, but the pattern of dispersal depends of the surrounding soil and its environment. Considering all of these, it is strongly recommended to perform the test in at least two perpendicular directions. If enough space is available for additional testing, more measurements will increase the accuracy of the soil model and will help eliminate the errors caused by nearby buried conductors, pipes or other metallic parts.

Figure 1-2: Ground Resistance Testing

Current

Remote Current Electrode Neutral

Current

LEP-1003

Revised: 09/09/05

Ground System Testing (Fall of Potential Method)

Lyncole XIT Grounding www.Lyncole.com

2. Testing Procedures 2.1 Safety Warning Information

There is a possibility that a fault on a power system will cause a current flow on the ground system while a test is in progress, causing unexpected high voltages on the current and voltage probes. If a significant risk exists, it is recommended that the persons performing the test use protective rubber gloves and a rubber safety mat during the test. Note: The grounding system must be electrically isolated during this test. This should only be performed by qualified personnel and after permission is granted by all responsible personnel. Check for current on the ground before disconnecting. Do not disconnect the ground of a live circuit. Disconnecting the ground of a live circuit could cause severe injury or even death.

2.2 Equipment

A 4-Pole or a 3-Pole Digital - Ground Resistance Tester At least three probes Insulated wire leads Tape measure Hammer (to secure probes into earth)

LEP-1003

Revised: 09/09/05

Ground System Testing (Fall of Potential Method)

Lyncole XIT Grounding www.Lyncole.com

2.3 Procedures

Note 1: In order for the test to provide valid results, the ground system must be de-energized and disconnected from the utility neutral system. Any connections that could provide a path to the utility neutral must be disconnected. Note 2: operation. 1) Check your operators manual for detailed meter

Isolate the grounding grid under test from all other supplemental grounds (i.e. water pipes, building steel, etc.). Also disconnect any neutral connections and all telco. If a 4-pole ground resistance meter is used, some meters require a connection between the C1 and P1 terminals. If a 3-pole ground resistance meter is used, no connection between the terminals is required. Connect the C1 connection to the ground rod or system to be tested. Install the current probe (Z) at a distance equal to 5-10 times the length of the ground rod or 5-10 times the diagonal distance of the ground grid under test. If a ring or grid is being tested, the distance must be measured from the outer edge of the ring. The probe must have good contact with the earth. Connect this probe to the C2 connection on the meter. Install the voltage probe (Y) at approximately 3% of the distance from the ground system and the (Z) probe. The (Y) probe must be in line with the ground and the (Z) probe. Connect the probe to the P2 connection on the meter. Push button to activate the meter. When a measurement is shown, allow the reading to stabilize and record the reading in the chart of page 11.

2)

3) 4)

5)

6)

LEP-1003

Revised: 09/09/05

Ground System Testing (Fall of Potential Method)

Lyncole XIT Grounding www.Lyncole.com

Procedures (Continued)

7) Move the (Y) probe to 10% of the distance between ground system and (Z). Test as in step 6 and record the results in a chart as on page 11. Repeat this step (moving the probe at 10% intervals) until the 90% distance is reached. Once all the readings have been recorded, plot a graph with the measured resistances as the y-axis. The distance from the (X) probe is the x-axis. At approximately 62% of the total distance, a plateau or flat spot should be noticeable in the plot. The resistance at this plateau is the resistance of the system under test. If there is no leveling of the plot, then the test is to be considered invalid since the (Z) probe is not far enough from the (X) probe. If the plateau is very low and flat, then the test is considered invalid and most like still has an intentional or unintentional neutral connection. See Figures 2-1, 2-2, 2-3, pgs.9-10. If difficulty is encountered in obtaining readings, it is most likely caused by a high probe to earth resistance. Pouring water or Gatorade on the probes sometimes helps. This will not have any significant effect on the reading. If available installing longer probes that provide a more surface contact may also help. Some meters have less difficulty overcoming the probe to earth resistance than others. Perform additional testing in at least one perpendicular direction. The readings should be averaged.

8)

9)

10)

11)

Note: If a AEMC 4500 meter is used, first select 2 mA on the Test Current selector, set the Range to 20 kOhms and press the Test button. If the display blinks, lower the range until it blinks again. Then increase the Range one setting. If the display never stops blinking, increase the Test Current to 10 mA and start again. If the pointer appears in the upper left corner of the display, there is excessive electrode resistance and transient noise. Check all the connections if this occurs. If the measurement is over the range of the meter, the display will read 1 of the display will blink and the indicator in the upper left corner will be lit. Increase the Range or Test Current, as needed. Also check for proper cable connections and probe contact with the soil.

LEP-1003

Revised: 09/09/05

Ground System Testing (Fall of Potential Method)

Lyncole XIT Grounding www.Lyncole.com

Figure 2-1 Valid Test Graph Plateau, or Resistance of the Ground System

Measured Resistance Of The System

Y Probe Distance

Figure 2-2 Invalid Test Graph 1

Invalid Test Graph No Plateau Not enough distance between Ground System and the Z probe

Measured Resistance Of The System

Y Probe Distance

LEP-1003

Revised: 09/09/05

Ground System Testing (Fall of Potential Method)

Lyncole XIT Grounding www.Lyncole.com

Figure 2-3 Invalid Test Graph 2

Invalid Test Graph

Measured Resistance Of the System

Neutral not disconnected

Y Probe Distance

LEP-1003

10

Revised: 09/09/05

Ground System Testing (Fall of Potential Method)

Lyncole XIT Grounding www.Lyncole.com

Lyncole Technical Services 3547 Voyager St. #104 Torrance, CA 90503 800-962-2610 Tel 310-214-1114 Fax TECHNICAL SERVICES www.lyncole.com

Fall-of-Potential Ground Resistance Field Report

COMPANY CONFIDENTIAL

Project Number:

LEF-1003.01

Where Grounding Bonds With Science TM

Date of Test: Client: Project Name: Conditions: Test Location: Test Completed by: Test Method: Fall-of-Potential Test Instrument: Testing Layout:

Copy to: Soil:

Serial Number:

Calibration Date:

Testing Results: Distance From Grid

%

Test Data

Ft.

1 ft 10% 20% 30% 40% 50% 60% 70% 80% 90% C2 Total 1Ft 10% 20% 30% 40% 50% 60% 70% 80% 90% C2 (Probe P2 Distance From Ground Grid)

Additional Notes:

LEP-1003

11

Revised: 09/09/05

Potrebbero piacerti anche

- Electromagnetic Compatibility: Analysis and Case Studies in TransportationDa EverandElectromagnetic Compatibility: Analysis and Case Studies in TransportationNessuna valutazione finora

- Wenner Four Point MethodDocumento8 pagineWenner Four Point MethodSushant Kumar Singh100% (1)

- App Ground SoilResistivityDocumento7 pagineApp Ground SoilResistivityPrashanth Reddy GouniNessuna valutazione finora

- Manual Soil Resistivity Wenner MethodDocumento14 pagineManual Soil Resistivity Wenner MethodShashikant Kr K100% (2)

- Fluid Dynamics in Complex Fractured-Porous SystemsDa EverandFluid Dynamics in Complex Fractured-Porous SystemsBoris FaybishenkoNessuna valutazione finora

- Earth Resistance TesterDocumento8 pagineEarth Resistance TesterAnonymous vcadX45TD7Nessuna valutazione finora

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984Da EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984Nessuna valutazione finora

- Abdalla Aly Issa - 4915Documento8 pagineAbdalla Aly Issa - 4915Abdalla El DemrdashNessuna valutazione finora

- Hall-Effect Sensors: Theory and ApplicationDa EverandHall-Effect Sensors: Theory and ApplicationValutazione: 5 su 5 stelle5/5 (1)

- GeoPlus OiengDocumento98 pagineGeoPlus Oiengjazz217Nessuna valutazione finora

- Soil Resistivity ProcedureDocumento7 pagineSoil Resistivity Procedurephelo1100% (1)

- Design of Earthing SystemDocumento4 pagineDesign of Earthing SystemhughgossNessuna valutazione finora

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Brosur GAOTek ERT101 Soil Resistivity Earth Resistance Tester (Enc)Documento10 pagineBrosur GAOTek ERT101 Soil Resistivity Earth Resistance Tester (Enc)wahyu handriyantoNessuna valutazione finora

- Operational Amplifier Noise: Techniques and Tips for Analyzing and Reducing NoiseDa EverandOperational Amplifier Noise: Techniques and Tips for Analyzing and Reducing NoiseValutazione: 5 su 5 stelle5/5 (1)

- Grounding TestDocumento8 pagineGrounding TestAmin JamaludinNessuna valutazione finora

- SOIL CHARACTERISTICSDocumento10 pagineSOIL CHARACTERISTICSRamesh AnanthanarayananNessuna valutazione finora

- Fundamentals of Fault Current and Grounding in Electrical SystemsDa EverandFundamentals of Fault Current and Grounding in Electrical SystemsValutazione: 4 su 5 stelle4/5 (3)

- Critical Facility Grounding - John Howard - Lyncole XIT Grounding PDFDocumento37 pagineCritical Facility Grounding - John Howard - Lyncole XIT Grounding PDFBaskar ElNessuna valutazione finora

- 10HS Manual PDFDocumento24 pagine10HS Manual PDFShivam JaiswalNessuna valutazione finora

- Flight Test Instrumentation: Proceedings of the Third International Symposium 1964Da EverandFlight Test Instrumentation: Proceedings of the Third International Symposium 1964M. A. PerryNessuna valutazione finora

- New Senate Building Project: Method StatementDocumento2 pagineNew Senate Building Project: Method Statementjerrick raulNessuna valutazione finora

- Refurbish Antique Telephones for Fun and Hobby: Step by Step Instructions to Take an Old Telephone and Return It to Its Original Working Order. No Electronics or Telephone Knowledge Needed.Da EverandRefurbish Antique Telephones for Fun and Hobby: Step by Step Instructions to Take an Old Telephone and Return It to Its Original Working Order. No Electronics or Telephone Knowledge Needed.Nessuna valutazione finora

- Design Cathodic ProtectionDocumento19 pagineDesign Cathodic ProtectionDikaAfriandiNessuna valutazione finora

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsDa EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNessuna valutazione finora

- Megger Det 5 4 Earth Tester ManualDocumento72 pagineMegger Det 5 4 Earth Tester ManualmanorajcvNessuna valutazione finora

- DEC 10HS Manual - 750Documento24 pagineDEC 10HS Manual - 750AlbertoBlascoNessuna valutazione finora

- Foundation Testing Data Sheet 1 Pile Integrity Testing - TDR MethodDocumento5 pagineFoundation Testing Data Sheet 1 Pile Integrity Testing - TDR MethodNishit PatelNessuna valutazione finora

- EMC Test of Sandler Sample DC-DC ConvertersDocumento11 pagineEMC Test of Sandler Sample DC-DC Convertersherber_28Nessuna valutazione finora

- Earth Ground Resistance Testing Methods for Accurate Low-Voltage System EvaluationsDocumento8 pagineEarth Ground Resistance Testing Methods for Accurate Low-Voltage System EvaluationsTana AzeezNessuna valutazione finora

- App ADocumento2 pagineApp AAracely CeladaNessuna valutazione finora

- In-Situ Soil Resistivity TestDocumento6 pagineIn-Situ Soil Resistivity TestPriodeep ChowdhuryNessuna valutazione finora

- Grounding PresentationDocumento29 pagineGrounding Presentationykresna1631Nessuna valutazione finora

- Measure Earth Resistance Using Digital Earth TesterDocumento5 pagineMeasure Earth Resistance Using Digital Earth Testerrishika chhibberNessuna valutazione finora

- Cyme GridDocumento6 pagineCyme Gridprabhakaran_hdec100% (1)

- ELECTROLYTIC GROUNDING SYSTEM SPECIFICATIONSDocumento6 pagineELECTROLYTIC GROUNDING SYSTEM SPECIFICATIONSrrcardoso230Nessuna valutazione finora

- Principles of Grounding DesignDocumento16 paginePrinciples of Grounding DesignvanpatoNessuna valutazione finora

- Ground TestDocumento7 pagineGround TestHemendra JaniNessuna valutazione finora

- Earthing Resistance Test ProsedureDocumento6 pagineEarthing Resistance Test ProsedureUtku Can Kılıç0% (1)

- Weather Proof LouvreDocumento6 pagineWeather Proof Louvrentt_121987Nessuna valutazione finora

- Soil Test Resistance MeterDocumento11 pagineSoil Test Resistance Meterjames_frankNessuna valutazione finora

- Earth electrode and earth loop impedance testingDocumento40 pagineEarth electrode and earth loop impedance testingIqbal UsmaniNessuna valutazione finora

- Nguyen 2020 IOP Conf. Ser. Mater. Sci. Eng. 869 052005Documento11 pagineNguyen 2020 IOP Conf. Ser. Mater. Sci. Eng. 869 052005Tom NgNessuna valutazione finora

- Acl 800 Megohmmeter: Operation ManualDocumento13 pagineAcl 800 Megohmmeter: Operation ManualChiew Siew TanNessuna valutazione finora

- Method Statement for Earthing ProtectionDocumento8 pagineMethod Statement for Earthing ProtectionUtku Can KılıçNessuna valutazione finora

- Earth Ground Testing FundamentalsDocumento29 pagineEarth Ground Testing FundamentalsSamyakShahSamyakNessuna valutazione finora

- Electrical Safety ManualDocumento6 pagineElectrical Safety ManualRose ParkNessuna valutazione finora

- Method Statement For Earthing ResistanceDocumento6 pagineMethod Statement For Earthing ResistanceUtku Can Kılıç0% (1)

- 4 Important Methods of Ground Resistance TestingDocumento5 pagine4 Important Methods of Ground Resistance TestingAbdul Mohid SheikhNessuna valutazione finora

- Earth Resistance Testing Methods ExplainedDocumento8 pagineEarth Resistance Testing Methods ExplainedVenkataramanan SNessuna valutazione finora

- Three-And Four-Point Method: Resistance MeasurementsDocumento8 pagineThree-And Four-Point Method: Resistance MeasurementsbcqbaoNessuna valutazione finora

- Earth Electrode and Loop Booklet V2Documento40 pagineEarth Electrode and Loop Booklet V2wizaarz100% (1)

- Measuring Soil Resistivity for Grounding System DesignDocumento34 pagineMeasuring Soil Resistivity for Grounding System DesignRamesh AnanthanarayananNessuna valutazione finora

- Earth Ground Resistance Tester Model 382152: User's ManualDocumento6 pagineEarth Ground Resistance Tester Model 382152: User's ManualZeeshan YasinNessuna valutazione finora

- Samsung Aw109AbDocumento49 pagineSamsung Aw109AbevaristoNessuna valutazione finora

- Samsung SSD Data Migration User Manual English v1.0Documento6 pagineSamsung SSD Data Migration User Manual English v1.0evaristoNessuna valutazione finora

- Book 4: Alternating Current Electric CircuitDocumento566 pagineBook 4: Alternating Current Electric CircuitMAT JIBRUD100% (3)

- Manual Del Constructor PopularDocumento247 pagineManual Del Constructor PopularevaristoNessuna valutazione finora

- Samsung Plasma Training ManualDocumento57 pagineSamsung Plasma Training ManualevaristoNessuna valutazione finora

- 6series Power Consumption2 LCD TVDocumento2 pagine6series Power Consumption2 LCD TVevaristoNessuna valutazione finora

- 775 I 945 GZDocumento41 pagine775 I 945 GZjovicakNessuna valutazione finora

- Samsung Plasma Training ManualDocumento57 pagineSamsung Plasma Training ManualevaristoNessuna valutazione finora

- 6series Power Consumption2 LCD TVDocumento2 pagine6series Power Consumption2 LCD TVevaristoNessuna valutazione finora

- Isa-05 3Documento22 pagineIsa-05 3evaristoNessuna valutazione finora

- Manual Del Constructor PopularDocumento247 pagineManual Del Constructor PopularevaristoNessuna valutazione finora

- GaN technology powers bright LEDsDocumento13 pagineGaN technology powers bright LEDsluciowwNessuna valutazione finora

- Previews AGA XQ9902 PreDocumento6 paginePreviews AGA XQ9902 PreAldrin HernandezNessuna valutazione finora

- NDI Manual 2013 - v10Documento13 pagineNDI Manual 2013 - v10Yudha Bhakti NugrahaNessuna valutazione finora

- Sinusverteiler Multivalent SolutionsDocumento13 pagineSinusverteiler Multivalent SolutionsIon ZabetNessuna valutazione finora

- Equilibrium of A Particle, The Free-Body Diagram & Coplanar Force SystemsDocumento24 pagineEquilibrium of A Particle, The Free-Body Diagram & Coplanar Force SystemsAtef NazNessuna valutazione finora

- Stressman Engineering - Brochure Norway 2018-6Documento8 pagineStressman Engineering - Brochure Norway 2018-6FelipeNessuna valutazione finora

- InverterDocumento8 pagineInverterrajinipre-1Nessuna valutazione finora

- Tabla 1 Engine ControlDocumento2 pagineTabla 1 Engine Controljulio montenegroNessuna valutazione finora

- Carimin Acacia Stability-Onhire Loading JerunDocumento6 pagineCarimin Acacia Stability-Onhire Loading Jerunh2sbnj86b4Nessuna valutazione finora

- Aso Airfield Standards Quick ReferenceDocumento66 pagineAso Airfield Standards Quick ReferenceRahul RanaNessuna valutazione finora

- 2 Interference in Spur GearsDocumento2 pagine2 Interference in Spur Gearschris100% (1)

- For Steel Cage Lapping by Using U-ClipDocumento4 pagineFor Steel Cage Lapping by Using U-Cliptin aungtunNessuna valutazione finora

- Asme B36.10M-2018Documento36 pagineAsme B36.10M-2018امينNessuna valutazione finora

- Galvanize Galvanize Business Unit: Trust Us To GalvanizeDocumento6 pagineGalvanize Galvanize Business Unit: Trust Us To GalvanizeAdet WildanNessuna valutazione finora

- DMD Documentation Error - Freetronics ForumDocumento3 pagineDMD Documentation Error - Freetronics ForumapofviewNessuna valutazione finora

- Please Note That This Form Details Exploration and Production Api Titles Available For OrderDocumento8 paginePlease Note That This Form Details Exploration and Production Api Titles Available For Orderhaotran68Nessuna valutazione finora

- Calculate heating and cooling loads for buildingsDocumento8 pagineCalculate heating and cooling loads for buildingsdpadrianNessuna valutazione finora

- Models - Rf.bowtie Antenna OptimizationDocumento14 pagineModels - Rf.bowtie Antenna OptimizationbkmmizanNessuna valutazione finora

- Rockaway Beach Branch Community Impact StudyDocumento98 pagineRockaway Beach Branch Community Impact StudyHanaRAlbertsNessuna valutazione finora

- Crompton Greaves LimitedDocumento3 pagineCrompton Greaves LimitedNitish SinghNessuna valutazione finora

- Pull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLineDocumento7 paginePull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLinecnuneza4Nessuna valutazione finora

- Seminar ReportDocumento30 pagineSeminar Reportshashank_gowda_7Nessuna valutazione finora

- Customize ADFS sign-in page brandingDocumento4 pagineCustomize ADFS sign-in page brandingmicu0% (1)

- Iraqi Code for Reinforced Concrete StructuresDocumento71 pagineIraqi Code for Reinforced Concrete Structuresmamandawe50% (2)

- Grounding and JumperingDocumento16 pagineGrounding and Jumperingferreiramarco56Nessuna valutazione finora

- Operator Interface Hmi Touch Screen Cmore - 10Documento54 pagineOperator Interface Hmi Touch Screen Cmore - 10QuantumAutomation100% (1)

- Motores SumergiblesDocumento68 pagineMotores SumergiblescyberespiaNessuna valutazione finora

- Adaptive ArchitectureDocumento27 pagineAdaptive ArchitectureSanjeev BumbNessuna valutazione finora

- Zener DataDocumento2 pagineZener Dataapi-27149887Nessuna valutazione finora

- Wrangling Logs With Logstash and ElasticSearch PresentationDocumento38 pagineWrangling Logs With Logstash and ElasticSearch PresentationMohammad Syafiq Bin HussainNessuna valutazione finora