Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Exercise 1: To Know The PT Curve

Caricato da

Shiyamala SubramaniamDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Exercise 1: To Know The PT Curve

Caricato da

Shiyamala SubramaniamCopyright:

Formati disponibili

Exercise 1: to know the PT curve

CASE1-compare 3 envelope and critical

Refrigerated Gas Plant

Use HE(weighted)-5 intervals

See the graph of T vs Heat flow

***Important Points 1. 2. 3. 4. 5. Always save your case! Know the objectives of your simulation. Models are purpose built. Must always do material and energy balance before starting your modeling Always know your phase envelope Thermal state variables in HYSYS are generally: a. Vf b. T c. P d. Molar enthalpy Of these only two can be specified Make sure u understand the system u are working with when choosing the thermodynamic package. Components, processes. a. Parafic o&g b. . Keep track of your dof. They can be user defined (blue) or defined by some unit op (black). Always imagine what is happening in the simulation/problem Always ASK what is the definition of standard/normal conditions, HYSYS Standard conditions are T=60F, P=1atm When using HE module in HYSYS as a heat balance/ design a. Single phase: end point b. Phase change: weighted Always use meaning labels when labeling utilities, etc Use of Adjust a. Only on monotonic functions or when the bounded region is monotonic b. Cant use if the line gets flat c. Spec min max step size d. Spec min and max boundaries Learn how to calculate T, P, DP(vf=1), and BP(Vf=0). a. Make sure u plot the phase env u may hv a retrograde region Hypotheticals, need: a. Normal boiling point b. Std liq density c. MW Recommended to have at least (a) and (b) Shortcut labels: Shift T, P, F, M to view variables values instead of stream names for labels When doing some design, make sure u always have some margin! When using the UO, make sure u understand the thermodynamics behind them Eg: a. Valve: isenthalpic b. Mixer: adiabetic

6.

7. 8. 9. 10.

11. 12.

13. 14.

15. 16. 17.

18. 19. 20.

21. 22. 23. 24. 25.

c. Compressor/pump: isentropic/polytropic for case study, make sure you specify the upper and lower limit intensive properties dont depend on how much material there is when defining phases, you must be specific: a. subcooled b. saturated c. critical for mixed component system with broad boiling point component instead of the critical point of defining maxima, u will have the cricon and cricon for HE u can use approach fuction to fix the temp approach you could also simply define stream temp but u will need ti update them when condition change provide meaningful name for utilities other obj in ur simulation., it will make them easier to indentify in list process sim software cant make a bad eng better make sure you RTFM!!!

Potrebbero piacerti anche

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringDa EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNessuna valutazione finora

- Refrigeration Syllabus92 DFSFSFDocumento10 pagineRefrigeration Syllabus92 DFSFSFMuhammad AwaisNessuna valutazione finora

- Che 481 Test 1Documento7 pagineChe 481 Test 1Melissa HuynhNessuna valutazione finora

- Model LibraryDocumento119 pagineModel Librarydongjinzong2004Nessuna valutazione finora

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersDa EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersValutazione: 4 su 5 stelle4/5 (13)

- 118 - Steady State Thermal Analysis PDFDocumento16 pagine118 - Steady State Thermal Analysis PDFSameOldHatNessuna valutazione finora

- Practice2023 CN4122Documento25 paginePractice2023 CN4122Carmen ChanNessuna valutazione finora

- Cooling Tower Experimental NotesDocumento3 pagineCooling Tower Experimental NotesidigitiNessuna valutazione finora

- Worked Examples in Turbomachinery: (Fluid Mechanics and Thermodynamics)Da EverandWorked Examples in Turbomachinery: (Fluid Mechanics and Thermodynamics)Valutazione: 4.5 su 5 stelle4.5/5 (5)

- Thermal Sizing of A S&T ExchangerDocumento67 pagineThermal Sizing of A S&T Exchangerraja raniNessuna valutazione finora

- Conjugate Heat Transfer in A Heating Coil: Tutorial 14Documento30 pagineConjugate Heat Transfer in A Heating Coil: Tutorial 14Sam SilviyaNessuna valutazione finora

- Process Heat Transfer: Principles, Applications and Rules of ThumbDa EverandProcess Heat Transfer: Principles, Applications and Rules of ThumbValutazione: 4.5 su 5 stelle4.5/5 (11)

- H84ACM Coursework GuidelinesDocumento6 pagineH84ACM Coursework GuidelinesYeeXuan TenNessuna valutazione finora

- Process Simulation Essentials - Example Book PDFDocumento60 pagineProcess Simulation Essentials - Example Book PDFhamzashafiq1100% (1)

- Aspen Plus - Cetic Anhyhdrate ReactorsDocumento6 pagineAspen Plus - Cetic Anhyhdrate ReactorsGyan PrameswaraNessuna valutazione finora

- Denco CH2Documento12 pagineDenco CH2Madan DhakalNessuna valutazione finora

- Evaporation Tutorial PDFDocumento18 pagineEvaporation Tutorial PDFSafi AhmedNessuna valutazione finora

- Turton Et Al.: I. Base Case Level-1 Simulation. Uses Provided Information With Simplified Heat ExchangersDocumento4 pagineTurton Et Al.: I. Base Case Level-1 Simulation. Uses Provided Information With Simplified Heat ExchangerssekharbhattaNessuna valutazione finora

- Equipment SizingDocumento5 pagineEquipment SizingPandu RockingNessuna valutazione finora

- Destilacion: Subdirección de ProcesosDocumento32 pagineDestilacion: Subdirección de ProcesosJesus GarcíaNessuna valutazione finora

- 1St Asian Physics Olympiad: Karawaci, IndonesiaDocumento4 pagine1St Asian Physics Olympiad: Karawaci, IndonesiaDiana PonceNessuna valutazione finora

- Sec01 - GroupE - (Unsteady State Heat Transfer)Documento11 pagineSec01 - GroupE - (Unsteady State Heat Transfer)Dzulfadhly ShaariNessuna valutazione finora

- Separations and Reaction Engineering Design Project Production of MTBEDocumento10 pagineSeparations and Reaction Engineering Design Project Production of MTBEParaZzzitNessuna valutazione finora

- 02 BoilDocumento18 pagine02 BoilWeb LogueandoNessuna valutazione finora

- 1.3.9 Rating Heat ExchangerDocumento18 pagine1.3.9 Rating Heat ExchangerMelva NainggolanNessuna valutazione finora

- Adiabatic Production of Acetic AnhydrideDocumento7 pagineAdiabatic Production of Acetic AnhydrideSunilParjapatiNessuna valutazione finora

- Chapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocumento85 pagineChapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallNadirah RahmanNessuna valutazione finora

- CHEE220 Heat Engine Lab Jan2014Documento4 pagineCHEE220 Heat Engine Lab Jan2014mfuzdnldNessuna valutazione finora

- Melab HT Fall2015Documento16 pagineMelab HT Fall2015SCNessuna valutazione finora

- 01 2d Berl Edm PDFDocumento17 pagine01 2d Berl Edm PDFdfiorilloNessuna valutazione finora

- Rating Heat ExchangersDocumento16 pagineRating Heat ExchangersSyed Muzamil Ahmed100% (1)

- Temperature LabDocumento6 pagineTemperature LabNew songsNessuna valutazione finora

- Stoichiometric Reactor (Updated 8/3/05) : Problem StatementDocumento9 pagineStoichiometric Reactor (Updated 8/3/05) : Problem StatementTugyam Irem EsNessuna valutazione finora

- Nanomaterials CharacterDocumento70 pagineNanomaterials CharacterLogicAndFacts ChannelNessuna valutazione finora

- Intro1 M12 ThermalDocumento22 pagineIntro1 M12 ThermalAyush ChoudharyNessuna valutazione finora

- Phase Change SimulationDocumento106 paginePhase Change SimulationAshish AgarwalNessuna valutazione finora

- Lab 12Documento13 pagineLab 12Kashaf TehreemNessuna valutazione finora

- Lecture 2 Unsteady State Heat TransferDocumento5 pagineLecture 2 Unsteady State Heat TransferMahir MahmoodNessuna valutazione finora

- Experimental Mapping of The Thermodynamic Losses in Vapor Compression Refrigeration SystemsDocumento7 pagineExperimental Mapping of The Thermodynamic Losses in Vapor Compression Refrigeration SystemssatyabrataNessuna valutazione finora

- CPE603 GuideDocumento6 pagineCPE603 GuideainmnrhNessuna valutazione finora

- Evaporator CalculationDocumento3 pagineEvaporator CalculationMuhammad RiswanNessuna valutazione finora

- Thermodynamics and Simulation of Mass Transfer Equipment 2Documento8 pagineThermodynamics and Simulation of Mass Transfer Equipment 2David DualNessuna valutazione finora

- ASPEN PLUS Example ProblemDocumento5 pagineASPEN PLUS Example ProblemAlbert Powa0% (1)

- Distillation 1Documento42 pagineDistillation 1Zakariya MohamedNessuna valutazione finora

- Optimum Temperature Gradients in Tubular Reactors-I: Olegh Bilocs NealDocumento12 pagineOptimum Temperature Gradients in Tubular Reactors-I: Olegh Bilocs NealSandip LadvaNessuna valutazione finora

- LoadMatch Temperature Cascade2Documento3 pagineLoadMatch Temperature Cascade2سامح الجاسمNessuna valutazione finora

- Experiment 1Documento3 pagineExperiment 1bobflyerNessuna valutazione finora

- Lab ManualDocumento58 pagineLab ManualAkhil KumarNessuna valutazione finora

- Refrigeration Unit: Muhammad Tarmizi Bin Abdul Murad (2019883632)Documento4 pagineRefrigeration Unit: Muhammad Tarmizi Bin Abdul Murad (2019883632)Lehbron JemsNessuna valutazione finora

- B10 - Guided Interpretation #10Documento12 pagineB10 - Guided Interpretation #10Markus LandingtonNessuna valutazione finora

- 02 - Heat ExchangersDocumento107 pagine02 - Heat ExchangersMaheshNessuna valutazione finora

- Exe C-HumidificationDocumento4 pagineExe C-HumidificationBen MachariaNessuna valutazione finora

- Fluidcasio Cfx-9850g Libif97 DocuDocumento18 pagineFluidcasio Cfx-9850g Libif97 DocuLili SugengNessuna valutazione finora

- Horizontal Film BoilingDocumento11 pagineHorizontal Film BoilingShruti SoniNessuna valutazione finora

- L5 - Plotting Graph - Online LearningDocumento29 pagineL5 - Plotting Graph - Online LearningShiyamala SubramaniamNessuna valutazione finora

- L1 SI Units, Calculations and Prefixes-Online LearningDocumento31 pagineL1 SI Units, Calculations and Prefixes-Online LearningShiyamala SubramaniamNessuna valutazione finora

- L4 - Density (II) - Online LearningDocumento10 pagineL4 - Density (II) - Online LearningShiyamala SubramaniamNessuna valutazione finora

- L2 - Length and Time - Online LearningDocumento19 pagineL2 - Length and Time - Online LearningShiyamala SubramaniamNessuna valutazione finora

- Summary of ChemistryDocumento3 pagineSummary of ChemistryShiyamala SubramaniamNessuna valutazione finora

- Unit, 5: ChangesDocumento6 pagineUnit, 5: ChangesShiyamala Subramaniam0% (1)

- Clues For Greece LandmarksDocumento1 paginaClues For Greece LandmarksShiyamala SubramaniamNessuna valutazione finora

- A Drink That Contains Caffeine What Contains Nicotine?Documento1 paginaA Drink That Contains Caffeine What Contains Nicotine?Shiyamala SubramaniamNessuna valutazione finora

- Exam QuestionDocumento8 pagineExam QuestionShiyamala SubramaniamNessuna valutazione finora

- Lab - PH - VirtualDocumento4 pagineLab - PH - VirtualShiyamala SubramaniamNessuna valutazione finora

- Summary of ChemistryDocumento3 pagineSummary of ChemistryShiyamala SubramaniamNessuna valutazione finora

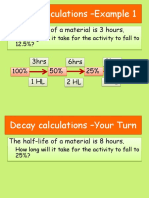

- Assignment: Half-Life Calculation Page 1 / 5: Printed From ClasskickDocumento5 pagineAssignment: Half-Life Calculation Page 1 / 5: Printed From ClasskickShiyamala SubramaniamNessuna valutazione finora

- 25 September 2017: LO: To Develop Our Atlas SkillsDocumento4 pagine25 September 2017: LO: To Develop Our Atlas SkillsShiyamala SubramaniamNessuna valutazione finora

- A Drink That Contains Caffeine What Contains Nicotine? - Cigarette/vapeDocumento1 paginaA Drink That Contains Caffeine What Contains Nicotine? - Cigarette/vapeShiyamala SubramaniamNessuna valutazione finora

- LO and SC: (Extinction) : ShouldDocumento5 pagineLO and SC: (Extinction) : ShouldShiyamala SubramaniamNessuna valutazione finora

- Radioactivity-5 - Activity-And-Half-Life-1 - Online Learning - ClasskickDocumento7 pagineRadioactivity-5 - Activity-And-Half-Life-1 - Online Learning - ClasskickShiyamala SubramaniamNessuna valutazione finora

- Radioactivity-5 - Activity-And-Half-Life-1 - Online LearningDocumento20 pagineRadioactivity-5 - Activity-And-Half-Life-1 - Online LearningShiyamala SubramaniamNessuna valutazione finora

- Minerals FactsheetsDocumento8 pagineMinerals FactsheetsJabir KhalidNessuna valutazione finora

- IGCSE Physics Exam Revision NotesDocumento34 pagineIGCSE Physics Exam Revision NotesCoolman Poon88% (17)

- Circulatory System QR CODEDocumento3 pagineCirculatory System QR CODEShiyamala SubramaniamNessuna valutazione finora

- Instructions Roulunds Belt Tension Gauge For Industrial V-BeltsDocumento2 pagineInstructions Roulunds Belt Tension Gauge For Industrial V-BeltsShiyamala Subramaniam100% (1)

- East RansDocumento1 paginaEast RansShiyamala SubramaniamNessuna valutazione finora

- Physics Form 5 Chapter 1Documento2 paginePhysics Form 5 Chapter 1Shiyamala SubramaniamNessuna valutazione finora

- Interpolation Filters For Oversampled Audio DACsDocumento23 pagineInterpolation Filters For Oversampled Audio DACsIvar Løkken100% (3)

- Data Sheet AGI 400Documento23 pagineData Sheet AGI 400JOSE LUIS CRISTANCHONessuna valutazione finora

- Ma102intro PDFDocumento9 pagineMa102intro PDFSarit BurmanNessuna valutazione finora

- Ipsotek VISuite DatasheetDocumento2 pagineIpsotek VISuite DatasheetMaria PredanNessuna valutazione finora

- Sel 387L - IM - 20100609 - DNP3 MapDocumento2 pagineSel 387L - IM - 20100609 - DNP3 Mapdiegomm2Nessuna valutazione finora

- Math 7 or Math 1 Summative TestDocumento1 paginaMath 7 or Math 1 Summative TestCris Capilayan76% (21)

- Limit Queue Tree MikrotikDocumento4 pagineLimit Queue Tree MikrotikRiski Ramadhan FratamaNessuna valutazione finora

- Hybrid Decision Tree-Based Machine Learning Models For Short-Term Water Quality Prediction.Documento14 pagineHybrid Decision Tree-Based Machine Learning Models For Short-Term Water Quality Prediction.Андрій ШебекоNessuna valutazione finora

- Objective QuesDocumento8 pagineObjective QuesArun GoyalNessuna valutazione finora

- Job Title: Role: Function/ Discipline: Pay Grade: Reports To (Title)Documento2 pagineJob Title: Role: Function/ Discipline: Pay Grade: Reports To (Title)Allen Earl Dela CruzNessuna valutazione finora

- TCL Assignment 1 3 QuestionDocumento2 pagineTCL Assignment 1 3 QuestionNaveen SilveriNessuna valutazione finora

- CUDA - Quick Reference PDFDocumento2 pagineCUDA - Quick Reference PDFjmlescainNessuna valutazione finora

- Implementation Steps For Oracle Alert ModuleDocumento12 pagineImplementation Steps For Oracle Alert Modulemzee1981Nessuna valutazione finora

- Cisco Packet Tracer For Beginners Num 2Documento9 pagineCisco Packet Tracer For Beginners Num 2Scarlet Baby100% (1)

- Example 2aDocumento4 pagineExample 2aboone37Nessuna valutazione finora

- Digital Signal Processing Practical 2Documento8 pagineDigital Signal Processing Practical 2ravisankarmurugan217Nessuna valutazione finora

- LTIB For I.mx28 A Step-By-step GuideDocumento10 pagineLTIB For I.mx28 A Step-By-step Guideವಿನಯ್ ಶಿವ ರಾಮ್Nessuna valutazione finora

- Big Data of Materials Science: Critical Role of The DescriptorDocumento5 pagineBig Data of Materials Science: Critical Role of The DescriptorDivyansh SrivastavaNessuna valutazione finora

- SAP Implementation Companies in India-SAP Implementation PartnersDocumento3 pagineSAP Implementation Companies in India-SAP Implementation Partnerskiran hiremathNessuna valutazione finora

- Floating Point DSPs by BhaskarDocumento44 pagineFloating Point DSPs by BhaskarSai Anirudh SanagaramNessuna valutazione finora

- Sap MM TicketsDocumento9 pagineSap MM TicketsSatyajit Sahoo100% (1)

- Model QBDocumento5 pagineModel QBTina StanleyNessuna valutazione finora

- Scinotws KeyDocumento3 pagineScinotws KeyNgọc Thùy Vân NguyễnNessuna valutazione finora

- Dell PowerEdge R300Documento186 pagineDell PowerEdge R300marathuNessuna valutazione finora

- Oracle Backup and RecoveryDocumento55 pagineOracle Backup and RecoverySantanu Das100% (1)

- Useful SitesDocumento2 pagineUseful SitesRezen Rana BhatNessuna valutazione finora

- Changing From CIE30.2 To CIE140Documento1 paginaChanging From CIE30.2 To CIE140juanca1963Nessuna valutazione finora

- Compiler ConstructionDocumento16 pagineCompiler Constructionzeeshan maseehNessuna valutazione finora

- Java Notes-BskDocumento85 pagineJava Notes-BskFayaz SkNessuna valutazione finora

- Codex Marianus GlagoliticusDocumento667 pagineCodex Marianus GlagoliticusДарио КршићNessuna valutazione finora