Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ipc2012 90072

Caricato da

Marcelo Varejão CasarinDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ipc2012 90072

Caricato da

Marcelo Varejão CasarinCopyright:

Formati disponibili

RISK ASSESSMENT OF MODERN PIPELINES

James N. Mihell

Dynamic Risk, Ltd.

1324 17

th

Ave. S.W.

Calgary, Alberta, T2T 5S8,

Canada

Cameron Rout

Dynamic Risk, Ltd.

1324 17

th

Ave. S.W.

Calgary, Alberta, T2T 5S8,

Canada

ABSTRACT

Proponents of new pipeline projects are often asked by

regulators to provide estimates of risk and reliability for their

proposed pipeline. On existing pipelines, the availability of

operating and assessment data is generally considered to be

essential to the task of performing an accurate and defendable

risk or reliability assessment. For proposed or new pipelines,

the absence of these data presents a significant challenge to

those performing the analysis. The reliance on industry incident

data presents problems, since the vast majority of loss-of-

containment incidents relate to older pipelines in which the

design, routing criteria, material properties, material

manufacturing processes, and early operating practices differ

significantly from those that are characteristic of modern

pipelines. As a consequence, much of the available failure

incident data does not accurately reflect the threats or the

magnitudes of the threats that are associated with modern

pipelines. In order to address this problem, 'adjustment factors'

are often applied against incident data to try to account for

threat differences between the source data and the intended

application. The selection of these adjustment factors can often

be quite subjective, however, and open to judgment; therefore,

they can be difficult to justify.

With the rapidly growing practice of regular in-line inspection

(ILI) on transmission pipelines, an extensive repository of ILI

data has been accumulated - much of it relating to modern

pipelines. Through the judicious selection of source data, ILI

data sets can be mined so that an analogue data set can be

created that constitutes a reasonable representation of the

attributes of reliability of a specific new pipeline of interest.

Key reliability properties, such as tool error distribution, feature

incidence rate, feature size distribution, and apparent feature

growth rate distribution can be derived from such analogue

data. By applying these reliability properties in an analysis

along with known pipeline design and material properties and

their associated distributions, and by taking consideration of

planned inspection intervals, a reliability basis can be derived

for estimating pipeline risk and reliability. Estimates of risk and

reliability that are derived in this manner employ

methodologies that are repeatable, defendable, transparent, and

free of subjectivity.

This paper outlines an approach for completing risk and

reliability estimates on new pipelines, and presents the results

of some sample calculations. The reliability estimates

illustrated are based on an approach whereby corrosion feature

size and growth rates are obtained from analogue ILI datasets,

and treated as random variables. In that regard, they constitute

the probability of exceeding a limit state that represents an

approximation of the condition for failure.

INTRODUCTION

One of the challenges of employing a quantitative risk

assessment on a new pipeline is that industry failure statistics

are not directly applicable to modern pipeline designs,

materials, and operating (i.e., assessment) practices. A review

of industry failure statistics indicates that the vast majority of

pipeline failures occur on pipelines that were installed in the

1970s or earlier (1, 2). These pipelines where largely

developed prior to the advent of several risk-critical

technologies, such as:

- High-performance coating systems, such as three-layer

coatings and fusion bonded epoxy coating systems,

- Design-phase identification of interference effects and

development of mitigation plans through diagnostic

testing of cathodic protection systems, and

- Design-phase identification of internal corrosion threat

factors and the design of mitigation plans through

internal corrosion modeling.

Proceedings of the 2012 9th International Pipeline Conference

IPC2012

September 24-28, 2012, Calgary, Alberta, Canada

IPC2012-90072

1 Copyright 2012 by ASME

- Design-phase identification of geotechnical threats,

and mitigation through threat avoidance

Because of these factors, the use of historical incident data

is not a sound foundation for estimating failure frequency in

modern pipelines.

The use of statistical analysis and reliability methods,

supported by high-resolution in-line inspection data has become

common practice in making failure likelihood estimates for

existing pipelines in which such data exists (3, 4). As these

methods intrinsically address variables such as wall loss feature

incidence rate, growth rate and size distributions, they can be

employed to make estimates of reliability and failure likelihood

for both external corrosion and internal corrosion. By carefully

selecting ILI data sets to address conditions that influence

factors that affect these variables, an analogue data set can be

obtained that can be superimposed on the design conditions

representing a new pipeline. In this manner, estimates of

reliability and failure likelihood can be derived for the new

pipeline for any future timeframe, given exposure to similar

corrosive environments and the implementation of similar

protective measures.

NOMENCLATURE

ILI In-Line Inspection

Reliability Methods A statistical approach used to

estimate the probability of a system

or structure completing its expected

function during an interval of time.

PDF Probability density function: The

density function of a continuous

random variable

CDF Cumulative distribution function:

The function that describes the

probability that a random variable

will be found at a value less than or

equal to a set value.

MIC Microbially Induced Corrosion

Monte Carlo A class of computational algorithms

that rely on repeated random

sampling to compute results.

SELECTION OF ANALOGUE ILI DATA

The reliability approach described in this paper employs

the superposition of an analogue ILI dataset upon the

contemplated new pipeline design. In this respect, the

reliability analysis of a new pipeline using analogue ILI data

essentially models how the new pipeline materials and design

responds to an anticipated degradation process and establishes

how quickly the reliability degrades to a point where failure

likelihood becomes significant. For this reason, it is essential

that the analogue ILI dataset is representative of the

degradation process, including defect incidence rate, defect size

distribution, and defect growth rate distribution.

Several factors must be considered in selecting an

appropriate ILI dataset that can be held as being representative

of corrosion performance anticipated for a new pipeline. First

and foremost among these factors is the quality of the ILI

dataset itself. Tool quality factors such as detection reliability

and sizing accuracy on both length and depth should be

reviewed to ensure that they represent the current state of the

art in tool performance. Ultimately, as will be discussed later,

tool error plays a critical role in making reliability predictions,

and the use of data that is associated with a high tool error

distribution may give rise to an excessively conservative result.

ILI data should be reviewed to identify and remove wall

loss data that is not attributed to active corrosion. Otherwise,

the presence of wall loss that is associated with benign features,

such as manufacturing imperfections might result in a gross

over-estimation of corrosion feature density. Furthermore, non-

zero wall loss rates will be inferred from the presence of such

benign features, and those wall loss rates will be assigned to

what are in fact static features. The misinterpretation of benign

wall loss features in this fashion will result in an overly-

conservative estimate of pipeline reliability.

When evaluating internal corrosion susceptibility, one of

the simplest methods to perform screening is to view

orientation charts for internal wall loss features. Where water

drop-out and accumulation is an essential aspect of the internal

corrosion mechanism that is associated with the product and

flow characteristics being considered, wall loss that is

associated with internal corrosion should be expected at the

bottom of the pipe, as is illustrated in Figure 1. This is

especially true where concentrations of internal wall loss can be

seen to coincide with steeper pipeline inclination angles or

receipt points.

Figure 1. Internal Wall Loss Characteristic of Internal

Corrosion

On the other hand, a random distribution of internal wall

loss features around the circumference of the pipe, with no

apparent trends relative to inclination angle or receipt points

might be more representative of benign manufacturing

imperfections, as is represented in Figure 2.

2 Copyright 2012 by ASME

Figure 2. Random Internal Wall Loss Characteristic of

Manufacturing Imperfections

One effective method that can be used to screen for active

wall loss is to use data derived from pit-matching of separate

in-line inspections. Figures 3 through 6 are derived from ILI

data that is representative of the same section of pipeline.

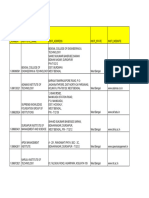

Figure 3 shows the distribution of apparent external wall loss

rates obtained by pit matching ILI data taken four years apart.

When plotted as a probability density function, Figure 4

illustrates that the external wall loss is, in this example,

normally distributed, with a mean of 0.00 mm/yr, and a

standard deviation of 0.01 mm/yr. The inclusion of negative

growth rate values over half the distribution is indicative of the

fact that the apparent feature growth rate is insignificant

relative to pit matching error. Figure 5 shows the distribution

of apparent external wall loss rates for the same section of

pipeline that is inferred from only one set of ILI data. In this

case, estimates of growth rates were derived by assuming linear

growth to the date of in-line inspection. This is generally

considered to be a conservative assumption, since it ignores the

tendency for growth rates to attenuate over time due to

polarization caused by the build-up of corrosion products.

When plotted as a probability density function, Figure 6

illustrates that the external wall loss is, for this example, best

represented as a Weibull distribution, having a mean of 0.03

mm/yr and a standard deviation of 0.02 mm/yr. It is apparent

from a comparison of Figures 3/4 with Figures 5/6 that in this

case, the vast majority of external wall loss features are

dormant (quite possibly benign manufacturing wall loss

features), and if only un-matched data were used as the basis of

the analysis, this would result in highly conservative reliability

results for the pipeline.

Figure 3. Apparent External Wall Loss Rate Based on

Matched ILI Data

Figure 4. Apparent External Wall Loss Rate

Distribution Based on Matched ILI Data

Figure 5. Distribution of Apparent External Wall Loss

Rate Based on Single Set of ILI Data

3 Copyright 2012 by ASME

Figure 6. Apparent External Wall Loss Rate

Distribution Based on Single Set of ILI Data

Beyond the quality of ILI data, several other factors must

be considered in selecting an appropriate ILI dataset. For the

evaluation of external corrosion threats, factors such as coating

type, coating specification, operating environment, and

cathodic protection standards and history should be evaluated

to confirm that those conditions are similar between those

represented by the analogue ILI dataset and those that are

proposed for the new pipeline.

For reliability estimates of the threat of internal corrosion,

an evaluation should be made of the corrosion susceptibility of

the pipeline from which analogue ILI data is being considered,

relative to the corrosion susceptibility that would be

characteristic of the new pipeline. A variety of internal

corrosion evaluation techniques exist, and while it is not the

intent of this paper to delve into these evaluation techniques in

detail, some mention is made here of factors that require

consideration.

Internal corrosion evaluation techniques are largely based

on product stream characteristics and flow rates. For liquid

products, the important parameters that should be included in a

comparison of Corrosivity are water content, erosion and

erosion/corrosion, flow velocity, temperature, susceptibility to

under-deposit corrosion (solid deposition, MIC potential, and

water chemistry), and mitigation measures (use of inhibition,

biocides, or pigging). In order to ensure that the corrosion

mechanism and corrosivity that is represented by the analogue

ILI dataset is representative of that which would be expected in

the new pipeline, an evaluation of all of these parameters must

be conducted.

An evaluation of water content should include

consideration of bottom sediment and water (BS&W), as well

as characterization of the flow regime as either turbulent (in

which water will be entrained) or lamellar (in which there may

be opportunities for water stratification and accumulation).

Consideration of solids should include an evaluation of the

potential for settling of the solids, given consideration of flow

velocity and flow properties.

Microbially Induced Corrosion (MIC) can greatly enhance

corrosion rates, especially in conjunction with solid deposition,

and the temperature range 15

o

C - 70

o

C is known to be

associated with increased MIC activity, leading to localized

attack.

Besides MIC activity, chloride concentration also plays an

important role in the overall corrosion and under-deposit

mechanisms. In respect of the overall corrosion rate, chlorides

increase the conductivity of the corrosive solution due to a

change in ionic strength, leading to an increase in the corrosion

rate. In the under-deposit corrosion mechanism, chlorides can

promote the removal of protective scales (if there are any),

leading to localized attack. In addition, strong changes in

temperature might form hydrochloric acid from the reaction of

the chlorides with water vapour. However, pipeline operators

have not experienced this phenomenon with temperature

changes below 150 C.

Sulphur may be co-produced with sour gas and sour oil.

As a result of pressure and temperature changes (in most cases

a reduction) in the flowing conditions or in shut-in conditions,

sulphur may precipitate from polysulphides and cause plugging

and / or corrosion problems. From the corrosion viewpoint,

sulphur can increase corrosion in many ways, including

compromising protective iron sulphide layers, enhancing

cathodic reactions, and impairing inhibitor performance.

Erosion-corrosion could be a factor that enhances wall loss

rates if the flow velocity is higher than approximately 3 m/s,

and BS&W exceeds 0.5%.

Changes in temperature can lead to a rapid increase in the

corrosion rate if the corrosion mechanism is controlled by

diffusion. However, in a pipeline environment, temperature

also affects other important driving parameters, such as scale

deposition, chemical reactions rates, microbiological activity,

and presence of undissociated organic acid (short chain e.g.

acetic acid) .

ANALYSIS APPROACH

The above section described screening considerations for

selecting an appropriate analogue ILI dataset that is

representative of the corrosion mechanism and severity that is

expected on the new pipeline. This screening and selection of

appropriate analogue ILI data must be completed separately for

internal corrosion and external corrosion. Once this has been

completed, the analogue ILI dataset can be incorporated into

the procedure described in this section in order to establish

estimates of pipeline reliability as a function of year of

operation.

A Monte Carlo approach has been developed to assimilate

distributions derived from size and growth rate distributions

derived from the analogue ILI dataset, and to apply those

distributions against a failure limit state for volumetric wall

loss. In the example described here, the failure limit state

function is the modified ASME B31.G criterion, which, for the

purposes of the analysis, is rearranged to determine depth at the

limiting condition:

4 Copyright 2012 by ASME

( )

( )

(

(

(

(

(

|

|

|

|

|

.

|

\

|

|

|

.

|

\

|

=

o

o

o o

M

t

t . d

op

op

f

85 . 0

, 8 0 MIN

(1)

Where,

d

f

= depth at the limiting condition;

t = Wall thickness;

op

= Operating Stress;

o = Flow stress;

2

2 2

003375 . 0 6257 . 0 1

|

.

|

\

|

+ =

Dt

L

Dt

L

M

) 50 (for Dt L s

Dt

L

M

2

032 . 0 3 . 3 + =

) 50 (for Dt L >

L = Defect length (which is described as a

probability distribution characteristic of the dataset,

incorporating tool error on length measurement)

In the Monte Carlo analysis, the variables of pipe diameter,

wall thickness, yield strength, and operating pressure that are

specific to the new pipe design are considered dynamic

segments. Each dynamic segment of the new pipeline for

which the risk analysis is being evaluated requires a separate

reliability analysis. Corrosion feature incidence rates, and the

distribution parameters for corrosion feature length and depth

are determined from the analogue ILI data, as are corrosion

feature growth rates. When using ILI data for the purposes of

establishing these parameters, it is important to recognize that

the quantities derived represent values at a particular point in

time (i.e., the date of last inspection). Furthermore, these

quantities are subject to tool measurement error. Corrosion

feature size is therefore considered characteristic of the size

after some period of time. For example, when applied to a new

pipeline, the depth distribution must be adjusted downwards

(accounting for some assumed corrosion growth rate) when the

modeled pipeline age is smaller than that from which the

analogue ILI data was obtained. Similarly, the depth

distribution must be adjusted upwards when the modeled

pipeline age is larger than that from which the analogue ILI

data was obtained. This is illustrated in Figure 7, which shows

how the flaw distribution flattens and translates with time, t.

Specifically, as can be seen in this Figure, as time increases, the

mean of the flaw depth distribution increases, and that the

standard deviation of the flaw depth distribution also increases.

Figure 7. Illustration of How Flaw Depth Distribution

Changes With Time

In the absence of any other information pertaining to how

growth rate varies with time, a linear growth rate assumption

can generally be considered a reasonable, yet conservative

approximation, since it ignores the polarizing effects of the

accumulation of corrosion product.

The high-performance coating systems that are

characteristic of modern pipelines, such as fusion bonded epoxy

are not susceptible to time-dependent coating degradation to the

extent that older vintage coating systems are. Therefore, it is

often realistic to assume that any coating damage that is

inferred from the presence of a corrosion feature was created at

the time of installation, and that the arial extent of coating

damage, and hence the potential for increases in wall loss area

(i.e., length and width) does not change appreciably with time.

Similarly, the introduction of new corrosion features may be

limited by the absence of time-dependent coating breakdown.

In the Monte Carlo simulation, corrosion feature size, as a

function of time, is sampled stochastically, based on the

probability density functions for those parameters derived from

the analogue ILI dataset. A further stochastic adjustment is

made to account for the tool error associated with the ILI tool

from which the analogue data was derived. In performing this

stochastic adjustment for tool error, it is preferred to use

correlations derived from <Tool-Predicted> to <In-Ditch

Measurement> data pairs. When using this approach, it is

important to minimize variability of in-ditch measurements

through standardization of in-ditch measurement practices, and

the implementation of quality control measures. If direct

measurement of tool measurement error isnt available, the ILI

vendors published tool error can be used. For instance, tool

error on depth measurement is often characterized at 10% w.t.,

80% of the time. In statistical terms, this corresponds to a

normal error distribution having a mean of 0, and a standard

deviation of 7.8% of the wall thickness.

Assuming a linear growth model, the stochastically-

sampled flaw depth estimate is adjusted to account for the

difference between the age of the analogue pipeline at the time

that the ILI data was acquired, and the modeled age of the new

pipeline:

5 Copyright 2012 by ASME

ILI

A

o

A

o

T

T d

d

=

(2)

Where,

0

A

d

= Stochastically sampled flaw depth at the specific

time assumed in the analysis;

0

d = Stochastically sampled flaw depth, derived from the

analogue ILI dataset (incorporating stochastic

adjustment for analogue ILI tool error)

T

A

= Year of operation for the new pipeline that is being

assumed in the analysis

T

ILI

= Year of operation that the for the analogue pipeline

when the ILI assessment was completed.

For the purposes of the Monte Carlo simulation, all pipe

parameters that are contained in the limit state function shown

in Equation (1) (i.e., pipe wall thickness, operating stress level,

and flow stress) correspond to the new pipeline for which

failure probability values are being sought.

Limit state exceedance is predicted when the stochastically

sampled flaw size has a depth component that exceeds the

limiting condition (derived from Equation (1)). When the

Monte Carlo simulation is performed through multiple

iterations, the probability of limit state exceedance for the given

year of analysis is defined as the proportion of those iterations

that return a result that exceeds the limit state. This probability

is defined as the conditional probability, given the presence of a

corrosion feature, P

f,F

. The overall probability for a given

dynamic segment of the new pipeline in the year of operation

being considered in the analysis is defined as:

F e DS

ILI

N

ILI DS e

P L

D

D

P

, ,

=

(3)

DS e

P

,

= Probability per dynamic segment

ILI

= Corrosion feature density per unit length of pipeline

derived from the analogue ILI dataset

N

D = Diameter of the new pipeline

ILI

D

= Diameter of the pipeline from which the analogue

ILI data was derived

DS

L = Length of the dynamic segment in the new pipeline

F e

P

,

= Conditional probability, given the presence of a

corrosion feature

Note that in the above expression, the ratio: D

N

/D

ILI

is

employed in recognition of the assumption that the frequency

of occurrence of coating defects (and hence corrosion features)

will be proportional to the pipe surface area (with pipe surface

area being proportional to diameter).

By performing a separate analysis for each year of

operation, and for each dynamic segment, a profile can be

generated that represents the probability of exceeding the

reliability limit for each year of operation of the new pipeline,

an example of which is provided in Figure 8.

Figure 8. Frequency Profile Example

In order to support a risk analysis, the output from the

above analysis must be relevant to the consequence analysis.

Therefore, the results should specify more than frequency of

occurrence; instead, the frequencies of occurrence should be

tied to an outcome, with outcome being related to magnitude of

a potential release, and hence hole-size. The proportion of

ruptures can be derived by first calculating the critical through-

wall flaw size as a function of material properties and operating

parameters of the new pipeline. There are a variety of through-

wall fracture criteria relationships; an example of which is the

NG-18 flaw equation (5):

(

=

=

o

o t

t

o

2

sec ln

8 12

2

2

h T

c

v

c

M c

A

E C

K

(4)

The above relationship can be used to determine the

maximum size defect that will leak rather than rupture. At high

toughness values, it represents a flow-stress or plastic

instability criterion (typical of the failure mode of most

corrosion features), whereas at lower toughness values, it may

represent a conservative representation of the leak/rupture

boundary for corrosion features.

As is illustrated in Figure 9, the cumulative distribution

function for flaw length, derived from the analogue ILI dataset

is compared against the critical through-wall flaw length for the

new pipeline. Using this approach, the proportion of features

that have the potential to penetrate through-wall at a length

greater than the critical through-wall flaw length can

6 Copyright 2012 by ASME

conservatively be said to have the potential to fail in rupture

mode, while the remainder of the flaws will fail as leaks.

Figure 9. Determination of Fraction of Leaks and

Ruptures from Corrosion Feature Length CDF and

Critical Through-wall Flaw Size

The breakdown of leak sizes can be obtained from the

distribution of flaw areas (length x width) for those flaws that

are predicted to fail by leak mode. A reasonable, yet

conservative representation of the outcome associated with a

leak can be represented by the 50

th

percentile of flaw size area,

as is depicted in Figure 10.

Figure 10. Determining Hole Area From Distribution of

Flaw Area for Leak-Designated Corrosion Features

CONCLUSIONS

An approach based on probability of exceedance

methodologies has been advanced for estimating failure

likelihood to support risk assessments of new pipelines. This

approach addresses the problems that have historically been

associated with the use of failure incident data. These failure

incident data are unduly influenced by older vintage pipelines

for which the material performance and design features are not

a good representation of modern pipelines. The approach

described is transparent, defendable and repeatable, and for

these reasons is a sound basis for making realistic estimates for

the purposes of supporting risk assessments in modern

pipelines.

REFERENCES

1. Keifner, J.F., Trench, C.J., Oil Pipeline

Characteristics and Risk Factors: Illustrations from the

Decade of Construction API Publication, December,

2001.

2. U.S. Department of Transportation Pipeline &

Hazardous Materials Safety Administration Pipeline

Safety Stakeholder Communications, Significant

Incident Data, 1986-2001.

3. Chan, P.D., and Webster, D., Probabilistic

Assessment of ILI Metal Loss Features, ASME, 2010

International Pipeline Conference (IPC), IPC2010-

31298, September, 2010.

4. Mora R.G., Parker C., Vieth P., Delanty B.,

Probability of Exceedance (POE) Methodology for

Developing Integrity Programs Based on Pipeline

Operator-Specific Technical and Economic Factors,

ASME, 2002 Internal Pipeline Conference (IPC),

IPC2002-27224, October 2002.

5. Eiber, R.J., and Leis, B.N., Fracture Control

Technology for Natural Gas Pipelines Circa 2001,

PRCI Report No. PR-003-00108, July, 2001.

7 Copyright 2012 by ASME

Potrebbero piacerti anche

- IBP1142 - 19 Offshore Development: Submarine Pipelines-Soil InteractionDocumento13 pagineIBP1142 - 19 Offshore Development: Submarine Pipelines-Soil InteractionMarcelo Varejão CasarinNessuna valutazione finora

- IBP1146 - 19 Maintenance Productivity Measurement Study at TranspetroDocumento8 pagineIBP1146 - 19 Maintenance Productivity Measurement Study at TranspetroMarcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1135 Riopipeline2019 t1135 JST Av1Documento8 pagineRiopipeline2019 1135 Riopipeline2019 t1135 JST Av1Marcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1137 201906031307ibp1137 19 Increas PDFDocumento10 pagineRiopipeline2019 1137 201906031307ibp1137 19 Increas PDFMarcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1138 Rio Paper Rev01 PDFDocumento11 pagineRiopipeline2019 1138 Rio Paper Rev01 PDFMarcelo Varejão CasarinNessuna valutazione finora

- IBP1141 - 19 The Use of Optical Sensor To Investigate Dissolved Oxygen in CrudeDocumento12 pagineIBP1141 - 19 The Use of Optical Sensor To Investigate Dissolved Oxygen in CrudeMarcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1120 Ibp1120 19 Transpetro S Worklo PDFDocumento9 pagineRiopipeline2019 1120 Ibp1120 19 Transpetro S Worklo PDFMarcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1140 Ibp 1140 Nao Intrusivos Final PDFDocumento4 pagineRiopipeline2019 1140 Ibp 1140 Nao Intrusivos Final PDFMarcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1124 Worlds First Remote Deepwater PDFDocumento10 pagineRiopipeline2019 1124 Worlds First Remote Deepwater PDFMarcelo Varejão CasarinNessuna valutazione finora

- IBP1123 - 19 Caliper Ili Experience in Offshore Pre-CommissioningDocumento10 pagineIBP1123 - 19 Caliper Ili Experience in Offshore Pre-CommissioningMarcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1126 Article Number Ibp1126 19 PDFDocumento11 pagineRiopipeline2019 1126 Article Number Ibp1126 19 PDFMarcelo Varejão CasarinNessuna valutazione finora

- IBP1128 - 19 In-Service Welding Hot Tap of Refinary Pipeline With Hydrogen and EthyleneDocumento10 pagineIBP1128 - 19 In-Service Welding Hot Tap of Refinary Pipeline With Hydrogen and EthyleneMarcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1127 Article Number Ibp1127 19 PDFDocumento10 pagineRiopipeline2019 1127 Article Number Ibp1127 19 PDFMarcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1113 201906031824ibp Riopipeline 11 PDFDocumento10 pagineRiopipeline2019 1113 201906031824ibp Riopipeline 11 PDFMarcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1117 Ibp1117 19 Versao Final para e PDFDocumento8 pagineRiopipeline2019 1117 Ibp1117 19 Versao Final para e PDFMarcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1115 201906070716fm 3811 00 Formato PDFDocumento13 pagineRiopipeline2019 1115 201906070716fm 3811 00 Formato PDFMarcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1121 201906051235ibp1121 19 Final PDFDocumento8 pagineRiopipeline2019 1121 201906051235ibp1121 19 Final PDFMarcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1112 FM 1112 FinalDocumento10 pagineRiopipeline2019 1112 FM 1112 FinalMarcelo Varejão CasarinNessuna valutazione finora

- IBP1119 - 19 Internal Corrosion Detection: Conference and Exhibition 2019Documento4 pagineIBP1119 - 19 Internal Corrosion Detection: Conference and Exhibition 2019Marcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1104 201906031512fm 3811 00 Formato PDFDocumento11 pagineRiopipeline2019 1104 201906031512fm 3811 00 Formato PDFMarcelo Varejão CasarinNessuna valutazione finora

- IBP1122 - 19 High Grade Sawl Linepipe Manufacturing and Field Weld Simulation For Harsh EnvironmentsDocumento11 pagineIBP1122 - 19 High Grade Sawl Linepipe Manufacturing and Field Weld Simulation For Harsh EnvironmentsMarcelo Varejão CasarinNessuna valutazione finora

- IBP1095 - 19 in Flexible Pipes Systems and AncillariesDocumento8 pagineIBP1095 - 19 in Flexible Pipes Systems and AncillariesMarcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1107 201905201751ibp1107 19 Jacques PDFDocumento7 pagineRiopipeline2019 1107 201905201751ibp1107 19 Jacques PDFMarcelo Varejão CasarinNessuna valutazione finora

- IBP1099 - 19 Deep Water Pip Installation Using Reel-Lay MethodDocumento12 pagineIBP1099 - 19 Deep Water Pip Installation Using Reel-Lay MethodMarcelo Varejão CasarinNessuna valutazione finora

- IBP 1102 - 19 A Gas Routing Identification System On A Pipeline NetworkDocumento12 pagineIBP 1102 - 19 A Gas Routing Identification System On A Pipeline NetworkMarcelo Varejão CasarinNessuna valutazione finora

- IBP1110 - 19 The Relevance of Fuel Transmission Pipelines in BrazilDocumento10 pagineIBP1110 - 19 The Relevance of Fuel Transmission Pipelines in BrazilMarcelo Varejão CasarinNessuna valutazione finora

- IBP1111 - 19 Best Alternative For Rigid Offshore Pipelines Decommissioning - A Case StudyDocumento13 pagineIBP1111 - 19 Best Alternative For Rigid Offshore Pipelines Decommissioning - A Case StudyMarcelo Varejão CasarinNessuna valutazione finora

- IBP1101 - 19 Element Simulations and Offshore ObservationsDocumento13 pagineIBP1101 - 19 Element Simulations and Offshore ObservationsMarcelo Varejão CasarinNessuna valutazione finora

- Riopipeline2019 1093 201905221205final Paper Overpi PDFDocumento12 pagineRiopipeline2019 1093 201905221205final Paper Overpi PDFMarcelo Varejão Casarin100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- SLA in PEGA How To Configue Service Level Agreement - HKRDocumento7 pagineSLA in PEGA How To Configue Service Level Agreement - HKRsridhar varmaNessuna valutazione finora

- Model 255 Aerosol Generator (Metone)Documento20 pagineModel 255 Aerosol Generator (Metone)Ali RizviNessuna valutazione finora

- Webinar Gizi - Patho StuntingDocumento16 pagineWebinar Gizi - Patho StuntingMiftahul HikmahNessuna valutazione finora

- Algoritm BackTracking EnglezaDocumento6 pagineAlgoritm BackTracking Englezaionutz_67Nessuna valutazione finora

- PDF Chapter 5 The Expenditure Cycle Part I Summary - CompressDocumento5 paginePDF Chapter 5 The Expenditure Cycle Part I Summary - CompressCassiopeia Cashmere GodheidNessuna valutazione finora

- Kiritsis SolutionsDocumento200 pagineKiritsis SolutionsSagnik MisraNessuna valutazione finora

- Standard Answers For The MSC ProgrammeDocumento17 pagineStandard Answers For The MSC ProgrammeTiwiNessuna valutazione finora

- Dermatology Skin in Systemic DiseaseDocumento47 pagineDermatology Skin in Systemic DiseaseNariska CooperNessuna valutazione finora

- Chapter 2Documento13 pagineChapter 2Kumkumo Kussia KossaNessuna valutazione finora

- Speech On Viewing SkillsDocumento1 paginaSpeech On Viewing SkillsMera Largosa ManlaweNessuna valutazione finora

- Delonghi Esam Series Service Info ItalyDocumento10 pagineDelonghi Esam Series Service Info ItalyBrko BrkoskiNessuna valutazione finora

- Head Coverings BookDocumento86 pagineHead Coverings BookRichu RosarioNessuna valutazione finora

- Applications SeawaterDocumento23 pagineApplications SeawaterQatar home RentNessuna valutazione finora

- Injections Quiz 2Documento6 pagineInjections Quiz 2Allysa MacalinoNessuna valutazione finora

- What's New in CAESAR II: Piping and Equipment CodesDocumento1 paginaWhat's New in CAESAR II: Piping and Equipment CodeslnacerNessuna valutazione finora

- Desktop 9 QA Prep Guide PDFDocumento15 pagineDesktop 9 QA Prep Guide PDFPikine LebelgeNessuna valutazione finora

- Genetics Icar1Documento18 pagineGenetics Icar1elanthamizhmaranNessuna valutazione finora

- UT Dallas Syllabus For Govt4396.002.08s Taught by Gregory Thielemann (Gregt)Documento2 pagineUT Dallas Syllabus For Govt4396.002.08s Taught by Gregory Thielemann (Gregt)UT Dallas Provost's Technology GroupNessuna valutazione finora

- MultiLoadII Mobile Quick Start PDFDocumento10 pagineMultiLoadII Mobile Quick Start PDFAndrés ColmenaresNessuna valutazione finora

- Illustrating An Experiment, Outcome, Sample Space and EventDocumento9 pagineIllustrating An Experiment, Outcome, Sample Space and EventMarielle MunarNessuna valutazione finora

- Bom Details FormatDocumento6 pagineBom Details FormatPrince MittalNessuna valutazione finora

- WBDocumento59 pagineWBsahil.singhNessuna valutazione finora

- CV Augusto Brasil Ocampo MedinaDocumento4 pagineCV Augusto Brasil Ocampo MedinaAugusto Brasil Ocampo MedinaNessuna valutazione finora

- Radon-222 Exhalation From Danish Building Material PDFDocumento63 pagineRadon-222 Exhalation From Danish Building Material PDFdanpalaciosNessuna valutazione finora

- Prevention of Waterborne DiseasesDocumento2 paginePrevention of Waterborne DiseasesRixin JamtshoNessuna valutazione finora

- 7TH Maths F.a-1Documento1 pagina7TH Maths F.a-1Marrivada SuryanarayanaNessuna valutazione finora

- Eggermont 2019 ABRDocumento15 pagineEggermont 2019 ABRSujeet PathakNessuna valutazione finora

- Tutorial 5 SolvedDocumento3 pagineTutorial 5 SolvedAshutoshKumarNessuna valutazione finora

- Cooperative Learning: Complied By: ANGELICA T. ORDINEZADocumento16 pagineCooperative Learning: Complied By: ANGELICA T. ORDINEZAAlexis Kaye GullaNessuna valutazione finora

- Cisco BGP ASPATH FilterDocumento115 pagineCisco BGP ASPATH FilterHalison SantosNessuna valutazione finora