Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Untitled

Caricato da

Anonymous m65TTcfOTDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Untitled

Caricato da

Anonymous m65TTcfOTCopyright:

Formati disponibili

What is "hipot" testing? Many people are familiar with a continuity test.

A continuity test checks for "g ood connections." You do a continuity test by seeing if current will flow from o ne point to another point. If current flows easily enough then the points are co nnected. Many people aren't familiar with a hipot test. "Hipot" is short for hig h potential (high voltage). A hipot test checks for "good isolation." You do a h ipot test by making sure no current will flow from one point to another point. I n some ways a hipot test is the opposite of a continuity test. Continuity Test: "Make sure current flows easily from one point to another point ." Hipot Test: "Make sure current won't flow from one point to another point (and t urn up the voltage really high just to make sure no current will flow)." In the simple case a hipot test takes two conductors that should be isolated and applies a very high voltage between the conductors. The current that flows is w atched carefully. Ideally not much current will flow. If too much current flows the points are not well isolated and they should fail the test. Why high voltage test? You use a hipot test to make sure you have good isolation between the parts of a circuit. Having good isolation helps to guarantee the safety and quality of ele ctrical circuits. Hipot tests are helpful in finding nicked or crushed insulatio n, stray wire strands or braided shielding, conductive or corrosive contaminants around the conductors, terminal spacing problems, and tolerance errors in IDC c ables. All of these conditions might cause a device to fail. What kinds of high voltage tests are there? There are three common high voltage tests. Dielectric Breakdown Test Dielectric Withstanding Test Insulation Resistance Test What is "dielectric breakdown testing?" With dielectric breakdown testing you are trying to answer the question "How muc h voltage can I apply between the wires before the insulation fails?" You increa se the voltage until the current suddenly increases. You are finding the highest voltage the cable can stand before it fails. Once the cable fails it is usually damaged or destroyed. What is "dielectric withstand testing" (DW)? In dielectric withstand testing you are trying to answer the question "Will this cable withstand a required voltage for a required time?" You apply the voltage for the amount of time and watch the current that flows. Ideally no current flow s and the cable is not harmed. What is "insulation resistance testing" (IR)? In insulation resistance testing you are trying to answer the question "Is the r esistance of the insulation high enough?" You apply a voltage and very carefully measure the current. You then calculate the insulation resistance using Ohm's L aw (R = V/I). How do these "hipot" tests affect quality? All of these tests are tools you can use to better understand how a cable will p erform and to monitor any changes in the cable's performance. Dielectric breakdown testing is used in product design and qualification stages. It helps establish the maximum voltage of the design. It can also be used on a random sample basis to verify that the maximum voltage is not changing. Dielectr ic breakdown testing may be required during the development of assemblies used i n critical applications. Many test specifications require a Dielectric Withstand Test on every cable prod uced. The test is usually done at about 75% of the typical breakdown voltage. It is done as a safety net. The test is sensitive to arcs or corona so it often fi nds terminal spacing problems, over-mold problems, tolerance errors in IDC cable s, or any problem that might produce arcs. This test doesn't significantly degra de the cable. The Insulation Resistance test is typically done on every cable tested. It is us

ually done at 300 to 500 Vdc with 100 to 500 Megahoms resistance. The test is a very sensitive to contamination in the assembly process. Solder flux, oils, mold release agents, and skin oil all can cause problems. This test excels at identi fying insulation that will conduct in the presence of moisture. Doing this test on every cable allows you to detect contamination changes in the manufacturing p rocess. Additional High Voltage Testing Resources: AC Hipot Testing Guidelines for using Voltage to Detect Insulation Defects High Voltage arc distance. With all the high voltage being used, what about my safety? During a hipot test you may be at some risk. The risk can be reduced by using a tester designed to be safe and by using that tester according the manufacturer's instructions. Products being designed today usually must comply with product safety regulation s. Some of these regulations work to reduce the chance of you receiving a harmfu l electrical shock. Modern equipment is more likely to follow these regulations. When it comes to hipot charge, energy, and voltage you should select the "safes t" machine that will still test your cables. To minimize your risk of injury from electrical shock make sure your hipot equip ment follows these guidelines: The total charge you can receive in a shock should not exceed 45 uC. The total hipot energy should not exceed 350 mJ. The total current should not exceed 5 mA peak (3.5 mA rms) The fault current should not stay on longer than 10 mS. If the tester doesn't meet these requirements then make sure it has a safety int erlock system that guarantees you can not contact the cable while it is being hi pot tested. These guidelines come from the test standard EN61010-1, Safety requirements for electrical equipment for measurement, control and laboratory use, April 1993, CE NELEC. Over the last decade many of the safety regulations have been harmonized (standardized) and EN61010-1 is similar to UL 61010A-1 (formerly UL3101-1). While you are testing cables there are several things you can do to reduce the r isk even more: Verify the correct operation of the safety circuits in the equipment every time you calibrate it. Follow all of the manufacturer's instructions and safety guidelines. Don't touch the cable during hipot testing. Allow the hipot testing to complete before removing the cable. Wear insulating gloves. If you have any health condition that can be aggravated by being startled then d on't use the equipment. Don't allow children to use the equipment. If you have any electronic implants then don't use the equipment. Where is the high voltage applied? To understand a how hipot testing works you'll need to understand where to conne ct the high voltage supply. Hipot testers usually connect one side of the supply to safety ground (Earth ground). The other side of the supply is connected to t he conductor being hipoted. With the supply connected like this there are two pl aces a given conductor can be connected: high voltage or ground. When you have more than two contacts to be hipot tested you connect one contact to high voltage and connect all other contacts to ground. Testing a contact in t his fashion makes sure it is isolated from all other contacts. What happens when you test something more complicated than just contacts? A seri es of contacts that are connected with wires, resistors, capacitors, diodes, and other components is called a "network" of connections (or "net"). To hipot test a net you connect all of the contacts in the net to high voltage and connect al l other contacts in the device to ground. For example, if you have a wire that c onnects two pins, the high voltage will be simultaneously apply to both of those pins and the entire wire will be raised in voltage. All other wires and pins wi

ll be held at ground. If you have a resistor that connects two pins, both pins a re raised in voltage, the voltage drop across the resistor is always zero. The e ntire resistor is raised in voltage. In short, all pins of a component see the s ame voltage at all times. Applying the voltage in this fashion makes sure the bo dy of the component is isolated from the rest of the device. Where is the current measured? During the hipot test the current that flows out of the high voltage supply is m easured. What causes current to flow through an insulator? Insulation "does not conduct." But if you use enough voltage even the best of in sulations will allow some current to flow. You may wonder why the current flows? There are several reasons current will flow through insulation during a hipot t est. Resistance, capacitance, arcs, electrochemical effects, and corona are all effects that describe current flow. All of these effects add together during a h ipot test shape the outcome of the test. http://www.ce-mag.com/archive/01/Spring/Ahmadi.html Understanding the How and Why of Electrical Product Safety Testing Homi Ahmadi Knowing why to perform required electrical safety tests is as important as knowi ng how to perform them. With so many electrical product safety standards currently in use and many civil and legal actions pending in various courts around the world, electrical safety testing is more critical than ever to ensure that all products are safe before they reach the end-user. Fortunately, the majority of manufacturers are fully aw are of the hazards associated with electrical equipment and the ramifications of noncompliance with relevant safety standards or test house agreements. Electrical safety tests can be roughly divided into two areas: those tests carri ed out during the approvals process by test houses (known as type tests) and tho se carried out at the end of each production line by the manufacturer (known as routine production tests). For type tests, a product is subjected to tests and evaluations in accordance wi th a specific product safety standard. For production tests, a manufacturer can select a few tests, ensuring that each product is subjected to those tests in ac cordance with its own procedures. Most manufacturers, in particular information technology (IT) equipment manufacturers, choose four primary product safety test s to be routine at the end of the production line. These include dielectric, ins ulation resistance, ground continuity, and leakage current. These tests are designed to ensure that the user does not get electrocuted or ot herwise hurt by operating a piece of equipment that has hazardous voltages or hi gh fault current as a result of electrical fault. This article looks at the fund amentals behind each test and analyzes the reasoning behind each test, as well a s discussing appropriate limits and equipment. Dielectric Strength Test The dielectric strength test, also known as dielectric withstand test or hipot t est, is probably the best known and most often performed production-line safety test. It is part of virtually every standard, which indicates its importance. Th e hipot test is a nondestructive test that determines the adequacy of electrical insulation for the normally occurring overvoltage transient. This is a high-vol tage test that is applied to all devices for a specific time in order to ensure that the insulation is not marginal. Another reason for conducting the hipot tes t is that it also detects possible defects such as inadequate creepage and clear ance distances introduced during the manufacturing process. During type testing, the hipot test is applied after tests such as fault conditi on, humidity, and vibration to determine whether any degradation has taken place . The production-line hipot test, however, is a test of the manufacturing proces s to determine whether the construction of a production unit is about the same a s the construction of the unit that was subjected to type testing. Some of the p rocess failures that can be detected by a production-line hipot test include, fo

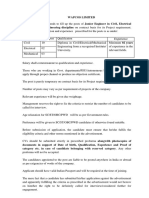

r example, a transformer wound in such a way that creepage and clearance have be en reduced. Such a failure could result from a new operator in the winding depar tment. Other examples include identifying a pinhole defect in insulation or find ing an enlarged solder footprint. Most safety standards use the 2U + 1000 V formula as the basis for testing basic insulation, where U is the operating rms voltage. Although this formula is a gu ideline, each standardin particular IEC 60950refers the user to a specific table i n the standard showing the exact test voltage based on the working voltage measu rements.1 The reason for using 1000 V as part of the basic formula is that the i nsulation in any product can be subjected to normal day-to-day transient overvol tages. Experiments and research have shown that these overvoltages can be as hig h as 1000 V. Test method. Normally the high voltage is applied between the two parts across t he insulation being tested, such as the primary circuit and metal enclosure of t he equipment under test (EUT). If the insulation between the two is adequate, th en the application of a large voltage difference between the two conductors sepa rated by the insulator would result in the flow of a very small current. Althoug h this small current is acceptable, no breakdown of either the air insulation or the solid insulation should take place. Therefore, the current of interest is t he current that is the result of a partial discharge or breakdown, rather than t he current due to capacitive coupling. Another example would be to test the insulation between the primary and secondar y circuits of a power supply. Here, all the outputs are shorted together. The gr ound probe from the hipot tester is placed in contact with this cable bunch, and the high-voltage probe is placed in contact with L and N connectors, which are shorted together (see Figure 1). The EUT does not run during the hipot test. It must also be noted that when applying the high voltage during the type test, the ideal situation would require that not more than half of the prescribed voltage be applied, and then raised gradually over a period of 10 seconds to the full v alue and maintained for 1 minute. Most test equipment, however, either turns on directly to the full voltage or has an electronically controlled ramp. Figure 1. Typical hipot test setup. Test Duration. If the test is part of an agency certification process, then the test duration must be in accordance with the safety standard being used. For ins tance, the test time for most standards, including products covered under IEC 60 950, is 1 minute. However, when testing products in the production line, it is n ormally not practical to hipot test each product for 1 minute, and manufacturers normally conduct the test to a much shorter time, such as a few seconds, but wi th higher voltages. A typical rule of thumb is 110120% of 2U + 1000 V for 12 secon ds. The duration and procedure should be in agreement with any test houses conce rned. It should be noted that although the reduced time and increased voltage ar e approximate, experiments and the manufacturers' data sheets indicate that each insulating material has its own specific voltage-time characteristics. Current Setting. Most modern hipot testers allow the user to set the current lim it. However, if the actual leakage current of the product is known, then the hip ot test current can be predicted. Choosing the trip level really depends on the product being tested. The best way to identify the trip level is to test some pr oduct samples and establish an average hipot current. Once this has been achieve d, then the leakage current trip level should be set to a slightly higher value than the average figure. Another method of establishing the current trip level w ould be to use the following mathematical formula: The reason for the factor of 2 is that the line leakage current provides current through a single Y capacitor while the hipot test provides current through capa citors on each line. By solving the equation for I (hipot), one can predict the hipot test current. Therefore, the hipot tester current trip level should be set high enough to avoid nuisance failure related to leakage current and, at the sa me time, low enough not to overlook a true breakdown in insulation. Test Voltage. The majority of safety standards allow the use of either ac or dc

voltage for a hipot test. When using ac test voltage, the insulation in question is being stressed most when the voltage is at its peak, i.e., either at the pos itive or negative peak of the sine wave. Therefore, if one decides to use dc tes t voltage, one must ensure that the dc test voltage is 2 (or 1.414) times the ac test voltage, so the value of the dc voltage is equal to the ac voltage peaks. F or example, for a 1500-V-ac voltage, the equivalent dc voltage to produce the sa me amount of stress on the insulation would be 1500 x 1.414 or 2121 V dc. One of the advantages of using a dc test voltage is that the leakage current tri p can be set to a much lower value than that of an ac test voltage. This would a llow a manufacturer to filter those products that have marginal insulation, whic h would have been passed by an ac tester. It must be noted that when using a dc hipot tester, the capacitors in the circuit could be highly charged and, therefo re, a safe-discharge device or setup is needed. However, it is a good practice t o always ensure that a product is discharged, regardless of the test voltage or its nature, before it is handled. Another advantage of a dc hipot tester is that it applies the voltage gradually. By monitoring the current flow as voltages increase, an operator can detect a p otential insulation breakdown before it occurs. A minor disadvantage of the dc h ipot tester is that because dc test voltages are more difficult to generate, the cost of a dc tester may be slightly higher than that of an ac tester. One of the advantages of an ac hipot test is that it can check both voltage pola rities, whereas a dc test charges the insulation in only one polarity. This may become a concern for products that actually use ac voltage for their normal oper ation. The test setup and procedures are identical for both ac and dc hipot test s. A minor disadvantage of the ac hipot tester is that if the circuit under test ha s large values of Y capacitors, then, depending on the current trip setting of t he hipot tester, the ac tester could indicate a failure. Most safety standards a llow the user to disconnect the Y capacitors prior to testing or, alternatively, to use a dc hipot tester. The dc hipot tester would not indicate the failure of a unit even with high Y capacitors because the Y capacitors see the voltage but don't pass any current. Insulation Resistance The insulation resistance test is also known as a Megger test. Its objective is to measure the total resistance between any two points separated by insulation. The test, therefore, determines how effective the insulation is in resisting the flow of electrical current. The voltage is typically around 5001000 V dc; hence, the current is very low. Because the current is so low, this test is useful for checking the quality of the insulation not only when a product is first manufac tured, but also over time as the product is used. Test Procedure. The EUT is connected to the measuring instrument, and the voltag e is ramped up from zero to the final value, which in most cases is 500 V dc. On ce the voltage reaches the selected value, it is kept at that value for a brief period (typically up to 5 seconds) before the resistance test is measured. The m easured value should be very high (typically in the megohm region). The insulati on resistance test is mandatory in some product safety standards, including IEC 60065 and UL 6500.2,3 Ground Bond Test Also known as the ground bond continuity test, the ground bond test must be cond ucted on all Class I products. The purpose of the test is to ensure that all acc essible conductive parts of the product that could become live in the event of a single insulation fault are connected securely to the final earth point of the supply input. In other words, a ground bond test verifies integrity of the groun d path by applying a high-current, low-voltage source to the ground-path circuit . Compliance is checked by measuring the resistance of the connection between the protective earthing terminal or earthing contact and the parts to be earthed to ensure that resistance does not exceed certain values when subjected to a high c urrent as specified in various product safety standards. It is important to bear in mind that from the constructional and design points of view, the protective

earthing conductors should not contain switches or fuses. Test Requirements. Most safety standards require the following parameters for co nducting the ground bond test: The EUT must be subjected to a high ac or dc current with a low test voltage for a certain period. The voltage drop between the protective earthing terminal or earthing contact and the part to be earthed must be measured. The resistance must be calculated from the current and the resulting voltage dro p using Ohm's law. The resistance should not exceed certain values as stated in various safety stan dards. For example, IEC 60950 requires that the test voltage not exceed 12 V. Th e current can be either ac or dc at 1.5 times the current consumption of the pro duct or 25 A, whichever is greatest. The test duration must be 1 minute, and the resistance of the connection between the protective earthing terminal or earthi ng contact and parts required to be earthed must not exceed 0.1 . This value does not include the resistance of the power cable. Some standards, such as CAN/CSAC22.2 No. 60950-00 or UL 60950 with Canadian deviation, require the test to be c onducted at 30 A and for 2 minutes if the current rating of the circuit under te st is 16 A or lower.4,5 Understanding Resistance Values. With the exception of the Canadian standard, mo st standards require 25 A for 1 minute. The value of 25 A for 1 minute represent s the worst current and the longest operation time of a mains overcurrent device . The maximum 25 A is approximately 1.5 times the mains circuit breaker value in stalled for most pluggable type A cord-connected equipment rated up to 16 A. The Canadian National Wiring Code requirements are very similar to these in the sen se that they assume that fuses are expected to operate no more than 1 minute at twice their rated current. Because most mains circuits are protected with a 1516 A fuse, the fault current would be 30 A for no more than 2 minutes. Earth Leakage Current Some standards, including IEC 60950, 3rd ed., have named the leakage current tes t "touch current." This refers to the electric current through a human body or t hrough an animal body when it touches one or more accessible parts of installati on or equipment. There is also another concept known as "protective conductor cu rrent," and this refers to the current that flows in a protective conductor. A p rotective conductor current, therefore, can never be the source of an electric s hock because, by definition, the protective conductor is connected to earth. If touch current is excessive, an operator could receive an electric shock, whic h could result in a serious injury, depending on a person's body weight. Typical ly, currents of more than 1.0 mA can cause an electric shock to an operator. The shock may or may not be serious, depending on the amount of the current and the body weight. Like the other tests, the leakage current test is also a very important safety t est, and most safety standards require the test to be conducted under various co nditions such as normal operating condition, switches open as well as closed, re versed line polarity, and so on. The measured earth leakage current must not exc eed specified limits during any of the tested conditions. Table I shows some typ ical limits.

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Recruitment in Management CadreDocumento14 pagineRecruitment in Management CadreAnonymous m65TTcfOTNessuna valutazione finora

- Electrical Engineering Volume 64 Issue 6 1945 (Doi 10.1109/EE.1945.6441080) Clarke, Edith - Impedances Seen by Relays During Power Swings With and Without FaultsDocumento13 pagineElectrical Engineering Volume 64 Issue 6 1945 (Doi 10.1109/EE.1945.6441080) Clarke, Edith - Impedances Seen by Relays During Power Swings With and Without FaultsAnonymous m65TTcfOTNessuna valutazione finora

- Remanent Flux in Current-Transformer Cores: SynopsisDocumento6 pagineRemanent Flux in Current-Transformer Cores: SynopsisAnonymous m65TTcfOT100% (1)

- ABB Differential ProtectionDocumento30 pagineABB Differential ProtectionErbil Keskin100% (1)

- 1MRK502066-UUS A en Technical Manual Generator Protection REG670 2.1 ANSIDocumento1.452 pagine1MRK502066-UUS A en Technical Manual Generator Protection REG670 2.1 ANSIAnonymous m65TTcfOTNessuna valutazione finora

- OTS100AF, OTS80AF & OTS60AF Laboratory Oil Test Set: User GuideDocumento22 pagineOTS100AF, OTS80AF & OTS60AF Laboratory Oil Test Set: User GuideAnonymous m65TTcfOTNessuna valutazione finora

- 1431928792session II CT & VTDocumento201 pagine1431928792session II CT & VTAnonymous m65TTcfOTNessuna valutazione finora

- No. of Post QualificationDocumento2 pagineNo. of Post QualificationAnonymous m65TTcfOTNessuna valutazione finora

- Dlro 600 High Current, Low Resistance Ohmmeter: User ManualDocumento15 pagineDlro 600 High Current, Low Resistance Ohmmeter: User ManualAnonymous m65TTcfOTNessuna valutazione finora

- CDTTSDocumento2 pagineCDTTSAnonymous m65TTcfOT100% (1)

- List of International StandardsDocumento6 pagineList of International StandardsAnonymous m65TTcfOT100% (3)

- Pilot-Wire Circuits For Protective Relaying - Experience and PracticeDocumento2 paginePilot-Wire Circuits For Protective Relaying - Experience and PracticeAnonymous m65TTcfOTNessuna valutazione finora

- 7UT6121 7UT6121: Relay Details CT Ratio Existing Relay Settings Fault CurrentDocumento2 pagine7UT6121 7UT6121: Relay Details CT Ratio Existing Relay Settings Fault CurrentAnonymous m65TTcfOTNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Rm-07 Ac DC Hipot PF DuarteDocumento9 pagineRm-07 Ac DC Hipot PF DuarteEngr Irfan AkhtarNessuna valutazione finora

- 09SS003 Duke Doosan Buck CTCC - Final Electrical Tests - Rev.2Documento8 pagine09SS003 Duke Doosan Buck CTCC - Final Electrical Tests - Rev.2SteveNessuna valutazione finora

- Baker d65r HIPOTDocumento2 pagineBaker d65r HIPOTjon1224100% (1)

- What Is HIPOT Testing Dielectric Strength TestDocumento4 pagineWhat Is HIPOT Testing Dielectric Strength TesthafizgNessuna valutazione finora

- Section Cover Page: Section 26 13 90 Medium Voltage Power 2008-06-02 System MaintenanceDocumento22 pagineSection Cover Page: Section 26 13 90 Medium Voltage Power 2008-06-02 System MaintenancecerkadilerNessuna valutazione finora

- HIPOT TestingDocumento4 pagineHIPOT Testingparuchurivenkat5272100% (1)

- Model 19032-19032-P Data SheetDocumento8 pagineModel 19032-19032-P Data SheetmanchuricoNessuna valutazione finora

- SCI - Modular Home Testing Comparison Advantages and Disadvantages of AC and DC Hipot PDFDocumento1 paginaSCI - Modular Home Testing Comparison Advantages and Disadvantages of AC and DC Hipot PDFTTaanNessuna valutazione finora

- Philips 200p7Documento107 paginePhilips 200p7IvaneWahyuHidayatNessuna valutazione finora

- Dielectric Withstand TestDocumento3 pagineDielectric Withstand TestGilberto ManhattanNessuna valutazione finora

- Philips Xh3 HP l1502 l1523 Compaq Fp5315Documento65 paginePhilips Xh3 HP l1502 l1523 Compaq Fp5315BAAAKNessuna valutazione finora

- Hipot Cable TestingDocumento13 pagineHipot Cable Testingsofyan_shah100% (4)

- Manual Surge Test Baker St106aDocumento2 pagineManual Surge Test Baker St106aDiego AndradeNessuna valutazione finora

- ExperienceswithCommissioning HV CablesDocumento20 pagineExperienceswithCommissioning HV CablesafwdNessuna valutazione finora

- Testing & Comm Procedure-Rev 10-EnppiDocumento41 pagineTesting & Comm Procedure-Rev 10-EnppiTarek Fawzy100% (2)

- Hi Pot Test DetailsDocumento7 pagineHi Pot Test Details2003vinay100% (1)

- 00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkDocumento12 pagine00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkAbdul Mohid SheikhNessuna valutazione finora

- TClad Selection GuideDocumento27 pagineTClad Selection GuideTheBergquistCompanyNessuna valutazione finora

- What Is Partial Discharge Testing - Vertiv InsightsDocumento5 pagineWhat Is Partial Discharge Testing - Vertiv InsightsAlexander WijesooriyaNessuna valutazione finora

- Putting High Voltage Cable To The TestDocumento2 paginePutting High Voltage Cable To The TestTuong Nguyen Duc MinhNessuna valutazione finora

- Chroma 19073-Manual PDFDocumento79 pagineChroma 19073-Manual PDFAgeu SilvaNessuna valutazione finora

- Baker Manual # 1Documento38 pagineBaker Manual # 1manuelaNessuna valutazione finora

- Sunnyworld Quotation of 10MW Solar Panel Production LineDocumento5 pagineSunnyworld Quotation of 10MW Solar Panel Production LineChandra GalajuNessuna valutazione finora

- EIC 09 - Stator Winding Hipot TestingDocumento5 pagineEIC 09 - Stator Winding Hipot Testingmanoharig7578Nessuna valutazione finora

- PRO Series 100 - 400V2 Pre-Service and Calibration Manual: (Models 110 - 410)Documento42 paginePRO Series 100 - 400V2 Pre-Service and Calibration Manual: (Models 110 - 410)quankddNessuna valutazione finora

- Mining Equipment Testing: Application GuideDocumento8 pagineMining Equipment Testing: Application Guiderk6482100% (1)

- IB-DU1001Cable Bus DuctDocumento30 pagineIB-DU1001Cable Bus Ductdestro57Nessuna valutazione finora

- MaintenanceDocumento55 pagineMaintenanceAshraf EnjoyingNessuna valutazione finora

- 1100H Users Manual Version 2014.1.0Documento109 pagine1100H Users Manual Version 2014.1.0Anonymous lLqH6jEJNessuna valutazione finora

- Method Statement GSSDocumento4 pagineMethod Statement GSSkannanrk1984Nessuna valutazione finora