Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Experiment No. 1 Aim: Study of Various Types of Compressors Used For Refrigeration and Air Conditioning Purpose

Caricato da

Sanjeev Kumar GhaiDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Experiment No. 1 Aim: Study of Various Types of Compressors Used For Refrigeration and Air Conditioning Purpose

Caricato da

Sanjeev Kumar GhaiCopyright:

Formati disponibili

EXPERIMENT No. 1 Aim: Study of various types of Compressors used for refrigeration and air conditioning purpose.

Introduction: The refrigeration system consists of four basic componentst h e compressor, the condenser, the liquid receiver, the evaporator, and the control devices. These components are essential for any system to operate on the principles previously discussed. Information on these components is described in the following sections. Compressors Refrigeration compressors have but one purposeto withdraw the heat-laden refrigerant vapor from the evaporator and compress the gas to a pressure that will liquefy in the condenser. The designs of compressors vary, depending upon the application and type of refrigerant. There are three types of compressors classified according to the principle of operation reciprocating, rotary, and centrifugal. Compressors will not be explained further here except to discuss the special methods used to seal compressors to prevent escape of refrigerant. Many refrigerator compressors have components besides those normally found on compressors, such as unloaders, oil pumps, mufflers, and so on. These devices are too complicated to explain here. Before repairing any compressor, check the manufacturer's manual for an explanation of their operation, adjustment, and repair. External Drive Compressor.An external drive or open-type compressor is bolted together. Its crankshaft extends through the crankcase and is driven by a flywheel (pulley) and belt, or it can be driven directly by an electric motor. A leak proof seal must be maintained where the crankshaft extends out of the crankcase of an open-type compressor. The seal must be designed to hold the pressure developed inside of the compressor. It must prevent refrigerant and oil from leaking out and prevent air and moisture from entering the compressor. Two types of seals are usedthe stationary bellows seal and the rotating bellows seal. An internal stationary crankshaft seal shown in figure 6-15 consists of a corrugated thin brass tube (seal bellows) fastened to a bronze ring (seal guide) at one end and to the flange plate at the other. The flange plate is bolted to the crankcase with a gasket between the two units. A spring presses the seal guide mounted on the other end of the bellows against a seal ring positioned against the shoulder of the crankshaft. As the pressure builds up in the crankcase, the bellows tend to lengthen, causing additional force to press the seal guide against the seal ring. Oil from the crankcase lubricates the surfaces of the seal guide and seal ring. This forms a gastight sea whether the compressor is operating or idle.

An external stationary bellows crankshaft seal is shown in figure 6-16. This seal is the same as the internal seal, except it is positioned on the outside of the http://www.sweethaven02.com/MechTech/Refrig01/crankcase.

An external rotating bellows crankcase seal is shown in figure 6-17. This seal turns with the crankshaft. This seal also consists of a corrugated thin brass tube (seal bellows) with a seal ring fastened to one end and a seal flange fastened to the other. A seal spring is enclosed within the bellows. The complete bellows assembly slips on the end of the crankshaft and is

held in place by a nut. The seal ring that is the inner portion of the bellows is positioned against a nonrotating seal fastened directly to the crankcase.

During operation, the complete bellows assembly rotates with the shaft, causing the seal ring to rotate against the stationary seal. The pressure of the seal spring holds the seal ring against the seal. The expansion of the bellows caused by the pressure from the crankcase also exerts pressure on the seal ring. Because of this design, double pressure is exerted against the seal ring to provide a gastight seal. Hermetic CompressorIn the hermetically sealed compressor, the electric motor and compressor are both in the same airtight (hermetic) housing and share the same shaft. Figure 6-18 shows a hermetically sealed unit. Note that after assembly, the two halves of the case are welded together to form an airtight cover. Figure 6-19 shows an accessible type of hermetically sealed unit. The compressor, in this case, is a double-piston reciprocating type. Other compressors may be of the centrifugal or rotary types.

Cooling and lubrication are provided by the circulating oil and the movement of the refrigerant vapor throughout the case. The advantages of the hermetically sealed unit (elimination of pulleys, belts and other coupling methods, elimination of a source of refrigerant leaks) are offset somewhat by the inaccessibility for repair and generally lower capacity.

EXPERIMENT NO. 2 Aim: Detailed study of condensers. Introduction: In systems involving heat transfer, a condenser is a device or unit used to condense a substance from its gaseous to its liquid state, typically by cooling it. In so doing, the latent heat is given up by the substance, and will transfer to the condenser coolant. Condensers are typically heat exchangers which have various designs and come in many sizes ranging from rather small (hand-held) to very large industrial-scale units used in plant processes. For example, a refrigerator uses a condenser to get rid of heat extracted from the interior of the unit to the outside air. Condensers are used in air conditioning, industrial chemical processes such as distillation, steam power plants and other heat-exchange systems. Use of cooling water or surrounding air as the coolant is common in many condensers. Types of condensers:

A surface condenser is an example of such a heat-exchange system. It is a shell and tube heat exchanger installed at the outlet of every steam turbine in thermal power stations. Commonly, the cooling water flows through the tube side and the steam enters the shell side when the condensate occurs on the outside of the heat transfer tubes. The condensate collects at the bottom, often in a built-in pan called a hotwell. The shell side often operates at a vacuum or partial vacuum, often produced by attached air ejector. In chemistry, a condenser is the apparatus which cools hot vapors, causing them to condense into a liquid. See "Condenser (laboratory)" for laboratory-scale condensers, as opposed to industrial-scale condensers. Examples include the Liebig condenser, Graham condenser, and Allihn condenser. This is not to be confused with a condensation reaction which links two fragments into a single molecule by an addition reaction and an elimination reaction. In laboratory distillation, reflux, and rotary evaporators, several types of condensers are commonly used. The Liebig condenser is simply a straight tube within a cooling water jacket, and is the simplest (and relatively least expensive) form of condenser. The Graham condenser is a spiral tube within a water jacket, and the Allihn condenser has a series of large and small constrictions on the inside tube, each increasing the surface area upon which the vapor constituents may condense. Being more complex shapes to manufacture, these latter types are also more expensive to purchase. These three types of condensers are laboratory glassware items since they are typically made of glass. Commercially available condensers usually are fitted with ground glass joints and come in standard lengths of 100, 200, and 400 mm. Air-cooled condensers are unjacketed, while water-cooled condensers contain a jacket for the water.

Larger condensers are also used in industrial-scale distillation processes to cool distilled vapor into liquid distillate. Commonly, the coolant flows through the tube side and distilled vapor through the shell side with distillate collecting at or flowing out the bottom. A condenser unit used in central air conditioning systems typically has a heat exchanger section to cool down and condense incoming refrigerant vapor into liquid, a compressor to raise the pressure of the refrigerant and move it along, and a fan for blowing outside air through the heat exchanger section to cool the refrigerant inside. A typical configuration of such a condenser unit is as follows: The heat exchanger section wraps around the sides of the unit with the compressor inside. In this heat exchanger section, the refrigerant goes through multiple tube passes, which are surrounded by heat transfer fins through which cooling air can move from outside to inside the unit. There is a motorized fan inside the condenser unit near the top, which is covered by some grating to keep any objects from accidentally falling inside on the fan. The fan is used to blow the outside cooling air in through the heat exchange section at the sides and out the top through the grating. These condenser units are located on the outside of the building they are trying to cool, with tubing between the unit and building, one for vapor refrigerant entering and another for liquid refrigerant leaving the unit. Of course, an electric power supply is needed for the compressor and fan inside the unit. Direct contact condenser In this type of condenser, vapors are poured into the liquid directly. The vapors lose their latent heat of vaporization; hence, vapors transfer their heat into liquid and the liquid becomes hot. In this type of condensation, the vapor and liquid are of same type of substance.

EXPERIMENT NO. 3

Aim: Study of Ice plant. Introduction This note briefly describes the design and operation of icemaking plants. Space, power and refrigeration requirements are discussed, and the main types of icemaker are described. Methods of handling, transporting and storing ice are outlined. Classification of ice plants The term ice plant is used in this note to mean a complete installation for the production and storage of ice, including the icemaker itself that is the unit that converts water into ice together with the associated refrigeration machinery, harvesting and storage equipment, and the building. Ice plants are usually classified by the type of ice they produce; hence there are block ice plants, flake ice plants, tube, slice or plate ice plants and so on. Ice plants may be further subdivided into those that make dry or wet ice. Dry ice here means ice at a temperature low enough to prevent the particles becoming moist; the term does not refer in this note to solid carbon dioxide. In general, dry subcooled ice is made in plants that mechanically remove the ice from the cooling surface; most flake ice plants are of this type. When the cooling surface of an icemaker is warmed by a defrost mechanism to release the ice, the surface of the ice is wet and, unless the ice is then subcooled below 0C, remains wet in storage; tube ice and plate ice plants are of this type. Types of icemaker Block ice Tapered rectangular metal cans filled with water are immersed in a tank containing refrigerated sodium chloride brine. The dimensions of the can and the temperature of the brine are usually selected to give a 24 hour production time, and batches of cans are emptied and refilled in sequence during that period. Ice block weight can range from 12 to 150 kg depending on requirements; 150 kg is regarded as the largest size of block one man can conveniently handle. A block ice plant requires continuous attention and is labour intensive. The icemaker and the store require a good deal of floor space and impose heavy loads on the building structure. For these reasons block ice plants are going out of use, and more modern automatic plants are replacing them. Rapid block ice

It is possible to reduce the freezing time for blocks considerably, and thus reduce the space required for the icemaker. This is done by reducing the thickness of ice to be frozen; in one type of rapid icemaker this is achieved by passing refrigerant through tubes around which the ice forms and fuses into a block. The blocks can be released by defrosting and harvested automatically, thus markedly reducing the labour requirement, but the storage space required is slightly larger than for the same weight of conventional block ice because the blocks have hollow centres after the tubes are removed. Flake ice A sheet of ice 2-3 mm thick is formed by spraying water on the surface of a refrigerated drum, and scraping it off to form dry subcooled flakes, usually 100-1000 mm2 in area. In some models the drum rotates against a stationary scraper on its outer surface; in others the scraper rotates and removes ice from the inner wall of a double walled stationary drum. In some models the drum is horizontal, but more usually it is mounted vertically. No water is sprayed on that part of the drum immediately before the scraper, so that the ice becomes dry and subcooled prior to removal. Refrigerant temperature, drum or scraper speed, and degree of subcooling are all variable within designed limits so that the capacity of the icemaker and the thickness of the ice can be altered. Typical refrigerant temperature in a flake ice machine is - 20 to - 25C, lower than in most other types of icemaker, to give rapid cooling and thus make the machine compact. The low operating temperature requires more power, but this is to some extent compensated for by the absence of a need to defrost. FIG 1. Flake ice machine

Key: 1. 2. 3. 4. Ice subcooling zone. Tube ice

Water Rotating Scraper

supply

pipe. drum. bar.

Water is frozen on the inner surface of vertical refrigerated tubes to form hollow cylinders of ice about 50 mm in diameter and with walls 10-12 mm thick. The ice cylinders are released by defrosting the tubes automatically, and are chopped into pieces about 50 mm long by a rotating cutter as they slide out. The cylindrical pieces can be subcooled by storing them at - 5C, but they may require further crushing before being suitable for some applications in the fish industry.

Plate ice Water is frozen on one face of a vertical refrigerated plate, and the sheet of ice is released by running warm water on the other face of the plate. The size of ice particle is variable, but the optimum thickness is 10-12 mm. The plates are usually mounted in banks, often above the refrigeration machinery, to form a self contained unit. Water for defrosting has to be heated if its temperature is below 23C. Like most other icemakers the plate ice machine will operate unattended on an automatic timing cycle. Other icemakers Machines are available that make ice by methods other than those described here, but the size of unit is usually small, producing at the most only a few hundred kilograms of ice a day; these are suitable for retail and catering services, but are unlikely to be of interest to those providing icemaking services to the catching and processing sectors of the fish industry. Capacity of ice plants Manufacturers usually quote a wide range of daily output for specific icemaker units, because their capacity can be affected by a number of factors, but this flexibility usually exists only at the planning stage; once the icemaker has been matched to suitable refrigeration machinery under given operating conditions, there is little scope for changing the capacity of the installed unit. Changes in demand are best catered for by reducing running time or by installing multiple units and operating only as many as arc needed.

Since the capacity of both the icemaker and the refrigeration machinery is lower in warmer weather, the size of the plant should be selected for warm weather operation, when demand for ice is also likely to be greatest. Ice plant requirements Space Modern icemakers arc compact in comparison with block ice equipment, but it is not always possible to compare directly the space occupied by different types; for example they may not be available in the same unit sizes. However some guidance on the space requirements for icemakers with a nominal capacity of 50 tonnes a day is given in Table 1; the figures are for icemakers only, and the space for refrigeration machinery, handling and storage will usually amount to far more than for the ice-maker.

Table 1 Space required for an icemaker producing 50 t/day type of ice block rapid block tube flake floor area m2 190 30 33 27 height m 50 35 66 37

Power Average power and peak power requirements may be different, and both have to be considered at the planning stage. The average power relates to the energy consumed in making a tonne of ice, and this is important in calculating operating cost. Peak power is important to the designer since it will determine what electrical supply is required, and may also affect operating cost if a peak demand factor is applicable. The energy required to make a tonne of ice is not constant. It varies widely depending on a number of factors, the most important of which are Type of icemaker Operating temperature Make-up water temperature

Water

Cooling water temperature Air temperature Size of plant Utilization of plant Method of refrigeration

In addition to water for making ice, water may be required for cooling, as in a refrigeration plant condenser, or for heating, as in a warm water defrosting system. The amount of water required for making ice is roughly equal to the amount of ice being produced plus some allowance for wastage and for prevention of build up of solids in the water circulating system. Fresh water for making ice for use with fish must satisfy the requirements for drinking water. In addition, the chemical composition of water for making ice must meet the equipment manufacturers' requirements; hard water containing excessive amounts of solids may foul the icemaker and may also yield a soft wet ice. On the other hand pure water may cause problems, particularly in flake ice plants, because the ice sticks hard to the drum; the remedy is to fit a dosing device that puts 200-500 g salt into each tonne of water to improve release of the ice without making the ice detectably salty when used on fish. It is inadvisable to use shell and tube condensers in a refrigeration system where cooling water is run to waste, unless a plentiful supply of cheap water is available, independent of the domestic drinking water supply; otherwise water costs may be prohibitive, since 15 tonnes of cooling water at 10C or 60 tonnes at 25C are required for each tonne of ice produced. Other factors can affect cooling water consumption, and manufacturers' precise figures should be used at the detailed planning stage. Air cooled condensers can be used on small plants, but for most commercial installations evaporative condensers, or shell and tube condensers with a cooling tower, are more likely to be supplied. Evaporative condensers and cooling tower cooling systems normally use less than 1/2 tonne of water for each tonne of ice, plus some small additional allowance if an overspill is necessary to prevent build up of solids in the recirculated water. Water for defrosting plate icemakers has to be of the same high quality as water for making ice. About 2 tonnes of water is required for each tonne of ice if the water is run to waste, but consumption can be reduced to almost nothing by making a closed circuit and reheating the water between defrosts. The refrigeration system Most modern icemakers are designed to work unattended 24 hours a day with only routine inspection and maintenance. The system is therefore designed for reliability, with safeguards against failure or malfunction. Most manufacturers recommend the refrigeration system best

suited to their icemakers, but where local installation engineers propose a system, the purchaser should ensure that the contractor is aware of the need for continuous automatic running and for rapid repair after breakdown. The refrigeration system for an icemaker should be independent of any other refrigeration requirement; it should not be shared for example with a freezer or a cold store. The only exception to this rule is when a complex system is installed and a competent engineer is in fulltime attendance. Manufacturers often recommend a separate system for each icemaking unit, so that in a multiple unit installation there is considerable flexibility, and a reasonable guarantee that at least some of the units are always in production. Choice of refrigeration machinery and of refrigerant is a job for the refrigeration expert, and the advice of the ice plant manufacturer or competent consultant should be sought before making any decision. Storage of ice Manufacture of ice can seldom be matched to meet immediate demand; therefore storage is necessary to cater for peak demand and to allow the icemaker to be operated continuously. Storage also acts as a buffer against interruption of production due to breakdown or routine maintenance. The size of store required will depend on the pattern of operation, but it is never advisable to store less than 2 days' production, and in most installations it is useful to be able to store 4-5 times the daily production. Stowage rates vary with the kind of ice being made, and Table 3 gives the storage space required for the principal types. Table 2 Storage space for ice type of ice flake plate tube crushed block space m/tonne 22-23 17-18 16-20 14-15

The type of ice storage may range from a simple insulated bin to a large refrigerated silo or bin with automatic loading, unloading and weighing of ice. Silo Storage Silos are generally used only for freeflowing subcooled ice, such as flake ice, and an independent refrigeration system for the silo is essential to keep the ice sub-cooled in storage.

It is usual to provide an air cooler to refrigerate the jacket space between the inner lining of the silo and the outer insulated structure; typically the air cooler is located next to the icemaker on top of the silo, and cold air either falls by gravity into the jacket or is circulated by fan. Ice is removed from the bottom of the silo, gravity flow being assisted by an agitator, usually a rotating chain; this means the oldest ice is always used first. Ice adhering to the silo wall needs to be freed periodically; otherwise this wall of ice becomes permanent, and only the central core of ice in the silo remains freeflowing. Silo storage is expensive for small amounts of ice; units have been made to hold as little as 10 tonnes, but silos are best suited for storing 40-100 t. Bin storage Bins can be used to store any kind of fragmented ice, and may be of any size from a simple box to hold 1/2 tonne to an installation holding 1000 t or more. Refrigeration of the bin is not always essential but, whatever the size, adequate insulation is necessary to reduce meltage; 100-150 mm of cork, or an equivalent thickness in many other suitable insulating materials, should be used. A simple bin system is suitable for factories making ice for their own use. The icemaker can be mounted above the bin, so that ice flows by gravity to a take off point at the bottom of the bin; thus the oldest ice is used first. Where ice has to be distributed to customers, bins with a capacity of up to 50 tonnes can be made with a sloping floor and so mounted that rapid discharge direct to lorry or conveyor is possible. Some means of access to the bin is advisable in order to be able to dislodge any compacted ice.

FIG 2. Silo ice store for 10-100 tonnes.

Key: 1. Ice makers. 2. Concrete or steel silo 3. Agitator with chain 4. Sliding hatch. 5. Screw conveyor 6. Ice discharge. 7. Jacket cooler unit. Depth of ice storage in a bin is limited to about 5 m to avoid fusion of ice under pressure; therefore large bins occupy considerable floor space, and usually require some mechanical means of unloading. Rakes, mechanical shovels and movable screw conveyors have all been used to remove ice from large bins. Rakes and shovels normally remove the topmost layer of ice in the bin, leaving older ice untouched at the bottom. It is therefore necessary to clear the bin periodically to remove all the old ice. Screw conveyors work at the bottom of a bin and remove oldest ice first, but an additional mechanism is required to distribute ice uniformly throughout the bin, and the screw drive takes up some space outside the bin area. FIG. 3. Small ice store for 5-15 tonnes.

Block ice storage Block ice can be crushed and stored in the same way as other fragmented ice, but it is more usual to store the blocks and crush them as required before delivery of the ice. Because of their weight and shape it is difficult to store blocks other than in a single layer; thus a considerable floor area is required. However there is usually some extra storage available in the icemaker itself, since all of the ice cans are normally kept full. Handling, conveying and weighing Icemakers located directly above the store feed the ice by gravity. Where an ice-maker produces wet ice, it is advisable to drain off excess water before storing it; this is normally done on a conveyor between icemaker and store. Large bins require some means of distributing ice evenly throughout the storage space; silos and small bins do not require such an arrangement. Both dished belt and screw conveyors are used extensively for transporting ice. Screws allow both horizontal and vertical movement, but can operate only over a limited distance. Belts are generally used for long hauls, and special ribbed belts can be used on an incline. Delivery into lorry or fishing vessel is by means of a chute that can be moved to distribute the ice evenly.

Pneumatic systems have been used for moving ice, but the method is unsuitable for ice that is to be stored again. The energy used in moving the ice is dissipated as heat which can cause some meltage, and more heat is transferred to the ice from the blown air, unless the air is precooled. In addition the ice is broken down into smaller particles by impact on the duct walls, so that a proportion of the ice at the delivery point appears as wet snow that cannot be stored, for example in a trawler fishroom. The use of pneumatic systems should therefore be confined to distributing ice to the point of use, for instance into fish boxes. Ice can be weighed automatically on a conveyor belt to within 2 per cent. Elsewhere ice is usually measured by volume, the contents of a standard container having been weighed to determine the density. Weight of crushed block ice supplied is checked by counting the number of blocks delivered to the crusher. Cost of ice plant It is impossible to generalize about cost of ice plant, since so much depends on local conditions. When a new installation is being planned, it may be necessary to take into account cost of land, buildings, roads, electrical and water supplies, drainage and so on as well as the cost of the icemaking and storage equipment. Annual fixed costs are likely to include depreciation, maintenance, interest on capital, tax, insurance and other overheads, while the main operating costs will include power, labour, water and possibly transport. Cost estimating at an early stage may well influence the choice of plant size, since many of the costs are largely independent of size, and it may prove more economic for the plant operator to make more than he needs himself and become a supplier. Maintenance cost may be of great importance in remote areas; although modern plants operate with minimum attention, regular professional maintenance is necessary. Direct comparison of capital and running cost of different types or makes of ice plant is not possible except on so general a basis as to be of little value to a prospective purchaser; each particular project has to be costed individually, using current prices.

EXPERIMENT NO. 4

Aim: Study of Electrolux Vapor Absorption Refrigeration system. Working of Electrolux Vapor Absorption Refrigeration system: This refrigerator had no compressor or valves, just a small flame or electric heater, and worked continuously without noise or vibration. In spite of their advantages, absorption refrigerators are not much used at present. First, we should review the operation of the compression-cycle refrigerator, which is by far the most common type. The refrigerant is compressed, and then gives up heat to the environment, condensing to a liquid. This high-pressure liquid is throttled through a valve to a low-pressure region, where it evaporates, absorbing heat from the volume to be cooled. If Q is the heat absorbed at the low temperature, Q' the heat rejected at the high (environmental) temperature, and W the work done on compression, then conservation of energy gives W = Q' - Q. The coefficient of performance P is P = Q/W = Q/(Q' - Q). If the cycle is reversible, which is an idealization, then Q'/T' is equal to Q/T, where T is the high temperature and T' the low. This gives P = T/(T' - T). Typically, if T' = 290K, T = 273K, then P = 16. This means that the heat absorbed, the cooling effect, is 16 times the heat equivalent of the work input.

The absorption cycle refrigerator uses ammonia refrigerant, water absorber, and hydrogen pressurization. The general arrangement is shown in the figure. The whole working volume is at a single high pressure, perhaps 10 atm. There are, therefore, no valves. Three circuits can be identified: ammonia, water and hydrogen. The gas on what would be the highpressure side of an ordinary refrigerator is mostly ammonia, so the ammonia is at high pressure. It is also warm, and is cooled to the environment in the usual way, upon which it condenses. The liquid passes to the evaporator, which is also at a high total pressure, but now the pressure is mainly hydrogen. The ammonia pressure is kept low by absorption in

water. The liquid ammonia then evaporates, cooling as usual. The ammonia-water solution flows to a generator, where it is heated by a small flame or electric heater. This releases the ammonia, which by a percolator action lifts water to a vapor-liquid separator. This lift provides the pressure difference to keep the water flowing. The ammonia replaces the hydrogen on this side, and is condensed in the condenser as described above. The water, depleted in ammonia, is now cooled and absorbs more ammonia, keeping its partial pressure low in the evaporator. It then goes to the generator, closing the water cycle. This slow movement of the water continues to keep the partial pressure in the evaporator low, and the partial pressure in the condenser high, maintaining the refrigeration effect. The water cycle is the essential action in the refrigerator. The hydrogen mainly fills the lowpressure side, taking no part in the action aside from keeping the total pressure constant. In this cycle, heat q is absorbed at the high temperature of the generator, as well as heat Q from the evaporator. Heat Q' is rejected to the environment in the condenser, as well as heat Q" in the absorber. Conservation of energy gives q + Q - Q' - Q" = 0. The coefficient of performance is P = Q/q, considering the heat input at the generator to be the input and Q the output. This is not as easily related to the temperatures, since the cycle is considerably irreversible.

References

M. W. Zemansky, Heat and Thermodynamics, 4th ed. (New York: McGraw-Hill, 1957). pp. 235-237.

Potrebbero piacerti anche

- Refrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearDocumento9 pagineRefrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearKhaled HakimNessuna valutazione finora

- Refrigeration System Components ExplainedDocumento21 pagineRefrigeration System Components ExplainedJanine RenojoNessuna valutazione finora

- Study of Single Stage Air CompressorDocumento28 pagineStudy of Single Stage Air CompressorRealKimJongUnNessuna valutazione finora

- How Surface Condensers WorkDocumento12 pagineHow Surface Condensers WorkPrabir Kumar Pati100% (1)

- Refrigeration: "Refrigeration Is The Process of Removing Heat From An Enclosed Space, orDocumento16 pagineRefrigeration: "Refrigeration Is The Process of Removing Heat From An Enclosed Space, ordjgondalNessuna valutazione finora

- Refrigeration Laboratory Manual 2011Documento19 pagineRefrigeration Laboratory Manual 2011Himanshu Uniyal0% (1)

- CondenserDocumento2 pagineCondenserAgustinus PrassetoNessuna valutazione finora

- Hvac TrainingDocumento33 pagineHvac TrainingABHILASH THAKRENessuna valutazione finora

- Hvac LabDocumento20 pagineHvac LabMuhammad AhmadNessuna valutazione finora

- Ice Plant ModelDocumento12 pagineIce Plant ModelAtul Sartape100% (2)

- Chilled Water SystemsDocumento10 pagineChilled Water SystemsLavanya...100% (5)

- Carrier Split SystemDocumento12 pagineCarrier Split SystemabuMalakNessuna valutazione finora

- Vapor Compression Refrigeration Cycle ExplainedDocumento16 pagineVapor Compression Refrigeration Cycle ExplainedDiether RigorNessuna valutazione finora

- Day 1 - 2 Basic VRV ComponentsDocumento38 pagineDay 1 - 2 Basic VRV ComponentstehtehtehNessuna valutazione finora

- Types of compressors and their advantages and disadvantagesDocumento4 pagineTypes of compressors and their advantages and disadvantagesAj Ax100% (1)

- Rac PPT Rough WorkDocumento3 pagineRac PPT Rough Worktej shahNessuna valutazione finora

- Positive Displacement and Dynamic, DynamicDocumento15 paginePositive Displacement and Dynamic, DynamicdausszNessuna valutazione finora

- Components of RefrigerationDocumento10 pagineComponents of RefrigerationMuhammad SarimNessuna valutazione finora

- Basic Heat Pump ComponentsDocumento6 pagineBasic Heat Pump Componentsdrabc123Nessuna valutazione finora

- ME LAB ASSESSMENT 2 and 3Documento20 pagineME LAB ASSESSMENT 2 and 3Emilio Joaquin FloresNessuna valutazione finora

- HVAC1Documento107 pagineHVAC1deesing100% (1)

- Refrigeration System DiagramDocumento7 pagineRefrigeration System DiagramNama Saya ZulNessuna valutazione finora

- RefrigerationDocumento96 pagineRefrigerationAliNessuna valutazione finora

- Your Guide to Air Conditioning ComponentsDocumento9 pagineYour Guide to Air Conditioning ComponentsRicaMyrivilleArellagaNessuna valutazione finora

- Ministory of Education: West Yangon Technological University Department of Mechanical EngineeringDocumento23 pagineMinistory of Education: West Yangon Technological University Department of Mechanical EngineeringThaungShanHtet PalatarNessuna valutazione finora

- Air Conditioning - Building ServiceDocumento12 pagineAir Conditioning - Building ServiceHarini Andal AgnihotramNessuna valutazione finora

- The Automotive Air Conditioning SystemDocumento5 pagineThe Automotive Air Conditioning SystemGeneza Del RosarioNessuna valutazione finora

- Analysis of Small Scale Ice Plant Model COPDocumento23 pagineAnalysis of Small Scale Ice Plant Model COPThaungShanHtet PalatarNessuna valutazione finora

- Classification of CompressorsDocumento20 pagineClassification of CompressorsDeepakNessuna valutazione finora

- Screw Type of CompressorDocumento9 pagineScrew Type of CompressorAnish KumarNessuna valutazione finora

- Aim:-To Study Various Types of Compressors Used For Refrigeration Cycle. TheoryDocumento8 pagineAim:-To Study Various Types of Compressors Used For Refrigeration Cycle. TheoryAamer MohammedNessuna valutazione finora

- Refrigerant System Components and ControlsDocumento16 pagineRefrigerant System Components and ControlssrybsantosNessuna valutazione finora

- 2-COMPRESSIONDocumento28 pagine2-COMPRESSIONVijay RajaindranNessuna valutazione finora

- Color Coding and Other Info For ProjectDocumento11 pagineColor Coding and Other Info For ProjectTanya Nataniel NoahNessuna valutazione finora

- Aim: To Study Various Type of Compressors. TheoryDocumento6 pagineAim: To Study Various Type of Compressors. TheoryAamer MohammedNessuna valutazione finora

- Automobile AC System Components and OperationDocumento15 pagineAutomobile AC System Components and Operationcpt.ghostNessuna valutazione finora

- Chiller CompressorDocumento41 pagineChiller Compressorabidch143Nessuna valutazione finora

- Window Air Conditioner Literature ReviewDocumento27 pagineWindow Air Conditioner Literature ReviewMohd SalmanNessuna valutazione finora

- Overview of Chiller Compressors-R1Documento41 pagineOverview of Chiller Compressors-R1Mo ajNessuna valutazione finora

- Chiller CompressorsDocumento41 pagineChiller Compressorsdennrich100% (2)

- R&AC Lab ManualDocumento29 pagineR&AC Lab ManualPARAMESHNessuna valutazione finora

- Basic Refrigeration CycleDocumento12 pagineBasic Refrigeration CycleApet GriffinNessuna valutazione finora

- Components of VCRS NewDocumento37 pagineComponents of VCRS Newmesfn derbNessuna valutazione finora

- Refrigeration Compressor Types & FunctionsDocumento13 pagineRefrigeration Compressor Types & FunctionsLaka 98Nessuna valutazione finora

- Different Type of ChillersDocumento7 pagineDifferent Type of ChillersMAGDY KAMEL100% (3)

- Perception Mapping & Analyzing Prospectives for Condensing UnitsDocumento52 paginePerception Mapping & Analyzing Prospectives for Condensing UnitsAkshay ShahNessuna valutazione finora

- AIR-CONDITIONER AND REFRIGERATION TECHNOLOGY TRAINING NOTESDocumento14 pagineAIR-CONDITIONER AND REFRIGERATION TECHNOLOGY TRAINING NOTESOba-Elvis IkenyenweNessuna valutazione finora

- Implant TrainingDocumento5 pagineImplant Trainingrsrinath91Nessuna valutazione finora

- UNIT I - Air ConditionDocumento62 pagineUNIT I - Air ConditionNeha JojanNessuna valutazione finora

- Refrigeration & Air-Conditioning Laboratory: Aurko Chatterjee 10ME10069Documento25 pagineRefrigeration & Air-Conditioning Laboratory: Aurko Chatterjee 10ME10069Anurag porteNessuna valutazione finora

- Ec & Us Manual PDFDocumento111 pagineEc & Us Manual PDFRamnarayan MeenaNessuna valutazione finora

- Chiller CompressorsDocumento40 pagineChiller CompressorsAnkush NayarNessuna valutazione finora

- Split Air Conditioner Learning SimulationDocumento19 pagineSplit Air Conditioner Learning SimulationkablasNessuna valutazione finora

- Oral and Practical Review: Reflections on the Part 147 CourseDa EverandOral and Practical Review: Reflections on the Part 147 CourseNessuna valutazione finora

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ADa EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AValutazione: 5 su 5 stelle5/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Process Engineering: Facts, Fiction and FablesDa EverandProcess Engineering: Facts, Fiction and FablesValutazione: 3 su 5 stelle3/5 (2)

- Numerical Investigation of Combustion Instabilities in Swirling Flames With Hydrogen EnrichmentDocumento41 pagineNumerical Investigation of Combustion Instabilities in Swirling Flames With Hydrogen EnrichmentSanjeev Kumar GhaiNessuna valutazione finora

- Impact of Flame Generated Turbulent Intensity and Flame Speed On The Low Order Modelling of Light RoundDocumento20 pagineImpact of Flame Generated Turbulent Intensity and Flame Speed On The Low Order Modelling of Light RoundSanjeev Kumar GhaiNessuna valutazione finora

- Gmail - Your Leave Has Been GrantedDocumento1 paginaGmail - Your Leave Has Been GrantedSanjeev Kumar GhaiNessuna valutazione finora

- Attendance Data ME690ADocumento8 pagineAttendance Data ME690ASanjeev Kumar GhaiNessuna valutazione finora

- Simple Steps To Avoid Plagiarism and Improve Scientific WritingDocumento2 pagineSimple Steps To Avoid Plagiarism and Improve Scientific WritingaissaboulmerkNessuna valutazione finora

- S.No. Roll No. Name Dept Lecture-4 Lecture-5 Lecture-6 Lecture-7Documento2 pagineS.No. Roll No. Name Dept Lecture-4 Lecture-5 Lecture-6 Lecture-7Sanjeev Kumar GhaiNessuna valutazione finora

- JNNFM Momentum TransferDocumento23 pagineJNNFM Momentum TransferSanjeev Kumar GhaiNessuna valutazione finora

- DPGC Meeting ScheduleDocumento1 paginaDPGC Meeting ScheduleSanjeev Kumar GhaiNessuna valutazione finora

- Lab Calender For ME 401ADocumento1 paginaLab Calender For ME 401ASanjeev Kumar GhaiNessuna valutazione finora

- CC PI and ID Making Slots For 20th JulyDocumento1 paginaCC PI and ID Making Slots For 20th JulySanjeev Kumar GhaiNessuna valutazione finora

- Stratified Jet Flames in A Heated (1390K) Air Cross Flow With Autoignition 2012 Combustion and FlameDocumento10 pagineStratified Jet Flames in A Heated (1390K) Air Cross Flow With Autoignition 2012 Combustion and FlameSanjeev Kumar GhaiNessuna valutazione finora

- Template New GraduateDocumento3 pagineTemplate New GraduateMohneet RaiNessuna valutazione finora

- BiotechnologyDocumento21 pagineBiotechnologySanjeev Kumar GhaiNessuna valutazione finora

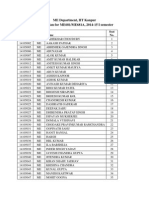

- ME681&ME681A Seating Plan - 2014-15IDocumento3 pagineME681&ME681A Seating Plan - 2014-15ISanjeev Kumar GhaiNessuna valutazione finora

- Introduction To Non Conventional MC ProcessDocumento18 pagineIntroduction To Non Conventional MC ProcessSanjeev Kumar GhaiNessuna valutazione finora

- NTPC Limited Registration Slip for Executive Trainee - 2014Documento1 paginaNTPC Limited Registration Slip for Executive Trainee - 2014Sanjeev Kumar GhaiNessuna valutazione finora

- Presentation 2Documento1 paginaPresentation 2Sanjeev Kumar GhaiNessuna valutazione finora

- Steps To Perform 26AS RegistrationDocumento20 pagineSteps To Perform 26AS RegistrationSanjeev Kumar GhaiNessuna valutazione finora

- Kerpen Power & ControlDocumento78 pagineKerpen Power & Controlnixsol75Nessuna valutazione finora

- AKPDocumento3 pagineAKPEhab Ahmed Hussein ReyadNessuna valutazione finora

- Group 12 Constant Mesh GearboxDocumento74 pagineGroup 12 Constant Mesh GearboxBirhanu Asfaw100% (3)

- Concrete Mix Design ReportDocumento5 pagineConcrete Mix Design ReportAniruddha ChakrabortyNessuna valutazione finora

- DeltaChill & DeltaChill FreeCool Chiller 110-1080kW SB UKDocumento16 pagineDeltaChill & DeltaChill FreeCool Chiller 110-1080kW SB UKNay Myo OoNessuna valutazione finora

- Laplace Transform Problems in Heat Transfer and Mass TransferDocumento7 pagineLaplace Transform Problems in Heat Transfer and Mass TransferMuhammad Irfan MalikNessuna valutazione finora

- 50X75 Tie Beam 50X75 Horizontal Member: A Proposed Residential HouseDocumento1 pagina50X75 Tie Beam 50X75 Horizontal Member: A Proposed Residential HousefredrickNessuna valutazione finora

- Kuwait Oil Company (K.S.C.) : Engineering GroupDocumento15 pagineKuwait Oil Company (K.S.C.) : Engineering GroupAravindan Ganesh KumarNessuna valutazione finora

- Prefabrication Concrete ShellsDocumento202 paginePrefabrication Concrete ShellsGabriel Riso100% (1)

- Main panel single line diagramDocumento15 pagineMain panel single line diagramEr.AROCKIA STEPHAN VSGNessuna valutazione finora

- EductorsDocumento1 paginaEductorscesar luis gonzalez rodriguez100% (1)

- Pipe Hangers, Supports and Accessories Base Price ListDocumento56 paginePipe Hangers, Supports and Accessories Base Price ListBrian AlbarracínNessuna valutazione finora

- 1 - Final Attic Stock MonitoringDocumento1 pagina1 - Final Attic Stock MonitoringJQ INTERNATIONAL CONSTRUCTION COMPANYNessuna valutazione finora

- Aaon ChartDocumento2 pagineAaon ChartpabloNessuna valutazione finora

- Do Mai Lam PHD Thesis. Vapor Phase SolderingDocumento105 pagineDo Mai Lam PHD Thesis. Vapor Phase SolderingDo Mai LamNessuna valutazione finora

- Fastenr GradesDocumento5 pagineFastenr GradesVipul ShereNessuna valutazione finora

- CurtainDocumento257 pagineCurtainvranceanu100% (13)

- How to use Energy Audit Instruments EffectivelyDocumento65 pagineHow to use Energy Audit Instruments EffectivelyUlhas VajreNessuna valutazione finora

- Korodur Copetti Floor PDFDocumento1 paginaKorodur Copetti Floor PDFIbrahim SahinNessuna valutazione finora

- Farnsworth House SummaryDocumento6 pagineFarnsworth House SummaryAshtonNessuna valutazione finora

- Carbon BlackDocumento7 pagineCarbon BlackJahidul OnirNessuna valutazione finora

- Technical Specification of The ProjectDocumento6 pagineTechnical Specification of The ProjectyeabtsegaNessuna valutazione finora

- Group Assignment: Ska3013 Analytical Chemistry SEMESTER 2 SESSION 2019/2020Documento23 pagineGroup Assignment: Ska3013 Analytical Chemistry SEMESTER 2 SESSION 2019/2020Lau Lee LingNessuna valutazione finora

- Acceptance Criteria for Welds Visual and Radiographic ExaminationDocumento3 pagineAcceptance Criteria for Welds Visual and Radiographic ExaminationerboalNessuna valutazione finora

- (2002) Simplified Design Procedure For Piled Raft FoundationsDocumento18 pagine(2002) Simplified Design Procedure For Piled Raft FoundationsRaghu MahadevappaNessuna valutazione finora

- Trosifol SentryGlas SecurityDocumento13 pagineTrosifol SentryGlas SecurityVolkan Çağlar ÖzcanNessuna valutazione finora

- X854Documento10 pagineX854RimNessuna valutazione finora

- Future Directions For Design, Specification, Testing, and Construction of Durable Concrete StructuresDocumento17 pagineFuture Directions For Design, Specification, Testing, and Construction of Durable Concrete StructuresSophia LiuNessuna valutazione finora

- ASTM B833 Standard Specification For Metal Injection Molding (MIM), Ferrous Structural Parts1Documento4 pagineASTM B833 Standard Specification For Metal Injection Molding (MIM), Ferrous Structural Parts1David VegaNessuna valutazione finora

- Design of An Electrical Installation of A Storey - 15Documento11 pagineDesign of An Electrical Installation of A Storey - 15Engr. Najeem Olawale AdelakunNessuna valutazione finora