Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Southren Railways

Caricato da

Kuldeep GolaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Southren Railways

Caricato da

Kuldeep GolaCopyright:

Formati disponibili

ADHIPARASAKTHI ENGINEERING COLLEGE DEPARTMENT OF ELECTRONICS AND COMMUNICATION ENGINEERING INPLANT TRAINING REPORT SOUTHERN RAILWAYS PERAMBUR Submitted

by M.Saranya IV-ECE- A

DEPARTMENTS o Train Lighting Section o Delux Section o Power Section 2

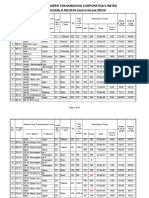

Index S.NO 1. CONTENTS PAGE NO. TRAIN LIGHTING SECTION Alternators Regulators and Rectifiers Battery Light and Fan 2. 4 4 6 7 8 DELUX SECTION Alternator Compressor Condensor And Evaporator Battery 3. 9 9 9 11 12 POWER SECTION Substation VCB Relays 13 13 13 14 3

TRAIN lighting section ALTERNATORS: Principle of operation: Alternators generate electricity by the same principle as DC generators, namely, when the magnetic field around a conductor changes, a current is induced in the conductor. Typically, a rotating magnet called the rotor turns within a station ary set of conductors wound in coils on an iron core, called the stator. The fie ld cuts across the conductors, generating an induced EMF, as the mechanical inpu t causes the rotor to turn. The rotating magnetic field induces an AC voltage in the stator windings. Often there are three sets of stator windings, physically offset so that the rotating magnetic field produces three phase currents, displa ced by one-third of a period with respect to each other. The rotor magnetic fiel d may be produced by induction (in a "brushless" alternator), by permanent magne ts (in very small machines), or by a rotor winding energized with direct current through slip rings and brushes. The rotor magnetic field may even be provided b y stationary field winding, with moving poles in the rotor. Automotive alternato rs invariably use a rotor winding, which allows control of the alternator genera ted voltage by varying the current in the rotor field winding. Permanent magnet machines avoid the loss due to magnetizing current in the rotor, but are restric ted in size, owing to the cost of the magnet material. Since the permanent magne t field is constant, the terminal voltage varies directly with the speed of the generator. Brushless AC generators are usually larger machines than those used i n automotive applications. Construction: A brushless alternator is composed of two alternators built end-to-end on one sh aft. Smaller brushless alternators may look like one unit but the two parts are readily identifiable on the large versions. The larger of the two sections is th e main alternator and the smaller one is the exciter. The exciter has stationary field coils and a rotating armature (power coils). The main alternator uses the opposite configuration with a rotating field and stationary armature. Working: Harmonics in generated voltage waveforms of brushless alternators of inductor ty pe, used in railway coaches are often the cause for excessive heating and tooth tip saturation and compel de-rating of such machines. This paper discusses a nov el technique to overcome this problem at the design level itself, by predetermin ing the generated voltage waveform and analyzing it for the harmonic content for improving the output power quality. Analysis of three-dimensional feature like rotor slot skew is performed with two-dimensional electromagnetic field formulat ion, which results in significant reduction in computational effort. A modified time stepping finite element method is proposed for shape optimisation of certai n design parameters and a multislice technique is employed to take into account the axial variations of the field, introduced by rotor skew. Comparisons of comp utational and experimental results obtained from a 4.5 kW alternator, confirm th e great potential and usefulness of the proposed methodology. 4

Frequent breakdowns due to broken shafts in three-phase inductor-type brushless alternators that are used in railway coaches for supplying loads like lights and fans and for charging the coach battery have been reported by the Indian Railwa ys. These failures, besides other mechanical reasons, can be attributed to unbal anced magnetic pull (UMP) due to rotor eccentricity. Accurate calculation of the UMP has always proved difficult due to the inability of machine models to cope with air-gap variations. Hence, analytical closed-form expressions are developed in this paper for the calculation of the UMP and for axial flux, considering va rious rotor positions. The rotor skew and conical motions of the rotor are also taken into account. A 2-D finite-element method is also proposed for the analysi s, for the sake of comparison of results. Furthermore, this paper describes a si mple method for detecting even a slight rotor asymmetry on the basis of the gene rated voltage harmonic pattern, which, on further analysis, illustrates how roto r eccentricity can be identified in the alternator for condition-monitoring tech niques. Fig:alternator Specification: 4. 5 KW train lighting system consists of three phase homopolar type alternator and a static Regulator-rectifier unit. Alternators render a trouble free longing service without practically any maintenance as it is completely free from any m oving contacts or winding in rotor. The regulator has been designed for a reliab le performance in any operational conditions by eliminating transistors and thyr istors which are comparatively less reliable. Brushless alternator is of totally enclosed construction capable of developing a constant voltage of 120 volts at a load current of 37. 5 from a minimum speed for full output to maximum speed. T he machines are used for A) charging the coach battery B) operation of fans & li ghts etc in Coach. Output data: Output voltage-124 v + -5% Voltage setting range-120 v-124 v Rated current-37. 5 a Maximum current-43 amps Cut-in-speed 350 RPM (approx 19 kmph train speed with half worn wheel) Minimum speed for full output-550 rpm (approx 29 kmph train sp eed with half worn wheel) Maximum speed-2500 RPM (approx 140 kmph train speed wi th half worn wheel) Class of insulation-'f' Resistance between phase-0. 400 ohms at 20 deg c Resistance of field winding-4: 38 ohms at 20 deg c REGULATOR CUM RECTIFIER: 5

Rectifier Regulator units are supplied with the Alternators used for converting the AC to DC for Battery Charging and Train Lighting system. The rectifier regul ating equipment (RRU) along with alternators of 4.5 KW rating so far been used i n conventional self generating coaches is based on magnetic amplifier with assoc iated electronic control circuiting. The design of magnetic amplifier based (RRU ) is having inherent limitations of voltage regulation. The rectifier cum regula tor unit has mainly following functions: (i) To rectify the 3 phase AC output of the alternator through DC full wave bridge rectifier. (ii) Regulating the volta ge generated by the alternator at the set value. (iii)Regulating the output curr ent. Clean regulator externally. Open regulator terminal cover and check for sig ns of overheating in all the terminals/bus bars/etc. Checking: Check up for loose connections and tighten the same. If the terminal board is fo und affected due to heat, replace terminal board with new one. Check for any dam age to the phase and field wires /cables inter connecting regulator and alternat or and its anchoring arrangement. Check and secure properly the terminal cover a nd regulator cover. If the generator is normal, check the cable termination of t he regulator visually for any abnormality. If the alternator arrived without gen eration, open the regulator and check for any abnormality and ensure the fuses a re intact. Check the cable for any abnormality from the alternator to the regula tor by using test lamp, if found open/short attend the same. Ensure the residual magnetism is available in the alternator. If needed change the regulator and en sure the generator by running the alternator with a portable motor. Fig: Regulator cum Rectifier Battery: 6

Two kinds of batteries are used. They are Conventional Lead Acid Battery VRLA Batter ies (i)Conventional Lead Acid Batteries: Record specific gravity of individual cells/mono block. "Switch on" full load of the coach and record individual voltage of cells and total voltage. "Switch off " load. If the specific gravity is less than that painted on the battery box, ch arge the cells as specified under "Trip Examination" after topping up with DM wa ter, if required. Use battery charging terminals provided on coaches for chargin g purposes. Charging should be continued till the specific gravity rises to the value of mentioned in battery box, on "Pilot" cells. In case pilot cells show no appreciable improvement, check specific gravity of adjacent cells. If the speci fic gravity does not improve in spite of charging, replace the battery by anothe r set and send the defective battery to Depot/Shop for treatment at the earliest . Cells should be handled with due care while unloading and in transit to avoid breakage. Adequate facilities should be created in Depot for treatment of cells which do not pick up charge. Sulphation will be the main cause for this and Sulp hated cells should be treated for their recovery as specified. On completion of charging, record the specific gravity of individual cells. If there is any wide variation in the specific gravity/ voltage of cells, disconnect and replace thos e cells showing low specific gravity/voltage by spare ones. In case there are mo re than 1/3 of total cells with low specific gravit y, the entire set should be replaced. Cells showing reverse voltage, zero volts should be withdrawn and repl aced by charged cells immediately. Record individual voltage of cells and the to tal voltage on full load of the coach. (ii)VRLA Batteries: Storage of VRLA Batteries : The conventional batteries were formed at site and d ue to this fact a lot of time was required to install the battery. The VRLA batt eries are formed in the factory. At site only interconnection of cells is requir ed to be done, hence these batteries are less time consuming as far as commissio ning is concerned. The VRLA batteries are transported and stored in the fully fo rm condition. It is therefore essential that these batteries are installed and c ommissioned in the shortest possible time after their dispatch from the factory. This is because all the batteries including VRLA batteries lose their charge du e to self discharge. If these batteries are allowed to remain idle for a very lo ng time, say more than six months these battery may get damaged beyond recovery due to sulphation. 7

LIGHT AND FAN: FAN: The fan body, guards and blade shall be thoroughly cleaned with cloth. All fans shall be opened and condition of commutator, brushes and brush gear shall be tho roughly checked. Action should be taken where necessary as given under "Trip Att ention". Studs used for fixing the fan to coach body, shall be checked and tight ened, wherever necessary. Availability of all the three fixing studs should be e nsured. All the switches controlling the fans shall be checked for its smooth op eration and correct working and replaced, where necessary. Fan regulators in Upp er class coaches shall be checked for smooth operation from one position to the other. In case the regulators are not regulating the fan speed, the resistance b ox shall be checked and replaced, where necessary. Fan blades shall be replaced if found bent, or if there is no proper air discharge. LIGHT: Open each fitting with the dome key and remove the dust of the fitting both from inside and outside. Ensure free operation of locking mechanism and replace defe ctive fitting. Clean glass domes first with wet cloth and then with a clean dry cloth. Replace rusted fittings and fittings with damaged surface. n Check up wat tage of lamps and replace with that of correct wattage. n Check up whether toggl e switches are marked to indicate lighting control "L", night light control `NL' , side lamps in guards compartment as `SL', tail lamps as `TL-Rear', `TL-Front', luggage room as `LRL'. Check up all lighting circuit fuses in each coach for co rrect sizes and replace if necessary. Stencil the size of fuses near the locatio ns, if not already done. fig:light DELUX SECTION 8

Air conditioning: Air conditioning of railway coaches on Indian Railways began in 1960s. These wer e equipped with under slung equipment's, interconnected with pipelines. The intr oduction of self contained roof mounted package units in coaches, with complete equipment's, pre-charged and tested needing only electrical and ducting connecti ons is of recent origin. With the introduction of more and more fast trains on I ndian Railways, the need for air-conditioned coaches has also increased. Not onl y for improving comfort, but also from operating point of view, since with highe r train speeds, the need to avoid opening of windows due to wind resistance cons iderations also assumes importance. ALTERNATORS: DEVELOPMENT OF 25 KW ALTERNATORS FOR SELF-GENERATING AIR-CONDITIONE D COACHES. Belt driven alternator along with rectifier-regulator is used to generate electr ical power by utilizing the mechanical power of the train to provide power suppl y for air conditioning system, light and fan loads in the coaches. At present, t here are mainly two types of coaches (i) Air-conditioned coaches which are provi ded with 18/22.75 kW alternators with rectifier-regulator and (ii) Non-AC coache s with 110 V system which are provided with 4.5 kW, 110V ac alternator. In order to improve the reliability of these alternators for AC coaches, it is necessary to provide adequate design margins in the rating. Research, Designs and, Standa rds, Organization (RDSO) has undertaken development of 25 kW alternator and regu lator using state-of-art technology of power electronics and controls. RDSO has successfully developed these alternators indigenously through the existing manuf acturers. These alternators are now in regular use by the production units. The design features of various makes have also been standardized to ensure inter-cha ngeability. COMPRESSOR: The compressor normally consists of the following elements. a. The compressing e lement, consisting of air cylinders, heads and pistons, and air inlet and discha rge valves. b. A system of connecting rods, piston rods, crossheads, and a crank shaft and flywheel for transmitting the power developed by the driving unit to t he air cylinder piston c. A self-contained lubricating system for bearings, gear s, and cylinder walls. Compressor includes a reservoir or sump for the lubricati ng oil, and a pump, or other means of delivering oil to the various parts. On so me compressors a separate force-fed lubricator is installed to supply oil to the compressor cylinders. d. A regulation or control system designed to maintain th e pressure in the discharge line and air receiver (storage tank) within a predet ermined range of pressure. e. An unloading system, which operates in conjunction with the regulator, to reduce or eliminate the load put on the prime mover when starting the unit. 9

Location of Compressor The location of air compressors and the quality of air dr awn by the compressors will have a significant influence on the amount of energy consumed. Compressor performance as a breathing machine improves with cool, cle an, dry air at intake. Air Intake Temperature The effect of intake air on compre ssor performance should not be underestimated. Intake air that is contaminated o r hot can impair compresso r performance and result in excess energy and mainten ance costs. If moisture, dust, or other contaminants are present in the intake a ir, such contaminants can build up on the internal components of the compressor, such as valves, impellers, rotors, and vanes. Such build-up can cause premature wear and reduce compressor capacity. The compressor generates heat due to its c ontinuous operation. This heat gets dissipated to compressor room/ chamber leadi ng to hot air intake. This results in lower volumetric efficiency and higher pow er consumption. As a general rule, Every 4oC rise in inlet air temperature results in a higher energy consumption by 1percent to achieve equivalent output . Hence the intake of cool air improves the energy efficiency of a compressor When an intake air filter is located at the compressor, the ambient temperature should be kept at a minimum, to prevent reduction in mass flow. This can be accomplished by lo cating the inlet pipe outside the room or building. When the intake air filter i s located outside the building, and particularly on a roof, ambient consideratio ns may be taken into account. Inter and After-Coolers Most multi-stage compresso rs use intercoolers, which are heat exchangers that remove the heat of compressi on between the stages of compression. Intercooling affects the overall efficienc y of the machine. As mechanical energy is applied to a gas for compression, the temperature of the gas increases. After-coolers are installed after the final st age of compression to reduce the air temperature. As the air temperature is redu ced, water vapor in the air is condensed, separated, collected, and drained from the system. Most of the condensate from a compressor with intercooling is 10

removed in the intercooler(s), and the remainder in the after-cooler. Almost all industrial systems, except those that supply process air to heat-indifferent op erations, require after-cooling. In some systems, after-coolers are an integral part of the compressor package, while in other systems the after-cooler is a sep arate piece of equipment. Some systems have both. Use of water at lower temperat ure reduces specific power consumption. However, very low cooling water temperat ure could result in condensation of moisture in the air, which if not removed wo uld lead to cylinder damage. Pressure Setting For the same capacity, a compresso r consumes more power at higher pressures. Compressors should not be operated ab ove their optimum operating pressures as this not only wastes energy, but also l eads to excessive wear, leading to further energy wastage. The volumetric effici enc y of a compressor is also less at higher delivery pressures CONDENSER &EVAPOURATOR: To turn the basic vapour compression cycle into a practical refrigerator, the ev aporator should superheat the refrigerant after all the liquid has evaporated. I t is not practical to control precisely at the point where evaporation is just f inished. Unless it is complete, some liquid will leave the evaporator, which is useful cooling potential wasted. Moreover, compressors do not generally apprecia te liquid arriving with the vapour. It can cause damage. So control is provided in such a way as to ensure that the vapour leaving the evaporator is superheated . The upper diagram shows the refrigeration circuit, and the lower one is the co rresponding P-h diagram The process starts with evaporation of the refrigerant i n the evaporator. Point 2 is in in the vapour region, to the right of the satura ted vapour curve. Compression raises the pressure of the refrigerant, point 3. T he vapour is now hot, and is cooled before condensation starts. It is not possib le in practice to control exactly the completion of condensation. We want liquid to flow through the line from the condenser to the control or expansion valve. If some vapour is present here, it can cause excessive pressure drop and reducti on in performance of the system. The pressure drop should occur in the valve its elf. Some degree of subcooling is necessary to ensure 100% liquid flow. This sub cooling can occur in the condenser, and further cooling of the liquid can take p lace between the condenser and the valve. Point 4 is now in the liquid region, t o the left of the saturated liquid curve, the pressure is reduced in an expansio n device, and the refrigerant is returned to its original condition 1. Superheat and Subcooling occupy quite small sections of the diagram, but they ar e very important for the effective working of the system. When refrigerant flows from one process to the next it always moves through the pipes as either a supe rheated vapour or a subcooled liquid. The amount of superheat or subcool may be quite small. 11

Connect up, use fans to circulate air over the evaporator (the air will be coole d), and condenser (the air will be heated), switch on the compressor and we have a refrigeration machine. Sounds simple, but careful design and specification of components is needed. The control valve is a key component. Usually termed "Exp ansion Valve" this device regulates the superheat at the outlet of the evaporato r. The temperature sensor at the outlet of the evaporator is connected to the va lve to provide feedback on the adjustment of the valve. Most valves work automat ically by means of a diaphram, and are termed Thermostatic Valves, whilst other types are electronic. The properties of the Refrigerant or Working Fluid are kno wn to a high level of accuracy and by measuring the pressure and temperature at points 1, 2, 3, 4 the P-h diagram can be established. In practice only two press ure measurements 2 and 3 are required. Instrumentation and computer techniques a re now available which allow fast diagnostics of almost any system. BATTERY (Similar to lighting section) 12

POWER SECTION SUBSTATION: Current rail gaps are also provided where the substations feed the line (diagram , left). Normally, each track is fed in each direction towards the next substati on. This allows for some over supply and provides for continuity if one substati on fails. These substation gaps are usually marked by a sign or a light which in dicates if the current is on in the section ahead. A train must stop before ente ring the dead section. Since the current may have been switched off to stop an a rc or because of a short circuit, it is important that the train does not connec t the dead section to the live section by passing over the gap and allowing its busline to bridge the gap. Some of the more sophisticated systems in use today n ow link the traction current status to the signalling so that a train will not b e allowed to proceed onto a dead section. At various points along the line, ther e will be places where trains can be temporarily isolated electrically from the supply system. At such places, like terminal stations, "section switches" are pr ovided. When opened, they prevent part of the line for being fed by the substati on. They are used when it is necessary to isolate a train with an electrical fau lt in its current collection system. VCB: Circuit breakers provide protection for electrical systems from electrical fault conditions such as current overloads, short circuits, and low level voltage con ditions. Circuit breakers are mechanical switching devices capable of making, ca rrying, and breaking currents under normal circuit conditions and also making, c arrying for a specified time, and breaking currents under specified abnormal con ditions. Circuit breakers are useful for controlling and protecting electrical s ystems, apparatus and networks. Electrical power distribution systems and their components need protection from numerous types of malfunctions, including overcu rrent conditions, overvoltage conditions, undervoltage conditions, reverse curre nt flow, and unbalanced phase voltages. Electrical distribution and protection e quipment is an important element in many applications, particularly those employ ing medium to high electrical voltages. The integrity of operability of any powe r distribution system ultimately depends on the proper functioning of the circui t breakers. Circuit breakers are rated by voltage, insulation level, current int errupting capabilities, transient recovery voltage, interruption time, and trip delay. The circuit breaker is divided into an AC circuit 13

breaker and a DC circuit breaker according to an applied line. Typically, circui t breakers include at least one circuit interrupter, which contains a spring-pow ered operating mechanism that opens electrical contacts in response to abnormal conditions in order to interrupt the current passing through the conductors in a n electrical system. The medium in which circuit interruption is performed may b e designated by a suitable prefix, for example, air-blast circuit breaker, gas c ircuit breaker, oil circuit breaker, or vacuum circuit breaker. The vacuum circu it breaker is one of the breakers by which the circuit can be broken rapidly by extinguishing an arc in a vacuum chamber when the circuit is opened/closed and w hen the circuit is broken by a generation of the accident current. Vacuum circui t breakers in particular are useful for controlling and protecting electrical sy stems. Circuit breakers provide protection for electrical systems from electrica l fault conditions such as current overloads, short circuits, and low level volt age conditions. Circuit breakers are mechanical switching devices capable of mak ing, carrying, and breaking currents under normal circuit conditions and also ma king, carrying for a specified time, and breaking currents under specified abnor mal conditions. Circuit breakers are useful for controlling and protecting elect rical systems, apparatus and networks. Electrical power distribution systems and their components need protection from numerous types of malfunctions, including overcurrent conditions, overvoltage conditions, undervoltage conditions, revers e current flow, and unbalanced phase voltages. Electrical distribution and prote ction equipment is an important element in many applications, particularly those employing medium to high electrical voltages. The integrity of operability of a ny power distribution system ultimately depends on the proper functioning of the circuit breakers. Circuit breakers are rated by voltage, insulation level, curr ent interrupting capabilities, transient recovery voltage, interruption time, an d trip delay. The circuit breaker is divided into an AC circuit breaker and a DC circuit breaker according to an applied line. Typically, circuit breakers inclu de at least one circuit interrupter, which contains a spring-powered operating m echanism that opens electrical contacts in response to abnormal conditions in or der to interrupt the current passing through the conductors in an electrical sys tem. The medium in which circuit interruption is performed may be designated by a suitable prefix, for example, air-blast circuit breaker, gas circuit breaker, oil circuit breaker, or vacuum circuit breaker. The vacuum circuit breaker is on e of the breakers by which the circuit can be broken rapidly by extinguishing an arc in a vacuum chamber when the circuit is opened/closed and when the circuit is broken by a generation of the accident current. Vacuum circuit breakers in pa rticular are useful for controlling and protecting electrical systems. RELAYS GROUND RELAY: An electrical relay provided in diesel and electric traction systems to protect the equipment against damage from earths and so-called "grounds". The result of such a relay operating is usually a shut-down of the electrical drive. Also some times called an Earth Fault Relay NO-VOLT RELAY A power circuit relay which detected if power was lost for any reason and made s ure that the control sequence was returned to the starting point before power co uld be re-applied. See Motor Protection. OVERLOAD RELAY A power circuit relay which detected excessive current in the circuit and switch ed off the 14

power to avoid damage to the motors. CONCLUSION: Thus the SOUTHERN RAILWAYS has performed lots and lots of services in transport. This report has highlighted with brief explanations about some of the important sections of the train. 15

Potrebbero piacerti anche

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- EY Offshore Wind in Europe PDFDocumento16 pagineEY Offshore Wind in Europe PDFjobinhoeljovenNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- MCCB Catalogue PDFDocumento84 pagineMCCB Catalogue PDFSudipta ChatterjeeNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- S LV SWG Aux - 00Documento35 pagineS LV SWG Aux - 00afsar.erNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Project Using DVRDocumento68 pagineProject Using DVRKranthiNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Earth Leakage Relays Elrm44v-1-ADocumento1 paginaEarth Leakage Relays Elrm44v-1-Aapi-230026640Nessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Isabela State University: Isui - Eie - Pre - 001 Effectivity: January 1, 2017 Revision: 0Documento2 pagineIsabela State University: Isui - Eie - Pre - 001 Effectivity: January 1, 2017 Revision: 0Christine Joy U. DugayNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Powerguard Heavy DutyDocumento12 paginePowerguard Heavy DutyOdion Usunobun Julius100% (1)

- Icm SPMRDocumento2 pagineIcm SPMRmahmoud4871Nessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- 0152 - Interational Confrence On 1200kV National Test StationDocumento346 pagine0152 - Interational Confrence On 1200kV National Test StationsreejitvpNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- System Data For Website - KERC 400 & 220 KVDocumento28 pagineSystem Data For Website - KERC 400 & 220 KVಶ್ರೀಕಾಂತ್ ತಿಪ್ಪೇರುದ್ರಪ್ಪNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- GeneradorDocumento8 pagineGeneradorNANDORG27Nessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Project Name: Umar+Project: Created With PV Sol Premium 2021 (R4) Valentin Software GMBHDocumento37 pagineProject Name: Umar+Project: Created With PV Sol Premium 2021 (R4) Valentin Software GMBHumar khanNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Electrical TechnologyDocumento8 pagineElectrical TechnologyswarnasugandhNessuna valutazione finora

- User Manual: SUN2000 (8KTL-28KTL)Documento130 pagineUser Manual: SUN2000 (8KTL-28KTL)Smoc DenisNessuna valutazione finora

- ZX0.2 Technical Catalogue PDFDocumento74 pagineZX0.2 Technical Catalogue PDFRadu Nanu100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Chapter 3 Synchronous GeneratorDocumento21 pagineChapter 3 Synchronous Generatorahmad abufaresNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Testing of Distance RelaysDocumento10 pagineTesting of Distance Relayschilamkurti_sivasankararaoNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Socomec Masterys BC & Delphys BCDocumento2 pagineSocomec Masterys BC & Delphys BCsy4nNessuna valutazione finora

- Indian Electricity Rules (1956)Documento14 pagineIndian Electricity Rules (1956)622 MANSI TANJILANessuna valutazione finora

- Energy ConversionDocumento47 pagineEnergy Conversionkass00488_18085260988% (8)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Polim-R..N: Surge ArrestersDocumento2 paginePolim-R..N: Surge Arrestersjosedavid2898980Nessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- 6 RPT 50269 Draft Wind Turbine Specification Report Final 20121127 CDDocumento16 pagine6 RPT 50269 Draft Wind Turbine Specification Report Final 20121127 CDemilioaraNessuna valutazione finora

- 04 Komatsu Cargador WA320 5 P3 PDFDocumento376 pagine04 Komatsu Cargador WA320 5 P3 PDFLuisTocoraNessuna valutazione finora

- Knowledge Sharing Session (KSS) On MEP - 26 February 2020Documento15 pagineKnowledge Sharing Session (KSS) On MEP - 26 February 2020Esham RaihanNessuna valutazione finora

- Interview Questions MS WordDocumento20 pagineInterview Questions MS Wordhassan iftikhar100% (1)

- Over Current Relay Working Principle TypesDocumento3 pagineOver Current Relay Working Principle TypesSaleem Javed0% (1)

- High Voltage Circuit Breakers 3AP Type 72.5 KV To 800 KV: Answers For EnergyDocumento12 pagineHigh Voltage Circuit Breakers 3AP Type 72.5 KV To 800 KV: Answers For EnergyThành DanhNessuna valutazione finora

- Start Sequence of MotorsDocumento4 pagineStart Sequence of MotorsSamuel AdamuNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- 11 JayaramDocumento92 pagine11 JayaramNamiraNessuna valutazione finora

- Nandini Gupta Ngupta@iitk - Ac.inDocumento41 pagineNandini Gupta Ngupta@iitk - Ac.inAditya TiwariNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)