Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ferrotherm 4742

Caricato da

Özlem KarataşDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ferrotherm 4742

Caricato da

Özlem KarataşCopyright:

Formati disponibili

C: Si: Cr: Al:

max. 0,12 0,7 1,4 17,0 19,0 0,70 - 1,20

FERROTHERM 4742

X10CrAlSi18

Ferrotherm 4742

Stainless heat resistant ferritic chromium steel with aluminium addition Relevant current and obsolete standards: EN 10095 : 1.4742 X10CrAlSi18 AISI : 442 BS : JIS : SUH21 AFNOR : Z10CAS18 DIN : 1.4742 SIS : SEW 470 : 1.4742 X10CrAl18 General properties corrosion resistance mechanical properties forgeability weldability machinability : average : average : good : limited : average Typical applications high temperature nozzles and jets high temperature conveyor systems mechanical engineering furnace engineering, grills cement industry - chains

Processing properties automated machining machinable hammer and die forging cold forming cold heading : seldom : seldom : yes : yes : not common

Product forms and conditions wire rod 5,5 - 27 bright wire h9, 4 - 20 solution annealed pickled drawn straightened peeled ground

Special properties - resistant to scaling in air up to 1000C Physical properties - density (kg/dm ) - electrical resistivity 2 at 20C (W mm /m) - magnetisable - thermal conductivity at 20C (W/m K) at 500C (W/m K) - specific heat capacity at 20C (J/kg K) - melting point (C) - thermal expansion (mm/mK) between: 20 and 200C 20 and 400C 20 and 600C 20 and 800C 20 and 1000C

3

: 7,7 : 0,93 : yes : 19 : 25 : 500 : 1420 : 10,5 : 11,5 : 12,0 : 12,5 : 13,5

Demand tendency

Ferrotherm 4742 is a heat resistant, ferritic stainless steel which is characterised by its resistance sulphur bearing gasses. Due to its higher chromium content, Ferrotherm 4742 is more resistant to high temperature oxidation than Ferrotherm 4724, but is less resistant than Ferrotherm 4762, which contains even more chromium.

Revision No. 4742-1 Created: 19.03.2003

Properties, applications and processing

High temperature corrosion resistance Ferrotherm 4742 is highly resistant to oxidising sulphur bearing gases and displays somewhat less, but still good, resistance to sulphur bearing gasses in reducing environments. Ferrotherm 4742 is moderately resistant to carburising gasses, but is not resistant to high temperature nitridng or oxygen denuded gasses. This grade of steel is resistant to scaling in air up to temperatures of 1000C. Heat treatment / mechanical properties Optimal material properties are realised after annealing by holding in the temperature range 800 - 860C , followed by rapid cooling in air or water. In this condition the following mechanical properties can be expected when testing in the longitudinal direction at room temperature:

Property - yield strength (N/mm2) - tensile strength (N/mm2) - tensile elongation (%) - hardness Specification Rp0,2 : 270 Rm : 500 700 : 15 A5 HB : 212 Typical 370 580 18

formed in the temperature range 650 to 800C when large differences in cross-section exist and/or when the components have been extensively cold worked. If an austenitic filler metal is used and the component is destined for use in either a sulphur containing or carburising environment, then the austenitic weld bead must be over-laid with a ferritic weld run to ensure some resistance to the operational environment. Novonit 4820 is suitable for use as a filler material when welding Ferrotherm 4742. Elevated temperature properties Due to the much poorer high temperature mechanical properties of Ferrotherm 4742, compared to the heat resistant austenitic grades, this steel can only be used in applications where the high temperature mechanical requirements are not too great. Forging Forging is usually performed at 1150 - 800C followed by rapid cooling in air or water. Generally, forging is followed by the heat treatment described previously. Machining properties Ferritic stainless steels such as Ferrotherm 4742 tend to smear during machining which results in the formation of longer swarf thereby making machining difficult. When machining this grade of steel with coated hard metal cutting/machining tools, the following machining parameters can be used as a guideline:

tensile strengths Rm in N/mm

2

The high chromium content and fully ferritic microstructure of this steel makes it susceptible to 475 embrittlement when held at temperatures within the range 400 to 550C. Slow heating or cooling through this temperature range should thus be avoided. The effects of 475 embrittlement can be reversed by briefly heating to within the temperature range 700 to 800C. Due to the high chromium content of this steel, it is susceptible to embrittlement by sigma phase formation within the temperature range 600 to 800C. The effects of sigma phase formation may be reversed by heating to above 1050C to take all of the sigma phase into solution again. A slight tendency for grain growth and embrittlement exists at above temperatures of 950C. It must be noted that any properties that are adversely affected by grain coarsening occurs cannot be recovered by simple thermal treatments.

When heat treatment is performed in a continuos furnace, the upper temperature must be aimed for and in some cases can even be exceeded.

Depth of cut (mm) Feed (mm/rev) 6 mm 3 mm 1 mm 0,5 mm/r 0,4 mm/r 0,2 mm/r 130 m/min 150 m/min

solution annealed (550 - 650) 100 m/min

General comments Ferrotherm 4742 is less formable than the austenitic grades and is best formed within the temperature range 600 to 800C, especially when the cross section is greater than 3mm.

Welding Ferrotherm 4742 is weldable using all usual welding processes with preheating to a temperature between 200 and 300C, being recommended. Low heat inputs should be used when welding to reduce any possible grain coarsening. Although post weld heat treatment is not necessary, a stress relief treatment is sometimes perRevision No. 4742-1 Created: 19.03.2003

Potrebbero piacerti anche

- 1.4742 en PDFDocumento2 pagine1.4742 en PDFArielNessuna valutazione finora

- 1.4742 enDocumento2 pagine1.4742 enGoran ErakovicNessuna valutazione finora

- Remanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La CarteDocumento36 pagineRemanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La Cartepipedown456Nessuna valutazione finora

- Ss 1145Documento2 pagineSs 1145wholenumberNessuna valutazione finora

- X17Crni 16-2: C: 0,19 - 0,22 CR: 15,5 - 17,0 Ni: 1,5 - 2,5Documento2 pagineX17Crni 16-2: C: 0,19 - 0,22 CR: 15,5 - 17,0 Ni: 1,5 - 2,5Aadhya engineering ServicesNessuna valutazione finora

- 1 4713 4724 4742 4762Documento4 pagine1 4713 4724 4742 4762Ján KožičkaNessuna valutazione finora

- Nirosta 4104: Krupp EdelstahlprofileDocumento2 pagineNirosta 4104: Krupp EdelstahlprofileLuis MayorgaNessuna valutazione finora

- Sirius 314: A 25% CR - 1.8 % Si Heat Resistant Stainless SteelDocumento4 pagineSirius 314: A 25% CR - 1.8 % Si Heat Resistant Stainless SteelVíctor SandovskyNessuna valutazione finora

- 1.4006 en PDFDocumento2 pagine1.4006 en PDFdiego.peinado8856Nessuna valutazione finora

- 410 Spec SheetDocumento2 pagine410 Spec SheetGumersindo MelambesNessuna valutazione finora

- 17 4PH Spec SheetDocumento2 pagine17 4PH Spec Sheettrong tan dongNessuna valutazione finora

- Interlloy 440C MartensiticDocumento4 pagineInterlloy 440C MartensiticGuillaume BoyerNessuna valutazione finora

- Stainless Steel A564 PropDocumento4 pagineStainless Steel A564 PropArut MVNessuna valutazione finora

- 174 PHDocumento2 pagine174 PHSuriyachai NiamsornNessuna valutazione finora

- Alloy Steels 8620: Chemistry DataDocumento6 pagineAlloy Steels 8620: Chemistry DataVijay PalNessuna valutazione finora

- Aalco Metals LTD Stainless Steel 1.4542 17 4 PH 100Documento4 pagineAalco Metals LTD Stainless Steel 1.4542 17 4 PH 100Sergio CLNessuna valutazione finora

- Summary Note For CSWIP 3.1Documento9 pagineSummary Note For CSWIP 3.1Muhamad ShakyreenNessuna valutazione finora

- Anexo VII PDFDocumento1 paginaAnexo VII PDFIvo CostaNessuna valutazione finora

- 25CR20NIDocumento2 pagine25CR20NIShariq KhanNessuna valutazione finora

- Datenblatt 4105 UKDocumento2 pagineDatenblatt 4105 UKVahid SarfarazNessuna valutazione finora

- Age HardeningDocumento5 pagineAge Hardeninganum_nNessuna valutazione finora

- Recom. de Soldadura XARDocumento4 pagineRecom. de Soldadura XARelias667Nessuna valutazione finora

- Spring SteelDocumento2 pagineSpring Steelvaishu1502Nessuna valutazione finora

- X5CrNiCuNb 16-41.4542Documento2 pagineX5CrNiCuNb 16-41.4542nuesteNessuna valutazione finora

- Acero MadridDocumento46 pagineAcero MadridviyfNessuna valutazione finora

- 17 4phDocumento3 pagine17 4phrush_oceanNessuna valutazione finora

- Chemical CompositionDocumento6 pagineChemical CompositionAkbar DarmawansyahNessuna valutazione finora

- Alloy 330 Spec SheetDocumento2 pagineAlloy 330 Spec SheetAA.KarandishNessuna valutazione finora

- Low Alloy Steels For Cryogenic ApplicationsDocumento0 pagineLow Alloy Steels For Cryogenic ApplicationsidienNessuna valutazione finora

- AISI 4130 Alloy SteelDocumento2 pagineAISI 4130 Alloy SteelKandeepanNessuna valutazione finora

- AISI 4130 Alloy SteelDocumento2 pagineAISI 4130 Alloy SteelSantosh IngaleNessuna valutazione finora

- Materials For High Temperature High Pressure Applications andDocumento28 pagineMaterials For High Temperature High Pressure Applications andDrVRKNessuna valutazione finora

- Dillimax 690 eDocumento4 pagineDillimax 690 ePrabhakar TiwariNessuna valutazione finora

- 476 Data SheetDocumento1 pagina476 Data SheetinvidiuoNessuna valutazione finora

- Hoja de Especificaciones Del Acero T-410Documento2 pagineHoja de Especificaciones Del Acero T-410cristobal_tl2277Nessuna valutazione finora

- HT ManualDocumento17 pagineHT ManualAkhilesh KumarNessuna valutazione finora

- Fiche z38cdv5Documento1 paginaFiche z38cdv5Emmanuel LAIZETNessuna valutazione finora

- Aerospace Standard Materials - Mechanical Properties - Issue 12 - 2015Documento6 pagineAerospace Standard Materials - Mechanical Properties - Issue 12 - 2015Leandro González De CeccoNessuna valutazione finora

- EN26Documento3 pagineEN26Moldoveanu TeodorNessuna valutazione finora

- SS 1.4122Documento2 pagineSS 1.4122Bipin Sadasivan100% (2)

- D2 Tool Steel: Shipping PolicyDocumento2 pagineD2 Tool Steel: Shipping Policyالسيد ابراهيم عبدالعزيز عبداللهNessuna valutazione finora

- Amie Material Science NotesDocumento276 pagineAmie Material Science NotesRajendra Kumar Yadav100% (2)

- Steels For Cryogenic and Low-Temperature Service - KEY To METALS ArticleDocumento3 pagineSteels For Cryogenic and Low-Temperature Service - KEY To METALS Articlekumarpankaj030Nessuna valutazione finora

- Detail-Material Science NotesDocumento276 pagineDetail-Material Science Notessureshbabu7374Nessuna valutazione finora

- Duplex Stainless Steel 329 or 1.4460 PDFDocumento2 pagineDuplex Stainless Steel 329 or 1.4460 PDFtien100% (1)

- 422 Steel DatasheetDocumento2 pagine422 Steel DatasheetKashif MohiuddinNessuna valutazione finora

- Gas NitridingDocumento4 pagineGas NitridingPaul Joseph MonsaludNessuna valutazione finora

- Cryogenic MaterialsDocumento7 pagineCryogenic Materialsstudent1Nessuna valutazione finora

- Chemical Formula Topics Covered: Table 1. Composition Ranges For 410 Grade Stainless SteelDocumento4 pagineChemical Formula Topics Covered: Table 1. Composition Ranges For 410 Grade Stainless Steelaryanscrews2329Nessuna valutazione finora

- Material at Low TemperatureDocumento3 pagineMaterial at Low TemperatureGajendra GuptaNessuna valutazione finora

- AISI 440 Martensit PDFDocumento4 pagineAISI 440 Martensit PDFJimmyVargasNessuna valutazione finora

- High Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®Documento2 pagineHigh Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®ivanoliveira3261Nessuna valutazione finora

- Fti Vhssm50 InglesDocumento2 pagineFti Vhssm50 InglesAntonio Melgaço da SilvaNessuna valutazione finora

- LM4 Alloy DetailDocumento5 pagineLM4 Alloy Detailcharles_boyle_3Nessuna valutazione finora

- 904L (Valbruna)Documento2 pagine904L (Valbruna)Claudia MmsNessuna valutazione finora

- 1 4122Documento1 pagina1 4122Zeeshan AnwarNessuna valutazione finora

- 431 Stainless SteelDocumento2 pagine431 Stainless Steeldeden ibnuNessuna valutazione finora

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- Pub 115 Al Bronze Vs Stainless Steel PDFDocumento22 paginePub 115 Al Bronze Vs Stainless Steel PDFÖzlem KarataşNessuna valutazione finora

- STR 2013 2 10 12 KraenzlerDocumento3 pagineSTR 2013 2 10 12 KraenzlerÖzlem KarataşNessuna valutazione finora

- Duplex Stainless SteelDocumento2 pagineDuplex Stainless SteelÖzlem KarataşNessuna valutazione finora

- Outokumpu Duplex Stainless Steel Data SheetDocumento12 pagineOutokumpu Duplex Stainless Steel Data SheetbayumahardikaNessuna valutazione finora

- E 930 - 99 Test Methods For Estimating The Largest Grain Observed in A Metallographic Section (ALA Grain Size)Documento7 pagineE 930 - 99 Test Methods For Estimating The Largest Grain Observed in A Metallographic Section (ALA Grain Size)Özlem KarataşNessuna valutazione finora

- Red RiverDocumento16 pagineRed RiverNael100% (1)

- Handout Jacobs CSS - EUROCLAUS ProcessDocumento1 paginaHandout Jacobs CSS - EUROCLAUS ProcessZahra GhNessuna valutazione finora

- Songsorb CS 326 TDSDocumento2 pagineSongsorb CS 326 TDSdipen royNessuna valutazione finora

- Welding-Of-Metals-PPT Amar BhargavDocumento23 pagineWelding-Of-Metals-PPT Amar BhargavSagar BhargavNessuna valutazione finora

- Classification of Zinc Die Casting Defects V4-2022Documento4 pagineClassification of Zinc Die Casting Defects V4-2022tekno foniNessuna valutazione finora

- Welding Notes: Bill of Materials For Assembly MK'D: Ama3-9: Assy Qty: 16Documento1 paginaWelding Notes: Bill of Materials For Assembly MK'D: Ama3-9: Assy Qty: 16Seena NaikNessuna valutazione finora

- Unitor Maintenance and Repair Welding: The Solutions GuideDocumento1 paginaUnitor Maintenance and Repair Welding: The Solutions GuideNuzhat Ali100% (1)

- Feed Water Heater ManualDocumento16 pagineFeed Water Heater Manualfelix asadeNessuna valutazione finora

- 117BP - CNC Technologies PDFDocumento8 pagine117BP - CNC Technologies PDFvenkiscribd444Nessuna valutazione finora

- Arc-Welding-Report-PUO COMPELETEDDocumento13 pagineArc-Welding-Report-PUO COMPELETEDLenrd RajNessuna valutazione finora

- ATF - WelderTestPackage - v2 Welder and Welding Operator Perfomance Qualification RecordDocumento5 pagineATF - WelderTestPackage - v2 Welder and Welding Operator Perfomance Qualification Recordfallalovaldes61Nessuna valutazione finora

- Casting notes-EME-1Documento23 pagineCasting notes-EME-1AndrewNessuna valutazione finora

- CT22-Hot Finished LCHS 10-05-05Documento16 pagineCT22-Hot Finished LCHS 10-05-05Miguel Teixeira CouteiroNessuna valutazione finora

- Intercryl 520Documento4 pagineIntercryl 520Doby YuniardiNessuna valutazione finora

- CHEM 212 - RecrystallizationDocumento16 pagineCHEM 212 - RecrystallizationkristaNessuna valutazione finora

- RM 2000 Technical DataDocumento2 pagineRM 2000 Technical Datathrashmetalhead0% (1)

- Dulux Promise Smartchoice Exterior PdsDocumento3 pagineDulux Promise Smartchoice Exterior PdsJohn AbhishekNessuna valutazione finora

- PROCEDURE Piping ChevronDocumento44 paginePROCEDURE Piping Chevrongst ajah100% (3)

- EPIGEN 1311 HB Epoxy CoatingDocumento2 pagineEPIGEN 1311 HB Epoxy CoatingtirtharchuNessuna valutazione finora

- Glossary of Corrosion & Metallurgy Terminology: J W MartinDocumento7 pagineGlossary of Corrosion & Metallurgy Terminology: J W MartinSlim.BNessuna valutazione finora

- Specification Tuyauterie q3622011 02 220 Pe SPC 00001 - BDocumento96 pagineSpecification Tuyauterie q3622011 02 220 Pe SPC 00001 - BLAKHTIRINessuna valutazione finora

- Asme B31.4 (1998)Documento1 paginaAsme B31.4 (1998)Anonymous bIe9JSMphsNessuna valutazione finora

- Pds Hempadur 15570 En-GbDocumento3 paginePds Hempadur 15570 En-GbdcsamaraweeraNessuna valutazione finora

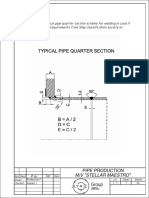

- Pipe Production DRWDocumento44 paginePipe Production DRWФилипп Бродарский100% (1)

- Compressed Air SystemDocumento39 pagineCompressed Air Systemchavali.irctcNessuna valutazione finora

- Lab ReportDocumento16 pagineLab ReportFgj Jhg100% (1)

- Relief and Blowdown Report: Page 1 of 21Documento21 pagineRelief and Blowdown Report: Page 1 of 21TarekNessuna valutazione finora

- Handheld Fiber Laser Welding Machine - DetailsDocumento18 pagineHandheld Fiber Laser Welding Machine - DetailsRasool SabeghiNessuna valutazione finora

- Guide For The Preparation and Bend Testing of Welder and Welding Procedure Qualification Test SpecimensDocumento2 pagineGuide For The Preparation and Bend Testing of Welder and Welding Procedure Qualification Test Specimensmadhu_raz6834Nessuna valutazione finora

- TIVAR88 FasteningDocumento2 pagineTIVAR88 FasteningPieter van der WaltNessuna valutazione finora