Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Spec 0120 Ohe

Caricato da

scribd14341Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Spec 0120 Ohe

Caricato da

scribd14341Copyright:

Formati disponibili

Page 1 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

GOVERNMENT OF INDIA MINISTRY OF RAILWAYS RESEARCH DESIGNS AND STANDARDS ORGANISATION MANAK NAGAR, LUCKNOW-226011 Specification for Steel, Stainless Steel Bolts, Nuts and Washers for 25 kV a.c. Traction Overhead Equipment 1. 1.1 SCOPE This specification covers the requirements of steel and stainless steel special head / hexagon straight bolts and screws, flat countersunk nib bolts and screw, U-bolts, Jbolts, hexagon nuts and lock nuts and plain and spring washers used on 25 kV a.c. traction overhead equipment. The term fasteners shall include bolts, nuts, and washer. The term nut shall include lock nuts. The term bolt shall include screws, special head bolts/screws. This specification supersedes RDSO Specification No. ETI/OHE/18(4/84) with A&C Slip No. 1 to 5. GOVERNING SPECIFICATIONS: The fasteners shall generally conform to the respective Indian Standards unless specified otherwise herein. The provisions of the governing specifications shall be applied in the manner altered/amended or supplemented by this specification. In preparation of this specification reference has been made to the following specifications. i) IS: 1363-2002 Black hexagon bolts nuts and lock nuts (Dia 6 to 39) & black hexagon screws (Dia 6 to 24 mm). IS: 1367 (Pt.2, 3, 5, 6, 7, 9, Technical supply conditions for threaded 10, 13, 18). Steel fasteners BS: 6105-1981 Corrosion resistant stainless steel fasteners IS: 1570 (Pt. 5) 1985 Schedule for wrought steels (Stainless & heat resisting steels) BS: 970: Pt.4 1970 Wrought steels (Stainless, heat resisting and valve steels). IS: 2016- 1967 Plain washers IS: 3063 1994 Spring washer for bolts, nuts & screws. BS: 2061 1953 Phosphor bronze spring washer for General engineering purposes. IS: 549 1974 Split pines.

1.2

2. 2.1

2.2

ii) iii) iv) v) vi) vii) viii) ix)

Page 2 of 26

Effective from May, 2012 IS: 9549 1980 IS: 9519 2005 IS: 8353 1977 IS: 730 1978 IS: 1368 1987 IS: 4172 1987 IS: 5369 1975 IS: 4206 1987

Specification No. TI/SPC/OHE/ FASTNERS/0120

x) xi) xii) xiii) xiv) xv) xvi) xvii) xviii) xix) xx) xxi) xxii) xxiii)

IS: 4213 I, II, III, IV, V IS: 2334 2001 IS: 1369 1995 IS: 2614 1969 IS: 2629 1985 IS: 4211 1993 IS: 6745 1972 IS: 2633 1986

xxiv)

xxv)

xxvi) IS: 9141 1979 xxvii) IS: 3203 - 1982

Dimension for split pin holes, wire holes and head slots for bolts. Dimensions for width across flats for hexagon head bolts & nuts. Flat countersunk nib bolts. Hook bolts for corrugated sheet roofing. Dimensions for ends of bolts and screws. Dimension for radii under the head of bolts and screws. General requirements for plain washers and lock washers. Dimensions for nominal lengths and thread lengths for bolts screws and studs. ISO metric screws threads. Gauging practice for ISO metric screw threads. Dimensions for screw thread run out sand undercuts. Methods for sampling of fasteners Recommended practice for hot dip galvanizing of iron and steel. Thread pitch gauges for ISO metric screws threads ( Pitch range 0.25 to 6.0 mm ). Methods for determination of mass of zinc coating on zinc coated iron & steel articles. Method for testing uniformity of coating on zinc coated articles. Code of practice for packing of fasteners Methods of testing local thickness of electroplated coatings.

3. 3.1

DEVIATION FROM SPECIFICATION: Any deviation from this specification calculated to improve the performance, efficiency and utility of fasteners proposed by the tenderer will be given due consideration provided full particulars with justification thereof are furnished. SERVICE CONDITIONS: The fasteners are used in conjunction with various fittings/components of traction overhead equipment including those carrying current.

4. 4.1

Page 3 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

4.2

Weather conditions : The weather conditions under which the fasteners are used vary widely. The limiting conditions which have to be withstood in service are indicated below : ---Max. temperature of air in shade Min. temperature of air in shade Max. temperature attainable by an object exposed to sun. Max. relative humidity Average annual rainfall Average number of dust Storm days per annum Number of thunder storm days per annum. No. of rainy days per annum Maximum wind pressure Altitude 45 C 0 C 65.5 C

----

100% 1750 to 6250 mm 35 days. Max.

--

35 days Max.

--4.3

120 days Max. 200 Kg/Sq. meter. Not exceeding 1000 m.

The fasteners are also subjected to chemical pollution from the effluent gases of chemical plants, exhaust of steam/diesel locomotives and to saline atmosphere in coastal areas. MATERIAL Ferrous fasteners : Steel bolts/screws/nuts shall conform to Grade-C specification in IS: 1367 (Part 2) 2002. Bolts/Screws shall comply with mechanical property class 4.6 of IS: 1367 (part 3) 2002. Nuts shall comply with the mechanical shall comply with mechanical property class 4.6 of IS:1367(Part 3) -2002. Nuts all comply with the mechanical property class 04, 4 or 5 (as applicable) of IS:1367 (Part 6) 1994. Stainless steel fasteners : The stainless steel bolts and nuts shall conform to property Class 50 (austenitic group) of BS:6105-1981. The stainless steel of bolts, nuts and washers shall conform to Grade A1 (austenitic group) of BS: 6105-1981 with 10% Ni and 0.5-0.6% Mo or grade 316 S 16 of BS: 970: (Part 4)-1970. These grades are equivalent to AISI grades 302 (with 10% Ni and 0.5-0.6% molybdenum) and 316 respectively.

5. 5.1

5.2

Page 4 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

5.3

Plain washers: Plain washers shall conform to IS: 2016 1967. Galvanized steel plain washers (Punched, type A) shall be used with galvanized steel bolts; and bronze, stainless steel or copper washers (punched type A) with stainless steel bolts. Spring washers: The spring washers shall conform to IS: 3063 1994. Galvanized steel spring washers with flat ends (type B) shall be used with galvanized steel bolts. Phosphor bronze spring washers conforming to BS: 2061 1953 shall be used with stainless steel bolts. GENERAL REQUIREMENTS : Workmanship: The bolts and nuts shall be clearly finished, sound & free from defects which may effect their serviceability, and shall be consistent with the grade prescribed. The fasteners shall have full surfaces and edges in keeping with the method of manufacturing used. These shall be free from burrs although barely perceptible thin burrs which results for example, from slotting and trimming operations, may be left out. The Black Grade bolts may have reasonable die seem on the shank; but in no case the shank diameter with such seams shall exceed the maximum permissible diameter. Stainless steel fasteners shall have bright finish. The washers shall be free from cracks, burrs, pits and other defects. The holes of plain washers shall be reasonably concentric with the outer periphery. All sharp edges shall be removed. Spring washers shall be supplied in natural finish. The surfaces of washers shall be free from die marks and shall be finished smooth. The ends shall be so severed as to prevent tangling. Bolts end nuts shall be classified by their nominal diameter. The dimensions of hexagons, chamfers, shank diameter and other dimensions for different nominal sizes of bolts and nuts, whether ferrous or stainless steel shall be in accordance with Table 1. Unless otherwise shown in the purchasers drawings, the nuts shall have single chamfer, and lock nuts shall have double chamfer. Bolts shall be drilled for split pins wherever shown in the purchasers drawings. Split pin holes shall be at right angles to the axis of bolts. The dimensions for split pin holes for a particular size of split pin shall be according to IS: 549 1974. The tolerance in the location of split pin holes shall be according to IS: 9549 1980.

5.4

6. 6.1

6.2

6.3

6.4

6.4.1

Page 5 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

7. 7.1

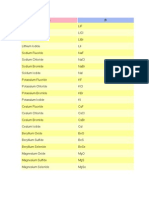

DIMENSIONS: The dimensions for hexagon bolts, screw and nuts shall be in accordance with Table 1 read in conjunction with the relevant purchasers drawings and IS:9519 2005 Specification for modified dimensions of width across flats for hexagonal bolts / screws and nuts normal series. The dimensions for special head bolts and screws, Ubolts, J-bolts shall be as shown in the purchasers drawings. Dimensions of flat countersunk nib bolts/screws shall conform to IS: 8353 1977 and those of J bolts shall conform to IS:730 1978. Dimensions of ends of bolts and screws shall be as per IS: 1363 2002 and the dimensions for radii under the head of bolts and screws shall be as per IS: 4172 1987. The cone point/ turncated cone point ends of bolts and screws shall be as shown in purchasers drawings. Dimensions of plain and spring washers shall be as shown in IS:2016 -1967 and IS: 3063-1994 respectively. The permissible deviations from dimensions of plain washers shall be in accordance with table 3 and 4 of IS: 5369 -1975. The dimensional tolerances for galvanized steel and stainless steel bolts, screws and nuts shall be as per Table 1. LENGTHS AND THREADED LENGTHS: The lengths and threaded lengths of bolts / screws shall be generally as per IS: 4206 1987. However, exact lengths and threaded lengths shall be as shown in purchasers drawings. THREADS (INTERNAL AND EXTERNAL) The threads shall be ISO metric. The internal and external thread profile shall be in accordance with IS : 4213 (Part I) 1976.

7.2

7.3

7.4

7.5

7.6

8. 8.1

9. 9.1

Page 6 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

Page 7 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

Page 8 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

Page 9 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

9.2

The diameter and pitch and combination shall be according to IS: 4213(Part II)1976. The pitch shall be coarse. The basic dimensions for profiles of ISO metric screw threads shall be as per IS: 4213 (Part III) 1976. The tolerance class for ISO metric screws threads shall be coarse as given in table 5 of IS:4213(Part IV)-1976. The deviations from basic dimensions for nut and bolt threads of the tolerance class specified in clause 9.4 shall be as tabulated in table 1. The tolerance class shall be 7H for nuts and 8g for bolt threads. The limits of sizes for tolerance class 7H for nut threads and 8g for bolt threads are given in table-1. These limits are applicable to ferrous fasteners in black condition and to stainless steel fasteners in finished condition. The thread run outs and undercuts shall be as per IS: 1369-1995. GALVANIZING OF FERROUS FASTNERS:: Dimensions:

9.3

9.4

9.5

9.6 10. 10.1

10.1.1 Fasteners with internal Threads Prior to galvanizing and subsequent tapping the dimensions of fasteners with internal threads shall conform to the relevant standards. Internal threads shall be tapped over-size after galvanizing and they shall be oiled for corrosion protection. 10.1.1.1 The oversize tapping allowance shall be as given in Table below. These allowances are applicable to major, pitch and minor diameters, the amended diameters being subject to the same manufacturing tolerances of the appropriate grade of threads stated in the relevant fastener standard. TABLE: ALLOWANCES FOR INTERNAL THREADS TO ACCOMMODATE GALVANIZED EXTERNAL THREADS. Diametral Allowances mm +0.40 +0.50 +0.65

Nominal Size Internal Threads. Below M16 M16 to M22 Over M22 and up to and including M36 10.1.2

Fasteners with External Threads Prior to galvanizing, the dimensions of fasteners with external threads shall conform to the relevant standards including thread sizes.

Page 10 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

10.1.2.1 The thickness of galvanized coating on external threads shall be so controlled in the galvanizing process that galvanized fasteners with external threads can be assembled by hand with internally threaded fasteners complying with 10.1.1. 10.1.2.2 Galvanized external threads shall not be re-cut. 10.1.3 Coating Requirements:

10.1.3.1 Mass of Coating - The mass of coating per square meter of the surface shall comply with the minimum average and minimum individual sample coating given in Table below. The mass of coating shall be determined by one the following methods: a) The stripping test described in Append-ix B; or b) Magnetic or electronic thickness measuring devices as covered in IS: 3203-1965 Method of testing local thickness of electroplated coatings. The mass of coating in g/m2 is found by multiplying the thickness in Micrometers by 7.0. 10.1.3.2 In case of dispute, the stripping test shall be the referee test. TABLE: MASS AND EQUZAVALANT THICKNESS OF COATING Minimum Average Mass Thickness g/m2 m 375 54 Minimum Individual Mass Thickness g/m2 m 300 43

10.1.4 Uniformity of Coating The uniformity of zinc coating shall be such that the coating shall withstand the copper sulphate test as given in IS : 2633- 1986. Methods of testing uniformity of coating on zinc coated articles (first revisions ) without showing any adherent red deposit of metallic copper upon the base metal with the following exceptions. a) A fine line of copper on the crest of the screw threads or on sharp edges of bolt/nut or at or adjacent to any cut of abrasion present in the original fastener shall not be considered a defect to cause rejection, and Any deposit of metallic copper with threads of fasteners which have been rethread rolled after galvanizing, is allowable.

b)

10.1.5

Adhesion of Coating - The coating shall withstand the knife test as covered in IS: 2629-1985.

Page 11 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

10.2

All ferrous fasteners including washers shall be hot dip galvanized for electrogalvanised to achieve a uniform adherent coating of zinc. The minimum thickness of zinc coating shall be of 400 g/m2 (55 microns). TESTS The manufacturers shall carry out the specified tests, during production on the samples, taken at regular intervals, separately for the different sizes, grade & material, which are being manufactured under similar processes of productions to ensure conformity to relevant specifications as also to maintain proper control over the process of manufacture. The manufacturer shall at the time of inspection, produce a certificate showing the records of various inspections / tests which have been exercised during manufacture. When the purchaser requires additional tests, related to his order but not specified hereunder, such tests shall be subject of agreement between the purchaser and the manufacturer. All the tests on the fasteners shall be carried out at manufacturers works. The manufacturer shall arrange, without making claim or charge, all the necessary machinery, apparatus, labour, assistance etc. required to get the prescribed tests conducted in the presence of purchasers representative. Type tests : i) ii) iii) iv) v) Visual examination ( 12.1) Measurement of dimensions (12.2) Gauging of threads ( 12.3) Chemical composition (12.4) Mechanical tests (12.5) a) Tensile test (12.5.1) b) Elongation after fracture (12.5.2) c) Hardness test (12.6) d) Proof load test (12.7) (for ferrous bolts and nuts and stainless steel nuts). e) 0.2% permanent strain test (12.8) (For S.S. bolts only) f) Head soundness test ( 12.9) g) Crushing test on nuts (12.10) (SS nuts only) h) Bend test on straight bolts (12.11) (SS bolts only). i) Torsion test on bolts & nuts (12.12) (for SS bolts & nuts only)

11. 11.1

11.2

11.3

11.4

Page 12 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

vi) vii)

Galvanizing test on ferrous fasteners (12.13) Inter-crystalline corrosion bend test (12.14) for SS fasteners, or Micro examination of SS fasteners (12.15) Permanent set test on spring washers (12.16) Twist test on spring washers (12.17)

viii) ix) 11.5

Routine tests Visual examination (12.1)

11.6

Acceptance tests i) ii) iii) iv) Visual examination ( 12.1) Measurement of dimensions (12.2) Gauging of threads (12.3) Chemical composition (12.4) ( only for stainless steel fasteners) Mechanical tests (12.5) a) Tensile test (12.5.1) b) Percentage elongation after fracture (12.5.2) c) Hardness test (12.6) d) Proof load test (12.7) (for ferrous bolts & nuts and for stainless steel nuts). e) Stress at 0.2% permanent strain test (12.8) f) Head soundness test for bolts (12.9) g) Crushing test on nuts (12.10) (SS nuts only) h) Bend test on straight bolts (12.11) ( SS bolt only) i) Torsion test on bolts & nuts (12.12) (for SS bolts & nuts only) Galvanizing test on ferrous fasteners (12.13) Inter-crystalline corrosion bend test on (12.14) stainless steel fastners. Or Micro examination of stainless steel (12.15) Fasteners. Permanent set test on spring washers (12.16) Twist test on spring washers(12.17)

v)

vi) vii)

viii) ix)

Page 13 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

11.6.1 Sampling procedure : 11.6.1.1 Lot : All the fasteners in a consignment belonging to the same size, grade , material and manufactured under similar process of production and submitted for inspection at one instance shall constitute a lot. 11.6.2 Scale of sampling : 11.6.2.1 Samples shall be selected at random and examined for each lot separately for ascertaining their conformity to the requirements of this specification. Only one set of samples as indicated in 11.6.2.2 shall be drawn from a lot for all the characteristics.

Page 14 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

TABLE 2 SCALE OF SAMPLING AND CRITERIA FOR CONFO RMITY FOR INSPECTION ( Clause 11.6.1, 11.6.2, 11.6.3 )

Lot size VISUAL CHARACTERISTICS

Sample Sample size Cumulative size A C Re

DUDS

Ac Re

DIMENSIONAL CHARACTERISTICS

Sample Sam ple size Cumul ative size BLACK FASTNERS Ac Re | Ac Re 2.5 | 4.0

12 13 14 15

STAINLESS STEEL FASTERNERS

Major defect Ac | Re 1.5 Major defect Ac | Re 2.5

18 19

10

11

16

17

First Upto 100 1013 00 3015 00 5011 000 1001 3000 3001 10000 10001 3500 0 Over 35000 Second First Second First Second First Second First Second First Second First Second First Second

20 20 32 32 50 50 80 80 125 125 200 200 315 315 500 500

20 40 32 64 50 100 80 160 125 250 200 400 315 630 500 1000

1 4 2 6 3 8 5 12 7 18 11 26 11 26 11 26

4 5 5 7 7 9 9 13 11 19 16 27 16 27 16 27

0 1 0 1 0 1 0 3 1 4 2 6 3 8 5 12

2 2 2 2 2 2 3 4 4 5 5 7 7 9 9 13

First Second First Second First Second First Second First Second First Second First Second First Second

8 8 13 13 20 20 32 32 50 50 80 80 125 125 200 200

8 16 13 26 20 40 32 64 50 100 80 160 125 250 200 400

0 1 0 1 0 3 1 4 2 6 3 8 5 12 7 18

2 2 2 2 3 4 4 5 5 7 7 9 9 13 11 19

0 1 0 3 1 4 2 6 3 8 5 12 7 18 11 26

2 2 3 4 4 5 5 7 7 9 9 13 11 19 16 27

0 1 0 1 0 1 0 3 1 4 2 6 3 8 5 12

2 2 2 2 2 2 3 4 4 5 5 7 7 9 9 13

0 1 0 1 0 3 1 4 2 6 3 8 5 12 7 18

2 2 2 2 3 4 4 5 5 7 7 9 9 13 11 19

Note:- Classification of major and minor defect is given in Appendix A of IS: 2614 1969. [ LEGEND + AQL= Acceptable quality Level ]

Page 15 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

11.6.2.2

Samples shall be drawn from each lot in accordance with Cols. 1, 2,3 of table 2 for visual and dimensional verifications and for inspection of physical and other properties. Criteria for conformity Visual characteristics : All the fasteners drawn in accordance with clause 11.6.2.2 shall be first examined for visual characteristics like type, finish, workmanship, duds, visual surface discontinuities and identification mark. To ascertain the conformity of the lot to the requirements of all visual characteristics, except duds, the procedure given in 11.6.3.1.1 shall be followed. For duds, procedure given in 11.6.3.1.2 shall be followed. Visual characteristics ( other then duds) : If in the first sample the number of defective fasteners with respect to all visual characteristics, except duds, is less than or equal to the corresponding acceptance number ( Ac) given in Col.5 of table 2 the lot shall be declared as conforming to the requirements for these characteristics. If the number of defectives is greater then or equal to the corresponding rejection number (Re) given in Col.6 of table 2 the lot shall be deemed as not meeting the requirements for these characteristics. If the number of defectives is greater than the acceptance number but less than the rejection number a second sample of the same x number of fasteners selected as the first sample shall be taken to determine the conformity or otherwise of the lot. The number of defectives found in the first and second sample shall be combined and if the combined number of defectives is less than or equal to the corresponding acceptance number the lot shall be declared as conforming to the requirements; otherwise not. Duds : If the number of defective fasteners in respect of duds is less than or equal to the corresponding acceptance number given in col.7 of table 2, the lot shall be declared as conforming to the requirements for duds. If the number of defective fasteners is greater than or equal to the rejection number given in col.8 of table 2, the lot shall be declared as not conforming to the requirements for duds. If the number of defective fasteners is greater than the acceptance number but less than the rejection number, a second sample of the same number of fasteners selected as the first sample shall be taken to determine the conformity or otherwise of the lot. The number of defective fasteners found in the first and second samples shall be combined and if the combined number of defective fasteners is less than or equal to the corresponding acceptance number, the lot shall be declared as conforming to the requirements for duds, otherwise not.

11.6.3 11.6.3.1

11.6.3.1.1

11.6.3.1.2

Page 16 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

11.6.3.2

Dimensional characteristics : The lot which has been found satisfactory in respect of visual characteristics ( See 11.6.3.1 ) shall be tested for dimensional characteristics like diameter, length etc. except pitch, basic dimensions of threads which will be tested as per clause 12.3 after stripping / case of ferrous fasteners. The fasteners for this purpose shall be taken at random in accordance with col.9 and 10 of table 2, from those already drawn for inspection of visual characteristics ( see 11.6.3.1) and tested for dimensional characteristics. If the number of fasteners failing to satisfy the requirements for these characteristics is less than or equal to the corresponding acceptance number given in col. 12,14,16 or 18 of table 2, the lot shall be declared as to have not the requirements of the specification in respect of these characteristics. If the number of defectives is greater than or equal to the corresponding rejection numbers given in col. 13,15,17 or 19 of table 2 the lot shall be deemed as not confirming to these characteristics. In case the number of defective lies in between the acceptance and rejection number, a second sample of the same size shall be taken and inspected for dimensional characteristics and inference drawn accordingly. Physical chemical & galvanising requirements : From the samples taken in accordance with 11.6.2.2 end which have been subjected to the visual and dimensional tests, samples in multiples of 5 or 6, as the case may be shall be drawn at random for mechanical, chemical and galvanizing tests in case of bolts and nuts. In case of spring washers, samples in multiples of 4 shall be selected for twist test and permanent set test. Galvanized fasteners : i) BOLTS : - The samples selected in accordance with clause 11.6.3.3.1 shall be divided in 6 equal parts. Each part shall be subjected to one of the following tests: a) Tensile / elongation test ( Cl.12.5.1 and 12.5.2 ) b) Proof load test (Cl.12.7) c) Head soundness test ( Cl. 12.9) d) Hardness test ( Cl.12.6) e) Galvanizing test ( Cl.12.13) f) Gauging of threads ( Cl. 12.3) and visual examination after stripping ( 12.1)

11.6.3.3 11.6.3.3.1

11.6.3.3.2

ii) NUTS : - The samples selected in accordance with clause 11.6.3.3.1 shall be divided into 4 equal parts. Each part shall be subjected to one of the following tests. a) Proof load test ( 12.7) b) Hardness test (12.6) c) Gauging of threads (12.3) d) Galvanizing test and visual examination. after stripping ( 12.13 & 12.1 )

Page 17 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

11.6.3.3.3 Stainless steel fasteners : (i) BOLTS : - The samples selected in accordance with clause 11.6.3.3.1 shall be divided in 6 equal parts. Each part shall be subjected to the following tests: a) b) c) d) e) f) Tensile strength / Extension ( 12.5.1 & 12.5.2) Stress at 0.2% permanent strain ( 12.8) Head soundness test (12.9) Bend test (12.11) Gauging of threads end Torsion test ( 12.3 & 12.12) Micro examination, hardness & Chem. Composition ( 12.15, 12.6 & 12.4 )

ii) NUTS : - The samples selected in accordance with clause 11.6.3.3.1 shall be divided into 4 equal parts. Each part shall be subjected to following tests. a) Proof load test ( 12.7) b) Gauging of threads and Crushing test ( 12.3 and 12.10) c) Micro examination ( 12.15 ) d) Chemical composition (12.4) e) Hardness test (12.6) 11.6.3.3.4 Should more than one sample fail in any test(s), the lot shall be rejected. If only one sample fails in any test, twice the number of samples shall be drawn and the test, twice the number of samples shall be repeated. The lot shall be accepted if there is no failure in the re-test. 12. 12.1 METHOD OF TESTS: Visual Examination : All the bolts & nuts shall be visually examined for finish, workmanship, chamfers and identification mark and for visual surface discontinuities referred in IS: 1367 (Part 9) 1993 and IS: 1367(Part.10) 2002. Stainless steel fasteners shall be examined for bright finish also. The bolts shall be examined for straightness of shank and for any eccentricity of shank with respect to head. Nuts & washers shall be examined for eccentricity of the holes, crack, burrs, pits and other defects. Zinc coating on ferrous fasteners shall be examined for defects defined in Appendix A of IS: 2629 1985. Measurement of dimensions : The dimensions of fasteners including lengths and threaded lengths of bolts shall be measured with the help of suitable gauges/devices and shall be within the limits specified in clause 7 & 8 of this specification or these specified in purchasers drawings.

12.2

Page 18 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

12.3

Gauging of threads: These tests shall be done in black condition of galvanized fasteners after stripping. The thread pitch for particular diameter combination ( See Table 1 of IS:4213 (Part II - 1976) and table 1) shall be measured with the help of thread pitch gauges conforming to IS:4211-1993. The thread profile shall be checked with the help of gauges in accordance with IS: 2334-2001. The limits of sizes of nut and bolt threads for tolerance class7H and 8g respectively are specified in Table -1. Chemical composition Ferrous fasteners: Chemical analysis of the galvanized steel bolts shall be carried out in accordance with IS: 228 1987 and parts and shall conform to Clause 4 of IS : 1367(Part 3) 2002 i.e. Carbon shall not exceed 0.55%, sulphure 0.06% and phosphorus 0.05% for bolts. The chemical composition for ferrous nuts shall be as follows: Property Class C %Max. 0.50 0.53 Mn %Min. 0.25 P %Max. 0.110 0.060 S %Min. 0.150 0.150

12.4 12.4.1

4,5 04 12.4.2

Stainless steel fasteners shall be analyzed in accordance with IS: 228-1987 and parts. The chemical composition shall conform to Grades Mentioned clause 5.2. Mechanical Tests Tensile test for bolts: G.S. Bolts: The tensile test shall be carried out on all sizes of bolts in finished condition where a. free threaded length equal to one diameter of bolt shall also be subjected to tensile load. The fracture shall occur in the shank or thread of bolt and not at the junction of the head and the shank. The calculation of the tensile strength is based on the stress area. The tensile strength shall not be less than 400 N/mm2. Stainless steel bolts and studs: The tensile test shall be carried out on all sizes of bolts and studs in finished condition where a free threaded length equal to one diameter of bolt shall also be subjected to tensile load. The fracture shall occur in the shank or thread of bolt and not at the junction of the head and the shank. The calculation of the tensile strength is based on the stress area. The tensile strength shall not be less than 500 N/mm2. Test rig: For the purpose of tensile test the rig shall be designed accordingly. The speed of testing shall not exceed 25 mm/min. The grips of testing machine should be self aligning to avoid side thrust on the specimen".

12.5 12.5.1 12.5.1.1

12.5.1.2

12.5.13

Page 19 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

12.5.2

Determination of percentage elongation after fracture:

12.5.2.1 G.S. bolts: The elongation test shall be carried out on full size bolts in finished condition where it is possible to mark the gauge length equal to 5.65 So on the shank. Where it is not possible to mark the gauge length on the shank, machined test pieces shall be used for the purpose of determination of percentage elongation after fracture as per clause 8.1 IS:1367 (Part 3):2002. The load shall be applied in the manner as in 12.5.1.3. The elongation after fracture in both the cases shall not be less than 22%. The applicability of the elongation test on the full size bolts in finished condition and on machined test pieces (refer Drg. No. ETI/C/0073 Mod. A) Shall be as under:Nominal thread / shank diameter (mm) 12 14 16 18 20 24 Dimensions for bolts as per Drg. No. ETI/C/0073 Mod. A Machined test pieces In finished condition. 60/30 and below All sizes 100/38 and below All sizes 100/46 and below All sizes 120/36 and above. 175/44 and above. 200/52 and above.

12.5.2.2 Stainless steel bolts and studs: The extension after fracture of stainless steel bolts and studs shall be measured during the tensile test (see sub- clause 12.5.1.2). The extension shall not be less than 0.6 d (where d is nominal diameter of bolt). 12.6 12.6.1 Hardness Test : Hardness test for galvanised steel fasteners shall be carried out after removal of zinc coating. On steel bolts, the test shall be carried out in accordance with Clause 8.4 of IS:1367(Part 3)-2002 and on steel nuts in accordance with Clause 8.2 of IS:1367(Part.6)-1994. On stainless steel bolts and nuts this test shall be carried out in accordance with Clause 6.7 of BS: 6105-1981. The values of hardness shall be within the ranges given in Table 3 below.

Page 20 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

Table 3 Property class 4.6 04 4 5 Stainless steel bolts & nuts All All Over M16 to M39 M10 M 16 Over M16 to M39 All Nominal size Hardness Minimum Maximum 120 HV 188 HV 117 HV 130 HV 146 HV 220 HV 302 HV 302 HV 302 HV 302 HV 183 HB

Fastener Steel Bolts Steel Nuts

12.7 Proof load test on bolts and nuts : 12.7.1 Proof load test on bolts and nuts shall be carried out in accordance with Clause 8.5 of IS:1367 (Part 3) - 2002 and Clause 8.1 of IS:1367 (Part.6)-1994 respectively. The steel bolts shall be capable of being fully loaded upto the proof load, as prescribed in Table 4. Steel and stainless steel nuts shall be capable of being fully loaded upto proof loads indicated in Table 5. Table 4 - PROOF LOADS FOR STEEL BOLTS ISO METRIC COARSE TIREAD Nominal Pitch Nominal Property class Thread of the Stress -------------------------------------------------------------------------------------Diameter Threads Area 4.6 2 mm mm mm Proof load N 6 7 8 10 12 14 16 18 20 22 24 27 30 33 36 39 1 1 1.25 1.5 1.75 2 2 2.5 2.5 2.5 3 3 3.5 3.5 4 4 20.1 28.9 36.6 58.0 84.3 115 157 192 245 303 353 459 561 694 817 976 4520 6500 8240 13000 19000 25900 35300 43200 55100 68200 79400 103000 126000 156000 184000 220000

Page 21 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

TABLE 5 PROOF LOAD VALUES FOR NUTS ISO METRIC COARSE TIREADS Nominal Size Pitch of the thread mm Nominal stress area of Mandrel mm2 Proof load N_____________ Steel Nuts Stainless steel nuts,(proof stress500 N/mm2) Property Property Class 4 Class5 ---------------------97900 125000 154500 180000 234100 286100 353900 416700 497800 11700 16800 21600 34200 51400 70200 95800 121000 154400 190900 222400 289200 353400 437200 514700 614900 10000 14500 18300 29000 42200 57500 78500 96000 122500 152000 476500 229500 280500 347000 408500 488000

Property Class04 7640 11000 13900 22000 32000 43700 59700 73000 93100 113100 134100 174400 213200 263700 310500 370900

M6 M7 M8 M10 M12 M14 M16 M18 M20 M22 M24 M27 M30 M33 M36 M39

1 1 1.25 1.5 1.75 2 2 2.5 2.5 2.5 3 3 3.5 3.5 4 4

20.1 28.9 36.6 58 84.3 115 157 192 245 303 353 459 561 694 817 976

12.8 12.8.1

Stress at 0.2% permanent strain test:(for stainless steel bolt only) This test shall be conducted in accordance with clause 6.3 of BS:6105 1981. The stress at 0.2% permanent strain shall not be less then 210 N/mm2. Head soundness test for bolts: This test is not applicable to U bolts, J bolts and flat countersunk nib bolts.. This test shall be carried out as illustrated in figure 2 (enclosed) and in Fig. 4 of IS:1367(Part-3)-2002. The bolt shall be inserted in a special steel die of the dimensions given in Table II of IS:1367(Part-3)-2002. The hole in the die shall be at an angle of 600 to its upper surface. When struck several blows with a hammer the head of bolt or screw should be bent to an angle (90-60)0 without showing any sign of cracking at the fillet between shank and head.

12.9 12.9.1 12.9.2 12.9.3

12.9.4

Page 22 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

12.9.5

Where screws are threaded upto the head the test will be regarded as established even if a crack should appear in the first thread, provided that head does not snap off. Crushing test on nuts : ( Stainless steel only)

12.10

12.10.1 The nut under test shall be placed edgewise on an anvil and crushed by hammering till its threads come in contact with a mandrel, the diameter of which shall be 0.9 D1 where D1 is the minor diameter of nut described in figure 1 of IS:4213(Part.I):1976. After crushing, the nut shall not exhibit any fracture or crack at any point. The nut may then be broken for further chemical analysis and inspection of structure. 12.11 Bond test on straight bolts : ( Stainless steel only) 12.11.1 This test is applicable only to straight bolts. 12.11.2 The threaded part of the bolt shall be so held in the jaws of a vice that the threaded part projects for a distance equal to at least half the nominal diameter. The projecting part shall then be bent by hammering so that the axis of free portion is at an angle of 165 degree to the axis of the portion held in the vice. On examination, the bend shall not exhibit any crack (see fig.3). 12.12 Torsion test on bolts and nuts ( For stainless steel bolts & nuts only ) 12.12.1 A torsion test shall be conducted on stainless steel bolts and nuts. The test shall be conducted as described in 12.12.2 in case of straight bolts and as described in 12.12.3 in case of U bolts. The ultimate torsional strength shall be not less than that specified in table 6. TABLE 6 ULTIMATE TORSIONAL MOMENT FOR STAINLESS STEEL BOLTS AND NUTS Diameter of bolt . 10 12 14 Ultimate torsional strength (Min.) (kg-m) . 6.5 12 16

12.12.2 The head of the bolt shall be gripped in a vice and a steel plate slipped over the thread, the diameter of the hole drilled in this steel plate being 11 mm in case of 10mm diameter bolts, 14 mm in case of 12 mm diameter bolts and 16 mm in the case of 14 mm diameter bolts. A flat steel washer is then placed between the steel plate and the nut (but none between plate and head of bolt). The total thickness of the steel plate and the washer shall be so chosen that the position of nut on the threaded portion of bolt is the

Page 23 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

same as when the bolt is in actual use. The test shall be carried out without lubrication of the parts in contact with each other. The torque shall be applied by means of torque spanner, the design of which is subject to the approval of the purchaser. The torque shall be increased in steps until the bolt fractures. After each increment of torque, the nut shall be unscrewed and the threads on both bolt and nut examined. 12.12.3 The torsion test on U bolts shall be conducted in a manner similar to that described in 12.12.2, but the U bolt shall be prevented from deforming in the course of the test by seating it on a mandrel, the radius of curvature of which is equal to that of the inner edge of the U bolt. A steel plate with two drilled holes shall be slipped over the two limbs of the U bolt, the diameter of the holes in the steel plate bearing the same relationship to the diameter of the bolt as in the case of straight bolts. The steep plate may be integral with the mandrel. A flat steel washer shall then be placed between the steel plate and the nut on each limb(Fig 4). The torsion test shall then be carried out as described in 12.2.2 after gripping the mandrel in a vice. It is sufficient if the test is conducted on one limb of the U-bolt. 12.12.4 The test shall result in fracture of the bolt, but not of the nut. The values of torque at fracture shall be not less then that indicated in Table-3. further, on unscrewing the nut at any value of torque below the value specified in table 3, the threads on bolt and nut shall be found to be undamaged and it shall be possible to work the nut along the entire threaded length of the bolt. 12.13 Galvanizing test :-The zinc coating on galvanized fasteners shall be tested for adherence, uniformity and mass. The mass of zinc coating shall be measured on the unthreaded portion by stripping method (IS:6745 -1972) or by previously calibrated elcometer ( magnetic method). The uniformity shall be checked by Preece test( IS:2633-1986) on the threaded portion of bolts. It shall withstand at least five one minute successive dips. Adherence shall be checked on the shank or head by any one of the methods prescribed in clause 6.4 of IS 2629-1985. Inter-crytallic corrosion bend test ( For stainless steel only )

12.14

12.14.1 The bend test pieces shall not be larger than 12.5 mm (1/2 inch) diameter. The test piece shall be sensitized by heating to a temperature of 6500C for the period stated in the relevant material specification, followed by cooling in air. All test pieces shall be immersed for 72 hours in boiling solution having the following composition: 111 g copper sulphate ( CuSo4.5 H2O), 98 g Sulphuric acid ( relative density (d) = 1.84) and made upto 1 litre with distilled water.

Page 24 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

Precautions shall be taken during the boiling to prevent concentration of the solution due to evaporation. After this preparation each test piece shall be bent through 90 round a radius equal to three times the diameter and thickness of the test piece, and shall withstand this treatment without cracking on the outer, convex surface. 12.15 Micro examination of stainless steel fasteners: (Test for freedom from carbide precipitation):

12.15.1 Micro examination on transverse section of stainless steel bolts and nuts shall be carried out to ascertain freedom from carbide precipitation at grain boundaries. In case any sample shows evidence of carbide precipitation, the lot represented by the same may be reheat treated, and resubmitted as a new lot at the discretion of the purchaser. Otherwise the lot shall be rejected. 12.16 Permanent sat test on spring washers:

12.16.1 The spring washers under test shall be compressed flat for 3 Min. duration and released between two plates having a hardness of 60 HRC, Min on release if the pressure, the free height (h2 = 2S indicated in IS:3063 1994) of the washer shall not be less then that given in table 2A &2B of IS:3063-1994. This compression and removal of pressure shall then be repeated 20 times in quick succession after which the free height shall not have further reduced. 12.17 Twist test on spring washers :

12.17.1 A portion of the washer shall be gripped in vice jaws and then equal portion shall be gripped in wrench jaws as shown in Fig. 1 of IS:3063-1994..Edges of the wrench jaws shall be sharp and parallel to vice jaws. The wrench shall than be rotated in a direction that increases the free height of the spring washer till the washer is twisted through on angle of 900. The washer shall show no sign of fracture. 13. 13.1 MARKING AND MODE OF DELIVERY The bolts shall be delivered assembled with their nuts and lock nuts and washers (wherever required). The nuts and lock nuts shall be fully screwed on by hand. Bolts, screws and nuts shall be provided with identification marking as laid down in IS: 1367 (Part.18)-1996.. The marking of the manufacturers trade mark of name is mandatory for all products covered by the obligatory marking requirements for property classes. The fasteners shall be packed as described in IS:9141-1979. Each package shall contain only one grade and dimension of fasteners.

13.2

13.3 13.4

Page 25 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

13.5

The packages shall be marked clearly and legibly with the following information. a) b) c) d) e) f) g) h) The product designation; A pictorial representation of the product, where possible; Total number of pieces in the package; Net and gross mass of package; Name or identification symbol of the manufacturer; Purchase order No. and consignee. Date of inspection and inspecting authority. Any other information as required by purchaser. --------

Page 26 of 26

Effective from May, 2012

Specification No. TI/SPC/OHE/ FASTNERS/0120

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Catalysis of A Reaction Between Sodium Thiosulfate and Iron (III) Nitrate SolutionsDocumento3 pagineCatalysis of A Reaction Between Sodium Thiosulfate and Iron (III) Nitrate Solutionssachin0002Nessuna valutazione finora

- Handwarmer 3Documento4 pagineHandwarmer 3api-250061096Nessuna valutazione finora

- API-571 Mockup Test-03-QuestionsDocumento12 pagineAPI-571 Mockup Test-03-QuestionsMetzer LLC100% (1)

- Analytical Chemistry 2Documento15 pagineAnalytical Chemistry 2kukuhNessuna valutazione finora

- Storage Raised Floor: Cooling Raised FloorDocumento10 pagineStorage Raised Floor: Cooling Raised Floormona.k.mNessuna valutazione finora

- Is144 07t Resurfacing Concrete FloorsDocumento8 pagineIs144 07t Resurfacing Concrete FloorsSteve LezamaNessuna valutazione finora

- Chem Project Class 12 With Investigatory Project On ' Antacids'Documento15 pagineChem Project Class 12 With Investigatory Project On ' Antacids'SHAHBAN55550% (1)

- Chemistry Ionic CompoundDocumento12 pagineChemistry Ionic CompoundEden YokNessuna valutazione finora

- Duplex Stainless SteelsDocumento7 pagineDuplex Stainless SteelsRizalzi BachtiarNessuna valutazione finora

- Bonding, Structure and Periodicity TestDocumento8 pagineBonding, Structure and Periodicity Testpaulcampbell37Nessuna valutazione finora

- Apples To Pears Science Fair ProjectDocumento7 pagineApples To Pears Science Fair Projectapi-297059067Nessuna valutazione finora

- AST3 Units Two and Three-Location and Three-StructureDocumento17 pagineAST3 Units Two and Three-Location and Three-StructureYoucef ABARNessuna valutazione finora

- Goldschmidt Classification of Elements - Note 3Documento10 pagineGoldschmidt Classification of Elements - Note 3Odebunmi PaulNessuna valutazione finora

- CH 14Documento29 pagineCH 14Amrik SinghNessuna valutazione finora

- Munson Walker Method 906 03Documento2 pagineMunson Walker Method 906 03Jose Luis Prado Arroliga100% (1)

- Chapter 1Documento41 pagineChapter 1Patchole Alwan TiarasiNessuna valutazione finora

- Copper Alloys InfoDocumento18 pagineCopper Alloys InfoPhung Tuan AnhNessuna valutazione finora

- Chemical Symbols and Valences of Elements and RadicalsDocumento1 paginaChemical Symbols and Valences of Elements and RadicalsproodootNessuna valutazione finora

- 0620 s07 Ms 3Documento6 pagine0620 s07 Ms 3Varun PanickerNessuna valutazione finora

- Canadian Steel Producers 2012 Member Directory en Final 8 Nov 2011Documento32 pagineCanadian Steel Producers 2012 Member Directory en Final 8 Nov 2011satyaseerNessuna valutazione finora

- Hardenability of Steel PDFDocumento59 pagineHardenability of Steel PDFMOHAC KILICASLANNessuna valutazione finora

- Failure Analysis of Corrosion Case HistoriesDocumento78 pagineFailure Analysis of Corrosion Case HistoriesNitin BuZz100% (1)

- SB 135Documento4 pagineSB 135AnilNessuna valutazione finora

- Electromagnetic FormingDocumento15 pagineElectromagnetic FormingHimanshu Gupta50% (4)

- Exp 01 Determination of DensityDocumento16 pagineExp 01 Determination of DensityParithyiMuraliTharanNessuna valutazione finora

- Modified TestDocumento12 pagineModified Testapi-299084383Nessuna valutazione finora

- Alloy Selection Chemical Resistences PDFDocumento9 pagineAlloy Selection Chemical Resistences PDFMarco VillanuevaNessuna valutazione finora

- Expanded MetalDocumento2 pagineExpanded Metalebastien2Nessuna valutazione finora

- Full Details Chromite Mining and ProcessingDocumento12 pagineFull Details Chromite Mining and ProcessingSameen BaberNessuna valutazione finora

- Zirconium Alloys Rev1 1Documento19 pagineZirconium Alloys Rev1 1Christian AganoNessuna valutazione finora