Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Optimization of The Deposition Parameters of Thick Atmospheric Plasma Spray Coatings

Caricato da

avencl0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

49 visualizzazioni8 paginePlasma spray process is one of the most versatile thermal spray deposition processes. There are great number of parameters that influence the quality and characteristic of deposited coating and their values must be defined precisely for each type of coating and used equipment individually. A review of the technology developed for deposition of ferrous-based powder spray (Fe-1.3Cr-1.5Mn-1.2C-0.3Ni (wt. %)) on flat Al-Si alloy substrate surfaces is presented in this paper. Also possible problems that may occur before and during the deposition process were pointed-out, as well as adequate solutions of those problems.

Titolo originale

Optimization of the deposition parameters of thick atmospheric plasma spray coatings

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoPlasma spray process is one of the most versatile thermal spray deposition processes. There are great number of parameters that influence the quality and characteristic of deposited coating and their values must be defined precisely for each type of coating and used equipment individually. A review of the technology developed for deposition of ferrous-based powder spray (Fe-1.3Cr-1.5Mn-1.2C-0.3Ni (wt. %)) on flat Al-Si alloy substrate surfaces is presented in this paper. Also possible problems that may occur before and during the deposition process were pointed-out, as well as adequate solutions of those problems.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

49 visualizzazioni8 pagineOptimization of The Deposition Parameters of Thick Atmospheric Plasma Spray Coatings

Caricato da

avenclPlasma spray process is one of the most versatile thermal spray deposition processes. There are great number of parameters that influence the quality and characteristic of deposited coating and their values must be defined precisely for each type of coating and used equipment individually. A review of the technology developed for deposition of ferrous-based powder spray (Fe-1.3Cr-1.5Mn-1.2C-0.3Ni (wt. %)) on flat Al-Si alloy substrate surfaces is presented in this paper. Also possible problems that may occur before and during the deposition process were pointed-out, as well as adequate solutions of those problems.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 8

OPTIMIZATION OF THE DEPOSITION PARAMETERS

OF THICK ATMOSPHERIC PLASMA SPRAY COATINGS

A. Vencl

Tribology Laboratory, Faculty of Mechanical Engineering, University of Belgrade,

Serbia, avencl@mas.bg.ac.rs

ABSTRACT

Plasma spray process is one of the most versatile thermal spray deposition

processes. There are great number of parameters that influence the quality and

characteristic of deposited coating and their values must be defined precisely for

each type of coating and used equipment individually. A review of the technology

developed for deposition of ferrous-based powder spray (Fe-1.3Cr-1.5Mn-1.2C-

0.3Ni (wt. %)) on flat Al-Si alloy substrate surfaces is presented in this paper. Also

possible problems that may occur before and during the deposition process were

pointed-out, as well as adequate solutions of those problems.

KEYWORDS: Atmospheric plasma spraying, Ferrous-based coatings, Parameters

optimization, Microstructure

1. INTRODUCTION

The surface enhancement of conventional materials that are being used in tribo-systems with

the coating deposition is a well-established practice. Thermal spray is flexible and economically

efficient procedure which enables superior tribological properties for machine elements that are

designed for demanding properties and is widely used for new parts as well as for repair

purposes. Thermal spraying is, in fact, a generic group of processes in which the coating

material is fed to a heating zone, where it becomes molten, and is then propelled to the surface

to be coated. Metallic, ceramic, cermets and some polymeric materials can be used in the form

of powder, wire, or rod for this purpose /1/. There are several different processes for thermal

spray coating deposition and mostly used are flame spray, electric arc wire spray, plasma spray

and high velocity oxy-fuel spray (HVOF) process /2/.

The plasma spray process is the most widely used coating method because it presents

process flexibility and coating quality in combination /3/. This process finds wide application

in aerospace, petrochemical, automotive and other industries /4-6/. Plasma spray process

poses several advantages compared to the other methods of coating deposition and other

surface engineering techniques. In comparison to the vapour deposition methods it requires

less expensive installations /7/. Chemical treatments like electroplating of chromium and

nickel coatings are becoming increasingly threatened by environmental regulation. Moreover,

one should prevent microscopic particles of chromium and nickel, a health hazard, from

entering the environment. Chemical treatments require complex chemistry and are relatively

expensive. One of the main advantages of the plasma spray process is that the substrate is

heated very little during the deposition, i.e. the substrate restrains its chemical composition,

structure and mechanical properties. During the plasma spray process, introduced thermal

energy melts the coating material (usually in the form of powder). Molten material is than

propelled, by the carrier gas, onto a cleaned and prepared specimen surface, where it bonds

to the substrate predominantly by mechanical bonding. Detailed description of the process

can be found elsewhere /2/, while the schematic diagram of obtained coating is shown in

Figure 1.

275

Proceedings of the 7

th

International Conference on Tribology (BALKANTRIB11)

Eo|reo oy. Prof. K.-D. Bouzakis,

0|reoror ol rne Laoorarory lor Vaon|ne Too|s ano Vanulaorur|ng Eng|neer|ng {EE/Vj ol rne

/r|srore|es un|vers|ry Tnessa|on|k| ano rne Fraunnoler Proeor 0enrer 0oar|ngs |n Vanulaorur|ng {P00Vj,

a o|nr |n|r|ar|ve oy Fraunnoler-Sese||sonalr ano 0enrre lor Pesearon ano Teonno|ogy le||as

Puo||sneo oy. EE/V ano P00V

3-5 October 2011,

Thessaloniki, Greece

Figure 1: Schematic diagram of a plasma sprayed coating.

Plasma spray process is one of the most versatile thermal spray deposition processes and it

can be configured to spray particles over a very wide range of temperatures and velocities /8/.

The plasma temperature can reach up to 16000 C, which enables melting and spraying of

many different materials onto a wide range of substrates (metallic alloys, ceramics, polymers)

and over a large range of particle size distribution (from 5 to 50 m for ceramics, 20 to 120 m

for metallic alloys) /9/. Possible coating thickness range is also wide. With plasma spray process

there are many problems, as well as with other coating deposition methods, which needs to be

solved in order to obtain the coatings with the desired characteristics. Regardless to the

application of the coating some characteristics are the same: coating composition and structure,

porosity, presence of unmelted particles and oxide inclusions, thickness, hardness and bond

strength. Coating characteristic are very dependent on substrate preparation and spray

parameters. According to some researchers /10/ there are more than 50 macroscopic

parameters that influence the quality of the coating and the production of coating is still based

on trial and error approach.

The aim of this paper is to point-out to the possible problems that may occur before and during

the Atmospheric plasma spraying (APS) deposition process of the ferrous-based coatings onto

the Al-Si alloy substrate, as well as, to give the adequate solutions of those problems.

2. THEORETICAL CONSIDERATIONS

Characteristics of the thermal spray coatings (metallography, hardness and tensile bond

strength) were accepted as a standard one by the Subcommittee for Standardization of Quality

Control Procedures for Plasma Sprayed Coatings, which is formed in April 1997 by the

European Airline Committee for Materials Technology (EACMT) /11/. These characteristics are

mutually connected and are dependent on many parameters. Generally these parameters

could be divided into two groups: substrate preparation parameters and spray deposition

parameters.

Substrate preparation parameters affect most of all bond strength between substrate and

coatings. They include: surface roughness and cleanliness, substrate temperature, presence of

the absorb moisture and gases and presence of entrapped particles used for surface

roughening. Prior to the deposition the surface of the substrate is roughened and activated so

the area for bonding of the sprayed particles is increased. Parameters that are important in

choosing the abrasive for surface roughening are: type, size, shape, purity and hardness.

Impact pressure and angle are also important. Inadequate surface cleanliness and presence of

entrapped abrasive particles decrease the bond strength, so they should be avoided. Interlayers

are also used to increase the bond strength.

276 BALKANTRIB - 2011

Substrate temperature can be important for presence of cracks, i.e. during cooling, if the

expansion coefficient (and hence the contraction) of the substrate material is appreciably less

than that of the coating, stresses build up and the coating may crack. That is why in some cases

substrate preheating is welcomed. Slow cooling after the deposition is also good practice,

regardless of the composition of the base metal. If the coating is cooled rapidly it will contract

while the core is still hot (and hence expanded) and cracking may occur. Presence of the

absorb moisture and gases can increase the porosity of coating, i.e. any foreign matter, on or

just below the surface of the base material, which tends to evolve gas during deposition can

cause bubbles. This is frequently a problem with porous castings which are difficult to clean

thoroughly, but it can also result from rolled-in contaminants in the substrate material or from

contaminants in the abrasive used for roughening.

There are many spray deposition parameters, and the most commonly used are: type, flow and

pressure of the primary and secondary plasma gas, electric current, powder feed rate and spray

distance. Speed of a spraying gun and substrate holder speed, maintained substrate

temperature during the process and number of passes (coating thickness) are also influential.

All these spray parameters directly influence the bond strength, amount of the unmelted

particles and precipitates, porosity and type and amount of formed oxides.

Powder feed rate and spray distance are responsible for the amount of unmelted particles and

precipitates. If the feed rate is too big or the spray distance is too short the powder particles did

not melt completely which results in a high amount of unmelted particles. As with all thermal

spray coatings, sprayed under normal conditions, tensile stresses exist prior to deposition.

These stresses increase with coating thickness. If the bond to the substrate is not adequate, the

bond may be destroyed by shear at the edges. One of the ways to avoid this is to blunt the

edges if it is possible. Bonding strength between layers of the coatings is also important.

Weaker bonding between layers is more pronounce with thick coatings and with coatings

deposited with pauses. Oxidation of the coating surface is possible if there are pauses so it is

recommended to continually perform the deposition.

Presence of the unmelted particles and precipitates decrease the coating characteristics.

Porosity shows similar effect although residual porosity of the plasma coating could also reduce

the coefficient of friction through a micro-cavity lubrication system, where micro-cavity serves as

a lubricant reservoir allowing improved lubrication process /12/. Presence of the oxides has dual

effect, positive and negative, depending on the type of oxide and some other properties. In our

case (ferrous-based coatings deposited by APS) presence of FeO (wustite) and Fe

3

O

4

(magnetite), as solid lubricants, improves the tribological properties of the coating. The

formation of Fe

2

O

3

(hematite) should be avoided, because it acts as abrasive.

3. EXPERIMENTAL DETAILS

3.1 Materials

Substrate material was an Al-Si alloy (EN AlSi10Mg). The substrate material was fabricated

using send casting, followed with solution annealing at 540 C with 35 C/h, water quenching

and artificial ageing at 1605 C for 6 h. Spray powder used in this experiment was Sulzer

Metco 4052, which is commercial brand names of Sulzer Metco Inc. The chemical composition

of the powder is shown in Table 1. The powder shows fine spherical morphology with size less

than 38 m in diameter.

Table 1: Chemical composition of used powder

Element C Mn Cr Ni Fe

wt. % 1.2 1.5 1.3 0.3 balance

277 Tribo-tests and tribo-aspects in various applications

3.2 Substrate preparation parameters and spray deposition parameters

Atmospheric Plasma Spraying, with METCO 7MB Plasma Flame Spray Gun, was utilized in the

experiment. Before the spraying process, surface of the aluminium alloy substrate was

roughened and the edges were blunted with radius 0.2 mm. A specimen radial speed was 500

mm/s. Traverse speed of a spraying gun was maintained constant at 4 mm/s. In order to get an

optimal coating structure certain parameters of the substrate preparation and spray deposition

were varied. All the parameters are summarised in the Table 2. Varied parameters (these

parameters were chosen as the most influential) were as follows:

x three abrasives for roughening: SiO

2

(d = 220 260 m, t 40 s), Al

2

O

3

(d = 106 125

m, t 6 s) and steel balls (d = 600 800 m, t 50 s);

x four spray distances (50, 75, 100 and 150 mm);

x four powder rates (2, 2.5, 4 and 4.5 kg/h);

x two thicknesses (150 and 250 m);

x presence of additional cooling (with and without).

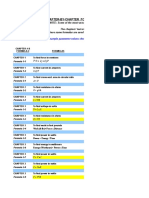

Table 2: Substrate preparation and spray deposition parameters

Parameter Value

*

Abrasive used for roughening SiO

2

/ Al

2

O

3

/ steel balls

Primary plasma gas (Ar) [l/min] 100

Secondary plasma gas (H

2

) [l/min] 5

Electric current [A] 500

Powder carrier gas (Ar) [l/min] 37

Powder feed rate [kg/h] 2 / 2.5 / 4 / 4.5

Spray distance [mm] 50 / 75 / 100 / 150

Coating thickness [m] 150 / 250

Additional cooling no / yes

*

parameters used after optimization are bolded

3.3 Metallographic examinations

Primary purpose of the metallographic examinations was to determine the quality of the

obtained coating (bonding, presence of cracks, unmelted particles and precipitates and

porosity). Metallographic examinations and characterization of the obtained coatings was done

according to the Pratt & Whitney standard /13/. The microstructure of the coatings and presence

of the cracks were analyzed with optical microscope (OM), where the coatings were sectioned

perpendicular to the coated surface. Metallographic samples were prepared in a standard way

applying grinding and polishing, with no etching.

4. RESULTS AND DISCUSSION

After a numerous test samples and their analysis (mainly microstructure analysis) optimal

parameters for the substrate preparation and spray deposition were obtained (see Table 2). The

microstructure of the optimal coating is shown in Figure 2. Elongated splats of molten powder

form a lamellar structure, with oxide layers in between, typical for spray coatings /14,15/. No

cracking was found in the coatings and no peeling was observed at the interface between the

coating and the substrate (Figure 2a). Big dark areas are pull-outs of splats or dirt formed during

polishing. Amount of pores, oxides, unmelted particles and precipitates (Figure 2b) were in

acceptable limits for this type of coating and used equipment. Further analysis of the obtained

coating i.e. investigation of the mechanical and tribological properties of coating (which is not

presented in this paper) confirmed the quality of the coating (and hence the choice of the used

parameters).

278 BALKANTRIB - 2011

In the optimization process first thing was to ensure adequate bonding between the coating

and the substrate. This bonding is mainly influenced by the substrate preparation.

Appearance of the substrate surface after activation with three different abrasives is shown in

Figure 3.

Figure 2: Cross-section micrographs (OM): a) whole coating and b) detail.

Figure 3: Substrate surface appearance after roughing with: (a) SiO

2

, (b) Al

2

O

3

and (c) steel

balls.

Substrate activation with SiO

2

and steel balls in most of the cases showed inadequate bonding

i.e. adhesion of the coating to the substrate was poor (Figure 4). That is why the optimisation

process was continued with the Al

2

O

3

as a roughening tool.

Figure 4: Poor bonding (adhesion) of the coating with the substrate in case: (a) SiO

2

(spray

distance: 75 mm; powder feed rate: 4 kg/h) and (b) steel balls (spray distance: 75

mm; powder feed rate: 4 kg/h).

279 Tribo-tests and tribo-aspects in various applications

As it is known, if the spray distance is to short and/or powder feed rate is too big than the

bonding (adhesive and cohesive) and the structure of the coating is poor (Figure 5). Poor

structure is manifested with unlamellar structure, presence of unmelted particles and

precipitates and high porosity.

Figure 5: Inadequate structure and poor bonding in case of unsatisfactory spraying

parameters: (a) and (b) spray distance: 50 mm; powder feed rate: 2.5 kg/h, (c) spray

distance: 75 mm; powder feed rate: 4 kg/h and (d) (f) spray distance: 100 mm;

powder feed rate: 4.5 kg/h.

280 BALKANTRIB - 2011

In cases when the spray distance was too short higher amount of heat was present in the

coating and as a result we have fusing of the melted particles and forming of clots i.e. we have

unlamellar structure (Figure 5a and b). In case of relatively small spraying distance and high

feed rate the structure is even worse (Figure 5c). When the spraying distance was bigger (with

the same, high, feed rate) the structure was more lamellar but still inadequate. Presence of

cracks and poor cohesion with high amount of precipitates was noticed as well as presence of

higher porosity (Figure 5d, e and f).

Variation of the coating thickness did not shown any significant influence on the coating

structure, while absence of additional cooling shows similar effect as small spray distance and

high feed rate. Even with the optimal distance and feed rate there were some common mistakes

like: deposition with the pauses and poor cleaning of the substrate (Figure 6a) or additional

cooling with higher air pressure than it is optimal (Figure 6b). In first case we had poor cohesion

between layers and in the second too mach precipitates (small parts of the original powder

particles) was formed.

Figure 6: Possible mistakes in coating deposition: (a) deposition pauses was too long and the

substrate was not cleaned well and (b) air pressure used for additional cooling was

too high.

5. CONCLUSIONS

The aim of this paper is to point-out to the possible problems that may occur before and during

the APS deposition process of the ferrous-based coatings onto the Al-Si alloy substrate, as well

as, to give the adequate solutions of those problems.

After a numerous test samples and their analysis optimal parameters for the substrate

preparation and spray deposition were obtained and as a result typical spray deposition

coatings was produced (with elongated splats of molten powder forming a lamellar structure,

with oxide layers in between).

Coating characteristic are very dependent on substrate preparation and spray parameters.

There are a lot of parameters that influence the quality of the coating, but some common

mistakes can be avoided (mainly connected with the substrate preparation).

Unfortunately finding of the optimal spray deposition parameters (if they are not known and

even in that cases, since each application requires some particularity) are still based on trial and

error approach.

281 Tribo-tests and tribo-aspects in various applications

6. REFERENCES

1. Gonzlez R., Garca M.A., Peuelas I., Cadenas M., del Roco Fernndez M., Hernndez

Battez A., Felgueroso D., Microstructural study of NiCrBSi coatings obtained by different

processes, Wear, 263 (2007) 619-624.

2. Vencl A., Mrdak M., Cvijovi I., Microstructures and tribological properties of ferrous

coatings deposited by APS (atmospheric plasma spraying) on Al-alloy substrate, FME

Transactions, 34 (2006) 151-157.

3. Samur R. and etiner B.G., Quantitative determination of microcracks on ceramic coatings

by computer image analysis, Metalurgija, 44 (2005) 41-44.

4. Koutsomichalis A., Vaxevanidis N., Petropoulos G., Xatzaki E., Mourlas A., Antoniou S.,

Tribological coatings for aerospace applications and the case of WC-Co plasma spray

coatings, Tribology in Industry, 31 (2009) 37-42.

5. Barbezat, G., Advanced thermal spray technology and coating for lightweight engine blocks

for the automotive industry, The International Conference on Metallurgical Coatings and

Thin Films ICMCTF 2-6 May 2005 San Diego, 2005, private conversation.

6. Barbezat G., Herber R., Breakthrough in improving car engine performance through

coatings, Sulzer Technical Review, 2 (2001) 8-11.

7. Bouzakls K.-D., Lontos A., Vidakis, N., David K., Kechagias V., Determination of

mechanical properties of thick coatings producted by the plasma spray method,

Proceedings of THE Coatings in Manufacturing Engineering 14-15 October 1999

Thessaloniki, 1999, pp: 269-282.

8. Dorfman M.R., Thermal spray basics, Advanced Materials & Processes, 160 (2002) 47-50.

9. Brossard S., Munroe P.R., Tran A.T.T., Hyland M.M., Study of the effects of surface

chemistry on splat formation for plasma sprayed NiCr onto stainless steel substrates,

Surface and Coatings Technology, 204 (2010) 1599-1607.

10. Lugscheider E., Barimani C., Eckert P., Eritt U., Modeling of the APS plasma spray process,

Computational Materials Science, 7 (1996) 109-114.

11. Sauer J., van Wonderen M., Standardization in coating evaluation: A universal system for

repair coatings, Proceedings of International Thermal Spray Conference ITSC 2002 4-6

March 2002 Essen, 2002, pp: 631-634.

12. Dohmen J., Hermsen F.G., Barbezat G., Untersuchungen an plasmabeschichteten

Zylinderlaufflchen, MTZ, 65 (2004) 204-208.

13. --, Turbojet Engine Standard Practices Manual (PN 582005), Pratt & Whitney, East

Hartford (2002)

14. Schorr B.S., Stein K.J., Marder A.R., Characterization of thermal spray coatings, Materials

Characterization, 42 (1999) 93-100.

15. Hwang B., Ahn J., Lee S., Correlation of microstructure and wear resistance of ferrous

coatings fabricated by atmospheric plasma spraying, Metallurgical and Materials

Transactions A, 33 (2002) 2933-2945.

282 BALKANTRIB - 2011

Potrebbero piacerti anche

- Friction and Wear Processes - Thermodynamic ApproachDocumento7 pagineFriction and Wear Processes - Thermodynamic ApproachavenclNessuna valutazione finora

- Ecological and Technical Aspects of The Waste Oils Influence On EnvironmentDocumento7 pagineEcological and Technical Aspects of The Waste Oils Influence On EnvironmentavenclNessuna valutazione finora

- Influence of Additives and Selective Transfer On Wear Reduction in The Lubricated ContactDocumento10 pagineInfluence of Additives and Selective Transfer On Wear Reduction in The Lubricated ContactavenclNessuna valutazione finora

- A Review of The Tribological Properties of PTFE Composites Filled With Glass, Graphite, Carbon or Bronze ReinforcementDocumento6 pagineA Review of The Tribological Properties of PTFE Composites Filled With Glass, Graphite, Carbon or Bronze ReinforcementavenclNessuna valutazione finora

- Friction and Wear Properties of Copper-Based Composites Reinforced With Micro - and Nano-Sized Al2O3 ParticlesDocumento8 pagineFriction and Wear Properties of Copper-Based Composites Reinforced With Micro - and Nano-Sized Al2O3 ParticlesavenclNessuna valutazione finora

- The Influence of Corrosion On The Microstructure of Thermally Treated ZA27/SiCp CompositesDocumento7 pagineThe Influence of Corrosion On The Microstructure of Thermally Treated ZA27/SiCp CompositesavenclNessuna valutazione finora

- Abrasive Wear of Chemical Nickel Coatings With Boron Nitride Nano-ParticlesDocumento7 pagineAbrasive Wear of Chemical Nickel Coatings With Boron Nitride Nano-ParticlesavenclNessuna valutazione finora

- Joining of Composite Materials Based On Al-Si Alloys by Using The GMAW ProcessDocumento1 paginaJoining of Composite Materials Based On Al-Si Alloys by Using The GMAW ProcessavenclNessuna valutazione finora

- Mechanical and Wear Behaviour of Titania Plasma-Sprayed CoatingsDocumento7 pagineMechanical and Wear Behaviour of Titania Plasma-Sprayed CoatingsavenclNessuna valutazione finora

- The Influence of Strontium Addition On The Tribological Properties of Zn25Al3Si Alloy in Boundary Lubricated ConditionDocumento8 pagineThe Influence of Strontium Addition On The Tribological Properties of Zn25Al3Si Alloy in Boundary Lubricated ConditionavenclNessuna valutazione finora

- The Influence of Strontium Addition On The Tribological Properties of Zn25Al1Si Alloy in Boundary Lubricated ConditionDocumento6 pagineThe Influence of Strontium Addition On The Tribological Properties of Zn25Al1Si Alloy in Boundary Lubricated ConditionavenclNessuna valutazione finora

- Influence of "Valena" Metal-Plating Additive On The Friction Properties of Ball BearingsDocumento7 pagineInfluence of "Valena" Metal-Plating Additive On The Friction Properties of Ball BearingsavenclNessuna valutazione finora

- Performance Investigation of Chain Saw Lubricants Based On New Sunflower Oil (NSO)Documento9 paginePerformance Investigation of Chain Saw Lubricants Based On New Sunflower Oil (NSO)avenclNessuna valutazione finora

- Abrasive Wear Resistance of The Iron - and WC-based Hardfaced Coatings Evaluated With Scratch Test MethodDocumento5 pagineAbrasive Wear Resistance of The Iron - and WC-based Hardfaced Coatings Evaluated With Scratch Test MethodavenclNessuna valutazione finora

- Testing of The Mechanical Properties For 15mo3 SteelDocumento2 pagineTesting of The Mechanical Properties For 15mo3 SteelavenclNessuna valutazione finora

- Multi Spindle GearboxDocumento4 pagineMulti Spindle GearboxAkash Kumar DevNessuna valutazione finora

- Green Tribology and Quality of LifeDocumento7 pagineGreen Tribology and Quality of LifeavenclNessuna valutazione finora

- Characterization and Comparison of The Carbides Morphologies in The Near Surface Region of The Single - and Double Layer Iron-Based Hardfaced CoatingsDocumento6 pagineCharacterization and Comparison of The Carbides Morphologies in The Near Surface Region of The Single - and Double Layer Iron-Based Hardfaced CoatingsavenclNessuna valutazione finora

- MMCs Based On Hypoeutectic Al-Si Alloy: Tribological Properties in Dry Sliding ConditionsDocumento7 pagineMMCs Based On Hypoeutectic Al-Si Alloy: Tribological Properties in Dry Sliding ConditionsavenclNessuna valutazione finora

- Tribological Properties of A356 Al-Si Alloy Base Composite Reinforced With Al2O3 Particles (MMC)Documento4 pagineTribological Properties of A356 Al-Si Alloy Base Composite Reinforced With Al2O3 Particles (MMC)avenclNessuna valutazione finora

- Microstructure and Mechanical Properties of The Mo-NiCrBSi Coating Deposited by Atmospheric Plasma SprayingDocumento6 pagineMicrostructure and Mechanical Properties of The Mo-NiCrBSi Coating Deposited by Atmospheric Plasma SprayingavenclNessuna valutazione finora

- Tribological Properties of Thixoforming Al-Alloy A356 and Influence of Heat TreatmentDocumento8 pagineTribological Properties of Thixoforming Al-Alloy A356 and Influence of Heat TreatmentavenclNessuna valutazione finora

- Influence of The Solid Lubricant Particles Reinforcement On Composites Tribological PropertiesDocumento6 pagineInfluence of The Solid Lubricant Particles Reinforcement On Composites Tribological PropertiesavenclNessuna valutazione finora

- Ferrous-Based Coatings For Engine Cylinder Bores Made of Aluminium Alloys: Tribological PropertiesDocumento9 pagineFerrous-Based Coatings For Engine Cylinder Bores Made of Aluminium Alloys: Tribological PropertiesavenclNessuna valutazione finora

- Tribological Properties of Thixocasted and Heat Treated Hypoeutectic Al-Si Alloy A356Documento9 pagineTribological Properties of Thixocasted and Heat Treated Hypoeutectic Al-Si Alloy A356avenclNessuna valutazione finora

- The Structure and Mechanical Properties of An Aluminium A356 Alloy Base Composite With Al2O3 Particle AdditionsDocumento5 pagineThe Structure and Mechanical Properties of An Aluminium A356 Alloy Base Composite With Al2O3 Particle Additionsavencl100% (1)

- Corrosion Behaviour of The As-Cast and Heat-Treated ZA27 AlloyDocumento7 pagineCorrosion Behaviour of The As-Cast and Heat-Treated ZA27 AlloyavenclNessuna valutazione finora

- Cylindrical Gears Modeling Using CATIA SoftwareDocumento5 pagineCylindrical Gears Modeling Using CATIA Softwareavencl100% (2)

- Tribological Properties of Al-Si Alloy A356 Reinforced With Al2O3 ParticlesDocumento5 pagineTribological Properties of Al-Si Alloy A356 Reinforced With Al2O3 ParticlesavenclNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Unban FormsDocumento74 pagineUnban FormsNoob ab AbNessuna valutazione finora

- D72140GC10 46777 UsDocumento3 pagineD72140GC10 46777 UsWilliam LeeNessuna valutazione finora

- 6303A HP Flare Drain DrumDocumento16 pagine6303A HP Flare Drain DrumMohammad MohseniNessuna valutazione finora

- Unit V DSS Development: Arun Mishra 9893686820Documento17 pagineUnit V DSS Development: Arun Mishra 9893686820Arun MishraNessuna valutazione finora

- Unit4questions 100415042439 Phpapp01Documento4 pagineUnit4questions 100415042439 Phpapp01Mohamad HishamNessuna valutazione finora

- Geometric Design of Highways for EngineersDocumento39 pagineGeometric Design of Highways for EngineersZeleke TaimuNessuna valutazione finora

- P108Documento1 paginaP108teban09Nessuna valutazione finora

- ALTERNATOR - ST170741: Parts ListDocumento2 pagineALTERNATOR - ST170741: Parts Listkaswade BrianNessuna valutazione finora

- SPP 40 Series Sponsored BE MTech Projects CollegewiseDocumento145 pagineSPP 40 Series Sponsored BE MTech Projects CollegewiseVinay KumarNessuna valutazione finora

- India's Growing Social Media Landscape and Future TrendsDocumento5 pagineIndia's Growing Social Media Landscape and Future Trendspriyaa2688Nessuna valutazione finora

- Deutz 1013Documento3 pagineDeutz 1013Retno Pudji LestariNessuna valutazione finora

- Touch Screen TechnologyDocumento18 pagineTouch Screen TechnologySmîlērNessuna valutazione finora

- JEDI Slides Intro1 Chapter 02 Introduction To JavaDocumento17 pagineJEDI Slides Intro1 Chapter 02 Introduction To JavaredbutterflyNessuna valutazione finora

- حل جميع المعادلات الكهربائيةDocumento60 pagineحل جميع المعادلات الكهربائيةGandhi HammoudNessuna valutazione finora

- Breaking Water Protection Paradigms: RTM Composite DomesDocumento52 pagineBreaking Water Protection Paradigms: RTM Composite DomesaerostressNessuna valutazione finora

- Kosice Schulze Bramey PDFDocumento13 pagineKosice Schulze Bramey PDFandrel_fariasNessuna valutazione finora

- Vantio CacheServe 7.2.0 Administrators Manual 20161208 PDFDocumento577 pagineVantio CacheServe 7.2.0 Administrators Manual 20161208 PDFPaulette Servin100% (1)

- CSE 390 Bash Command ReferenceDocumento3 pagineCSE 390 Bash Command Referencesam100% (1)

- Oracle SCM TrainingDocumento9 pagineOracle SCM TrainingVishnu SajaiNessuna valutazione finora

- Write Like An Academic: Designing An Online Advanced Writing Course For Postgraduate Students and ResearchersDocumento9 pagineWrite Like An Academic: Designing An Online Advanced Writing Course For Postgraduate Students and ResearchersLexi TronicsNessuna valutazione finora

- Teradata Version DifferencesDocumento3 pagineTeradata Version DifferencesShambuReddy100% (1)

- Player Alex's SEO-Optimized Character Sheet for Antero VipunenDocumento2 paginePlayer Alex's SEO-Optimized Character Sheet for Antero VipunenAlex AntiaNessuna valutazione finora

- Tda 1526Documento15 pagineTda 1526Adilcio Melo0% (1)

- Nazneen Wahab CVDocumento5 pagineNazneen Wahab CVRavi MittalNessuna valutazione finora

- Sample Lab ReportDocumento4 pagineSample Lab ReportHolley WrightNessuna valutazione finora

- Geo-Informatics and Nano-Technology For Precision FARMING (AGRO-301) 5 SemesterDocumento5 pagineGeo-Informatics and Nano-Technology For Precision FARMING (AGRO-301) 5 SemesterVinod Vincy67% (3)

- JupaCreations BWCGDocumento203 pagineJupaCreations BWCGsoudrack0% (1)

- Advanced Excel FormulasDocumento25 pagineAdvanced Excel Formulasskmohit singhalNessuna valutazione finora

- Turkle Sherry What Does Simulation Want PDFDocumento11 pagineTurkle Sherry What Does Simulation Want PDFmonterojuNessuna valutazione finora

- The Five Generations of Computers: AssignmentDocumento10 pagineThe Five Generations of Computers: Assignmentjismon_kjNessuna valutazione finora