Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Valdyn Design Valvetrain Timing Drive

Caricato da

stefan.vince536Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Valdyn Design Valvetrain Timing Drive

Caricato da

stefan.vince536Copyright:

Formati disponibili

The Use of VALDYN in the Design of the Valvetrain and Timing Drive of the new Ferrari V8 Engine

Domenico Noceti Ferrari Maranello, Italy

Riccardo Meldolesi Ricardo Consulting Engineers Ltd, UK

Abstract

Figure 1: Front engine view

A fully dynamic model of the cranktrain and timing drive of the Ferrari V8 engine was developed using the computer program VALDYN with the objective of understanding the interactions amongst the various components. The intent was to design the components to allow good control of the valve motion and the forces in the system. Results of a parametric study at low engine speed and low power output are presented. The work provided a thorough understanding of the factors affecting the phenomenon of rattling noise in the gears of the timing drive.

Introduction The Ferrari philosophy is to use the most advanced technologies to design and develop sportcars with a unique character. This is achieved utilising materials and design tools that were successfully tested in the highly competitive world of Formula One. The Ricardo software VALDYN is already a well established tool for the optimisation of valvetrains in Formula One engines [1]. VALDYN has since proved a very valuable tool for the analysis of the whole timing drive. In Ferrari the program was utilised for the optimisation of the new 3.5 litre V8 engine, for the successor of the F 355, the Ferrari two seater, mid engined sportscar. For the study of the engine, which is shown in Figure 1, three different models were developed: A fully detailed model of a single valvetrain, to simulate the valve dynamics (Figure 2) A simplified model of the whole timing drive, suitable for simulating the engine in conditions when the timing drive is not significantly influenced by the cranktrain, such as low speed, low power demand (Figure 3) A fully detailed model of the whole timing drive and cranktrain, to investigate any working condition of the model (Figure 4) This paper presents the results of the parametric activity carried out with the second model for light load, low speed, looking in particular at the behaviour of the first stage gear reduction.

Figure 2: Single Valvetrain Model

Figure 3: Low Speed Model

Figure 4: Complete Model 3

Background The new Ferrari engine is an uprated version of the existing V8 used on the F 355 car. The improvement of engine performance, in terms of both power and driveability, was achieved by increasing the engine displacement and introducing new features, including: Increased inlet and exhaust valve size New intake and exhaust port geometry New and more aggressive cam profiles Variable geometry intake system Variable exhaust valve timing

The adoption of more aggressive cam profiles and camshaft phase changing devices increased the torque required to drive the camshafts as well as their rotational inertia. At the same time the use of materials and surface treatments suitable for the reduction of friction losses reduced the damping in the system. The choice of two stage reduction in the timing drive follows from the need for: High volumetric efficiency High combustion efficiency Which in turn dictates: Five valves per cylinder arranged radially in order to achieve a hemispherical shaped combustion chamber Small angle between inlet and exhaust valves Direct attack valvetrain layout with hydraulic bucket tappet

Figure 5: First stage gear reduction

This resulted in a very compact design of the cylinder head, giving a short distance between the axis of the two overhead camshafts. The impossibility to accommodate large diameter pulleys for the drive by the toothed timing belt made the adoption of a two stage reduction unavoidable. The first motion reduction is achieved via three gears as displayed in Figure 5, one on the crank nose and the other two in either side of it, to transmit the motion to the two cylinder rows. The gear ratio is 1.5. The second stage is realised via two conventional toothed belts, one for each cylinder row. The total gear ratio between crankshaft and camshafts being two and 3/2 being already implemented in the gear drive, the timing belt drive reduces the motion with a ratio of 4/3 (Figure 6). This layout for the timing drive results in a very compact and stiff design, that contributes to achieving precise control of the valve event, ensuring high performance and low emissions. The downside of this architecture is a cost increase and possibility of generating gear rattle noise from the first stage reduction. The rattle noise would not be a problem on racing applications, but it must be avoided on road cars.

Figure 6: Belt drive

Other aspects considered in the design and development stage were: Reliability Sound quality Good refinement With these objectives in mind a dynamic analysis of valvetrains and timing drive was carried out with the purpose of verifying the design. Identification of rattle The rattle noise is caused by the torque reversals making the gears separate and impact. The energy involved in the impact is transmitted to the gear supports with a broad frequency content, characteristic of impact events. The gearcase vibrates at its natural frequency, excited by the different orders of the force on the gear supports. The gearcase vibrations are then transformed into sound noise and radiated outward. Modelling approach The assumptions made during the modelling of the system to investigate the low speed conditions were: Camshaft mass concentrated into two masses representing the camshaft and the camshaft pulley-cam phaser assembly Simple model of the valvetrain, with constant linear stiffness of the hydraulic lash adjuster. The valve springs were modelled as a constant linear stiffness and the mass of the active coils of the springs included into the valve mass The two exhaust valves of each cylinder were grouped together doubling mass, stiffness and damping values of a single valve. This allowed the size of the model to be reduced. The accuracy of the predictions were not reduced by this simplification, since the camshafts were simulated as infinitely stiff The same was done for the two side inlet valves, but the central one had to be modelled separately, since its timing is offset with respect to the others Simplified modelling of the crankshaft with a two mass, single stiffness system, tuned to the crankshaft natural frequency; this allows the crankshaft to react to the forces coming from the timing drive gears. One of the masses is concentrated on the crankshaft nose, where the timing drive gear is located. The second crankshaft mass was moved at a constant angular velocity to simulate the condition of light load, where the angular speed variation due to cylinder pressure and crankshaft torsional vibrations can be neglected Apart from these simplifications, all the rest of the system was modelled in all its details [2]: The gear support stiffnesses were modelled, together with the tooth pressure angle, tooth stiffness [3], tooth damping, gear assembly mass and polar inertia In addition, the gear backlash was modelled and used as a parameter in the parametric study

The timing belt was modelled using the specific VALDYN element that reacts with a force only when the timing belt is stretched The effect of the tensioner arm rotation on the timing belt tension was also implemented The belt tensioners were also fully modelled, including expansion spring, internal check valve, volume of the high pressure oil chamber, leaking passages and piston mass Results The analysis of the VALDYN results showed that, in the load conditions examined, the main source of excitation in the system comes from the valve actuation. Because the valvetrain is designed to run up to very high speeds, the valve spring loads required to keep the valves under control are very high, needing to be greater than the inertia forces on the valvetrain, that vary with the engine speed square. As a consequence at low speeds, where the inertia relief is low, the cam to tappet contact forces are high over the whole opening cycle; this results in high friction and a requirement for considerable levels of torque to drive the camshafts. Figure 7 shows a plot of the torque to drive the inlet camshaft at 1800 rev/min;

Figure 7: Camshaft driving torque at 1800 rev/min The harmonic content of the camshaft torque when an infinite camshaft torsional stiffness is assumed, shows harmonics at multiples of four camshaft revolutions, as shown on Figure 8.

Figure 8: Harmonic content of camshaft driving torque at 1800 rev/min

The different harmonics excite the timing drive causing torsional vibrations of the system according to its natural modes. Figure 9 Shows the first two mode shapes of the timing drive torsional vibrations, where one of the nodes is always close to the belt pulley driven by the crankshaft via the gear reduction stage. This is because the cranktrain inertia is much greater than the one of the camshafts. For the way the vibrations occur, the mode that is more likely to cause gear rattle noise is the first mode, because this mode of vibration generates torque reversal on the gears.

First Mode

Second Mode

Figure 9: Modes of vibration of the timing drive As in the more familiar case of crankshaft torsional vibrations, when the engine speed varies, the different harmonics of the camshaft torque excite the timing drive that vibrate in a combination of its natural modes. Generally the first mode prevails on the others in magnitude. When the frequency of an excitation coincides with the natural frequency of the first mode, a peak in the vibration amplitude is observed. For timing drive systems the cam torque harmonics that have significant amplitudes are the 12th, 8th and 4th; These, expressed in engine orders, become the 6th, 4th and 2nd, as displayed in Figure 10.

Second Order

Sixth Order

Fourth Order

Figure 10: Order plot of the Belt force in the tight span, right side

At the resonance speeds, energy is fed into the systems and it is dissipated into the timing belt and impacts when the backlashes present in the system close, particularly the ones in the first stage gear reduction. This phenomenon is shown in Figure 11 a-d, that contains the results of the simulation at the 6th order resonance speed of 1800 rev/min. Figure 11a shows the time history of the force in the tight side of the drive to the first camshafts. This gives alternate contacts between the gear teeth from the driving side (Figure 11b) to the trailing side (Figure 11c). The effect of these impacts can be detected into the gear support forces (Figure 11d) as high frequency vibrations that can cause noise. The effect of speed variation on the gear support forces can be seen in Figure 12 a-d: At 600 rev/min there is no resonance and the impacts are not severe

At 1800 rev/min the 6th order is in resonance and energy is fed into the impacts At 2200 rev/min there is no resonance as the speed lays in between the two resonances of the 6th and 4th order and the impacts are less severe (see also figure 14) At 2800 rev/min there is the 4th order resonance and again the impacts are more severe The result in terms of noise emission are displayed in Figure 13. These measurements were taken with a close field microphone and setting large values for the gear backlash. They show high noise at 1750 rev/min which is attributed to the 6th order resonance,a quiet period between 2000 and 2500 rev/min and high noise from 2500 rev/min upwards. In order to control the timing drive dynamics and the noise emissions, it is important to gain a good understanding of the system and the effect of the many design parameters of the whole valve actuation system. This was done undertaking a parametric study with VALDYN. Parametric study The transmission of gear rattle noise outside the engine is mainly structural rather than airborne. Therefore, the forces that excite the engine structure are an appropriate measure of noise level in the parametric study. It was decided to use the magnitude of the gear support forces instead of the tooth contact forces; this is because the latter had proved to be too nervous and too much influenced by the level of tooth damping to be reliable. The parametric study was undertaken on the following parameters and features: Gear backlash Gear inertia Split gears Belt tensioner Belt pretension Tooth stiffness Valve springs Camshaft damper

Figure 11 a (top) to d (bottom): Generation of gear rattle

10

Figure 12 a (top) to d (bottom): Time histories of gear support forces at various speeds

11

4000

3000 Rpm Measured 2000

Pa (dB A)

1000

1000

2000

Hz

3000

4000

5000

Figure 13: Noise measurements (Close field microphone, high tooth backlash) The results of the above parametric study were: Gear backlash The backlash was set to three different values: 0 m 35 m (baseline) 80 m

The results are shown in Figure 14. As it can be seen, the gear support force shows a significant sensitivity to the backlash. It allows placement of a lower limit to the force level achievable changing only the gear backlash. A higher limit is also set, as the rattle noise will arise inevitably as the backlash is increased. The results for the baseline and the cases with zero tooth backlash will be shown in dashed lines in all the following graphs as a background reference Gear inertia When thinking of a body hit with an hammer, it can be imagined that, leaving the impact velocity constant, the impact energy will depend on the hammer size [5]; in the same way, the range of the gear support force is affected by the gear inertia. Figure 15 shows that reducing the gear inertia reduces the gear support forces and vice versa. A reduction in the gear inertia can be achieved by keeping it as narrow as possible and having lightening holes in the hub. Tests at Ferrari though showed that fitting the gears with discs of high damping material like copper or cast iron, can reduce the noise emission significantly, despite the increase in the gear inertia. It follows that the best solution is to make the gears the lightest possible and then fit them with copper discs to increase their intrinsic damping. Split gears A split gear is composed by two gears connected together by a torsional spring that has a preload, which allows the gear to operate avoiding or sensibly reducing the amount of contact in the back side of the teeth.

12

Figure 14: Effect of gear backlash

Figure 15: Effect of gear inertia

This results in a reduction of the support forces, as displayed in Figure 16. The downside of this option is the increase in friction and in the cost of producing split gears. Belt tensioner The belt tensioner is responsible for keeping the belt in tension and for this purpose has a spring that assures initial tension in the belt; this spring has relatively low stiffness, in order to compensate the thermal expansion without varying the preload too much. The tensioner also has a chamber filled with oil that has its own compressibility which is proportional to the volume of the high pressure chamber itself. Reducing this volume, increases the stiffness of the drive and the resonance speeds as can be seen on Figure 17. The figure also shows that the forces on the gear supports increase as well and this is not wanted. There is also a lower limit to the tensioner stiffness, because the lower the stiffness the higher the amplitude of the vibrations; when the engine is running at full load and the crankshaft torsional vibrations are significant this can create problems of cam timing accuracy. Belt pretension The belt pretension was tested at two completely different levels: 125 N 1250 N (baseline)

The first value allows the belt to go slack, whilst the second exclude any loss of tension in the belt. The results are shown in Figure 18, where it can be seen that the range of the gear support force is not affected very much. Therefore it is advisable to keep the belt pretension at moderately low values in order not to overload the belt and increase its life.

13

Figure 16: Effect of split gears Tooth stiffness The tooth stiffness was set to two levels: 2.1 * 106 N/mm (baseline) 1.5 * 106 N/mm

Figure 17: Effect of tensioner stiffness

Usually increasing the compliance in the region close to the impact point reduces the peaks of the impact forces. In this case though, the simulations showed that the effect was negligible. Valve springs At low speed the valve actuation is the main excitation of the timing drive; hence, any reduction in the spring load via an optimisation of their design and a reduction of the valvetrain mass results in a reduction in friction and in camshaft driving torque that is responsible for feeding energy into the tooth impacts. Figure 19 shows what can be achieved reducing the total spring fitted force and the spring rate by 20%. Camshaft damper The use of camshaft torsional vibration dampers is an option when other attempts to reduce the cam TVs have proved insufficient [6]. Camshaft dampers are unusual in these kind applications and represent an extra cost for the engine. Their use though is possible and can be very effective. In the Ferrari V8 the use of the damper was simulated (Figure 20). Its effect was to smooth away all the peaks in the gear support forces.

14

Figure 18: Effect of belt preload

Figure 19: Effect of reduction in spring force

Figure 20: Effect of camshaft damper

15

Conclusions The use of VALDYN in the simulation of timing drive dynamics quantified the effect of the various design parameters on generating gear rattle noise. From the analysis it emerged that the key point is to control the energy involved in the impact and this can be done by: Implementing a tight control on the value of gear backlash When dealing with gear inertia, making the gears as light as possible and then fitting them with elements that increase their intrinsic damping. Adopting a split gear that can operate avoiding or sensibly reducing the amount of rattle; this results in a reduction of the support forces. Appropriately tuning the oil volume in the high pressure chamber of the belt tensioner. Setting the lowest possible values for valve spring fitted force and spring rate. Fitting a suitably tuned camshaft torsional vibration damper The parameters that did not show significant effects on the generation of gear rattle noise were: Belt pretension level Tooth stiffness. VALDYN has proved to be a very valuable tool for the concept study and the development of the engine. The results of the simulations allowed decisions to be made on the design and development of this new power unit at Ferrari. References: 1 Guido di Paola, Ferrari racing team: The use of VALDYN in the design of Formula 1 valvetrains - Proceedings of the 2nd Ricardo Software International User Conference, Detroit, 28 February 1997 2 Valdyn 2.0 user manual - Ricardo Consulting Engineers 3 MAAG Gear Company Maag Gear Book - ed 1990 4 William T. Thomson Theory of vibrations with applications ed Chapman and Hall, Fifth edition 1998 5 J. Derek Smith: Gears and their vibrations Macmillian Press Ltd. - 1983 6 Ker Wilson Practical solution of torsional vibration problems, Chapman and Hall, Third edition 1968

16

Potrebbero piacerti anche

- Tribological Processes in the Valve Train Systems with Lightweight Valves: New Research and ModellingDa EverandTribological Processes in the Valve Train Systems with Lightweight Valves: New Research and ModellingValutazione: 1.5 su 5 stelle1.5/5 (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- Analysis of Change in Intake Manifold Length and Development of Variable Intake SystemDocumento6 pagineAnalysis of Change in Intake Manifold Length and Development of Variable Intake SystemDarius TothNessuna valutazione finora

- Some Critical Technical Issues On The Steady Flow Testing of Cylinder HeadsDocumento16 pagineSome Critical Technical Issues On The Steady Flow Testing of Cylinder HeadsPrateek SinghNessuna valutazione finora

- Camshaft Design For An Inlet Restricted FSAE EngineDocumento10 pagineCamshaft Design For An Inlet Restricted FSAE EngineAllan MachadoNessuna valutazione finora

- The Basics of Valvetrain TechnologyDocumento9 pagineThe Basics of Valvetrain TechnologyChristina SchultzNessuna valutazione finora

- Efr Turbo Technical BriefDocumento126 pagineEfr Turbo Technical BriefTM125Nessuna valutazione finora

- Design of Intake ManifoldDocumento6 pagineDesign of Intake ManifoldShailendra SinghNessuna valutazione finora

- Boxer Engine: Group 4 MembersDocumento3 pagineBoxer Engine: Group 4 MembersHamed Quenta AlvarezNessuna valutazione finora

- Dallara P217 LMP2: User ManualDocumento25 pagineDallara P217 LMP2: User ManualarthurvalinhoNessuna valutazione finora

- Cosworth Performance Tuning Components Catalogue 2011Documento48 pagineCosworth Performance Tuning Components Catalogue 2011luisribeiropinhal100% (1)

- LOLA Racecar 2Documento14 pagineLOLA Racecar 2Marcos SoarNessuna valutazione finora

- RS - Petronas FP1 Engine DevelopmentDocumento49 pagineRS - Petronas FP1 Engine DevelopmentAiddie GhazlanNessuna valutazione finora

- Theissen 10 Years of BMW F1 EnginesDocumento17 pagineTheissen 10 Years of BMW F1 EnginesBlaze123xNessuna valutazione finora

- Whitepaper: Engine Intake OptimizationDocumento10 pagineWhitepaper: Engine Intake OptimizationgosculptorNessuna valutazione finora

- Dallara f308 Owners Manual 2013 AprobDocumento54 pagineDallara f308 Owners Manual 2013 AprobblancohccNessuna valutazione finora

- Intake and Exhaust Manifold DesignDocumento28 pagineIntake and Exhaust Manifold DesignDarius Toth100% (3)

- IMSA Lites1 Homologation Elan DP02 29thmay08Documento13 pagineIMSA Lites1 Homologation Elan DP02 29thmay08Keine Angbe100% (1)

- Choosing The Perfect Performance CamshaftDocumento9 pagineChoosing The Perfect Performance CamshaftDesotoJoe100% (1)

- Corky Bell Maximum BoostDocumento207 pagineCorky Bell Maximum BoostAerankasNessuna valutazione finora

- RCE CamsDocumento5 pagineRCE CamsAneesh Kalra100% (2)

- F308manual v03Documento40 pagineF308manual v03John McGillNessuna valutazione finora

- Cosworth StoryDocumento32 pagineCosworth StoryTanoV12-Formula1AmarcordNessuna valutazione finora

- Engine ExhaustDocumento18 pagineEngine ExhaustDivya Anurag DimriNessuna valutazione finora

- Grand Prix Motorcycle Engine Development Over Last 60 YearsDocumento35 pagineGrand Prix Motorcycle Engine Development Over Last 60 YearsShaswata Panja100% (1)

- CFD Analysis of Non-Symmetrical Intake Manifold For Formula SAE CarDocumento11 pagineCFD Analysis of Non-Symmetrical Intake Manifold For Formula SAE CarGtatlisNessuna valutazione finora

- Intake Plenum Volume and Its Influence On Engine PerformanceDocumento6 pagineIntake Plenum Volume and Its Influence On Engine PerformanceRidhan Riyal100% (1)

- GDIDocumento30 pagineGDIMartinchemNessuna valutazione finora

- Exhaust Manifold DesignDocumento30 pagineExhaust Manifold DesignSandeep Kr. MishraNessuna valutazione finora

- Technical Service Department 360 Modena UpdatesDocumento328 pagineTechnical Service Department 360 Modena UpdatesDoppel Vergaser100% (1)

- Lap Sim EngineDocumento5 pagineLap Sim Engineblack_oneNessuna valutazione finora

- Subaru FA20 D-4S Engine PaperDocumento18 pagineSubaru FA20 D-4S Engine Paperstefan.vince536100% (1)

- PA10 0132 Technical Manual GT3 CUP 991 2014 v2.6 enDocumento320 paginePA10 0132 Technical Manual GT3 CUP 991 2014 v2.6 enjlee_296737Nessuna valutazione finora

- F1 EnginesDocumento11 pagineF1 Enginessachin_sawant1985Nessuna valutazione finora

- Cam DesignDocumento56 pagineCam DesignmdrehmerNessuna valutazione finora

- Daytona CS ArticleDocumento4 pagineDaytona CS ArticleIan WilliamsNessuna valutazione finora

- OptimunG Springs&Dampers Tech Tip 3Documento4 pagineOptimunG Springs&Dampers Tech Tip 3Thomas Moura100% (1)

- JRZ Suspension EngineeringDocumento25 pagineJRZ Suspension EngineeringRajaSekarsajja100% (1)

- Adjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersDocumento13 pagineAdjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersJ.d. LangleyNessuna valutazione finora

- Penske 7800 Technical ManualDocumento12 paginePenske 7800 Technical ManualgeorgeNessuna valutazione finora

- Vincent TechnicalDocumento58 pagineVincent TechnicalCiprian MaiorNessuna valutazione finora

- Cosworthstory PDFDocumento25 pagineCosworthstory PDFmicheleNessuna valutazione finora

- Honda V8 F1 EngineDocumento5 pagineHonda V8 F1 EngineAlessio Scarabelli100% (2)

- Turbo Tech 102 - Advanced: Understanding Air FlowDocumento10 pagineTurbo Tech 102 - Advanced: Understanding Air FlowrodrigoracingNessuna valutazione finora

- SSP 341 4.2l V8 5V EngineDocumento41 pagineSSP 341 4.2l V8 5V EngineAcorda Iacanga SPNessuna valutazione finora

- Formula SAE Performance Exhaust DesignDocumento65 pagineFormula SAE Performance Exhaust Designpaulo negaoNessuna valutazione finora

- Puma Race Engines PDFDocumento8 paginePuma Race Engines PDFpichaidvNessuna valutazione finora

- Haltech f9v5 ManualDocumento99 pagineHaltech f9v5 ManualboxyhenricNessuna valutazione finora

- Secrets of A Cam DesignerDocumento40 pagineSecrets of A Cam Designerncampagna8134100% (2)

- Runner Size CalculationDocumento14 pagineRunner Size CalculationLuciano Rosado Soccol100% (4)

- Building High Performance Engines 2Documento26 pagineBuilding High Performance Engines 2lone_anarchistNessuna valutazione finora

- Chrysler's Motown Missile: Mopar's Secret Engineering Program at the Dawn of Pro StockDa EverandChrysler's Motown Missile: Mopar's Secret Engineering Program at the Dawn of Pro StockNessuna valutazione finora

- Bullit Owner Manual Hero enDocumento86 pagineBullit Owner Manual Hero enstefan.vince536Nessuna valutazione finora

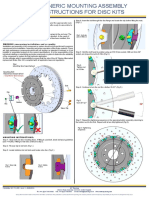

- Spare Parts For Endless CalipersDocumento4 pagineSpare Parts For Endless Calipersstefan.vince536Nessuna valutazione finora

- SFM125 Roadster 2013 K157FMI Big Bore 150cc L230 Camshaft 115mm JetDocumento1 paginaSFM125 Roadster 2013 K157FMI Big Bore 150cc L230 Camshaft 115mm Jetstefan.vince536Nessuna valutazione finora

- Whitepaper Bezinal XP XCDocumento4 pagineWhitepaper Bezinal XP XCBalakrishnan RagothamanNessuna valutazione finora

- ISR Brake Hose FittingsDocumento4 pagineISR Brake Hose Fittingsstefan.vince536Nessuna valutazione finora

- PFC Caliper CatalogueDocumento34 paginePFC Caliper Cataloguestefan.vince536Nessuna valutazione finora

- 10 Years of Excellence: Phone: +46 171 443488 Fax: +46 171 443489 Mobile: +46 709 137203 E-Mail: Info@endless-Brake - InfoDocumento6 pagine10 Years of Excellence: Phone: +46 171 443488 Fax: +46 171 443489 Mobile: +46 709 137203 E-Mail: Info@endless-Brake - Infostefan.vince536Nessuna valutazione finora

- Brake To Wheel Clearance TutorialDocumento5 pagineBrake To Wheel Clearance Tutorialstefan.vince536Nessuna valutazione finora

- Effect of Compression On T H E Shear Modulus of Rubber: of of of of of of ofDocumento3 pagineEffect of Compression On T H E Shear Modulus of Rubber: of of of of of of ofstefan.vince536Nessuna valutazione finora

- Dynamics of Torsional Vibration Damper (TVD) Pulley, Implementation of A Rubber Elastomeric Behavior, Simulations and ExperimentsDocumento20 pagineDynamics of Torsional Vibration Damper (TVD) Pulley, Implementation of A Rubber Elastomeric Behavior, Simulations and Experimentsstefan.vince536Nessuna valutazione finora

- Technical Data Sheet - Brake Caliper: This Caliper Is Designed To Operate Within The Following ParametersDocumento1 paginaTechnical Data Sheet - Brake Caliper: This Caliper Is Designed To Operate Within The Following Parametersstefan.vince536Nessuna valutazione finora

- P14.289 Issue 3 - 30-06-2014Documento1 paginaP14.289 Issue 3 - 30-06-2014stefan.vince536Nessuna valutazione finora

- (23005319 - Acta Mechanica Et Automatica) A Study of The Preload Force in Metal-Elastomer Torsion SpringsDocumento6 pagine(23005319 - Acta Mechanica Et Automatica) A Study of The Preload Force in Metal-Elastomer Torsion Springsstefan.vince536Nessuna valutazione finora

- Engine Vibration: 180 Zoar Valley Road - Springville, Ny 14141Documento16 pagineEngine Vibration: 180 Zoar Valley Road - Springville, Ny 14141stefan.vince536Nessuna valutazione finora

- Automotive Camshaft Design PDFDocumento120 pagineAutomotive Camshaft Design PDFstefan.vince536Nessuna valutazione finora

- DB 601A Flight 7nov40Documento4 pagineDB 601A Flight 7nov40stefan.vince536Nessuna valutazione finora

- CFD AidedDesignofanAirBoxforRaceCarDocumento11 pagineCFD AidedDesignofanAirBoxforRaceCarstefan.vince536Nessuna valutazione finora

- Development of Stainless Steel Sheets For Cylinder Head GasketDocumento7 pagineDevelopment of Stainless Steel Sheets For Cylinder Head Gasketstefan.vince536Nessuna valutazione finora

- Wheel Hub Fatigue Performance Under Non Constant Rotational Loading and Comparison To Eurocycle TestDocumento8 pagineWheel Hub Fatigue Performance Under Non Constant Rotational Loading and Comparison To Eurocycle Teststefan.vince536Nessuna valutazione finora

- Def Stan 00-970Documento11 pagineDef Stan 00-970stefan.vince536Nessuna valutazione finora

- Vector Vibration DamperDocumento6 pagineVector Vibration Damperstefan.vince536Nessuna valutazione finora

- Fulltext02 PDFDocumento143 pagineFulltext02 PDFstefan.vince536Nessuna valutazione finora

- Vector PDFDocumento6 pagineVector PDFstefan.vince536Nessuna valutazione finora

- Balancing Act - Drag Racing ActionDocumento3 pagineBalancing Act - Drag Racing Actionstefan.vince536Nessuna valutazione finora

- Camaro Z28 Tech Backgrounder 2013 PDFDocumento45 pagineCamaro Z28 Tech Backgrounder 2013 PDFstefan.vince536Nessuna valutazione finora

- Design of Crush Height For Reliable Press Fit of High Performance BearingsDocumento9 pagineDesign of Crush Height For Reliable Press Fit of High Performance Bearingsstefan.vince536Nessuna valutazione finora

- 2018 Isky CatalogDocumento186 pagine2018 Isky Catalogstefan.vince536Nessuna valutazione finora

- MMM 744 B77 Mum.: Hunt MMDocumento6 pagineMMM 744 B77 Mum.: Hunt MMstefan.vince536Nessuna valutazione finora

- Automotive Camshaft Design PDFDocumento120 pagineAutomotive Camshaft Design PDFstefan.vince536Nessuna valutazione finora

- Getting Inside The Power Cylinder - v3Documento27 pagineGetting Inside The Power Cylinder - v3stefan.vince536Nessuna valutazione finora

- Necromunda CatalogDocumento35 pagineNecromunda Catalogzafnequin8494100% (1)

- Alto Hotel Melbourne GreenDocumento2 pagineAlto Hotel Melbourne GreenShubham GuptaNessuna valutazione finora

- Agency Procurement Request: Ipil Heights Elementary SchoolDocumento1 paginaAgency Procurement Request: Ipil Heights Elementary SchoolShar Nur JeanNessuna valutazione finora

- ProjectDocumento22 pagineProjectSayan MondalNessuna valutazione finora

- L5T-112 Manual - 2007 - Issue 1.1 PDFDocumento16 pagineL5T-112 Manual - 2007 - Issue 1.1 PDFfluidaimaginacionNessuna valutazione finora

- A Tall Order - Cooling Dubai's Burj Khalifa: FeatureDocumento2 pagineA Tall Order - Cooling Dubai's Burj Khalifa: FeatureMohsin KhanNessuna valutazione finora

- GladioDocumento28 pagineGladioPedro Navarro SeguraNessuna valutazione finora

- Name of The Business-Rainbow Blooms LLC. Executive SummaryDocumento17 pagineName of The Business-Rainbow Blooms LLC. Executive SummaryAhamed AliNessuna valutazione finora

- Chapter S1 (Celestial Timekeeping and Navigation)Documento28 pagineChapter S1 (Celestial Timekeeping and Navigation)Марко Д. Станковић0% (1)

- Model DPR & Application Form For Integrated RAS PDFDocumento17 pagineModel DPR & Application Form For Integrated RAS PDFAnbu BalaNessuna valutazione finora

- Technology ForecastingDocumento38 pagineTechnology ForecastingSourabh TandonNessuna valutazione finora

- Catalogo Escavadeira EC27CDocumento433 pagineCatalogo Escavadeira EC27CNilton Junior Kern50% (2)

- PRINCIPLES OF TEACHING NotesDocumento24 paginePRINCIPLES OF TEACHING NotesHOLLY MARIE PALANGAN100% (2)

- Papalia Welcome Asl 1 Guidelines 1 1Documento14 paginePapalia Welcome Asl 1 Guidelines 1 1api-403316973Nessuna valutazione finora

- دور أخلاقيات الأعمال في تحسين أداء المنظماتDocumento14 pagineدور أخلاقيات الأعمال في تحسين أداء المنظماتChaima LaifaNessuna valutazione finora

- (QII-L2) Decorate and Present Pastry ProductsDocumento30 pagine(QII-L2) Decorate and Present Pastry ProductsLD 07100% (1)

- ADMT Guide: Migrating and Restructuring Active Directory DomainsDocumento263 pagineADMT Guide: Migrating and Restructuring Active Directory DomainshtoomaweNessuna valutazione finora

- Group 4&5 Activity Syntax AnalyzerDocumento6 pagineGroup 4&5 Activity Syntax AnalyzerJuan PransiskoNessuna valutazione finora

- Hauling AgreementDocumento2 pagineHauling AgreementE.A. Francisco Trucking100% (3)

- OMM 618 Final PaperDocumento14 pagineOMM 618 Final PaperTerri Mumma100% (1)

- Different Principles Tools and Techniques in Creating A BusinessDocumento5 pagineDifferent Principles Tools and Techniques in Creating A BusinessLuna LedezmaNessuna valutazione finora

- OracleCarrierManifestingPartnerIntegration PDFDocumento40 pagineOracleCarrierManifestingPartnerIntegration PDFvishal_vishnu11Nessuna valutazione finora

- Categories of Cargo and Types of ShipsDocumento14 pagineCategories of Cargo and Types of ShipsVibhav Kumar100% (1)

- Influence of Freezing and Pasteurization of The Physical Condition of The Plastik (PE, PP and HDPE) As Selar Fish Packaging (Selaroides Leptolepis) in Sendang Biru, Malang, East Java. IndonesiaDocumento7 pagineInfluence of Freezing and Pasteurization of The Physical Condition of The Plastik (PE, PP and HDPE) As Selar Fish Packaging (Selaroides Leptolepis) in Sendang Biru, Malang, East Java. IndonesiaInternational Network For Natural SciencesNessuna valutazione finora

- TABEL Sifat Uap Jenuh Tabel Suhu Dan TekananDocumento8 pagineTABEL Sifat Uap Jenuh Tabel Suhu Dan Tekanan21-002 Alditua sinabaribaNessuna valutazione finora

- Sheet (8) Synchronous Machine Problem (1) :: SolutionDocumento5 pagineSheet (8) Synchronous Machine Problem (1) :: Solutionمكاريوس عيادNessuna valutazione finora

- Assignment 1 Brief: ScenarioDocumento4 pagineAssignment 1 Brief: ScenarioChâu TrầnNessuna valutazione finora

- (Kazantzakis Nikos) Freedom or DeathDocumento195 pagine(Kazantzakis Nikos) Freedom or DeathTarlan FisherNessuna valutazione finora

- Types of Intermolecular ForcesDocumento34 pagineTypes of Intermolecular ForcesRuschan JaraNessuna valutazione finora

- 0409 Book About Minoru Yamasaki, ReviewDocumento4 pagine0409 Book About Minoru Yamasaki, RevieweviannNessuna valutazione finora