Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hakko 936 Schem-Pcb & Mod v1r7

Caricato da

dona8423Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hakko 936 Schem-Pcb & Mod v1r7

Caricato da

dona8423Copyright:

Formati disponibili

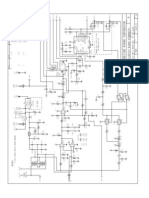

HAKKO 936 - Schematic

Rendered by: Tom Hammond - NSS

MAIN PC BOARD

VREF R11 180k 1% IC2B 5 R12 130k 1% C6 .01/25v 6 _ + OUT LM324 7 100k 1 3 R13 2 4 C9 VREF R16 1k2 R15 24k0 TEMP CTRL 5k0 HEATER LED R14 1k0 .01/25V R2 1k8

26 MAR 2011

v1.7

IC1 TRIAC DRIVER NC B A C G F E D 8 7 6 5 R4 1k C4 .01/50V R3 15k

NEC* PC1701C Zero Volt Switch

VREF VCC

ALPS RK09L 1140A65 5K (502B) LINEAR

IC2C NEC PC324A Lo-Pwr Quad OpAmp U1C 10 V+ 4 + 8 OUT _ 9 11

VCC

AC

R10

680 C2 47F 16V C1 220F 50V C3 47F 16V

R6 27k0 1% VREF

1N4148

D2 LM324 D1

V-

ZD2 5.1Vz 500mW

3 R9 66k5 1%

IC2A + OUT 1

VEE

2 _ LM324

ZD1 5.1Zv 500mW R1 360 2W metal film D3 1N4007 VEE VREF

R7 5k1 1%

Note: " " = CKT GND

Q1 T1 NEC AC05D 5A TRIAC T2 G

R17 1M0 SOLDERING IRON PLUG SLEEVE GND

5

R8 390 1%

CAL CTRL

300

1 3

HANDSET SOCKET

C7 SENSOR PINS 0.1 25V

13 12

IC2D LM324 OUT 14 SOLDERING IRON/CHASSIS GND

HEATER PINS

HANDSET TIP GND

R5

1k0 1% HOT BLK

120VAC 2A

CHASSIS GND

POWER XFMR

CHASSIS GND

C5

.01/25V

GRN

AC ON/OFF PC BOARD

NEUT GND

120VAC

24VAC

WHT

CHASSIS GND

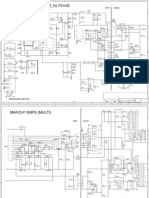

HAKKO 936 TEMPERATURE-CONTROLLED SOLDERING STATION PC BOARD LAYOUT

Rendered by: Tom Hammond, NSS 26 MAR 2011 v1.7 PC BOARD AS VIEWED FROM THE COPPER (SOLDER) SIDE

HAKKO 936 TEMPERATURE-CONTROLLED SOLDERING STATION PC BOARD LAYOUT

Rendered by: Tom Hammond, NSS 26 MAR 2011 v1.7 PC BOARD AS VIEWED FROM THE COMPONENT SIDE

HAKKO 936 TEMPERATURE-CONTROLLED SOLDERING STATION PC BOARD LAYOUT

Rendered by: Tom Hammond, NSS 26 MAR 2011 v1.7 PC BOARD AS VIEWED FROM THE COMPONENT SIDE

HEATSINK R4 Q1 R6 D1

R13 IC1 C2 +

VCC

T1 T2 G

D2 R7

VCC JP1 HTR

K A

C3 + C7 VEE VCC + C1

IC2 R2

PVR1

LED

N/C

FG

+ CN1 R15

VEE

5 4 3

1 2

R12

R10 VR2 VREF N/C R8

HAKKO 936 TEMPERATURE-CONTROLLED SOLDERING STATION PC BOARD LAYOUT

Rendered by: Tom Hammond, NSS 26 MAR 2011 v1.7 PC BOARD AS VIEWED FROM THE COMPONENT SIDE

HEATSINK

1k 100k AC05D B1081 27k 1% 1N4148 1N4148 5.1k 1% J 0.1 25v C324C 1.8k 5k 47uF 16v 47uF 16v

C1701C

24k 680 130k 1% 300

220uF 50v

390 1%

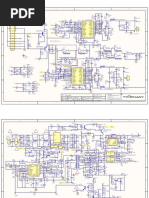

HAKKO 936-x PC Board Parts List

C1 C2 C3 C4 C5 C6 C7 C8, C10-C13 C9 D1 D2 D3 IC1 IC2 Q1 R1 R2 R3 R4 R5 R6 R7 R8 R9 R10 R11 R12 R13 R14 R15 R16 R17 ZD1 ZD2 PVR1 VR2 220uF 50V 47uF 16V 47uF 16V 0.01 (103) 50V Ceramic 0.01 (104) 25V Ceramic 0.01 (104) 25V Ceramic 0.1 (104) 25V Ceramic n/a 0.01 (104) 25V Ceramic 4N4148 Small Sig Sil, or similar 4N4148 Small Sig Sil, or similar 1N4001, or 50VDC (or higher) @ 1A NEC* PC1701C, Zero Volt Switch NEC* PC324A, Lo-Pwr Quad OpAmp NEC AC05D 5A Triac 360 2W 5% metal film 1.8k 1/4w 5% carbon film 15k 1/4w 5% carbon film 330 1/4w 5% carbon film 1.0k 1/4W 1% metal film 27.0k 1/4W 1% metal film 5.11k 1/4w 1% metal film 390 1/4w 1% metal film 66.5k 1/4w 1% metal film 680 1/4w 5% carbon film 180.0k 1/4W 1% metal film 130.0k 1/4W 1% metal film 100k 1/4w 5% carbon film 1k 1/4W 5% carbon film 24k 1/4w 5% carbon film 12k 1/4w 5% carbon film 1M 1/4w 5% carbon film 5.1Vz 500mW, 5.4Vz (measured) 5.1Vz 500mW, 5.2Vz (measured) TEMP ADJ POT - ALPS RK09L1140A65 5K (502B) LINEAR CAL TEMP POT - Bournes 3362P-1-501LF, see note below

* NOTE: NEC, is now part of Renesas Electronics Corp. CAL TEMP CTRL NOTE: In the 936, the CAL TEMP pot is 300 Ohms, however we were unable to find a pot in this physical format rated at 300 Ohms, so a 500 Ohm device has been specified as a suitable substitute.

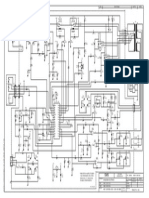

ADDING AN ON/OFF LED TO HAKKO 936-X TEMP-CONTROLLED SOLDERING STATIONS

by: Tom Hammond, NSS 03/09/2011, v.4.1

Is it turned ON or not?

By golly, it WAS, but how could you tell?

ADDING AN ON/OFF LED TO HAKKO 936-X TEMP-CONTROLLED SOLDERING STATIONS

by: Tom Hammond, NSS rev. 03/09/2011

The Hakko 936-x line of temperature-controlled soldering stations has one flaw. It offers no real POWER ON/OFF indication. There is a red LED which illuminates when heat is being applied to the tip of the iron, but it lights ONLY when heat is being applied. As a result, if you glance at the station when no heat's being applied to the tip, you might think the device is actually turned off. I've walked off and left the soldering station running for several days because the red LED was extinguished when I looked at it, even though power was still applied. Here's a fairly simple-to-install mod which will add a green LED to the right hand side of the front panel on the 936. This LED will be illuminated any time power is applied to the soldering station. 1. Remove four (4) screws from the bottom of the case, and lift off the case top. 2. Remove the temperature control knob and carefully loosen the setscrew in the temp-lock mechanism. Remove the setscrew and nut and set them aside in a safe place. 3. Lift the front panel/PC board combination out of the case and carefully desolder the 6-pin (five [5] pins and one [1] lug) soldering iron cable connector from the PC board. USE CARE HERE. 4. With the 6-pin connector free of solder, hold the front panel on its sides with both bands and use your thumb to press on the shaft of the temp. control pot to push the PC board assembly away from the front panel. 4. Using Figure 1 (see next page), a scale drawing of the front panel, as an overlay of the drilling template, lay the template onto the front panel and CAREFULLY center punch and then drill a 3/16" (4.75mm) hole. Then use a much larger (about 1/2" / 13mm) bit (hand-held), or a hand reamer bit, to 'hollow' out a bit of the back side of the hole just drilled to allow the new LED to extend out the front of the panel just a small distance. 5. Refer to Figure 2 (next page),SOLDER SIDE of the PC board. Using a #60 (0.040") or smaller drill bit, drill four (4) holes, as indicated, to accept the new LED (green, T1-3/4 size), and the current limiting resistor (RL,3.0k to 3.9k 1W, the exact value is not terribly critical, a metal film/oxide resistor was selected for its smaller physical size), Mouser Electronics #594-5083NW3K900J (3.9k 2W metal film). 6. Once the four holes have been drilled, use a sharp knife blade and scrape away the solder mask from the two points indicated in Figure 2. Once these two points are cleaned of solder mask, tin the bare copper. 7. Regarding the LED... generally, there is a flat side on the base of the LED body to indicate the CATHODE side. Additionally, on most (though not all) LEDs, the CATHODE lead is the SHORTER of the two (assuming a new LED with un-cut leads). 8. ALL REMAINING STEPS REFER TO FIGURE 3 (next page). Install (BUT DO NOT SOLDER) the LED with its CATHODE lead in the hole indicated by the illustration. DO NOT BEND THE LED LEADS AND DO NOT SOLDER YET!!! 9. Insulate and bend the leads of RL at right angles and at appropriate distances to allow RL to drop into its mounting holes. Raise RL about 1/8" (3 mm) above the PC board and solder ONLY the lead which is connected at the top of the resistor to the copper land. 10. BEND the bottom lead of RL to the right, and around the ANODE lead of the LED. Use wire cutters to trim any excess lead length once the lead has been bent around the LED anode lead. DO NOT SOLDER YET. 11. Temporarily re-assemble the front panel and the PC board, ensuring that the 6-pin connector is properly inserted into its PC board holes. Ensure that the front panel and the PC board are well mated and parallel to each other, then press the green LED into its hole in the front panel so it seats properly. 12. With the new LED in place, solder the junction of RL and the LED anode lead. 13. Bend the CATHODE lead of the LED flat against the PC board and so it touches the adjacent area of the PC board from which you scraped away the solder mask. Solder the LED CATHODE to this point on the PC board. 14. Re-solder all (6) of the 6-pin heating element connector leads. 15. Reassemble the soldering station.

0.70" (17.8mm)

Figure 1 - Cut out the template at right. Then cut out the two marked areas so the template will clear the temp. control bearing and the heating element jack when laid on top of the front panel. Tape the template into place on the FRONT SIDE of the front panel. CAREFULLY center punch the point where the hole is to be drilled. Drill a 3/16" (4.75mm) hole from the front. You may want to first drill a smaller 'pilot' hole and work up, in steps, to the larger final hole diameter. This will often help reduce the chances of paint chipping, etc. Then, use a larger (handheld) bit (or a reamer) from the back side to 'hollow out' the back of the hole just enough to allow the tip of the new LED to extend out the front of the front panel to the same extent as that of the red LED. If the green LED is allowed to protrude a bit farther than the red LED, it will be more readily noticed as you use the device in a normal working environment.

Cut away these two sections of the template to allow the template to fit over the temp control bearing & heating element connector

1.33" (33.8mm)

Drill 3/16" (4.75mm) hole here

Figure 1. HAKKO 936-X T/C Soldering Station Front Panel (Viewed from the FRONT SIDE) Rev.: 03/09/2011 v4.1 Figure 3. Hakko 936-x PC board - New Components (as viewed from the SOLDER SIDE of the PC board)

Figure 2. Hakko 936-x PC board preparation (as viewed from the SOLDER SIDE of the PC board)

Bend existing power resistor out of the way (TOP of PCB) Scrape solder mask away from this part of the land. Drill four (4) holes (.025" to .04" dia.) in PC board at points shown After drilling, scrape solder mask away from this part of the land.

LED (shorter) Cathode lead

Green T1-3/4 LED with flat (cathode) side away from RL and bent flat against PC board to touch cleaned and tinned land) Anode (longer lead) Limiting Resistor (RL) (Insulate Leads & raise above PC board)

Potrebbero piacerti anche

- Analog Soldering Station SchematicDocumento1 paginaAnalog Soldering Station Schematiczoran_stev86% (7)

- Monitoare FinalDocumento88 pagineMonitoare FinalCiprianIfrimNessuna valutazione finora

- OB3375 Demo Board Manual: For LCD Backlight Application Using OB3375Documento4 pagineOB3375 Demo Board Manual: For LCD Backlight Application Using OB3375danielNessuna valutazione finora

- Catalog Echivalente Diode PhilipsDocumento43 pagineCatalog Echivalente Diode PhilipsBorcan Cristi83% (6)

- Protection PinsDocumento2 pagineProtection PinsShehbaz Singh100% (1)

- Bn44-00744a L65c4l-Esm Pslf321c06aDocumento1 paginaBn44-00744a L65c4l-Esm Pslf321c06aGiovanni Carrillo VillegasNessuna valutazione finora

- APC Back UPS 250,400,600 - 1 PDFDocumento1 paginaAPC Back UPS 250,400,600 - 1 PDFSixto Aguero50% (2)

- Datasheet TransistorDocumento99 pagineDatasheet TransistorArif Susilo100% (1)

- Si4825 A10 PDFDocumento21 pagineSi4825 A10 PDFTuribio Almeida Barbosa100% (1)

- Series: Ultra Light Load High Efficiency, VIN 17V, Current Mode Step-Down Io 3A Buck Regulator ICDocumento15 pagineSeries: Ultra Light Load High Efficiency, VIN 17V, Current Mode Step-Down Io 3A Buck Regulator ICCube7 GeronimoNessuna valutazione finora

- Ic Osc FuenteDocumento6 pagineIc Osc FuenteLeonardo Flei100% (1)

- 29e50 Ob2273d+ob3362hpDocumento1 pagina29e50 Ob2273d+ob3362hprammerDankov100% (2)

- P-Board TNPA6029 Panasonic KM26 схемаDocumento4 pagineP-Board TNPA6029 Panasonic KM26 схемаบ้าน ปลาข่อ100% (3)

- Samsung Bn44-00158a Sma23-P Power Supply SCHDocumento2 pagineSamsung Bn44-00158a Sma23-P Power Supply SCHEnoel Vazquez Sanchez100% (3)

- Im1 - Service ManualDocumento47 pagineIm1 - Service Manualclone_zero0% (1)

- BN44 00597a+p43lf DdyDocumento2 pagineBN44 00597a+p43lf DdyLeonardo Fabian Santos Rodriguez50% (2)

- Fan7340 Slc1012c PWM Backlight Samsung 32Documento16 pagineFan7340 Slc1012c PWM Backlight Samsung 32Andres Alegria50% (4)

- Hakko936 150812042846 Lva1 App6891 PDFDocumento14 pagineHakko936 150812042846 Lva1 App6891 PDFLeoned Cova OrozcoNessuna valutazione finora

- Nobreak SMS Net Station 1200VA uST1200BiFX Esquema Elétrico - UnlockedDocumento1 paginaNobreak SMS Net Station 1200VA uST1200BiFX Esquema Elétrico - UnlockedFernandoBeliever64% (14)

- AN4102 (Uso 3S0680RF)Documento20 pagineAN4102 (Uso 3S0680RF)Cintya CardozoNessuna valutazione finora

- 21rf08 Chassis Strw6553+Tda11105Documento1 pagina21rf08 Chassis Strw6553+Tda11105Lefter TironNessuna valutazione finora

- Digital Soldering Station Atmega8 Schematic PDFDocumento1 paginaDigital Soldering Station Atmega8 Schematic PDFzoran_stev75% (4)

- DiodesDocumento12 pagineDiodesmnemonic79Nessuna valutazione finora

- 74HC04D 74HC04D 74HC04D 74HC04D: 600K Oscillating CircuitDocumento2 pagine74HC04D 74HC04D 74HC04D 74HC04D: 600K Oscillating CircuitTecnoaudio Guarapiche33% (3)

- Stetsom TH41204120 R1a S03Documento1 paginaStetsom TH41204120 R1a S03Everson Correa100% (1)

- LCR-0202 Analog Linear CouplingDocumento3 pagineLCR-0202 Analog Linear CouplingJaPan Life100% (1)

- Esquema Eletrico Aca 501 New XDocumento1 paginaEsquema Eletrico Aca 501 New XEletrônica Prime100% (2)

- GND GND GND GND GND: +5V +5V +5V +5V +5V +5V +5VDocumento1 paginaGND GND GND GND GND: +5V +5V +5V +5V +5V +5V +5Vzoran_stev60% (5)

- Sta 540 SaDocumento19 pagineSta 540 Satarzan20140% (1)

- SMD CODE Iniciando Por LetrasDocumento124 pagineSMD CODE Iniciando Por LetrasSidney Sant'Anna LeiteNessuna valutazione finora

- STK490 310Documento1 paginaSTK490 310Marcos Ivan Sanabria100% (1)

- AD52068 Ampli 2x20w 7.5vDocumento1 paginaAD52068 Ampli 2x20w 7.5vNestor Edgardo Minatta GranadosNessuna valutazione finora

- Ad82587d PDFDocumento45 pagineAd82587d PDFИван Алексиев50% (2)

- Philips-HTS6600-manual Service PDFDocumento77 paginePhilips-HTS6600-manual Service PDFjosenicolas12000Nessuna valutazione finora

- Nobreak Manger III - Onda SenoidalDocumento1 paginaNobreak Manger III - Onda SenoidalFenix Automação100% (1)

- EST7502C/EST7502CS Power Supply Supervisor With PWM ControllerDocumento8 pagineEST7502C/EST7502CS Power Supply Supervisor With PWM ControllerJose Domingo Maltez VallecilloNessuna valutazione finora

- Mosfet Cross ReferenceDocumento14 pagineMosfet Cross ReferencedenisharkNessuna valutazione finora

- 19v From A Car BatteryDocumento4 pagine19v From A Car Batterysafet100% (1)

- Yaesu FT 736r Ps RepairDocumento9 pagineYaesu FT 736r Ps RepairBravo KiloNessuna valutazione finora

- Qrpguys K8Tnd Regenerative Receiver: Please Read All The Instructions Before Starting To Assemble The ReceiverDocumento10 pagineQrpguys K8Tnd Regenerative Receiver: Please Read All The Instructions Before Starting To Assemble The ReceiverAltan KomanNessuna valutazione finora

- ADA MN3007 Rev5 Jan2010 Documentation Rev20120225Documento12 pagineADA MN3007 Rev5 Jan2010 Documentation Rev20120225ismaelsleiferNessuna valutazione finora

- Td3mods Version1 999Documento22 pagineTd3mods Version1 999Romain Beatlejuice DucNessuna valutazione finora

- клон Sunking - ver.3Documento7 pagineклон Sunking - ver.3popovolegNessuna valutazione finora

- Td3mods Version1 515Documento20 pagineTd3mods Version1 515Romain Beatlejuice DucNessuna valutazione finora

- Kenwood TH-K2 Serv PDFDocumento63 pagineKenwood TH-K2 Serv PDFAleksandar DimitrievskiNessuna valutazione finora

- PWMcircuit 08Documento10 paginePWMcircuit 08kcarringNessuna valutazione finora

- K168. Epe Wind Speed MeterDocumento3 pagineK168. Epe Wind Speed MeterFranc MejiNessuna valutazione finora

- Pana Bežični Manujal kx-tcd150FXDocumento77 paginePana Bežični Manujal kx-tcd150FXi4004Nessuna valutazione finora

- NEC Format Remote: Fig.: Atmel AVR Based Remote Controlled Fan RegulatorDocumento6 pagineNEC Format Remote: Fig.: Atmel AVR Based Remote Controlled Fan RegulatorJitendra JainNessuna valutazione finora

- Philips CD 650 ModsDocumento10 paginePhilips CD 650 ModsspikebitNessuna valutazione finora

- Beaver InstructionsDocumento29 pagineBeaver InstructionsMyles de BastionNessuna valutazione finora

- LCMeterHombrewmanual PDFDocumento5 pagineLCMeterHombrewmanual PDFwayan.wandira8122Nessuna valutazione finora

- Micro80D Builders Guide-Ver3Documento18 pagineMicro80D Builders Guide-Ver3knujdloNessuna valutazione finora

- Hfe Sony Cdp-Xa20es ServiceDocumento43 pagineHfe Sony Cdp-Xa20es ServiceMokaNessuna valutazione finora

- Welleman Illustrated Assembly Manual k8081 Rev2Documento36 pagineWelleman Illustrated Assembly Manual k8081 Rev2adibzzNessuna valutazione finora

- Picproe (B)Documento27 paginePicproe (B)sherazianNessuna valutazione finora

- Modification To AMP REV1Documento14 pagineModification To AMP REV1augustinetezNessuna valutazione finora

- Beko 14.2 PDFDocumento33 pagineBeko 14.2 PDFMos CraciunNessuna valutazione finora

- Cat BoxDocumento21 pagineCat BoxIvo Marco ZupicichNessuna valutazione finora

- Digital LED Thermometer with Microcontroller AVR ATtiny13Da EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Valutazione: 5 su 5 stelle5/5 (1)

- Design Guide For The Packaging of High Speed Electronic CircuitsDocumento5 pagineDesign Guide For The Packaging of High Speed Electronic CircuitsNgo van ChungNessuna valutazione finora

- Understanding Modern Power MOSFETsDocumento36 pagineUnderstanding Modern Power MOSFETsZhao XuNessuna valutazione finora

- Lab QuizDocumento4 pagineLab Quizvenktesh22Nessuna valutazione finora

- Seminar On PolyfuseDocumento25 pagineSeminar On PolyfuseLemi Hussain50% (2)

- Generator Paralleling and Protection Unit: Type Ppu / GsDocumento5 pagineGenerator Paralleling and Protection Unit: Type Ppu / GsSergio CaleroNessuna valutazione finora

- JBL Ceiling Speaker PDFDocumento23 pagineJBL Ceiling Speaker PDFKhay SaadNessuna valutazione finora

- DSP 6 - FIR Filter DesignDocumento23 pagineDSP 6 - FIR Filter DesignJehan Zeb BhattiNessuna valutazione finora

- Timing AnalysysDocumento15 pagineTiming AnalysysrrramananNessuna valutazione finora

- Expt-5 Lab Manual TE LabDocumento10 pagineExpt-5 Lab Manual TE LabRuham RofiqueNessuna valutazione finora

- AQZ102 NaisDocumento6 pagineAQZ102 NaishüseyinNessuna valutazione finora

- 5W Monaural Power Amplifier: Audio Output For TV ApplicationDocumento3 pagine5W Monaural Power Amplifier: Audio Output For TV ApplicationJose DelmarNessuna valutazione finora

- 24W04Documento2 pagine24W04maldomattNessuna valutazione finora

- General Purpose Rectifier: 1N4001-G 1N4007-GDocumento2 pagineGeneral Purpose Rectifier: 1N4001-G 1N4007-GCarloz FriazNessuna valutazione finora

- Quick Guide of PI8100 Operation6-7Documento24 pagineQuick Guide of PI8100 Operation6-7Luis Jaramillo100% (1)

- Wearable Impedance Analyzer Based On AD5933: Liviu Breniuc and Valeriu David Cristian-Győző HabaDocumento6 pagineWearable Impedance Analyzer Based On AD5933: Liviu Breniuc and Valeriu David Cristian-Győző HabajuanitoingNessuna valutazione finora

- Pioneer SK 909lDocumento19 paginePioneer SK 909lErnandesTorresBarbosaNessuna valutazione finora

- ISA ModelsDocumento5 pagineISA ModelsFahad Tanveer MalikNessuna valutazione finora

- EngDocumento3 pagineEngMarian RomsysNessuna valutazione finora

- Computer Languages: 1. Low Level Languages. 2. High Level LanguagesDocumento2 pagineComputer Languages: 1. Low Level Languages. 2. High Level LanguagessatyamNessuna valutazione finora

- Figure 1 - Data Integrity Field Appended To 512-Byte Standard BlockDocumento7 pagineFigure 1 - Data Integrity Field Appended To 512-Byte Standard BlockraghavaprakashNessuna valutazione finora

- RS-232/RS-485/422: UT-203 Interface Converter InstructionDocumento1 paginaRS-232/RS-485/422: UT-203 Interface Converter InstructionMahran MastouriNessuna valutazione finora

- HFBR 1523 AvagoDocumento20 pagineHFBR 1523 AvagoMouhanad HalabiNessuna valutazione finora

- Lecture33 - 16827 - Flat Panel DisplaysDocumento20 pagineLecture33 - 16827 - Flat Panel Displayssumayya shaikNessuna valutazione finora

- Stmicroelectronics Power Management Ics: Stmicroelectronics Micropower Voltage ComparatorsDocumento1 paginaStmicroelectronics Power Management Ics: Stmicroelectronics Micropower Voltage ComparatorsHectorNessuna valutazione finora

- Intel CPU Install PDFDocumento30 pagineIntel CPU Install PDFcernatandNessuna valutazione finora

- Max 8728Documento29 pagineMax 8728aliamservice6231Nessuna valutazione finora

- 4 X 13 W Dual/quad Power Amplifier: FeaturesDocumento25 pagine4 X 13 W Dual/quad Power Amplifier: FeaturesDaruslan StrNessuna valutazione finora

- Verilog Code For 4 Bit Ring Counter With TestbenchDocumento3 pagineVerilog Code For 4 Bit Ring Counter With Testbenchsoumya100% (1)

- CS302 Quiz Solved For MID TERM PDFDocumento25 pagineCS302 Quiz Solved For MID TERM PDFattiqueNessuna valutazione finora

- FIG. locus of - 1+Aβ - =1: vf V VDocumento13 pagineFIG. locus of - 1+Aβ - =1: vf V VMohanNessuna valutazione finora