Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

HBM Part 5

Caricato da

Sopna BalakrishnanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

HBM Part 5

Caricato da

Sopna BalakrishnanCopyright:

Formati disponibili

Currently there are a number of methods for rating integrated circuits for ESD performance within the manufacturing

environment. Human Body Model, Machine Model and Charged Device Model are three most common methods used. The Human Body Model (HBM)

The Human Body Model simulates the ESD phenomenon wherein a charged body directly transfers its accumulated electrostatic charge to the ESD-sensitive (ESDS) device. A common example of this phenomenon, and from which the name of this model was derived, is when a person accumulates static charge by walking across a carpet and then transferring all of the charge to an ESDS device by touching it. Of course, other 'non-human' materials that accumulate and transfer charge in a similar manner are also covered by the HBM.

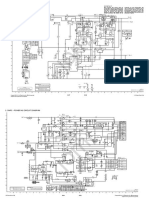

Figure 1. Basic HBM Test Circuit

The Machine Model (MM)

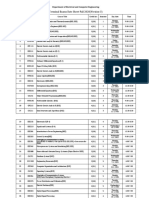

Originated in Japan as a result of investigating worst-case scenarios of the HBM, the Machine Model simulates a more rapid and severe electrostatic discharge from a charged machine, fixture, or tool. The MM test circuit consists of charging up a 200 pF capacitor to a certain voltage and then discharging this capacitor directly into the device being tested through a 500 nH inductor with no series resistor. Figure 2 shows a basic MM test circuit.

Figure 2. Basic MM Test Circuit

The Charged Device Model (CDM)

Not all ESD events involve the transfer of charge into the device. Electrostatic discharge from a charged device to another body is also a form of ESD, and a quite commonly encountered one at that.

A device can accumulate charge in a variety of ways, especially in situations where they undergo movement while in contact with another object, such as when sliding down a track or feeder. If they come into contact with another conductive body that is at a lower potential, it discharges into that body. Such an ESD event is known as Charged Device Model ESD, which can even be more destructive than HBM ESD (despite its shorter pulse duration) because of its high current. There are currently two widely-used models for CDM testing: 1) the Socketted Discharge Model (SDM); and 2) the Real-world Charged Device Model (RCDM). SDM simulates a device inserted in a socket, then charged from a high voltage source, and then discharged through a 1-ohm resistor. SDM is easy to conduct but is not always replicating real-world CDM ESD events.

Discharge to the device, discharge from the device and field-induced dicharge are the three main ESD events that cause electronic device failures.

Discharge to the Device An ESD event can occur when any charged conductor (including the human body) discharges to an ESDS (electrostatic discharge sensitive) device. The most common cause of electrostatic damage is the direct transfer of electrostatic charge from the human body or a charged material to the ESDS device. When one walks across a floor, an electrostatic charge accumulates on the body. Simple contact of a finger to the leads of an ESDS device or assembly allows the body to discharge, possibly causing device damage. The model used to simulate this event is the human body model (HBM). A similar discharge can occur from a charged conductive object, such as a metallic tool or fixture. The model used to characterize this event is known as the machine model. Discharge from the Device The transfer of charge from an ESDS device is also an ESD event. The trend towards automated assembly would seem to solve the problems of HBM ESD events. However, it has been shown that components may be more sensitive to damage when assembled by automated equipment. A device may become charged, for example, from sliding down a feeder. If it then contacts an insertion head or another conductive surface, a rapid discharge occurs from the device to the metal object. This event is known as the charged device model (CDM) event, and can be more destructive than the HBM for some devices. Although the duration of the discharge is very shortoften less than one nanosecondthe peak current can reach several tens of amperes. Field-Induced Discharges A very rare event that can directly or indirectly damage devices is termed field induction. As noted earlier, whenever any object becomes electrostatically charged, there is an electrostatic field associated with that charge. If an ESDS device is placed in that electrostatic field, a charge may be induced on the device. If the device is then momentarily grounded while within the electrostatic field, a transfer of charge from the device occurs.

Potrebbero piacerti anche

- EMT-Electromagnetic Floater ReportDocumento22 pagineEMT-Electromagnetic Floater ReportSopna BalakrishnanNessuna valutazione finora

- Cisco 640 554 v5.1Documento89 pagineCisco 640 554 v5.1kzl1806Nessuna valutazione finora

- Population State: KEDAHDocumento8 paginePopulation State: KEDAHSopna BalakrishnanNessuna valutazione finora

- Assignment Paper FormatDocumento3 pagineAssignment Paper FormatSopna BalakrishnanNessuna valutazione finora

- Completed Fauzi AssignmentDocumento5 pagineCompleted Fauzi AssignmentSopna BalakrishnanNessuna valutazione finora

- Learning Outcome Learning OutcomeDocumento8 pagineLearning Outcome Learning OutcomeSopna BalakrishnanNessuna valutazione finora

- The Prevention and Control of Part 5Documento5 pagineThe Prevention and Control of Part 5Sopna BalakrishnanNessuna valutazione finora

- Represents Primary Switch Exchanges Represents Tandem SwitchDocumento2 pagineRepresents Primary Switch Exchanges Represents Tandem SwitchSopna BalakrishnanNessuna valutazione finora

- Introduction To ESD and ESD Events Part 4Documento8 pagineIntroduction To ESD and ESD Events Part 4Sopna BalakrishnanNessuna valutazione finora

- ESD Standards Part 7Documento10 pagineESD Standards Part 7Sopna BalakrishnanNessuna valutazione finora

- Kedah Design MapDocumento4 pagineKedah Design MapSopna BalakrishnanNessuna valutazione finora

- EsdDocumento92 pagineEsdKuppusamy SundaramoorthyNessuna valutazione finora

- Criteria For Network DesignDocumento16 pagineCriteria For Network DesignSopna BalakrishnanNessuna valutazione finora

- TUTORIAL 5 Bent 3163 2 20112012Documento1 paginaTUTORIAL 5 Bent 3163 2 20112012Sopna BalakrishnanNessuna valutazione finora

- Img 0046Documento1 paginaImg 0046Sopna BalakrishnanNessuna valutazione finora

- Programming With Sci LabDocumento25 pagineProgramming With Sci LabSopna BalakrishnanNessuna valutazione finora

- Img 0057Documento1 paginaImg 0057Sopna BalakrishnanNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Course Title: Building Services (Electrical) : Prepared By: Olabode Oluwafemi. RDocumento25 pagineCourse Title: Building Services (Electrical) : Prepared By: Olabode Oluwafemi. ROlawale AdebesinNessuna valutazione finora

- RT 31021112017Documento8 pagineRT 31021112017JohnNessuna valutazione finora

- CM8340 Diagrama Fuente PDFDocumento2 pagineCM8340 Diagrama Fuente PDFLorenzo100% (2)

- Socomec AtysDocumento2 pagineSocomec AtysmehdivinciNessuna valutazione finora

- Phase-Control Alternatives For Single-Phase AC Motors Offer Smart, Low-Cost, SolutionsDocumento8 paginePhase-Control Alternatives For Single-Phase AC Motors Offer Smart, Low-Cost, SolutionsAdedotun J. AgbemukoNessuna valutazione finora

- Troubleshooting Schindler Miconic TX and TX-GCDocumento31 pagineTroubleshooting Schindler Miconic TX and TX-GCDon Luong100% (1)

- Operation Amplifier - Part1Documento16 pagineOperation Amplifier - Part1Abdelrahman RagabNessuna valutazione finora

- Laser Light Security System.Documento9 pagineLaser Light Security System.AshrayKunnurNessuna valutazione finora

- FN 660 Two-Stage General-Purpose Filter: Filter Selection Table ApprovalsDocumento2 pagineFN 660 Two-Stage General-Purpose Filter: Filter Selection Table ApprovalsDitzsu tzsuDiNessuna valutazione finora

- Date Sheet-Terminal Exams - Fall 20-1Documento6 pagineDate Sheet-Terminal Exams - Fall 20-1Muhammad Zaeem AkmalNessuna valutazione finora

- EE2001 Tutorial 8 QuestionsDocumento3 pagineEE2001 Tutorial 8 QuestionsPeiXuan HoNessuna valutazione finora

- Harmonics: Passive FiltersDocumento12 pagineHarmonics: Passive FiltersPop-Coman SimionNessuna valutazione finora

- Flomat EngDocumento8 pagineFlomat Engalex.amaral9292Nessuna valutazione finora

- QS4 QuickstartDocumento10 pagineQS4 QuickstartEvita Elizabeth Ramos CuevasNessuna valutazione finora

- EMT - Assingment (Electromagnatic Floater)Documento10 pagineEMT - Assingment (Electromagnatic Floater)Iqbal Haziq AzmiNessuna valutazione finora

- Power Electronics Experts ListDocumento8 paginePower Electronics Experts ListViswanathan ASNessuna valutazione finora

- Ac Power Distribution Switch BoardDocumento26 pagineAc Power Distribution Switch BoardAnonymous nL0QNemdINessuna valutazione finora

- EEN-021 Mechatronics Objective TYPE Q-ADocumento2 pagineEEN-021 Mechatronics Objective TYPE Q-APiyush AgnihotriNessuna valutazione finora

- SEW EX Asynchronous Servo MotersDocumento144 pagineSEW EX Asynchronous Servo Moterswickedness100% (1)

- Potentiometer and Strain Gauge PDFDocumento25 paginePotentiometer and Strain Gauge PDFSantanu SantraNessuna valutazione finora

- ARC-23304 Warrior Product DataDocumento4 pagineARC-23304 Warrior Product DataAmando FuentesNessuna valutazione finora

- Theoretical Modeling of Tm-Doped Silica Fiber LasersDocumento9 pagineTheoretical Modeling of Tm-Doped Silica Fiber Lasersteektak1Nessuna valutazione finora

- Smart Street Light SystemDocumento32 pagineSmart Street Light SystemRohit KumarNessuna valutazione finora

- 149 - Wipers and WashersDocumento84 pagine149 - Wipers and WashersGedas GvildysNessuna valutazione finora

- Sicam TM Io Module EngDocumento139 pagineSicam TM Io Module EngGokhan MertNessuna valutazione finora

- Diagrama Hydraulico Caterpillar 950 GCDocumento11 pagineDiagrama Hydraulico Caterpillar 950 GCJose PichinteNessuna valutazione finora

- Best X DC BrochureDocumento46 pagineBest X DC Brochureأياام زمانNessuna valutazione finora

- What Is Excitation System - Definition & Types of Excitation System - Circuit GlobeDocumento13 pagineWhat Is Excitation System - Definition & Types of Excitation System - Circuit Globerotimi olalekan fataiNessuna valutazione finora

- Busbar ProtectionDocumento4 pagineBusbar Protectiondundi_kumarNessuna valutazione finora

- Design and Analysis of High-Gain Medium-Voltage DC-DC Converters For High-Power PV ApplicationsDocumento5 pagineDesign and Analysis of High-Gain Medium-Voltage DC-DC Converters For High-Power PV ApplicationsHussain K. SayedNessuna valutazione finora