Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Stainless Steel 304 Product Info

Caricato da

arunava001Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Stainless Steel 304 Product Info

Caricato da

arunava001Copyright:

Formati disponibili

EN 1.4301, AISI 304 EN 1.

4307, AISI 304L

Product Information April, 2009

Austenitic stainless steel

Type X5CrNi18-10 stainless steels EN 1.4301, AISI 304 EN 1.4307, AISI 304L, low carbon (when SO2 used for preservation grade 1.4404, AISI 316L or 1.4432 is recommended), xylene and yeast. In chloride containing solutions pitting and crevice corrosion is possible depending on various parameters like chloride concentration, temperature, pH value, redox potential, crevice geometry and others. For instance in drinking water supply systems chloride concentration up to 200 mg/l are usually tolerable. When the temperature of chloride containing solutions exceeds 50C and the construction is loaded, stress corrosion cracking is possible. The best material performance is reached usually with the help of adequate design, correct post-weld treatment and regular cleaning during use (if applicable).

Applications

These are the most commonly used stainless steels, those resistant against corrosion is utilized e.g. in chemical, paper and food industry. These steels are also popular in household wares, architecture and transportation. Can be used at low temperatures down to -196C even as welded structures. Moderate strengths can be reached at elevated temperatures (~550C). Temperatures for excessive scaling are close to 850C.

Physical properties

Austenitic crystal structure, non-magnetic as soft annealed. Density: 7,9 g/cm3 -6 Coefficient of thermal expansion: 16x10 1/K T=20100C Thermal conductivity at 20C: 15 W/(m x K)

Welding

Weldability is good. The thermal expansion is 1,5-times larger compared with carbon steels. Chromium and nickel contents of the filler metal have to match or to be higher than the composition of the base metal, e.g. type 19-9. In welded plates with wall thickness exceeding 6 mm, steels with low carbon content (1.4307, AISI 304L) or (1.4541, AISI 321) are recommended. Cleaning the weld seam has a significant importance for corrosion resistance. Pickling is recommended.

Mechanical properties

According to EN 10088-2:2005

EN AISI Proof strength R p0,2 (N/mm2) Tensile strength Rm (N/mm2) Elongation after fracture A (%)

Forming and machining

Formability is good, thus forces needed and the elastic return is bigger compared with carbon steels. Because of a high ductility and a strong work hardening it is recommended to use sharp tools, an effective cooling and adequate feed of tool. Higher austenite stability and a lower work hardening rate can be achieved by an increase of nickel and some other alloying elements.

1.4301 304 1.4307 304L

min. 230 min. 220

540...750 520...670

min. 45 min. 45

Minimum values of 0,2 % proof strength (Rp0,2, N/mm2) at elevated temperatures, EN 10088-2:2005

EN 100 150 200 250 300 350 400 450 500

1.4301 157 142 127 118 110 104 1.4307 147 132 118 108 100 94

98 89

95 85

92 81

Corrosion resistance

Resistance to atmospheric corrosion is adequate for several applications. Special attention should be paid on surface finish and regular cleaning procedures in marine and industrial environments. These steels have a good resistance against oxidizing acids. Corrosion resistance in non-oxidazing acids like sulphuric acid, hydrofluoric acid and hydrochloride acid is limited. Can be used e.g. in the following chemically pure, boiling solutions: acetic acid (5%), acetone, ammonia, ammonia sulphate, benzene, benzene, citric acid (10%), copper sulphate, ethanol, ethylic ether, formaldehyde, fruit juice, HNO3 (45%), lactic acid (10%), NaOH (30%), Na2SO3 (50%), oil, phosphoric acid (20%), potassiumand sodium-carbonate, tartaric acid (15%), toluene, wine

EN

Chemical composition (typical)

C wt-% Cr wt-% Ni wt-% Fe wt-%

1.4301 1.4307

Max. 0,07 Max. 0,030

18,1 18,1

8,2 8,2

Bal. Bal.

Further information

Standard Specification EN 10088-2:2005 Standard Specification ASTM A-240-06c Corrosion Handbook, Outokumpu Technical Customer Service

Disclaimer: Information given in this document may be amended without notice. Care has been taken to ensure that the contents are accurate but Outokumpu and its affiliated companies makes no warranty underrating and have no liability for the anything in this document unless explicitly agreed in writing.

Outokumpu Tornio Works

FI-95400 Tornio, Finland Tel. +358 16 4521, Fax +358 16 452 620, www.outokumpu.com Domicile: Tornio, Finland. Business ID 0823315-9, VAT FI08233159

Potrebbero piacerti anche

- Ch-27.7 Alloying Element of Steel and Alloy SteelDocumento51 pagineCh-27.7 Alloying Element of Steel and Alloy SteelSmruti Ranjan PattanayakNessuna valutazione finora

- Is 513 PDFDocumento13 pagineIs 513 PDFManeesh Bangale100% (5)

- Carrier - Handbook of Air Conditioning System Design (Part 1)Documento162 pagineCarrier - Handbook of Air Conditioning System Design (Part 1)Jonathan Castro96% (93)

- Glossary of Metalworking TermsDocumento73 pagineGlossary of Metalworking Termsowox91Nessuna valutazione finora

- Basic Rules For Stainless Steel SpecificationDocumento9 pagineBasic Rules For Stainless Steel SpecificationmutemuNessuna valutazione finora

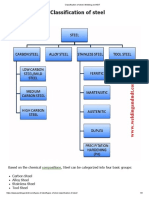

- Classification of Steel - Welding and NDTDocumento3 pagineClassification of Steel - Welding and NDTAshif Iqubal100% (1)

- All-Air Systems GuideDocumento62 pagineAll-Air Systems GuideradiopascalgeNessuna valutazione finora

- Tool Steels: Prepared byDocumento35 pagineTool Steels: Prepared bySWAPNIL NIGAMNessuna valutazione finora

- Funamental of MetallurgyDocumento235 pagineFunamental of Metallurgysoumyo broto dasNessuna valutazione finora

- Alloy Steels: Dr. Indika de SilvaDocumento25 pagineAlloy Steels: Dr. Indika de SilvaChandima K PriyamalNessuna valutazione finora

- Engineering MaterialsDocumento110 pagineEngineering MaterialsAthith D100% (1)

- Welding Metallurgy and Weldability of Nickel-Base AlloysDa EverandWelding Metallurgy and Weldability of Nickel-Base AlloysValutazione: 5 su 5 stelle5/5 (1)

- Carbon Steel Metallurgy DiagramDocumento17 pagineCarbon Steel Metallurgy Diagramwessamalex100% (1)

- Basics of WeldingDocumento88 pagineBasics of Weldingmujeebmehar100% (1)

- Flame HardeningDocumento29 pagineFlame Hardeningzaid sulaimanNessuna valutazione finora

- Effect of Elements in SteelDocumento3 pagineEffect of Elements in SteelJayakrishnan Radhakrishnan100% (1)

- Corrosion Mechanisms ExplainedDocumento36 pagineCorrosion Mechanisms Explainedmotasem100% (2)

- Damage Mechanisms Forms of Corrosion V1Documento49 pagineDamage Mechanisms Forms of Corrosion V1Anupam ChowdhuryNessuna valutazione finora

- SS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Documento3 pagineSS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Harish AmpoluNessuna valutazione finora

- Material BehaviorDocumento111 pagineMaterial BehaviorFajar LuqmanNessuna valutazione finora

- Galvanic and Corrosion Compatibility Dissimilar Metal Corrosion GuideDocumento21 pagineGalvanic and Corrosion Compatibility Dissimilar Metal Corrosion Guidehitesh_tilalaNessuna valutazione finora

- Martensitic Stainless SteelDocumento3 pagineMartensitic Stainless SteelVysakh VasudevanNessuna valutazione finora

- Steel ClassificationDocumento3 pagineSteel Classificationasfarjee100% (1)

- Ferrous Alloys GuideDocumento56 pagineFerrous Alloys Guidejayakrishnan psNessuna valutazione finora

- Presentation On Heat TreatmentsDocumento34 paginePresentation On Heat TreatmentsVinothkumarNessuna valutazione finora

- Will Schran - Cone 6 CrystalsDocumento4 pagineWill Schran - Cone 6 CrystalsStefan Van Cleemput100% (3)

- Basic Metallurgy: Numbering Systems For Metals and AlloysDocumento15 pagineBasic Metallurgy: Numbering Systems For Metals and AlloysAcid BurnsNessuna valutazione finora

- Cast Iron: Physical and Engineering PropertiesDa EverandCast Iron: Physical and Engineering PropertiesValutazione: 5 su 5 stelle5/5 (1)

- Creep Failures of Overheated Boiler TubesDocumento21 pagineCreep Failures of Overheated Boiler TubesKailas GophaneNessuna valutazione finora

- En 1.4301Documento1 paginaEn 1.4301sheinilaNessuna valutazione finora

- Applied Science in the Casting of MetalsDa EverandApplied Science in the Casting of MetalsK. StraussNessuna valutazione finora

- MT 03 - Mechanical Properties and Tests, A-Z Abbrev (Tinius Olsen - Kul 1)Documento25 pagineMT 03 - Mechanical Properties and Tests, A-Z Abbrev (Tinius Olsen - Kul 1)zingerNessuna valutazione finora

- Types of Corrosion 1690267481Documento35 pagineTypes of Corrosion 1690267481Sudeesh n100% (1)

- Boiler Refractory ASTM C71Documento2 pagineBoiler Refractory ASTM C71Ujang SonjayaNessuna valutazione finora

- Biological Treatment of Microbial Corrosion: Opportunities and ChallengesDa EverandBiological Treatment of Microbial Corrosion: Opportunities and ChallengesNessuna valutazione finora

- Lec 02Documento19 pagineLec 02أمير حامد100% (1)

- Chamber and Tube Furnaces 0001-G-EDocumento64 pagineChamber and Tube Furnaces 0001-G-EMutsikamahwe BrianNessuna valutazione finora

- Leaching Copper Sulfide OreDocumento3 pagineLeaching Copper Sulfide OreJHPNessuna valutazione finora

- CH 14 CarbonandAlloySteelsDocumento42 pagineCH 14 CarbonandAlloySteelsdarwin_hua100% (1)

- Effect of Alloying Elements On Steel Properties (SubsTech)Documento2 pagineEffect of Alloying Elements On Steel Properties (SubsTech)hguptabhel100% (1)

- Master TIG WeldingDocumento15 pagineMaster TIG WeldingOtladisa Otista TlhalerwaNessuna valutazione finora

- Duplex Stainless Steel 329 Round Bars ManufacturerDocumento2 pagineDuplex Stainless Steel 329 Round Bars Manufacturertien100% (1)

- Choosing The Best Pocket Knife: Knife Steel Composition ChartDocumento12 pagineChoosing The Best Pocket Knife: Knife Steel Composition ChartNguyễn Thống NhấtNessuna valutazione finora

- SKD61-Forged Hot Work Tool SteelDocumento1 paginaSKD61-Forged Hot Work Tool SteelAgustine SetiawanNessuna valutazione finora

- Difference Between Pipe and TubeDocumento3 pagineDifference Between Pipe and TubeAnonymous fQAeGFNessuna valutazione finora

- Outokumpu Supra Range DatasheetDocumento12 pagineOutokumpu Supra Range DatasheetMichelNessuna valutazione finora

- Killed and Capped Steel IngotsDocumento5 pagineKilled and Capped Steel IngotsalacalleNessuna valutazione finora

- Tool Steels E28093 Molybdenum High Speed SteelsDocumento5 pagineTool Steels E28093 Molybdenum High Speed Steelswulfgang66Nessuna valutazione finora

- Bresle Salt Test GuidingDocumento5 pagineBresle Salt Test GuidinglambtranNessuna valutazione finora

- 253MA High Temperature Resistant TubesDocumento2 pagine253MA High Temperature Resistant TubesBerkan FidanNessuna valutazione finora

- Alloy 625 Supplier GuideDocumento1 paginaAlloy 625 Supplier Guidevickyflyer1Nessuna valutazione finora

- Steel and Its AlloyDocumento23 pagineSteel and Its AlloyHemang ChopraNessuna valutazione finora

- Casting of Non-Ferrous Metal Alloys Study GuideDocumento59 pagineCasting of Non-Ferrous Metal Alloys Study GuideNarender KumarNessuna valutazione finora

- Heat Treatment of SteelDocumento11 pagineHeat Treatment of SteelMohamed El-gammalNessuna valutazione finora

- Characteristic of High Temperature MaterialsDocumento17 pagineCharacteristic of High Temperature MaterialsMuhammad Salman AttariNessuna valutazione finora

- Properties of NickelDocumento60 pagineProperties of NickelchodekiranNessuna valutazione finora

- 06-Fatigue and Creep of Materials - F17 PDFDocumento23 pagine06-Fatigue and Creep of Materials - F17 PDFsabavoonNessuna valutazione finora

- New Galvanizing TechnologyDocumento4 pagineNew Galvanizing Technologywmaddoxmec100% (1)

- Bohler ManualDocumento519 pagineBohler ManualCosmin OlteanuNessuna valutazione finora

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesDa EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNessuna valutazione finora

- The Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaDa EverandThe Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaD M R TaplinNessuna valutazione finora

- Continuous casting The Ultimate Step-By-Step GuideDa EverandContinuous casting The Ultimate Step-By-Step GuideNessuna valutazione finora

- 1 4418Documento2 pagine1 4418cristi_molinsNessuna valutazione finora

- Good Fabrication in Architectural Stainless Steel: ISBN 2-87997-062-8Documento10 pagineGood Fabrication in Architectural Stainless Steel: ISBN 2-87997-062-8pavi32Nessuna valutazione finora

- Central Water WorksDocumento20 pagineCentral Water Worksarunava001Nessuna valutazione finora

- NEST 2015 Brochure SyllabusDocumento18 pagineNEST 2015 Brochure Syllabusarunava001Nessuna valutazione finora

- Isometric DrawingsDocumento1 paginaIsometric Drawingsarunava001Nessuna valutazione finora

- Heat Load PDFDocumento107 pagineHeat Load PDFarunava001100% (1)

- Drift Eliminator GraphDocumento1 paginaDrift Eliminator Grapharunava001Nessuna valutazione finora

- 13 Cirlis T Flat RateDocumento10 pagine13 Cirlis T Flat Ratearunava001Nessuna valutazione finora

- Cooptimisation of Coc For Cooling Towerscorrected.......Documento20 pagineCooptimisation of Coc For Cooling Towerscorrected.......arunava001Nessuna valutazione finora

- Dear AllDocumento1 paginaDear Allarunava001Nessuna valutazione finora

- Cast Aluminium and Its Alloys - Ingots and Castings For General Engineering Purposes - SpecificationDocumento15 pagineCast Aluminium and Its Alloys - Ingots and Castings For General Engineering Purposes - Specificationarunava001Nessuna valutazione finora

- Opti GridDocumento1 paginaOpti Gridarunava001Nessuna valutazione finora

- SteamDocumento10 pagineSteamarunava001Nessuna valutazione finora

- ASTM F75 CoCr Alloy Material Properties and ApplicationsDocumento3 pagineASTM F75 CoCr Alloy Material Properties and Applicationsboni_briantoniNessuna valutazione finora

- Impurities in QuartzDocumento5 pagineImpurities in QuartzMarcus CasillasNessuna valutazione finora

- Advantages and Limitations of Martensitic Steels For FusionDocumento4 pagineAdvantages and Limitations of Martensitic Steels For FusionClaudia MmsNessuna valutazione finora

- Effect of Quench Media on Steel PropertiesDocumento4 pagineEffect of Quench Media on Steel PropertiesskluxNessuna valutazione finora

- Standard No. and Definition SummaryDocumento1 paginaStandard No. and Definition SummarymanbkkNessuna valutazione finora

- Copper e FinalDocumento12 pagineCopper e FinalgoranNessuna valutazione finora

- Hss Tools and AppilcationDocumento17 pagineHss Tools and AppilcationMeena SivasubramanianNessuna valutazione finora

- Defects SlagDocumento3 pagineDefects SlagMuhammed SulfeekNessuna valutazione finora

- Multi Element Association Analysis of Stream Sediment GeochemistryDocumento14 pagineMulti Element Association Analysis of Stream Sediment GeochemistryKarinto SuárezNessuna valutazione finora

- Aluminum As Alloy and DeoxidantDocumento5 pagineAluminum As Alloy and DeoxidantlarryjhNessuna valutazione finora

- Good Fabrication in Architectural Stainless Steel: ISBN 2-87997-062-8Documento10 pagineGood Fabrication in Architectural Stainless Steel: ISBN 2-87997-062-8pavi32Nessuna valutazione finora

- 02 Whole X XXXXXXXXXXXXXX 80Documento109 pagine02 Whole X XXXXXXXXXXXXXX 80Danem HalasNessuna valutazione finora

- Algodonite Mineral Data1Documento4 pagineAlgodonite Mineral Data1BlacksacerdoteNessuna valutazione finora

- Slides - 4Documento55 pagineSlides - 4Rahul PandeyNessuna valutazione finora

- Periodic Table MnemonicDocumento2 paginePeriodic Table MnemonicOliver DyasNessuna valutazione finora

- EPSRC Metallurgy Research Present and FutureDocumento15 pagineEPSRC Metallurgy Research Present and Futuresujit_sekharNessuna valutazione finora

- Fastener Material SelectionDocumento3 pagineFastener Material SelectionIzzah AmalinaNessuna valutazione finora

- Converting Raw Materials to Steel ProductsDocumento41 pagineConverting Raw Materials to Steel ProductsvtbkNessuna valutazione finora

- Graphite MouldDocumento2 pagineGraphite MouldKumarChirraNessuna valutazione finora

- Excel Lab For ChemistryDocumento33 pagineExcel Lab For ChemistryAbhishek Saxena100% (1)

- Chloride Chlorine Levels and Stainless S PDFDocumento1 paginaChloride Chlorine Levels and Stainless S PDFSH1961Nessuna valutazione finora

- Aluminum Joining ManualDocumento290 pagineAluminum Joining Manualsav33100% (1)

- Physics Data BookletDocumento14 paginePhysics Data BookletAbeer ZeestNessuna valutazione finora

- CrystalshapesDocumento7 pagineCrystalshapesapi-276687098Nessuna valutazione finora

- Aluminium Production in The World and Use of ElectricityDocumento6 pagineAluminium Production in The World and Use of ElectricityZoran OstricNessuna valutazione finora