Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Knox FDC Lockable Plug - Firefighter

Caricato da

sherpa285Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Knox FDC Lockable Plug - Firefighter

Caricato da

sherpa285Copyright:

Formati disponibili

OPERATING INSTRUCTIONS

The Knox FDC Plug has been designed for ease-of-use when installing or removing the plug from a connection. Fire personnel properly equipped with a Knox Keywrench can quickly remove the plug. In the event of debris or ice buildup on the locking bolt head, a small athead screwdriver or similar tool will quickly remove any foreign matter.

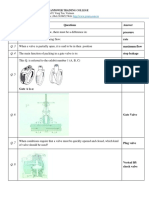

Swivel-Guard Pins Locking Bolt Head

Knox FDC Plug

Plug Identication

Each Knox FDC Plug is etched with a unique serial number on the plug face. The plug thread size and diameter is etched on the back of the plug. Verify that the connection coupling thread is the same size before attempting Diameter plug installation.

with Swivel-Guard

Keywrench

Threads per Inch Key Spanner

Installation

all debris from connection coupling threads and from inside the pipe. Flush system if necessary.

Taking the Knox Keywrench, turn the locking bolt counter clockwise until it stops to ensure it is fully unlocked.

Place the FDC Plug into coupling and hand turn clockwise until no threads are showing. Do not use spanner. Hand tighten ONLY.

Tighten locking bolt head clockwise with Knox Keywrench until rm.

For Swivel-Guard model, line up lugs on swivel with cut outs in swivel guard ring, then spin swivel to thread FDC plug into the connection. incorrect size.

Removal

CAUTION

Knox FDC Plugs are not designed to function as pressure-seal plugs for wet systems. If the check valve upstream is defective and leaks water, the water will go through the Plug to show leakage. The defective check valve must then be repaired. If your FDC system is back ushed for clean out, you must remember to remove all of the Knox FDC Plugs so that contaminated water and debris will not ood the plugs and cause contamination problems. This is especially important if the sprinkler system has developed microbial infestation. FDC plugs should be inspected by a qualied inspector at least once a year to ensure situations have not occurred that would damage the device.

1 2 3 4

Inspect locking bolt head and remove any debris, if necessary. Use the Knox Keywrench to turn the locking bolt head counter clockwise until fully unlocked Use the pins to unscrew the plug from the connection. If the locking bolt is completely loosened and the plug will still not release, use the spanner end of the Keywrench to engage the pins on the face of the FDC plug and unscrew counter clockwise as shown above.

KNOX COMPANY

OPE-KBSPEC-0024-B

Recommended Procedure to Install ALL FDC Brass Adapters Theft of materials such as copper and brass are a growing problem for both property owners and reghters. Unfortunately, FDC connections now fall victim to both vandalism and theft. Knox recommends taking the following steps to ensure the entire FDC assembly is permanently secured to the pipe thread on the building. The FDC brass must be well-secured to the pipe, or the entire housing and pipe is at risk of being stolen. This procedure involves installing one or more 5/16-18 Allen set screws as well as a special permanent adhesive in order to secure FDC Brass to the pipe thread on the building. This will minimize the chance of theft.

Installers Please Read!

Lip

Dont let FDC brass fall victim to theft!

Use Letter F drill bit to drill a hole entirely through the brass adapter lip, approximately provides extra security. Three provide much better security.

Clean pipe threads thoroughly with solvent, wire brush, and dry completely. NO grease or oil can be present on the pipe threads in order for adhesive to work properly.

BOTH threads on adapter and threads on pipe. Coating should be thin, but needs to completely coat the threads.

Tighten and position FDC brass adapter on pipe.

in adapter and into pipe DO NOT OVERDRILL TOO DEEP AND PIERCE PIPE.

Clean drill holes of debris then place a small amount of in hole and on set screws, then install set screws, securing

secured, insert a ball bearing into the screw head and use punch to hammer into place. with a permanent epoxy material. This will virtually eliminate removal attempts.

NOTE: To minimize potential of pipe being stolen, attach a clamp on the backside of install wall.

Spot Drill Detent

Siamese Brass Pipe Wall

KNOX COMPANY

Potrebbero piacerti anche

- S&D Firefighter Forcible Entry Door Prop PlansDocumento81 pagineS&D Firefighter Forcible Entry Door Prop Planssherpa28591% (11)

- S&D Firefighter Halligan Tuning GuideDocumento341 pagineS&D Firefighter Halligan Tuning Guidesherpa285100% (4)

- Firefighter: Active RIT PDFDocumento36 pagineFirefighter: Active RIT PDFsherpa285100% (4)

- Firefighter: Halligan vs. Nader Pin PDFDocumento5 pagineFirefighter: Halligan vs. Nader Pin PDFsherpa285Nessuna valutazione finora

- NIOSH LODD Report, Walt Harris, Detroit Fire Dept. 2010Documento32 pagineNIOSH LODD Report, Walt Harris, Detroit Fire Dept. 2010sherpa285Nessuna valutazione finora

- Fdny Strike PDFDocumento4 pagineFdny Strike PDFsherpa285Nessuna valutazione finora

- Butcher Bar Bored Lock Lock-Puller For Firefighter Forcible EntryDocumento15 pagineButcher Bar Bored Lock Lock-Puller For Firefighter Forcible Entrysherpa285Nessuna valutazione finora

- IAFF Firefighter Safety and Survival ManualDocumento100 pagineIAFF Firefighter Safety and Survival Manualsherpa285100% (5)

- Conventional Forcible Entry Training Drill From SEARCH & DESTROY FIRE TRAININGDocumento26 pagineConventional Forcible Entry Training Drill From SEARCH & DESTROY FIRE TRAININGsherpa285100% (1)

- Firefighter Conventional Forcible EntryDocumento38 pagineFirefighter Conventional Forcible Entrysherpa285Nessuna valutazione finora

- Green Door Conventional FE Door PDFDocumento79 pagineGreen Door Conventional FE Door PDFsherpa285100% (3)

- Bob Farrell: The Man Behind The Forcible Entry ToolsDocumento7 pagineBob Farrell: The Man Behind The Forcible Entry Toolssherpa2850% (1)

- S&D TTL Prop How-To-Build PDFDocumento10 pagineS&D TTL Prop How-To-Build PDFsherpa285100% (2)

- MIT Lockpicking GuideDocumento49 pagineMIT Lockpicking GuideNarrowPathPilgrim100% (10)

- FDNY Forcible Entry Manual PDFDocumento177 pagineFDNY Forcible Entry Manual PDFsherpa285100% (5)

- Firefighter's Forcible Entry Hinge-Pull Prop How-to-BuildDocumento11 pagineFirefighter's Forcible Entry Hinge-Pull Prop How-to-Buildsherpa285100% (4)

- Vehicle Extrication TechniquesDocumento95 pagineVehicle Extrication Techniquesgort400100% (3)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- MICODocumento4 pagineMICOmaniamsonNessuna valutazione finora

- UKCS-TI-32 Piping Joints Handbook PDFDocumento107 pagineUKCS-TI-32 Piping Joints Handbook PDF임재령Nessuna valutazione finora

- LNG Technology SelectionDocumento9 pagineLNG Technology SelectionWayne MonneryNessuna valutazione finora

- 3D Printing of Reduced Graphene Oxide NanowiresDocumento5 pagine3D Printing of Reduced Graphene Oxide NanowiresDuniaNessuna valutazione finora

- 01CS1S02Documento5 pagine01CS1S02raobabar21Nessuna valutazione finora

- PTC Thermistors As Limit Temperature Sensors PDFDocumento11 paginePTC Thermistors As Limit Temperature Sensors PDFmarckalhiNessuna valutazione finora

- Fabricated Bridge Products: CatalogDocumento24 pagineFabricated Bridge Products: CatalogMuhammad TobiNessuna valutazione finora

- PuneDocumento564 paginePuneANSHUMANNessuna valutazione finora

- SMM COMSOL Simulation MontiDocumento6 pagineSMM COMSOL Simulation Montitamarco85Nessuna valutazione finora

- Permanent Metal - Data - Sheet - AFP 1 209B NewDocumento1 paginaPermanent Metal - Data - Sheet - AFP 1 209B NewSunnyNessuna valutazione finora

- Quick Process DesignDocumento35 pagineQuick Process DesignAkshat JainNessuna valutazione finora

- 1805P ReguladoresDocumento8 pagine1805P ReguladoresALBERTONessuna valutazione finora

- No. Questions Answer Pressure Rate Maximum Flow Stop LeakageDocumento7 pagineNo. Questions Answer Pressure Rate Maximum Flow Stop LeakageTrường Tùng LýNessuna valutazione finora

- 2011 VND O&M ManualDocumento12 pagine2011 VND O&M Manualsequeira.cedric6742Nessuna valutazione finora

- Quab Cationization of PolymersDocumento11 pagineQuab Cationization of PolymersJose Luis Recalde AriasNessuna valutazione finora

- Downhole Gas CompressionDocumento40 pagineDownhole Gas CompressionYasir Mumtaz100% (2)

- Steel Angles D 1322Documento2 pagineSteel Angles D 1322Shanmuga SundaramNessuna valutazione finora

- Section 21-Elect Specs 08-03-08 LatestDocumento98 pagineSection 21-Elect Specs 08-03-08 LatestsasikalaNessuna valutazione finora

- Offshore - Packaged Air Conditioning UnitDocumento7 pagineOffshore - Packaged Air Conditioning UnitLovre PerkovićNessuna valutazione finora

- 09 Counter CellDocumento3 pagine09 Counter CellTana AzeezNessuna valutazione finora

- 2-1393774-1 - P1 Relay V23026Documento5 pagine2-1393774-1 - P1 Relay V2302606111981Nessuna valutazione finora

- LeachingDocumento8 pagineLeachingRodolfoSottoJr.Nessuna valutazione finora

- Samsung Fridge Manual PDFDocumento0 pagineSamsung Fridge Manual PDFKuldeep DidwaniaNessuna valutazione finora

- Mckinsey Report - Make It in AmericaDocumento88 pagineMckinsey Report - Make It in AmericaAbhishekJindalNessuna valutazione finora

- B&M Series 1000 SwitchesDocumento12 pagineB&M Series 1000 SwitchesscribdkhatnNessuna valutazione finora

- Acc Gearbox ManualDocumento47 pagineAcc Gearbox ManualShivakumar100% (1)

- PP H2222 36Documento2 paginePP H2222 36keyur1109Nessuna valutazione finora

- Fm200 Data SheetDocumento10 pagineFm200 Data SheetMahmoud EldusokyNessuna valutazione finora

- ACI 363r 92 State of The Art Report On HDocumento55 pagineACI 363r 92 State of The Art Report On Hosama anterNessuna valutazione finora

- Copper Loops For 222 and 440MHzDocumento5 pagineCopper Loops For 222 and 440MHzBenjamin Dover100% (1)