Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

D1 4scope

Caricato da

sunparamarDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

D1 4scope

Caricato da

sunparamarCopyright:

Formati disponibili

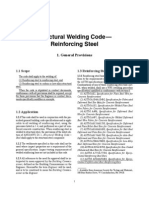

AWS D1.4/D1.

4M:2005

Structural Welding Code Reinforcing Steel

1. General Provisions

1.1 Scope

The code shall apply to the welding of: (1) Reinforcing steel to reinforcing steel, and (2) Reinforcing steel to carbon or low-alloy structural steel. When the code is stipulated in contract documents, conformance with all provisions shall be required, except for those provisions that the Engineer or contract documents specifically modifies or exempts.

1.2 Application

1.2.1 This code shall be used in conjunction with the prescribed general building code requirements and is applicable to all welding of reinforcing steel, using the processes listed in 1.4, and performed as a part of reinforced concrete construction. 1.2.2 The weldments specified in this code shall not be used where impact properties are a requirement of the general specification. Impact testing requirements of welded reinforcing bars are not included in this code. 1.2.3 All references to the need for approval shall be interpreted to mean approval by the Engineer.

(1) ASTM A 82/A 82M (2) ASTM A 496/A 496M (3) ASTM A 615/A 615M (4) ASTM A 706/A 706M (5) ASTM A 767/A 767M (6) ASTM A 775/A 775M (7) ASTM A 934/A 934M Manufacturing and testing requirements for mats and fabric are covered by the respective ASTM specification. For joining the ASTM A 82/A 82M and A 496/A 496M to other reinforcing wires, reinforcing bars, or structural steels, the Engineer shall specify filler metal and the provisions of this code shall apply. 1.3.2 When a reinforcing steel not listed in 1.3.1 is approved under the provisions of the general building code or by the Engineer, its chemical composition and carbon equivalent shall be provided and its weldability established by qualification in accordance with the requirements of 6.2 and all other requirements prescribed by the Engineer. 1.3.3 Base metal, other than those previously listed, shall be one of the structural steels listed in the latest edition of AWS D1.1, Structural Welding CodeSteel, or any steel stipulated in the contract documents or approved by the Engineer. 1.3.4 The carbon equivalent of reinforcing steel bars shall be calculated as shown in 1.3.4.1 or 1.3.4.2, as applicable. 1.3.4.1 For all steel bars, except those designated as ASTM A 706, the carbon equivalent shall be calculated using the chemical composition, as shown in the mill test report, by the following formula: C.E = %C + %Mn/6 (Eq. 1)

1.3 Reinforcing Steel Base Metal

1.3.1 Reinforcing steel base metal in this code shall conform to the requirements of the latest edition of one of the ASTM specifications listed within this paragraph. Combinations of any of these reinforcing steel base metals, when welded, shall use a WPS (welding procedure specification) qualified in conformance with Section 6.

AWS D1.4/D1.4M:2005

1.3.4.2 For steel bars designated ASTM A 706/ A 706M, the carbon equivalent shall be calculated using the chemical composition, as shown in the mill test report, by the following formula: C.E. = %C + %Mn/6 + %Cu/40 + %Ni/20 + %Cr/10 %Mo/50 %V/10 (Eq. 2) The carbon equivalent shall not exceed 0.55%. 1.3.4.3 If mill test reports are not available, chemical analysis may be made on bars representative of the bars to be welded. If the chemical composition is not known or obtained: (1) For bars number 6 [19] or less, use a minimum preheat of 300F [150C]. (2) For bars number 7 [22] or larger, use a minimum preheat of 500F [260C]. (3) For all ASTM A 706/A 706M bar sizes, use Table 5.2 C.E. values of over 0.45% to 0.55% inclusive.

1.7 Safety Precautions

This technical document does not address all welding and health hazards. However, pertinent information can be found in the following documents: (1) ANSI Z49.1, Safety in Welding, Cutting, and Allied Processes (2) Manufacturers safety literature on equipment and materials (3) Other pertinent documents as appropriate. These documents shall be referred to and followed as required (also see Annex D, Safe Practices). Note: This code may involve hazardous materials, operations, and equipment. The code does not purport to address all of the safety problems associated with its use. It is the responsibility of the user to establish appropriate safety and health practices. The user should determine the applicability of any regulatory limitations prior to use.

1.8 Standard Units of Measurement 1.4 Welding Processes

1.4.1 Welding shall be performed with shielded metal arc welding (SMAW), gas metal arc welding (GMAW), or flux cored arc welding (FCAW). 1.4.2 Other welding processes may be used when approved by the Engineer, provided that any special qualification test requirements not covered here are met to ensure that welds satisfactory for the intended application will be obtained. This standard makes use of both U.S. Customary Units and the International System of Units (SI). The measurements may not be exact equivalents; therefore, each system shall be used independently of the other without combining in any way. The standard with the designation D1.4:2005 uses U.S. Customary Units. The standard designation D1.4M:2005 uses SI Units. The latter are shown within brackets [ ].

1.9 Reference Documents 1.5 Definitions

The welding terms used in this code shall be interpreted in accordance with the definitions given in the latest edition of AWS A3.0, Standard Welding Terms and Definitions. The following standards contain provisions which, through reference in this text, constitute provisions of this AWS standard. For undated references, the latest edition of the referenced standard in use at the date of the contract bid submission shall apply. For dated references, subsequent amendments to, or revisions of, any of these publications do not apply. ASNT Standards1 (1) ASNT Recommended Practice No. SNT-TC-1A, Personnel Qualification and Certification in Nondestructive Testing

1. ASNT standards are published by the American Society for Nondestructive Testing, 1711 Arlingate Lane, Columbus, OH 43228-0518.

1.6 Welding Symbols

Welding symbols shall be those designated to the latest edition of AWS A2.4, Standard Symbols for Welding, Brazing, and Nondestructive Examination. Special conditions shall be fully explained by additional notes or details.

AWS D1.4/D1.4M:2005

ASME Standards2 (1) ASME B46.1, Surface Texture (2) ASME Boiler and Pressure Vessel Code ASTM Standards3 (1) ASTM A 82/A 82M, Specification for Steel Wire, Plain, for Concrete Reinforcement (2) ASTM A 496/A 496M, Specification for Steel Wire, Deformed, for Concrete Reinforcement (3) ASTM A 615/A 615M, Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement (4) ASTM A 706/A 706M, Specification for LowAlloy Steel Deformed and Plain Bars for Concrete Reinforcement (5) ASTM A 767/A 767M, Specification for ZincCoated (Galvanized) Steel Bars for Concrete Reinforcement (6) ASTM A 775/A 775M, Specification for EpoxyCoated Steel Reinforcing Bars (7) ASTM A 934/A 934M, Specification for EpoxyCoated Prefabricated Steel Reinforcing Bars (8) ASTM E 94, Standard Guide for Radiographic Examination (9) ASTM E 165, Standard Test Method for Liquid Penetrant Examination (10) ASTM E 709, Standard Guide for Magnetic Particle Examination (11) ASTM E 1032, Standard Test Method for Radiographic Examination of Weldments

2. ASME standards are published by the American Society of Mechanical Engineers, 3 Park Avenue, New York, NY 10017. 3. ASTM standards are published by the American Society for Testing and Materials, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959.

AWS Standards4 (1) ANSI Z49.1:1999, Safety in Welding, Cutting, and Allied Processes (2) AWS A2.4-98, Standard Symbols for Welding, Brazing, and Nondestructive Examination (3) AWS A3.0:2001, Standard Welding Terms and Definitions (4) AWS A5.1:2004, Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding Electrodes (5) AWS A5.5-96, Specification for Low-Alloy Steel Electrodes for Shielded Metal Arc Welding Electrodes (6) AWS A5.18:2001, Specification for Carbon Steel Electrodes and Rods for Gas Shielded Arc Welding (7) AWS A5.20:2005, Specification for Carbon Steel Electrodes for Flux Cored Arc Welding (8) AWS A5.28-96, Specification for Low Alloy Steel Filler Metals for Gas Shielded Arc Welding (9) AWS A5.29:1998, Specification for Low Alloy Steel Electrodes for Flux Cored Arc Welding (10) AWS D1.1:2004, Structural Welding Code Steel (11) AWS D12.1-75, Reinforcing Steel Welding Code (obsolete, superseded by D1.4-79) (12) AWS QC1-96, Standard for AWS Certification of Welding Inspectors CSA Standards5 (1) CSA Standard W178.2, Certification of Welding Inspectors

4. AWS standards are published by the American Welding Society, 550 N.W. LeJeune Road, Miami, FL 33126. 5. CSA standards are published by the Canadian Standards Association, 178 Rexdale Boulevard, Toronto, Ontario, Canada, M9W 1R3.

Potrebbero piacerti anche

- Sampling Procedure For Impact Testing of Structural SteelDocumento5 pagineSampling Procedure For Impact Testing of Structural Steelrodrigo nuñezNessuna valutazione finora

- Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used For RadiologyDocumento14 pagineDesign, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used For RadiologyJosé Ramón GutierrezNessuna valutazione finora

- AWS Guide To Abbreviations Certified WelderDocumento1 paginaAWS Guide To Abbreviations Certified Weldersigurdur hannessonNessuna valutazione finora

- Welder and Welding Operator Performance Qualification RecordDocumento1 paginaWelder and Welding Operator Performance Qualification RecordAsif HameedNessuna valutazione finora

- Mechanical Testing 01B: Part 2 Charpy Impact TestingDocumento25 pagineMechanical Testing 01B: Part 2 Charpy Impact Testingsamurai7_77100% (1)

- Industrial radiography A Complete Guide - 2019 EditionDa EverandIndustrial radiography A Complete Guide - 2019 EditionNessuna valutazione finora

- Ontario Bridge Steel Construction SpecificationDocumento20 pagineOntario Bridge Steel Construction Specificationumerfr2Nessuna valutazione finora

- Chartek 1709 Application Manual 2006 (Rev 5)Documento100 pagineChartek 1709 Application Manual 2006 (Rev 5)Tudor Moraru100% (1)

- Evaluating The Performance of Radiographic Digitization SystemsDocumento4 pagineEvaluating The Performance of Radiographic Digitization SystemsERNESTO ENRIQUE FERNANDEZ BAPTISTANessuna valutazione finora

- The Death of Welding InspectorDocumento1 paginaThe Death of Welding Inspectormekag94100% (1)

- Cast Carbon Steels in AWS D1.1 PDFDocumento3 pagineCast Carbon Steels in AWS D1.1 PDFIndra NainggolanNessuna valutazione finora

- CGC Welding Procedure SpecificationDocumento2 pagineCGC Welding Procedure SpecificationErick HoganNessuna valutazione finora

- Astm A 516 Gr.60n Plate SpecificationDocumento3 pagineAstm A 516 Gr.60n Plate Specificationharishbabuek100% (1)

- D 2527 - 83 R01 - Rdi1mjc - PDFDocumento2 pagineD 2527 - 83 R01 - Rdi1mjc - PDFsabaris ksNessuna valutazione finora

- STD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXDocumento2 pagineSTD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXAkshay KalraNessuna valutazione finora

- High Strength Structural Bolt Assemblies, Steel and Alloy Steel, Heat Treated, 144ksi Minimum Tensile Strength, Inch DimensionsDocumento11 pagineHigh Strength Structural Bolt Assemblies, Steel and Alloy Steel, Heat Treated, 144ksi Minimum Tensile Strength, Inch Dimensionsedder contreras maximoNessuna valutazione finora

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989Da EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookNessuna valutazione finora

- Norma Astm A-123 InglesDocumento8 pagineNorma Astm A-123 InglesMarilu' CrNessuna valutazione finora

- AWS Radio Graphic InterpreterDocumento5 pagineAWS Radio Graphic InterpreterShrey Gupta0% (1)

- Table 6 1 AWS D1 1 D1 1M 2010 PDFDocumento1 paginaTable 6 1 AWS D1 1 D1 1M 2010 PDFFu AdNessuna valutazione finora

- Schedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Documento2 pagineSchedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Caolboy ButchNessuna valutazione finora

- Astm f682 1982Documento7 pagineAstm f682 1982dharlanuctcomNessuna valutazione finora

- B467Documento8 pagineB467odqm_25Nessuna valutazione finora

- Q345B PDFDocumento2 pagineQ345B PDFAbdelkader DraïNessuna valutazione finora

- Aluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Documento1 paginaAluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Amin ThabetNessuna valutazione finora

- Certified Welding Inspector or CWI or Special InspectorDocumento4 pagineCertified Welding Inspector or CWI or Special Inspectorapi-77497104Nessuna valutazione finora

- Detecting and preventing lack of sidewall and inter-run fusion in weldsDocumento4 pagineDetecting and preventing lack of sidewall and inter-run fusion in weldsguru_terexNessuna valutazione finora

- SSPC QP 3Documento6 pagineSSPC QP 3anoopkumarNessuna valutazione finora

- A 586Documento4 pagineA 586Gustavo SuarezNessuna valutazione finora

- SSPC Chart PDFDocumento2 pagineSSPC Chart PDFABHISHEK SINGHNessuna valutazione finora

- Astm A6 2004 PDFDocumento64 pagineAstm A6 2004 PDFSofiaJabadanEspulgarNessuna valutazione finora

- Csa W48-23Documento70 pagineCsa W48-23Arnold Jose Batista RodriguezNessuna valutazione finora

- AWS D1.1 - Bend PDFDocumento1 paginaAWS D1.1 - Bend PDFVIVEKNessuna valutazione finora

- DIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationDocumento12 pagineDIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationHector Flores GarciaNessuna valutazione finora

- Astm e 428 Rev A 2005 PDFDocumento7 pagineAstm e 428 Rev A 2005 PDFJORGE ARTURO TORIBIO HUERTANessuna valutazione finora

- Astm17 0303Documento5 pagineAstm17 0303Edgardo Emilio CantillanoNessuna valutazione finora

- Fabrication of Large GRP Storage TanksDocumento60 pagineFabrication of Large GRP Storage TanksjoekaledaNessuna valutazione finora

- Epoch 4 Operations ManualDocumento164 pagineEpoch 4 Operations ManualpjhollowNessuna valutazione finora

- Astm A500 A500m-21Documento6 pagineAstm A500 A500m-21alvin duey100% (1)

- Hot Dip Galvanizing For FastenersDocumento3 pagineHot Dip Galvanizing For FastenersIrwin CastroNessuna valutazione finora

- Specification For The Certification of Radiographic InterpretersDocumento20 pagineSpecification For The Certification of Radiographic Interpreterscharles46Nessuna valutazione finora

- Ut ProcedureDocumento7 pagineUt Procedurearavindan100% (1)

- Certification: Structural Steel and Bolting Special Inspector Exam ID: S1Documento2 pagineCertification: Structural Steel and Bolting Special Inspector Exam ID: S1Ammar A. AliNessuna valutazione finora

- Astm A554 10Documento6 pagineAstm A554 10Lisandro ClaverolNessuna valutazione finora

- BS 2452 (1954)Documento30 pagineBS 2452 (1954)siswou100% (1)

- AWS D1.5/D1.5M Bridge Welding Code ChangesDocumento36 pagineAWS D1.5/D1.5M Bridge Welding Code ChangesedwinNessuna valutazione finora

- Schaeffler Diagram PDFDocumento16 pagineSchaeffler Diagram PDFrajesh_14Nessuna valutazione finora

- 16mo3 MıgMagDocumento4 pagine16mo3 MıgMagKerem İnanNessuna valutazione finora

- Approved Welding Procedures-Rebar Indirect Butt Joint With Splice AngleDocumento8 pagineApproved Welding Procedures-Rebar Indirect Butt Joint With Splice Anglecipele12Nessuna valutazione finora

- 4 5847992272976611240 PDFDocumento8 pagine4 5847992272976611240 PDFAyyappanSubramanianNessuna valutazione finora

- AA0850126 Rev 02Documento10 pagineAA0850126 Rev 02Manish KumarNessuna valutazione finora

- Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesDocumento10 pagineHot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesIsaac ZTNessuna valutazione finora

- Astm A 790-2020Documento10 pagineAstm A 790-2020Mohammed AliNessuna valutazione finora

- E1030e1030m 15Documento11 pagineE1030e1030m 15masoudNessuna valutazione finora

- Astm E2491 06Documento13 pagineAstm E2491 06phanthanhhungNessuna valutazione finora

- Structural Welding D1.4Documento2 pagineStructural Welding D1.4aashiith29% (7)

- Structural Welding Code for Reinforcing SteelDocumento2 pagineStructural Welding Code for Reinforcing SteelMohammed ShamilNessuna valutazione finora

- Astm A403Documento7 pagineAstm A403mtpiping2572100% (1)

- A 992Documento3 pagineA 992ivan_vanNessuna valutazione finora

- 13 Personal Finance Thumb Rules To Help Kick-Start Your Financial Planning - The Economic TimesDocumento4 pagine13 Personal Finance Thumb Rules To Help Kick-Start Your Financial Planning - The Economic TimessunparamarNessuna valutazione finora

- Janadriyah Festival Encourages Saudi Heritage and CultureDocumento2 pagineJanadriyah Festival Encourages Saudi Heritage and CulturesunparamarNessuna valutazione finora

- B35Documento3 pagineB35sunparamarNessuna valutazione finora

- Treatment of Cold JointsDocumento1 paginaTreatment of Cold JointssunparamarNessuna valutazione finora

- Mass ConcreteDocumento16 pagineMass Concretemohsin100% (1)

- Method Statement For Demolition of Concrete and Asphalt PavingDocumento3 pagineMethod Statement For Demolition of Concrete and Asphalt Pavingsunparamar75% (4)

- BalaDocumento5 pagineBalasunparamarNessuna valutazione finora

- Controlling Temperatures in Mass ConcreteDocumento4 pagineControlling Temperatures in Mass ConcreteBatepola Bac100% (1)

- Construction Safety Manual Drawings Anchor Bolt InstallationDocumento5 pagineConstruction Safety Manual Drawings Anchor Bolt Installationsunparamar50% (2)

- Idhu Andavan Kattalai - Rajinikanth PDFDocumento40 pagineIdhu Andavan Kattalai - Rajinikanth PDFmrithika25012011Nessuna valutazione finora

- Punch List Final-DatesDocumento32 paginePunch List Final-DatessunparamarNessuna valutazione finora

- BelbinDocumento70 pagineBelbinsunparamarNessuna valutazione finora

- Il Il: .Q FM) - / - F.'tfil" .1952Documento2 pagineIl Il: .Q FM) - / - F.'tfil" .1952Babu R SrinvasNessuna valutazione finora

- Robin SharmaDocumento69 pagineRobin SharmaAndreea CraciunNessuna valutazione finora

- Robin SharmaDocumento69 pagineRobin SharmaAndreea CraciunNessuna valutazione finora

- Amir36325203 - 2013 05 22 - 11 39 06Documento1 paginaAmir36325203 - 2013 05 22 - 11 39 06sunparamarNessuna valutazione finora

- Concrete RepairDocumento99 pagineConcrete RepairHamid Naveed75% (4)

- Pipe Freezing StudyDocumento8 paginePipe Freezing StudymirekwaznyNessuna valutazione finora

- CO Capture by Absorption With Potassium CarbonateDocumento23 pagineCO Capture by Absorption With Potassium CarbonatekumarNessuna valutazione finora

- Natural Fertilizer FormulationDocumento11 pagineNatural Fertilizer Formulationsyamsu alamNessuna valutazione finora

- p355n NH Nl1 Nl2 TubesDocumento4 paginep355n NH Nl1 Nl2 Tubesado31Nessuna valutazione finora

- Properties of Matter PresentationDocumento9 pagineProperties of Matter PresentationMica Ela MañoNessuna valutazione finora

- Manufacturing and Metal Working Process ClassificationDocumento5 pagineManufacturing and Metal Working Process ClassificationPeeka Prabhakara RaoNessuna valutazione finora

- Bioplastic ProjectDocumento15 pagineBioplastic ProjectSarthak Verma100% (1)

- DGT-eex digital gas detector for hazardous areasDocumento2 pagineDGT-eex digital gas detector for hazardous areasAli SadiqNessuna valutazione finora

- Sintering Effect On The Performance of Tungsten-Copper Powder LinerDocumento2 pagineSintering Effect On The Performance of Tungsten-Copper Powder LinermahsaNessuna valutazione finora

- A Simplified Method For The Cultivation of Extreme Anaerobic Archaea Based SULFIDE 2000 !!!!Documento6 pagineA Simplified Method For The Cultivation of Extreme Anaerobic Archaea Based SULFIDE 2000 !!!!Vera Brok-VolchanskayaNessuna valutazione finora

- An Updated Review On IPQC Tests For Sterile and Non Sterile ProductsDocumento12 pagineAn Updated Review On IPQC Tests For Sterile and Non Sterile ProductsJvnNessuna valutazione finora

- Safety Assessment of Methyl Glucose Polyethers and Esters As Used in CosmeticsDocumento29 pagineSafety Assessment of Methyl Glucose Polyethers and Esters As Used in CosmeticsCesar Miguel JuniorNessuna valutazione finora

- Sika 521Documento3 pagineSika 521Natasha KamalNessuna valutazione finora

- Air PollutionDocumento2 pagineAir PollutionBarani KingNessuna valutazione finora

- 31.PEAK Depressurization RATEDocumento1 pagina31.PEAK Depressurization RATEDILIP MATALNessuna valutazione finora

- PCA Ion Exchange Membranes - Technical Data SheetDocumento2 paginePCA Ion Exchange Membranes - Technical Data Sheettestuser010% (1)

- Vortex Quantum SeriesDocumento34 pagineVortex Quantum SeriesmiguelcNessuna valutazione finora

- Boron FamilyDocumento20 pagineBoron FamilyP. PARIS KATHERINE REBECCAH BCMBC2019Nessuna valutazione finora

- Ellc Rmnbemae Llce Bmmneera Lecl Mebmaren Lcel Nbmemaer: Cell MembraneDocumento9 pagineEllc Rmnbemae Llce Bmmneera Lecl Mebmaren Lcel Nbmemaer: Cell MembraneAlvin PaboresNessuna valutazione finora

- Recycling of Pad-Batch Washing Textile Wastewater Through Advanced Oxidation Processes and Its Reusability Assessment For Turkish Textile IndustDocumento7 pagineRecycling of Pad-Batch Washing Textile Wastewater Through Advanced Oxidation Processes and Its Reusability Assessment For Turkish Textile IndustGizem D.Nessuna valutazione finora

- Solidification ShrinkageDocumento4 pagineSolidification ShrinkagesubavlNessuna valutazione finora

- Monsal Enzymic Hydrolysis New Developments and Lessons LearntDocumento23 pagineMonsal Enzymic Hydrolysis New Developments and Lessons LearntAnonymous MVHQ97KEoPNessuna valutazione finora

- Polymer CharacterizationDocumento29 paginePolymer CharacterizationCarlos Miguel Dacaimat0% (1)

- Quiz 1 Fundamental PetroleumDocumento4 pagineQuiz 1 Fundamental PetroleumMuhammad Amran50% (2)

- 맥머리유기화학8판Documento1.177 pagine맥머리유기화학8판이경식Nessuna valutazione finora

- Coconut Shell Based Activated Carbon W No Greeen House Gas EmissionDocumento4 pagineCoconut Shell Based Activated Carbon W No Greeen House Gas Emissionmragul22Nessuna valutazione finora

- Chemistry 2pointsDocumento4 pagineChemistry 2pointsjovanniNessuna valutazione finora

- Effect of Sugarmill On Soil of DoiwalaDocumento11 pagineEffect of Sugarmill On Soil of DoiwalaBilal BhatNessuna valutazione finora

- (Re) Coating of Pylons With ZINGAENDocumento5 pagine(Re) Coating of Pylons With ZINGAENMarco Antonio MoncerrateNessuna valutazione finora

- Buffers BookletDocumento38 pagineBuffers BookletdgmansoNessuna valutazione finora