Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ChE-413-MSF Multi-Stage Flash Desal Ination

Caricato da

Denis TanDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ChE-413-MSF Multi-Stage Flash Desal Ination

Caricato da

Denis TanCopyright:

Formati disponibili

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Introduction

The MSF process is innovative where vapor formation takes place within the bulk liquid instead of the surface of hot tubes.

Water Desalination Multi-Stage Flash (MSF)

Introduction Principle of MSF MSF Classification Stage Configuration: Cross / Long tube

In other thermal processes, submerged tubes of heating steam are used to perform evaporation. This always resulted in scale formation on the tubes less heat transfer & costly scale inhibition or removal.

Once Through MSF

Brine recirculation MSF Energy Balances

Prof. Ibrahim S. Al-Mutaz King Saud University 1 Chemical Engineering Dep. Prof. Ibrahim S. Al-Mutaz King Saud University 2

Chemical Engineering Dep.

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Principle of MSF

Principle of MSF

Weirs

When saturated brine enters through slot at lower pressure stage. It senses the new lower pressure environment, and Flashes!

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Principle of MSF

Principle of MSF

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Principle of MSF - energy

from the energy flow diagram, the great part of the heat input to the MSF system is returned back to the sea with the seawater drain stream

Development in MSF

Plant operation has improved with

More efficient antiscalent Better corrosion control chemicals Construction material capable of standing harsh conditions

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Development in MSF

Increase in the unit capacity from 454.4 m3/d to a current capacity of 32731 m3/d. The largest unit was commissioned in Al-Taweela with a capacity of 57,734 m3/d. Each capacity doubling is associated with 24% reduction in unit product cost. Decreasing the specific power consumption cost from 7-25 kW/m3 in 1955 to 4-10 kW/m3

Pretreatment

Treatment of the intake seawater is limited to screening and filtration Treatment of the feed seawater includes:

Dearation Addition of antiscalent Addition of foaming inhibitors

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

10

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

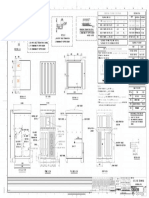

MSF Flashing stage

Demister

Tube Bundle

MSF Flashing stage

Air Buffle Vent Line

Distillate duct Outlet Distillate

Inlet Distillate

Distillate Tray

Outlet Brine Flashed off Vapor

Chemical Engineering Dep.

Inlet Brine Brine Pool

Prof. Ibrahim S. Al-Mutaz

Submerged Orifice

King Saud University 11 Chemical Engineering Dep. Prof. Ibrahim S. Al-Mutaz King Saud University 12

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

MSF Flashing stage

Demister Tube Bundle

MSF Flashing stage

Vent line Distillate Duct

Air Baffle

Outlet Distillate

Inlet Distillate Distillate Tray

Outlet Brine Brine Pool Orifice Weir

Chemical Engineering Dep. Prof. Ibrahim S. Al-Mutaz

Inlet Brine

King Saud University

13

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

14

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Single Stage Flash Desalination

Cooling Seawater M cw = 103.9 kg/s Xf = 42000 ppm T1 = 35 OC

Single Stage Flash Desalination

Intake Seawater M f+M cw= 115.44 kg/s Xf= 42000 ppm Tcw= 30 oC Distillate Product M d = 1 kg/s

Heating Steam M s = 1.18 kg/s Ts = 100 oC

Feed Seawater M f = 11.54 kg/s Xf = 42000 ppm To = 90 oC

Chemical Engineering Dep. Prof. Ibrahim S. Al-Mutaz

Reject Brine M b = 10.54 kg/s Xb = 45984.8 ppm Tb = 40 oC

King Saud University

15

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

16

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Assumptions

Distillate product is salt free Cp is the same for all streams and equal 4.18 kJ/kg

oC

Temperature profile

Brine Heater Ts Flashing Stage TTDh To Top Brine Temperature To T1 TTDc T1 DTst Feed Preheater

U is the same for preheater and brine heater and equal 2 kW/m2. oC Subcooling of condensate or superheating of the heating steam has negligible effect on the energy balance The heat loss is negligible Power consumption is not considered.

Tv

Tb DTloss

Tcw

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

17

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

18

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Advantages of Single Stage

Drawbacks of single stage

PR is always less than 1.0 The flow rate of the feed seawater is much larger than the distillate produced ( about ten times) which means a large amount of additives and chemicals needed for feed treatment The flow rate of cooling water is very high which increases the pumping power consumption

The salinity of the rejected brine is much smaller than maximum allowable The heat transfer area for the brine heater and preheater is small due to the large temperature driving force. The specific heat transfer area in the brine heater is inversely proportional to the performance ratio.

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

19

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

20

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

MSF Process Classification

MSF Process Classification

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

21

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

22

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

MSF Flow Configuration

Cross-Tube Configuration

Partiti on Walls

Cond enser Tubes Distilla te Brine

Demi ster

Condenser Tubes Demister Tube Sheet

Side Walls

Brine Side Walls

Cross-tube MSF distiller

Long-tube MSF

Chemical Engineering Dep. Prof. Ibrahim S. Al-Mutaz

Cross-tube MSF

King Saud University 23 Chemical Engineering Dep. Prof. Ibrahim S. Al-Mutaz King Saud University 24

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Cross-Tube Configuration

Cross-Tube Configuration

Partition Walls

Condenser Tubes

Demister

Tube Sheet

Brine Side Walls

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

25

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

26

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Cross-Tube Configuration

Cross-Tube Configuration

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

27

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

28

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Cross-Tube Internal Layout

Long-Tube Configuration

Long-tube MSF distiller

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

29

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

30

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Long-Tube Configuration

Long-Tube Configuration

Demister Condenser Tubes

Distillate Side Walls

Brine

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

31

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

32

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Long-Tube Configuration

Long-Tube Configuration

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

33

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

34

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Long-Tube Internal Layout

Comparison between Cross Tube and Long Tube MSF Plant Parameters

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

35

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

36

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Multi-stage MSF

There are 2 types of Multi-stage MSF Once Through (OT) MSF Brine recalculated (recycled)

Objective of Multi-stage MSF

To overcome the main drawbacks of the single flash units To improve the system performance ratio This is achieved by adding more flash units and reducing the temperature drop per stage

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

37

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

38

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

System Components

Once Through MSF

N number of stages : all of the stages are identical Brine heater No recycle of any portion of brine Does not contain cooling water stream: because the brine rejected with low temperature and large flow rate contains the energy to be removed from the system.

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

39

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

40

10

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Once Through MSF

Once Through MSF

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

41

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

42

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Once Through MSF

Once Through MSF

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

43

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

44

11

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Process description

The intake seawater at Tcw flow through the preheater of stage n to 1. When it leaves stage 1 its temperature increases to t1. The seawater leaving the condenser enters the brine heater, where its temperature rises from t1 to To The heated brine flashes off as it flows through the successive stages where its temperature decreases from To to Tn

Process description cont.

Simultaneously, flashing vapor condenses around the condenser tubes in each stage where it heats the the seawater flowing through the tubes. The collected distillate leaves from stage n. The brine leaving the last stage is rejected to the sea.

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

45

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

46

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Advantages vs. Disadvantages

Drastic increase in performance ratio Does not use cooling water for removing excess heat added in the brine heater. Operation at low salinity of both feed and flashed brine High flow rate of intake seawater High total condenser surface area

Brine recirculation (BR) MSF

Heat input Section

Heat Recovery Section

Heat Rejection Section

Cooling Seawater Mcw Condenser Tubes Water Boxes Distillate Trays Demister

Cooling Seawater Recycle Winter Temperature Control Intake Seawater Mf +Mcw

Heating Steam Ms 1 2 3 1 9 20 21 2 2 2 3 24

Distillate Product Md

Condensate

Feed Brine

Brine Pool Brine Recycle Mr Feed Seawater Mf Brine Blow-down Mb

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

47

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

48

12

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Brine recirculation (BR) MSF

It is considered the industry standard The process consists of three section

The heat recovery sections The heat rejection section (2-3 stages) The brine heater

Brine recirculation (BR) MSF

The heat rejection section is used to remove the excess heat added to the system in the brine heater It is used to control the temperature of the of the recycled brine This is achieved through recovery of a controlled amount of energy from the flashing brine into the brine recycle and rejection of the remaining energy into the cooling water stream

The system is driven by the heating steam which increases the temperature of the brine recycle or feed seawater to the desired value in the brine heater

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

49

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

50

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Advantage of brine recirculating MSF

Experience in design and operation of MSF has led to use of inexpensive construction material capable of standing harsh conditions at high salinity The MSF systems does not include moving parts other than pumps. Construction is simple and contains a small number of tubes which limits leakage problems and simplify maintenance work

Description

The hot brine flashes in the consecutive stages, where the brine recycle flow inside the condenser tubes recover the latent heat of the formed vapor. In the heat rejection section of brine circulation system, the excess heat added to the system by the hating steam is rejected to the environment by the cooling seawater stream

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

51

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

52

13

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Brine recirculation (BR) MSF

Process Description

The cooling water is introduced in the last stage of the heat recovery section. The cooling water leaving the first stage of the heat rejection section is divided into two parts

Cooling water to the sea Feed water to the dearator to remove O2

The feed is mixed with a portion of the brine from the last stage of the heat recovery section.

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

53

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

54

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Process Description cont.

The brine recirculation pump pumps the water through the condenser/preheater tubes of the last stage of the heat recovery section Leaving the condenser in the first stage, the feed is introduced into the brine heater (steam-heated), where the temperature rises to the top brine temperature Flashing occurs in each stage and a small amount of water is generated and is cascaded through the stages

Process Description cont.

Vapor formation results because of the reduction of brine saturation temperature

The stage temperature changes from the hot to cold The brine flows across the stages without the aid of pumping power (from high to low P).

The flashed-off vapor is condensed on the preheater tubes

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

55

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

56

14

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Process Description cont.

From the last stages

Part of brine is rejected to the sea Another part is recycled

Brine recirculation (BR) MSF

The rejection of the brine is necessary to control the salt concentration in the plant

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

57

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

58

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Brine recirculation (BR) MSF

Stream flow rate, salinity, and temperature

Brine recirculation (BR) MSF

Material balances on the heat rejection section

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

59

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

60

15

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Temperature Profile

Energy Balances

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

61

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

62

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Energy Balances

Energy Balances

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

63

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

64

16

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Energy Balances

Modelling a Flashing Stage

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

65

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

66

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Modelling a Brine Heater

Interface with Rest of the Plant: Layout

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

67

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

68

17

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Interface with Rest of the Plant: Layout

Interface with Rest of the Plant: Layout

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

69

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

70

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Multi Stage Flash

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

71

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

72

18

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

73

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

74

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

75

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

76

19

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

General view of low side flash chamber

Chemical Engineering Dep. Prof. Ibrahim S. Al-Mutaz King Saud University 77 Chemical Engineering Dep.

General view of low side flash chamber

Prof. Ibrahim S. Al-Mutaz King Saud University 78

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

General view of Cu-Ni 70-30 alloy heat transfer tubes in heat recovery section of Al-Kkafji MSF plant

Chemical Engineering Dep. Prof. Ibrahim S. Al-Mutaz King Saud University 79 Chemical Engineering Dep. Prof. Ibrahim S. Al-Mutaz King Saud University 80

20

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Al-Taweelah Az Power & Desalination Plant

Operational experience show desalination plants operating after 15 years successfully improved material selection suggests that the design life can be extended to 40 years operation

Chemical Engineering Dep. Prof. Ibrahim S. Al-Mutaz King Saud University 81 Chemical Engineering Dep. Prof. Ibrahim S. Al-Mutaz King Saud University 82

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Umm Al Nar Desalination Station B Plant

Shoaiba Desalination Plant, Saudi Arabia

Chemical 7 Section Engineering Dep. Prof. Ibrahim S. Al-Mutaz King Saud University 83 Chemical Engineering Dep. Prof. Ibrahim S. Al-Mutaz King Saud University 84

21

1/10/2011

ChE-413: Desalination and Water treatment

ChE-413: Desalination and Water treatment

Shoaiba Desalination Plant, Saudi Arabia Process type: Multi-Stage Flash Distillation (MSF) Estimated project cost: $1.06 billion Population served: 1.5 million Product water output: 74,000m/day (Phase 1); 450,000m/day (Phase 2) Final total production capacity: 150 million m/year Project Timeline: Construction started: 1997 Phase 1 completed: August 2000, Phase 2 completed: March 2003

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

85

Chemical Engineering Dep.

Prof. Ibrahim S. Al-Mutaz

King Saud University

86

22

Potrebbero piacerti anche

- Multi Effect Distillation DesalinationDocumento75 pagineMulti Effect Distillation DesalinationAnonymous tSOqJjO50% (2)

- Project ReportDocumento24 pagineProject ReportAdarsh RajNessuna valutazione finora

- Liquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentDa EverandLiquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentNessuna valutazione finora

- Adsorption from Solutions of Non-ElectrolytesDa EverandAdsorption from Solutions of Non-ElectrolytesValutazione: 5 su 5 stelle5/5 (1)

- Advances in Seawater Desalination TechnologiesDocumento23 pagineAdvances in Seawater Desalination TechnologiesFrank FanNessuna valutazione finora

- DeaeratorDocumento3 pagineDeaeratorpawangwlNessuna valutazione finora

- Multi Stage Flash Desalination Plant With Brine-Feed Mixing and CoolingDocumento8 pagineMulti Stage Flash Desalination Plant With Brine-Feed Mixing and CoolingMuhammadEhtishamSiddiquiNessuna valutazione finora

- Desalination EngineeringDocumento8 pagineDesalination EngineeringShafayet A SiddiqueNessuna valutazione finora

- Report On Multi Effect DistillationDocumento6 pagineReport On Multi Effect DistillationMohammadAsifNessuna valutazione finora

- Pom WTPDocumento46 paginePom WTPmuhammad85100% (1)

- Chlorine: International Thermodynamic Tables of the Fluid StateDa EverandChlorine: International Thermodynamic Tables of the Fluid StateNessuna valutazione finora

- Good One Chaube ZLD Techno Economic AnalysisDocumento5 pagineGood One Chaube ZLD Techno Economic AnalysisAmitNessuna valutazione finora

- Etp Process - RefineryDocumento3 pagineEtp Process - Refinerysumit gulatiNessuna valutazione finora

- Reverse Osmosis: Industrial Processes and ApplicationsDa EverandReverse Osmosis: Industrial Processes and ApplicationsNessuna valutazione finora

- Principles of Desalination (Part A)Da EverandPrinciples of Desalination (Part A)K SpeiglerNessuna valutazione finora

- Principles and Case Studies of Simultaneous DesignDa EverandPrinciples and Case Studies of Simultaneous DesignNessuna valutazione finora

- Simulated Moving Bed Technology: Principles, Design and Process ApplicationsDa EverandSimulated Moving Bed Technology: Principles, Design and Process ApplicationsNessuna valutazione finora

- The Analysis of CarbonDioxide in Natural GasDocumento4 pagineThe Analysis of CarbonDioxide in Natural GasBimo Gunners RespatiNessuna valutazione finora

- Boiler Water TreatmentDocumento5 pagineBoiler Water TreatmentUsamaNessuna valutazione finora

- Desalination in Water Treatment and SustainabilityDocumento86 pagineDesalination in Water Treatment and SustainabilityVishnuNessuna valutazione finora

- Membrane DistillationDocumento14 pagineMembrane DistillationMuhammad Ali100% (1)

- Analysis of Large Reverse Osmosis MembranesDocumento197 pagineAnalysis of Large Reverse Osmosis MembranesYoussefNessuna valutazione finora

- Mlti Stage Flash DistillationDocumento30 pagineMlti Stage Flash DistillationNitisha Rathore100% (1)

- Evaporation Technolgy Mechanical Vapour Recompression - GEA - Wiegand - enDocumento24 pagineEvaporation Technolgy Mechanical Vapour Recompression - GEA - Wiegand - enhardik033Nessuna valutazione finora

- Shortcut Nitrogen Removal-Nitrite Shunt and DeammonificationDa EverandShortcut Nitrogen Removal-Nitrite Shunt and DeammonificationNessuna valutazione finora

- Titan Boiler Water Treatment Handbook 1Documento33 pagineTitan Boiler Water Treatment Handbook 1Sunny OoiNessuna valutazione finora

- Design For EvaporatorDocumento5 pagineDesign For EvaporatorDevang GodhaniyaNessuna valutazione finora

- Introduction to Adsorption: Basics, Analysis, and ApplicationsDa EverandIntroduction to Adsorption: Basics, Analysis, and ApplicationsNessuna valutazione finora

- Chief Water Treatment Plant Operator: Passbooks Study GuideDa EverandChief Water Treatment Plant Operator: Passbooks Study GuideNessuna valutazione finora

- Multi Effects DesalinationDocumento18 pagineMulti Effects Desalinationabrar3831100% (1)

- Deionized For Cooling Tower PDFDocumento8 pagineDeionized For Cooling Tower PDFThipsuree KornboonraksaNessuna valutazione finora

- Natural Gas Processing from Midstream to DownstreamDa EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNessuna valutazione finora

- Pump Station Operator: Passbooks Study GuideDa EverandPump Station Operator: Passbooks Study GuideNessuna valutazione finora

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDa EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNessuna valutazione finora

- Principles of DesalinationDa EverandPrinciples of DesalinationK SpieglerNessuna valutazione finora

- Demineralization by Ion Exchange: In Water Treatment and Chemical Processing of Other LiquidsDa EverandDemineralization by Ion Exchange: In Water Treatment and Chemical Processing of Other LiquidsValutazione: 4 su 5 stelle4/5 (2)

- Sizing An Ion Exchange SystemDocumento14 pagineSizing An Ion Exchange Systemgnino2Nessuna valutazione finora

- Desalination Plant of TobrukDocumento21 pagineDesalination Plant of TobrukMotaz ZgogoNessuna valutazione finora

- Sanitary Engineer II: Passbooks Study GuideDa EverandSanitary Engineer II: Passbooks Study GuideNessuna valutazione finora

- Waste Water Treatment Plant For Copper RefineriesDocumento15 pagineWaste Water Treatment Plant For Copper RefineriesMehrdad AminkazemiNessuna valutazione finora

- Membrane Separation ProcessesDocumento93 pagineMembrane Separation ProcessesMohammad ShafiNessuna valutazione finora

- Evaporators SugarDocumento28 pagineEvaporators SugarAnkur KoulNessuna valutazione finora

- Water SOFTENERDocumento10 pagineWater SOFTENERWahluyo Budi UtomoNessuna valutazione finora

- Cycle of Concentration in Cooling Tower PDFDocumento1 paginaCycle of Concentration in Cooling Tower PDFNgoc Vũ TrầnNessuna valutazione finora

- fwctCoP Part 3Documento51 paginefwctCoP Part 3Simon LawNessuna valutazione finora

- Portable Seawater Desalination PlantDocumento1 paginaPortable Seawater Desalination PlantAnanda Setiyo IvannantoNessuna valutazione finora

- Section 01 Cold Lime SofteningDocumento6 pagineSection 01 Cold Lime SofteningSheikh SahabNessuna valutazione finora

- 2002 A Solar Desalination Plant For Domestic Water Needs in Arid Areas of South AlgeriaDocumento5 pagine2002 A Solar Desalination Plant For Domestic Water Needs in Arid Areas of South AlgeriaRahul TripathiNessuna valutazione finora

- Reverse Osmosis State of The Art in IndonesiaDocumento16 pagineReverse Osmosis State of The Art in IndonesiachrisNessuna valutazione finora

- 0910sem1 Ma1505Documento33 pagine0910sem1 Ma1505Denis TanNessuna valutazione finora

- Selections From MA1506 (Old Syllabus) Past PapersDocumento63 pagineSelections From MA1506 (Old Syllabus) Past PapersDenis TanNessuna valutazione finora

- My NUSMods - Com TimetableDocumento1 paginaMy NUSMods - Com TimetableDenis TanNessuna valutazione finora

- BOD Penalty Guidelines 2007Documento6 pagineBOD Penalty Guidelines 2007Denis TanNessuna valutazione finora

- Dynamic Modelling of Sedimentation in The Activated Sludge ProcessDocumento18 pagineDynamic Modelling of Sedimentation in The Activated Sludge ProcessDenis TanNessuna valutazione finora

- Chemical Engineering & Economics DDP Briefing by DenisDocumento42 pagineChemical Engineering & Economics DDP Briefing by DenisDenis TanNessuna valutazione finora

- KT Brochure FA 101110 Email SDocumento5 pagineKT Brochure FA 101110 Email SDenis TanNessuna valutazione finora

- Econ Major Requirements in The DDPDocumento1 paginaEcon Major Requirements in The DDPDenis TanNessuna valutazione finora

- Epoxylite TSA 220 - TDS - 2008Documento3 pagineEpoxylite TSA 220 - TDS - 2008Anonymous sAmJfcVNessuna valutazione finora

- Investor Presentation (Company Update)Documento42 pagineInvestor Presentation (Company Update)Shyam SunderNessuna valutazione finora

- Uh X PDFDocumento20 pagineUh X PDFRepresentaciones y Distribuciones FAL100% (1)

- C426Documento5 pagineC426Rufo CascoNessuna valutazione finora

- SE160 e BrochureDocumento2 pagineSE160 e BrochureAprilia KrisnawatiNessuna valutazione finora

- Durability of Clay BricksDocumento18 pagineDurability of Clay BricksEmmanuel okelloNessuna valutazione finora

- 008 Cat-6060 Attachment Functions FSDocumento37 pagine008 Cat-6060 Attachment Functions FSenrico100% (3)

- Technical Specification of Stay InsulatorDocumento11 pagineTechnical Specification of Stay Insulatorraj_stuff006Nessuna valutazione finora

- ASAP MethodologyDocumento14 pagineASAP MethodologyTiffany HughesNessuna valutazione finora

- 20e - cTI-60t - TI Pin Converter: Blackhawk™ Jtag Pin ConvertersDocumento2 pagine20e - cTI-60t - TI Pin Converter: Blackhawk™ Jtag Pin ConvertersvspuriNessuna valutazione finora

- 2935 9720 02 enDocumento8 pagine2935 9720 02 enemai2012Nessuna valutazione finora

- CV PDFDocumento4 pagineCV PDFSIVA0% (1)

- Wolkite University Clearance SystemDocumento16 pagineWolkite University Clearance SystemZa Yâ Yâ80% (10)

- Atlas CopcoDM 45 Spare PartsDocumento772 pagineAtlas CopcoDM 45 Spare PartsSergey Slomchinskiy0% (1)

- DSV SVDocumento1 paginaDSV SVPUNITHA KUMARNessuna valutazione finora

- Seicos 21l IntrustionDocumento61 pagineSeicos 21l IntrustionkhoaNessuna valutazione finora

- Hustler Mini Z 44/52 Parts ManualDocumento125 pagineHustler Mini Z 44/52 Parts ManualGary0% (1)

- V 112Documento4 pagineV 112simon_someone217Nessuna valutazione finora

- Geographic Information System of Public Complaint Testing Based On Mobile WebDocumento2 pagineGeographic Information System of Public Complaint Testing Based On Mobile WebArya HardinataNessuna valutazione finora

- Structural Welding Inspection: 2019 CBC: DSA Forms DSA PublicationsDocumento3 pagineStructural Welding Inspection: 2019 CBC: DSA Forms DSA PublicationsfracevNessuna valutazione finora

- 06-DC Compound MotorDocumento44 pagine06-DC Compound MotorN. iManNessuna valutazione finora

- Pvu-L0880er GaDocumento1 paginaPvu-L0880er GaarunghandwalNessuna valutazione finora

- Is 2571-1970Documento27 pagineIs 2571-1970Deboline MitraNessuna valutazione finora

- 3-Oracle Application Framework (OAF) Training Guide - EO, VO, Page, Query Region, LOV, PPRDocumento73 pagine3-Oracle Application Framework (OAF) Training Guide - EO, VO, Page, Query Region, LOV, PPRPreethi KishoreNessuna valutazione finora

- Aluminum Design Manual 2015Documento505 pagineAluminum Design Manual 2015Charlie Henke100% (2)

- Inlet DuctDocumento14 pagineInlet DuctAhmad ArmanNessuna valutazione finora

- Java ProgramsDocumento60 pagineJava ProgramsbagrechaamitNessuna valutazione finora

- Kiln Performance - Efficiency FormulasDocumento12 pagineKiln Performance - Efficiency FormulasMohamed ZayedNessuna valutazione finora

- SAIC-Q-1043 Asphalt Core Density Testing InspectionDocumento3 pagineSAIC-Q-1043 Asphalt Core Density Testing InspectionAbdul HannanNessuna valutazione finora

- 4.0L EngineDocumento347 pagine4.0L EngineCapssa Oscar100% (2)